Optimizing Profitability in Ammonium Nitrate Manufacturing: A Cost Model Approach

_11zon.webp)

What is Ammonium Nitrate?

Ammonium nitrate (NH4NO3) is a white solid that is widely used as a high-nitrogen fertilizer and as a component of industrial explosives. It is made by neutralization of ammonia with nitric acid and is very soluble in water, making it useful for its efficiency in providing nitrogen to plants.

Key Applications Across Industries:

Though widely applied in agriculture, ammonium nitrate also finds significant applications in the mining, quarrying, and construction industries because of its oxidizing characteristics when used in explosives like ANFO (Ammonium Nitrate Fuel Oil). In spite of being subject to regulatory oversight regarding safety and storage, ammonium nitrate continues to be an essential chemical compound in most industrial uses globally.

What the Expert Says: Market Overview & Growth Drivers

The global ammonium nitrate market size was valued at USD 17.7 Billion in 2024. According to IMARC Group, the market is projected to reach USD 24.52 Billion by 2033, exhibiting a CAGR of 3.70% during 2025-2033. The global market for ammonium nitrate is driven mainly by its two-way demand from the mining and agriculture sectors. In agriculture, the growing requirement of high-yielding crops and the rising population in the world are driving the application of nitrogenous fertilizers, with ammonium nitrate providing quick release of nutrients and a high nitrogen value. In the construction and mining industry, ammonium nitrate is used on a large scale in commercial explosives (such as ANFO), which find application for blasting.

Growing infrastructure development and mineral excavation activities, especially in developing economies, are driving demand. Moreover, improved technology in safer storage, handling, and transport has spurred uptake despite regulatory issues. Governments of nations such as India and China are also helping promote domestic fertilizer manufacturing, further igniting market expansion. Additionally, geopolitical tensions and defense modernization initiatives are driving production of military-grade explosives, adding to ammonium nitrate usage. Finally, strategic acquisitions and capacity increases by industry leaders are constructing a resilient worldwide supply base, cementing its position in high-priority areas.

Case Study on Cost Model of Ammonium Nitrate Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale ammonium nitrate manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed ammonium nitrate manufacturing plant in Botswana. This plant is designed to produce 200 kilo tons of ammonium nitrate annually.

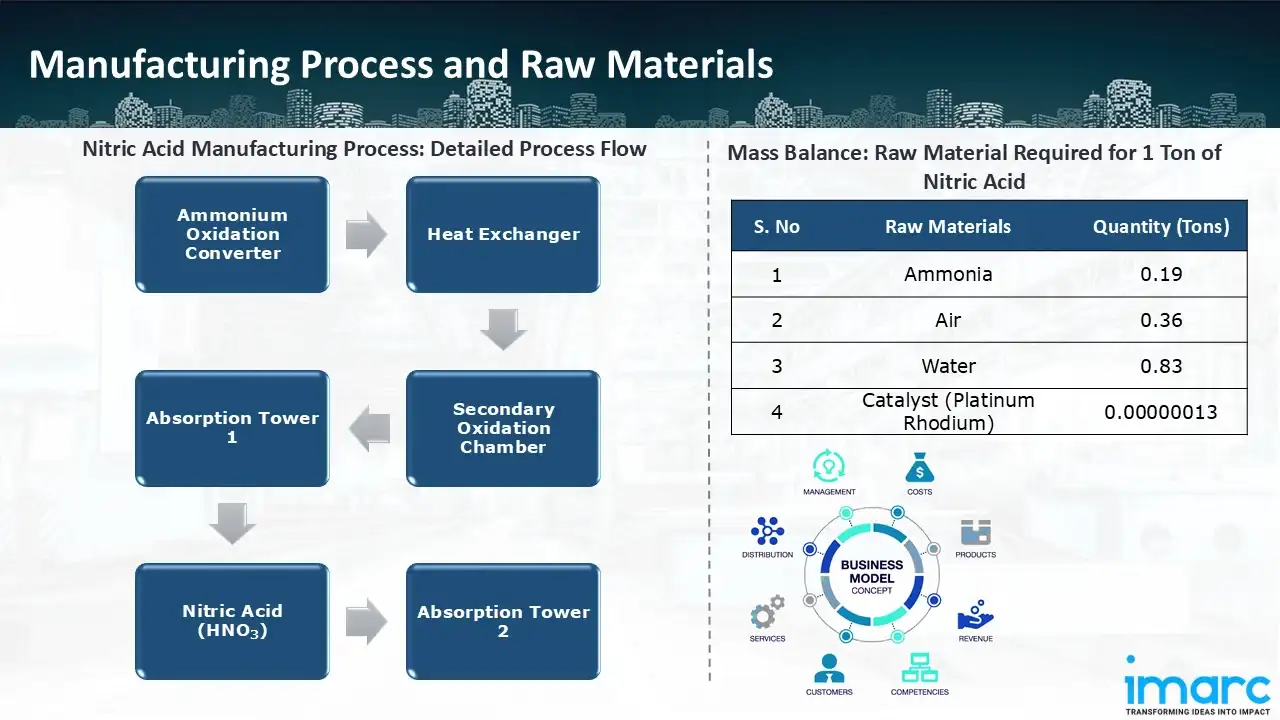

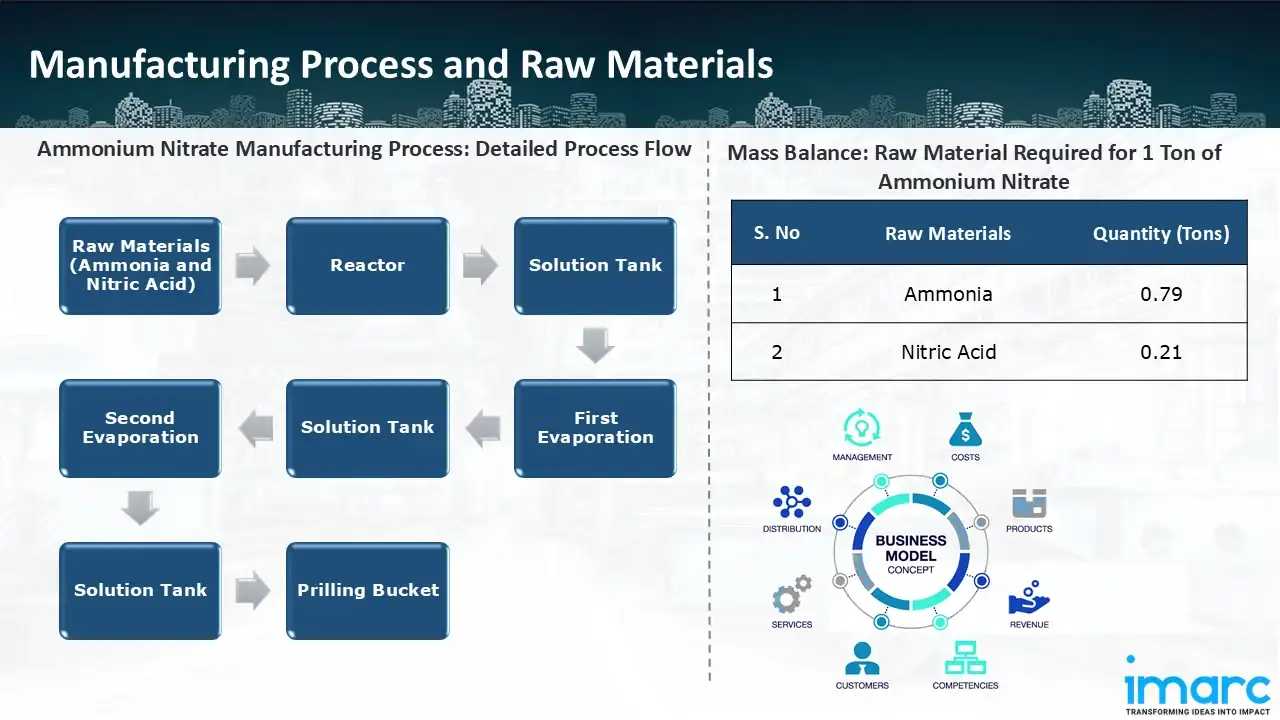

Manufacturing Process: The production of ammonium nitrate has three major processes: ammonia production, nitric acid synthesis, and neutralization to make ammonium nitrate. Ammonia is manufactured by the reaction of methane (natural gas) with steam and air to produce hydrogen and nitrogen. The gases are compressed and sent through a catalyst-reactor to produce ammonia synthetically, with the recovered heat utilized for energy. Then nitric acid is synthesized by oxidation of ammonia using a platinum catalyst at 600°C to produce nitric oxide (NO), which in turn gets oxidized to nitrogen dioxide (NO2). NO2 is then dissolved in water to give dilute nitric acid (HNO3), which is concentrated via the use of sulfuric acid as a dehydrating agent. Ammonium nitrate (NH4NO3) is lastly produced via neutralization of ammonia with nitric acid. The obtained solution is evaporated in a two-stage process. To avoid foaming and prilling problems induced by CO2 from carbonate additives, sulfuric acid is applied, and silicic acid is incorporated for enhanced product stability and processing.

Process 1

_11zon.webp)

Process 2

Process 3

Mass Balance and Raw Material Required: The primary raw materials used in the ammonia manufacturing plant include cold bed methane, natural gas and catalyst (iron). For a plant producing 1 ton of ammonia, 1.05 tons of cold bed methane, 0.80 cubic meter natural gas, and 0.01 tons of catalyst (iron) is required. Additionally, the primary raw materials used in the nitric acid manufacturing plant include ammonia, air, water, and catalyst (platinum rhodium). For a plant producing 1 ton of nitric acid, 0.19 tons of ammonia, 0.36 tons of air, 0.83 tons of water, and 0.00000013 tons of catalyst (platinum rhodium) is required. Furthermore, the primary raw materials used in the ammonium nitrate manufacturing plant include ammonia and nitric acid. For a plant producing 1 ton of ammonium nitrate, 0.79 tons of ammonia and 0.21 tons of nitric acid is required.

List of Machinery:

The following equipment was required for the proposed plant:

- Shell and tube Heat exchanger

- Heaters

- Packed Bed Column (Absorber & Stripper)

- Centrifugal pumps

- Air Compressors

- Syn Gas Compressors

- Ammonia Compressors

- Primary Reformer

- Secondary Reformer

- Packed Bed Reactor (Methanator Convertor)

- Storage vessels (Horton Spheres, Air Reservoir)

- Fans (ID and FD)

- Cooling Tower

- Ejector System

- Ion- Exchange Unit

- De-ionized water Cooler

- Air Compressor

- Ammonia Vaporizer

- Ammonia Super-heater

- Reactor

- Steam Super-heater

- Waste-heat Boiler

- Tail-gas Pre-heater

- Cooler/Condenser

- Oxidation Unit

- Secondary Cooler

- Absorber

- Stripping Column

- Storage Tank

- AN Neutralizer

- HNO3 Heater

- Ammonia Heater

- 2nd Neutralizer

- Evaporator

- Air Heater

- Air Blower

- Pump

- Melt Drainage Tank

- 2nd Stage Neutralizer Hydraulic Seal

- Melt Filter

- Melt Tank

- Pumps

- Scubbing Liquid Tank

- Head Tank

- Priller

- Scrubber

- Sectional Scrubber

- Buffer Tank

- Air heater and Air Conditioner

- Prills Cooler

- Conveyor

- Elevator

- Prills treatment by Agent

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

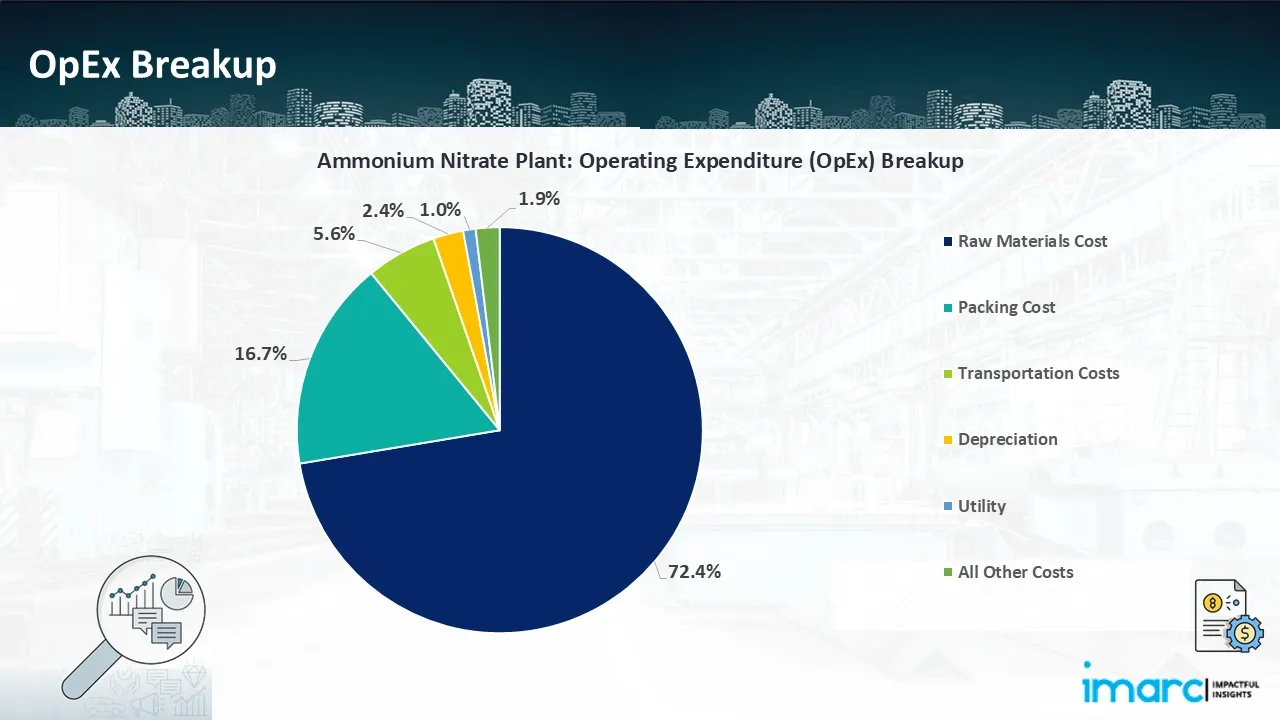

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

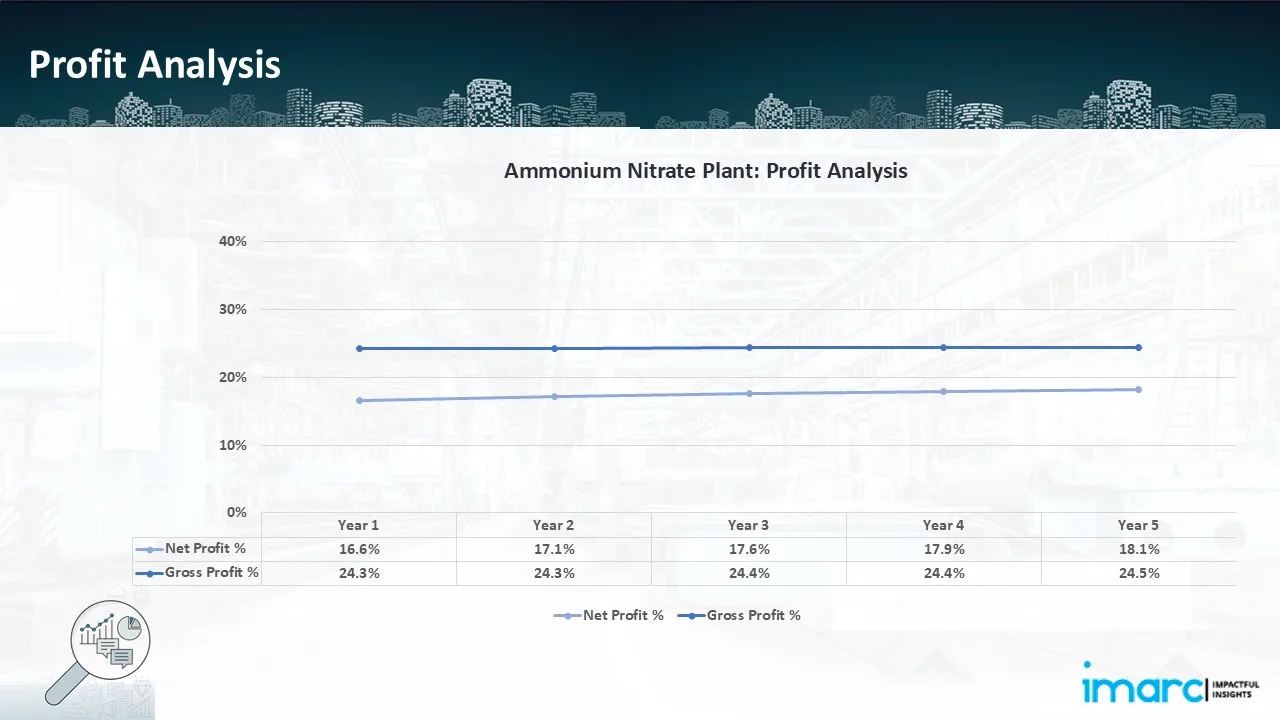

- Profitability Analysis Year on Year Basis: The proposed ammonium nitrate plant, with a capacity of 200 kilo tons of ammonium nitrate annually, achieved an impressive revenue of US$ 115.8 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 24.3% to 24.5% by year 5, and net profit rises from 16.6% to 18.1%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the ammonium nitrate manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of annually producing 200 kilo tons of ammonium nitrate, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In April 2024, the largest ammonia producer in the world, CF Industries Holdings, Inc. (NYSE: CF), and Japan's largest energy company, JERA Co., Inc. (JERA), today announced that they have signed a joint development agreement (JDA) to investigate the construction of greenfield low-carbon ammonia production capacity at CF Industries' Blue Point Complex in Louisiana.

- In February 2024, Coal India Limited and BHEL signed a Joint Venture Agreement to establish India’s first ammonium nitrate plant using surface coal gasification (SCG) technology in Odisha. With a capacity of 2,000 tonnes per day (~660,000 tonnes annually), this facility aims to reduce import dependence and support domestic mining needs.

- In January 2024, a non-binding MOU for the construction of an ammonium nitrate factory in Saudi Arabia has been announced by Dyno Nobel, a Saudi chemical company, and a Saudi investment firm. Saudi Chemical Company Limited (SCCL) and Dyno Nobel of Incitec Pivot Limited will collaborate to research the construction and running of a technical ammonium nitrate facility in Saudi Arabia.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104