Economic Feasibility Study for Electrolytic Manganese Dioxide Manufacturing Plant: A Detailed Study

What is Electrolytic Manganese Dioxide?

Electrolytic manganese dioxide (EMD) is made by dissolving manganese dioxide in sulfuric acid and placing between two electrodes.

Key Applications Across Industries:

Manganese dioxide, also referred to as Manganese (IV) oxide, is an inorganic compound that is commonly found in blackish or brown solid and is insoluble in water. EMD is a highly refined form of MnO2 designed to meet the specific electrical requirements of battery manufacturers.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global electrolytic manganese dioxide market was valued at US$ 1,126.6 Million in 2024, growing at a CAGR of 8.7% from 2019 to 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 8.5% from 2025 to 2033, reaching a projected value of US$ 2,351.6 Million by 2033. The growing population around the world coupled with improvement in living standards, and rising demand for power are some key factors creating positive outlook for the global EMD market. EMD is being frequently utilized in energy storage technologies.

It is getting more challenging to balance the existing energy supply with the energy demand because many alternatives, such as clean and renewable energy sources, are unstable. Due to the requirement for storage to enable the usage of energy when needed, there is an increase in the demand for energy storage batteries, which in turn is driving the demand for EMD. Furthermore, lithium, sodium, and magnesium-ion rechargeable batteries frequently include EMD. In recent years, the demand for EMD has significantly increased, driven by its widespread use in zinc-carbon and lithium-ion batteries.

Case Study on Cost Model of Electrolytic Manganese Dioxide Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale electrolytic manganese dioxide manufacturing plant in Zambia.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 10,000 tons of electrolytic manganese dioxide.

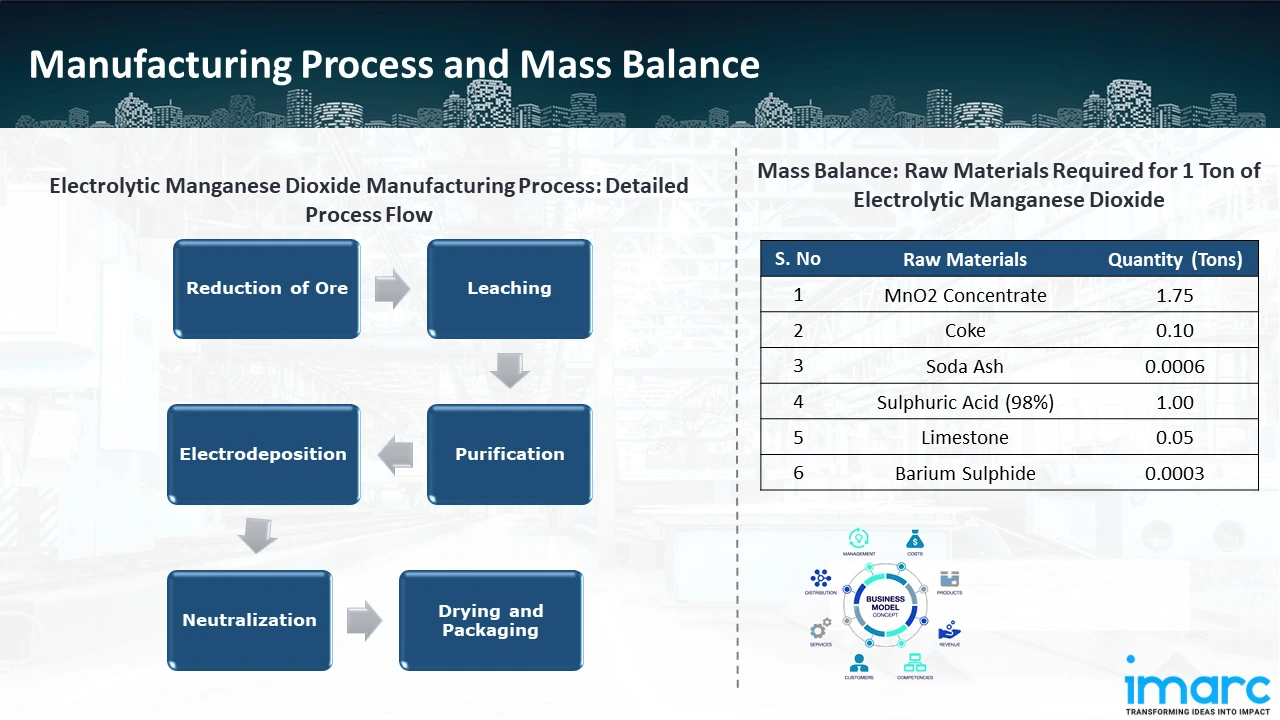

Manufacturing Process: Electrolytic manganese dioxide, or EMD, is made in a number of steps to create a high-purity product for industrial and battery uses. Initially, manganese ore is reduced in a furnace or kiln to transform higher manganese oxides into soluble forms. Manganese is extracted from the reduced ore by leaching, a process in which it combines with acid to form a soluble manganese sulphate solution. After that, a purification procedure is used to eliminate contaminants like iron, aluminium, and other metals from the solution, guaranteeing a clean electrodeposition feedstock. An electrodeposition cell is used to apply an electric current to the purified manganese solution. Electrochemical reactions deposit manganese dioxide as a high-purity solid onto the anode. Following electrodeposition, any remaining acidic solution is neutralised to protect the environment and recover any recyclable materials. After carefully removing the accumulated manganese dioxide, the area is dried to remove any remaining moisture and get the required consistency. Lastly, the EMD is packaged in controlled settings to guarantee product safety and quality throughout transit and storage. High purity and efficiency are guaranteed by this painstakingly planned procedure, which meets the exacting specifications of devices like batteries and electronics.

Mass Balance and Raw Material Required: The primary raw materials utilized in the electrolytic manganese dioxide manufacturing plant include soil conditioner, soda ash, coke, MnO2 concentrate, sulphuric acid, limestone, and barium sulphide. Around 1.75 Tons of manganese MnO2 concentrate, 0.10 tons of coke, 1.00 tons of sulphuric acid (98%), 0.05 tons of limestone, 0.0003 tons of barium sulphide and 0.0006 tons of soda ash are required to make 1 Ton of electrolytic manganese dioxide.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

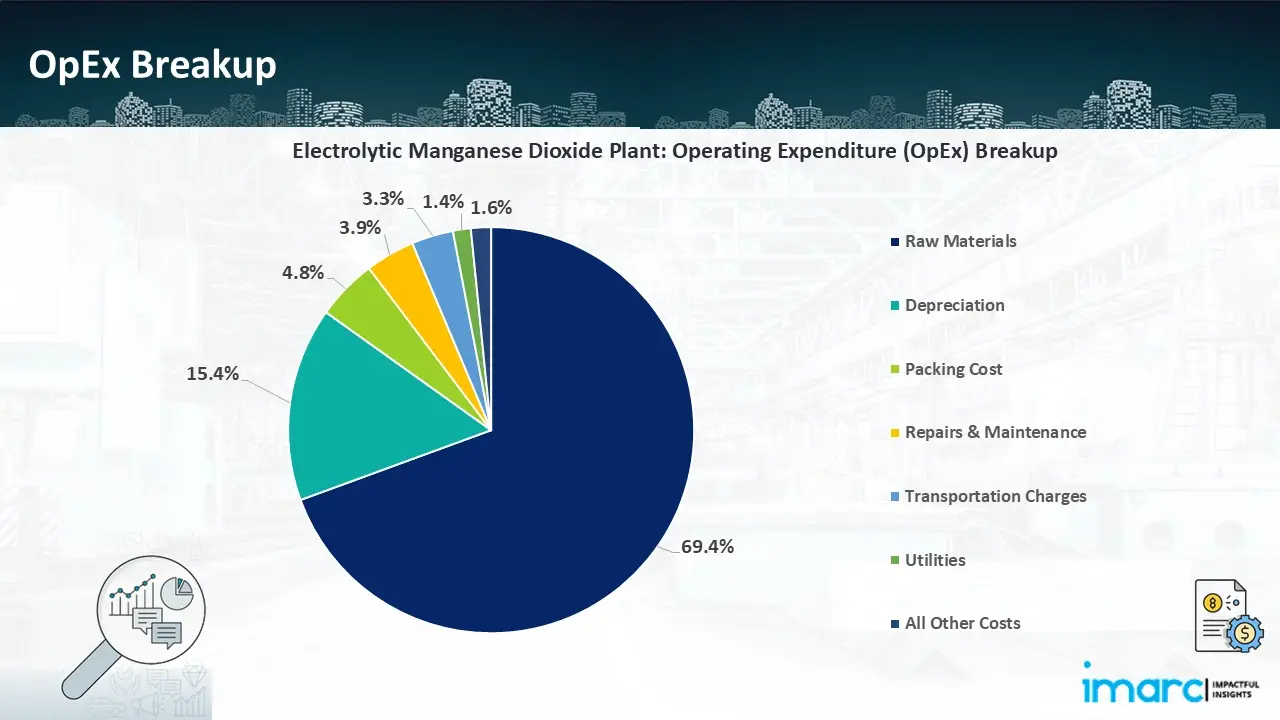

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

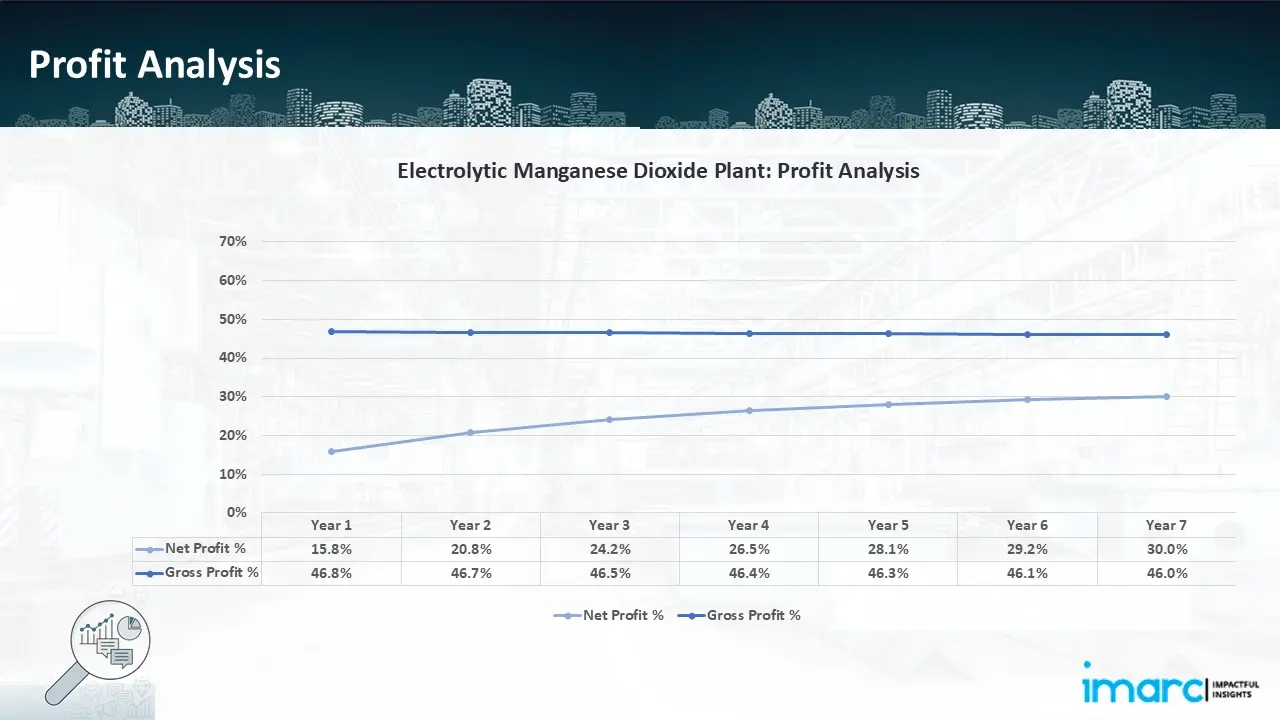

- Profitability Analysis Year on Year Basis: The proposed electrolytic manganese dioxide plant, with a capacity of 10,000 tons per annum, achieved an impressive revenue of US$ 13.20 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the period. Moreover, gross profit slightly reduced from 46.8% to 46.0%, and net profit rise from 15.8% to 30.0%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our financial model for the electrolytic manganese dioxide manufacturing plant was meticulously designed to meet the client’s objectives. It offered a comprehensive examination of production costs, covering capital expenditures, manufacturing procedures, raw materials, and operating costs. The model, which is specifically designed to meet the need of manufacturing 10,000 tons of electrolytic manganese dioxide per year, anticipates profitability while taking market trends, inflation, and any changes in raw material prices into account. This thorough financial model shows our dedication to providing accurate, customer-focused solutions that guarantee the long-term success of major industrial projects by providing the client with insightful information for strategic decision-making.

Latest News and Developments:

- In July 2024, Maxell Ltd., a company involved in battery and consumer electronics, has announced the release of its cutting-edge Cylindrical Type Lithium Manganese Dioxide Batteries (CR). These innovative batteries, which offer remarkable performance and durability, are poised to transform power supplies for smart meters, Internet of Things devices, and a variety of industrial applications.

- In June 2024, an updated pricing structure for different grades of manganese ore was announced, taking effect on July 1, 2024, according to Manganese Ore India Limited (MOIL), the India’s top manganese ore producer. This action reflects MOIL's approach to changing market conditions.

- In January 2024, the Customs and Tariff Committee's Trade Remedy Subcommittee, the Council on Customs, Tariff, Foreign Exchange and Other Transactions, informed the Finance Ministry of Japan that it was appropriate to prolong the taxable period of anti-dumping taxes on electrolytic manganese in China, as per the study conducted by them.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104