Detailed Cost Analysis of Silica Gel Manufacturing Plant: A Comprehensive Cost Model

_11zon.webp)

What is Silica Gel?

Silica gel is obtained from silica dioxide a naturally occurring compound in sand and comprises fine particles that can soak quantity of water. It is a drying agent that is frequently packaged in tiny paper or cloth packets as tiny, transparent beads or crystals of clear rock.

Key Applications Across Industries:

These packets are frequently included with business goods to guard against moisture-related damage. Food, clothing, and electronics are just a few of the many things that include silica gel packets. Although silica gel is typically non-toxic, it poses a choking hazard, particularly to young children.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global silica gel market size reached US$ 685.2 Million in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 3.04% from 2025 to 2033, reaching a projected size of US$ 898.5 Million by 2033. One major factor propelling the silica gel market growth is the expanding pharmaceutical industry. The need for silica gel for moisture control and preservation during packing is a result of the growing manufacturing of pharmaceuticals.

As worldwide healthcare spending and drug consumption rise, silica gel plays a crucial role in preserving the quality and shelf life of pharmaceuticals. Additionally, the COVID-19 pandemic increased e-commerce's appeal, necessitating the use of efficient packaging techniques to maintain product integrity throughout storage and transportation. As a result, the growth of e-commerce increased demand for packaged goods, many of which use silica gel to absorb moisture.

Case Study on Cost Model of Silica Gel Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale silica gel manufacturing plant in United Arab Emirates.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 25,000 tons of silica gel.

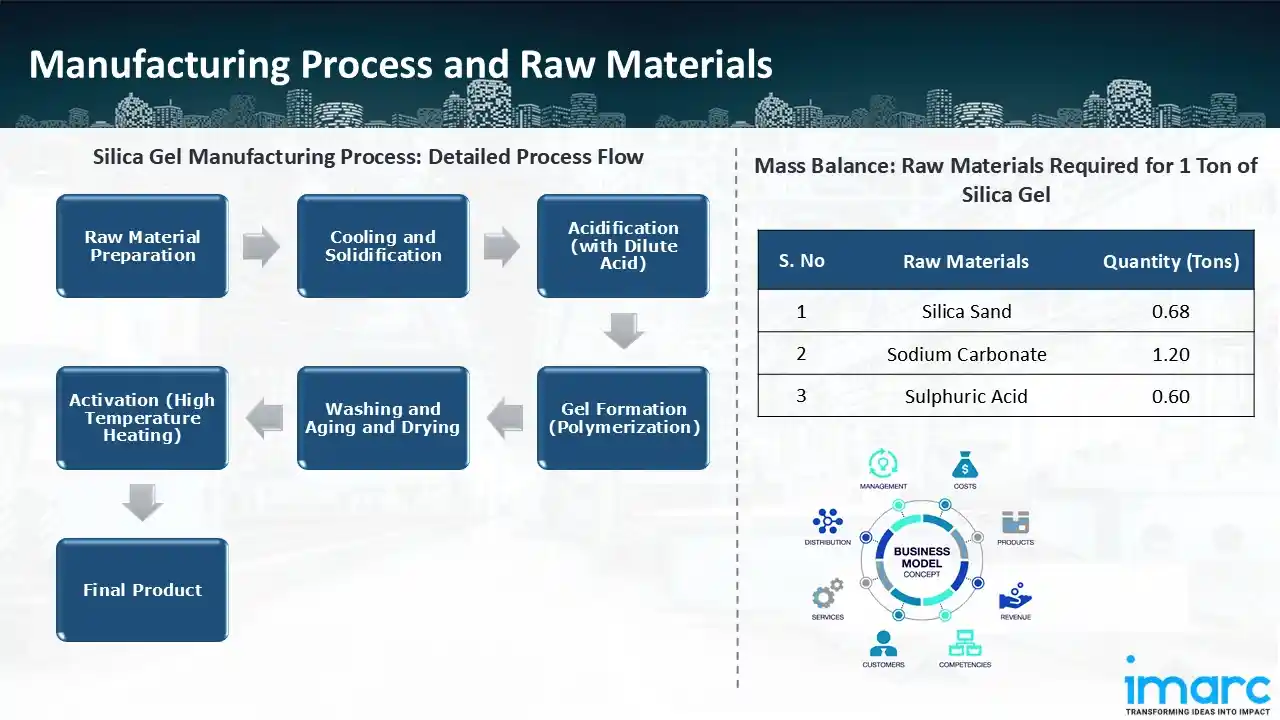

Manufacturing Process: The first step in making silica gel is preparing the raw materials, which involves mixing sodium silicate (water glass) with water to get a homogenous solution. The precursor for silica gel is created when this solution cools and solidifies, creating a mass that resembles jelly. A diluted acid, usually sulphuric acid, is then used to acidify the hardened bulk. This causes a chemical process that turns sodium silicate into silica gel. This causes silica particles to link together and form a porous structure, a process known as gel formation (polymerisation). After formation, the gel is cleaned, aged, and dried to improve its structural integrity and get rid of any remaining contaminants. As the silica gel ages, it acquires the appropriate pore size and adsorption capacity. Following drying, the gel is heated to a high temperature to activate it, eliminating moisture and improving its absorption capabilities. In order to be used in chromatography, moisture control, and catalyst support, the silica gel is lastly processed into different forms, such as granular, bead, or powder, and then packaged.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the silica gel manufacturing plant include silica sand, sodium carbonate and sulphuric acid. To manufacture 1 ton of silica gel, we require 0.68 ton of silica sand, 1.20 tons of sodium carbonate, and 0.60 tons of sulphuric acid.

List of Machinery:

The following equipment was required for the proposed plant:

- Intake equipment

- Dosing and weighting equipment

- Mixer and transportation equipment

- "Electric equipment and automatic batching control system"

- Refractory materials

- Mechanical equipment related to furnace

- Combustion equipment related to furnace

- Instrument and automatic control system

- Boiler

- Dissolved autoclave

- Measuring hopper

- Middle tank of liquid sodium silicate

- Waste heat recovery system equipment

- Plate-type Filter

- Liquid sodium silicate washing tank (tank only)

- Storage tanks of sodium silicate

- Pumps

- Steel platform for roller and plate-type filter

- Pipe of valves for internal system

- Sodium silicate dissolution and modulation system equipment

- Sodium silicate precipitation recovery system equipment

- Raw material storage system

- Raw material blending and refining system

- Synthetic reaction system

- Synthetic Electronic Control (DCS) System

- Filtering system

- Electric single beam crane

- Unloading system

- Drying system

- Drying tower

- Granulation/Crushing System

- Main bag filter

- Dry exhaust induced draft fan

- Hot air system

- Natural gas combustion furnace

- Purification air bag filter

- Spray scrubber tower

- Pipes, fittings, electrical appliances, and others

- Packaging system

- Material receiving bag filter

- Finished material silo

- Automatic vacuum packaging machine

- Laboratory and testing equipment

- transformer

- Air compressor

- Steam Boiler

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

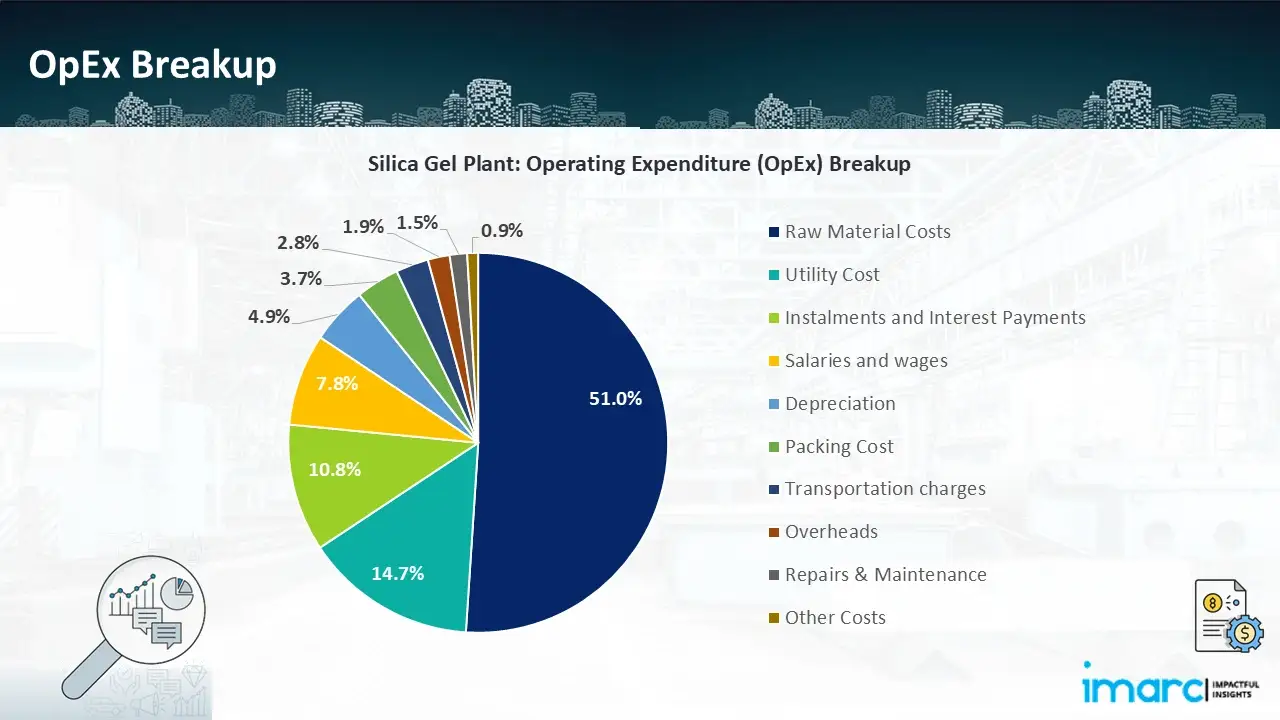

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

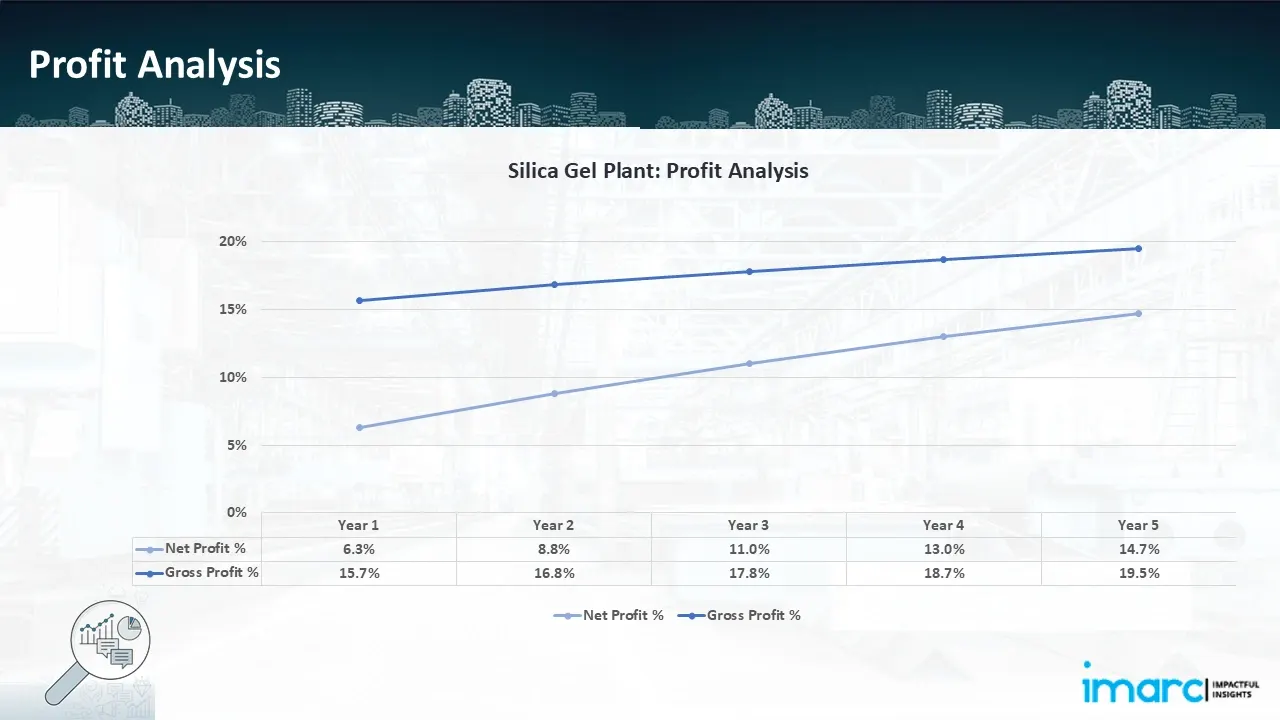

- Profitability Analysis Year on Year Basis: The proposed silica gel plant, with a capacity of 25,000 tons of silica gel annually, achieved an impressive revenue of USD 23.4 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Gross profit margins improved from 15.7% to 19.5% during the period, and net profit margins rise from 6.3% to 14.7%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our silica gel manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 25,000 tons of silica gel annually. Our commitment to offering precise, client-cantered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In January 2024, Mold-Tek Packaging Ltd announced an investment of ?120 crore to expand its manufacturing capacity by 5,500 metric tonnes per annum. This expansion includes enhancements at Tamil Nadu, Telangana, and Haryana focusing on high value-added pharmaceutical packaging, such as tubes for effervescent tablets, silica gel canisters, and molded bottles for over-the-counter products.

- In May 2024, Zeochem announced the successful acquisition of Swambe Chemicals and Sorbead India, which represents a significant step forward in our international expansion initiatives. The acquisition, which was first announced on January 23, 2024, was completed without incident on April 29, 2024, when the selling deal was formally finished. Under the name Sorbchem India Pvt. Ltd., Sorbead India and Swambe Chemicals will now become part of Zeochem, the Chemistry division of CPH Chemie + Papier Group.

- In May 2021, Grace's silica manufacturing factory expansion in Malaysia is now complete. The goal of this development is to boost production capacity in order to satisfy the rising demand for high-performance silica, which is utilised in the personal care, coatings, and tire industries. The expansion of the plant is a result of continued demand for Grace silica gel solutions.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104