Evaluating the Cost Competitiveness of an Active Dry Yeast Manufacturing Plant: A Comprehensive Cost Model

What is Active Dry Yeast?

Active dry yeast is a dehydrated form of yeast commonly used in baking and fermentation. Its dormant yeast cells spring to life when they are rehydrated with warm water.

Key Applications Across Industries:

In bread-making, brewing, and other fermentation operations, active dry yeast is frequently employed due to its extended shelf life and convenience of storing. It aids in flavour development and raises dough by generating carbon dioxide. It is a necessary component of both commercial and home baking due to its dependability and convenience.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global yeast market was valued at USD 7.8 Billion in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 6.6% from 2025 to 2033, reaching a projected value of USD 13.9 Billion by 2033. The growing demand for bakery goods, such as bread, cakes, and pastries, which is being driven by shifting consumer habits and growing urbanisation, is what is driving the active dry yeast market.

Demand has also increased as home baking has become more and more popular, especially after the epidemic. The market is also growing because of the growing food and beverage sector, which includes the production of bioethanol and brewing. Another important factor is growing knowledge of the nutritional advantages of yeast, such as its high protein and vitamin B content. Additionally, improvements in storage and packaging methods have increased the effectiveness and shelf life of active dry yeast, increasing its accessibility. Its demand is further driven by emerging markets and growing acceptance in the fermented and plant-based food industries.

Case Study on Cost Model of Active Dry Yeast Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale active dry yeast manufacturing plant in Damascus, Syria.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with a production capacity of 20 tons of active dry yeast per day.

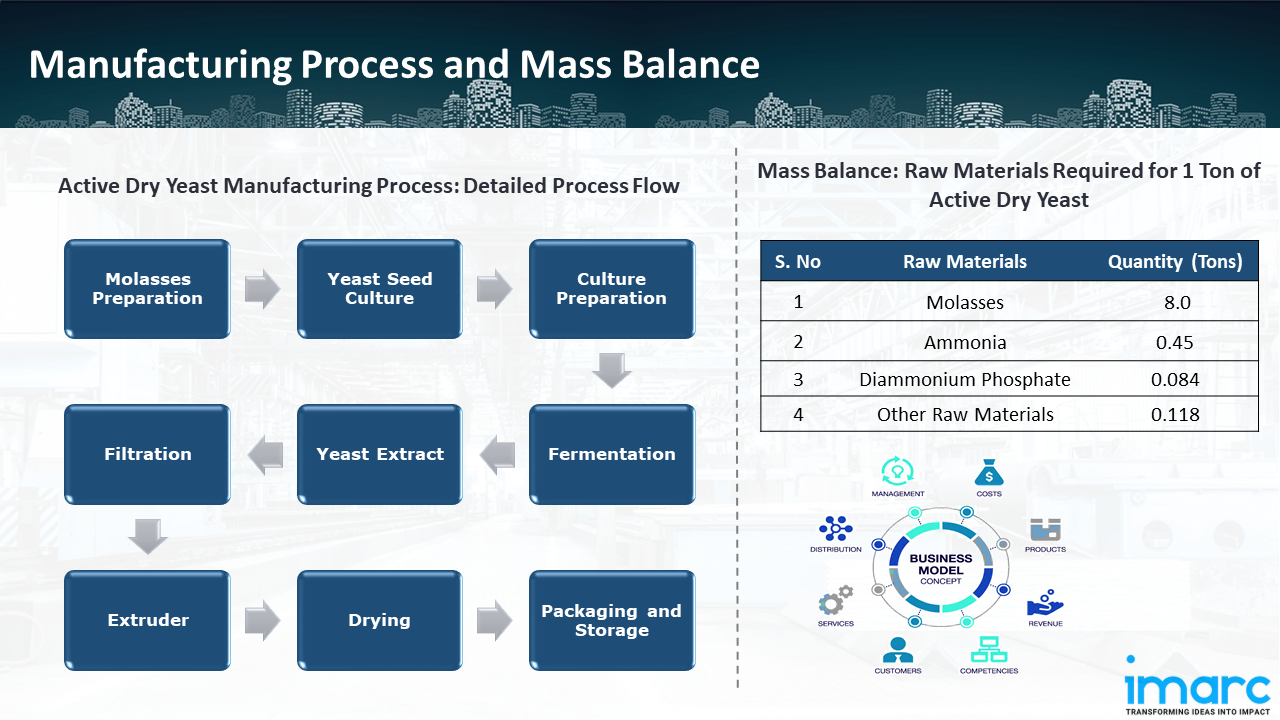

Manufacturing Process: In order to create active dry yeast, molasses, a by-product of sugar refinement, must first be diluted and treated to create a nutrient-rich environment for yeast development. Then, in yeast seed culture, a tiny quantity of yeast is grown under carefully monitored circumstances to guarantee high activity and purity. After that, the yeast cells are further reproduced in ever bigger fermenters as part of the culture preparation process. Under ideal temperature and aeration conditions, the yeast grows quickly during fermentation by feeding on the sugars in molasses. Following that, the resultant yeast biomass is processed to yield yeast extract, which could have additional uses. After that, the yeast is filtered, keeping the concentrated yeast cells while eliminating extra liquid. Small granules are created by passing the semi-solid yeast mass through an extruder; to preserve viability, these are subsequently dried at regulated temperatures. After undergoing quality and performance testing, the dried yeast is packaged and stored in airtight containers to guarantee a long shelf life. Around the world, the finished product is distributed for use in food applications, brewing, and baking.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the active dry yeast manufacturing plant include molasses, ammonia, diammonium phosphate and other raw materials. To produce 1 ton of active dry yeast, around 8.0 ton of molasses, 0.45 tons of ammonia, 0.084 tons of diammonium phosphate, and 0.118 tons of other raw materials.

List of Machinery:

The following equipment was required for the proposed plant:

- Molasses Storage Tank

- Mixers

- Clarifier

- Steriliser

- Molasses Holding Tank

- Culture-I with Internal Cooling System

- Culture-II with Internal Cooling System

- Culture-III with Internal Cooling System

- Fermenter (Pure Culture)

- Fermenter (2nd Stage)

- Fermenters (2nd Stage) with agitator

- Heat Exchanger

- Pump With Motor

- Ammonium Sulphate Tank with Dosing Arrangement

- Piping & Fittings

- Valves

- Centrifugal Yeast Separator

- Cream Storage Tank

- Filter

- Extruder

- Emulsifiers Tank with Dosing Pump Arrangement

- Cutting Oil Tank with Dosing Pump Arrangement

- Screw Feeder & Hopper

- Drive For Screw Feeder

- Rotary Vacuum Filter

- Flash Dryer

- Motors

- Rotary Airlock Valve

- Drive For Rotary Airlock Valve

- Exhaust Blower

- Exhaust Duct

- Inlet Air Filter

- Delivery Air Blower

- Steam Air Heater

- Hot Air Ducting

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

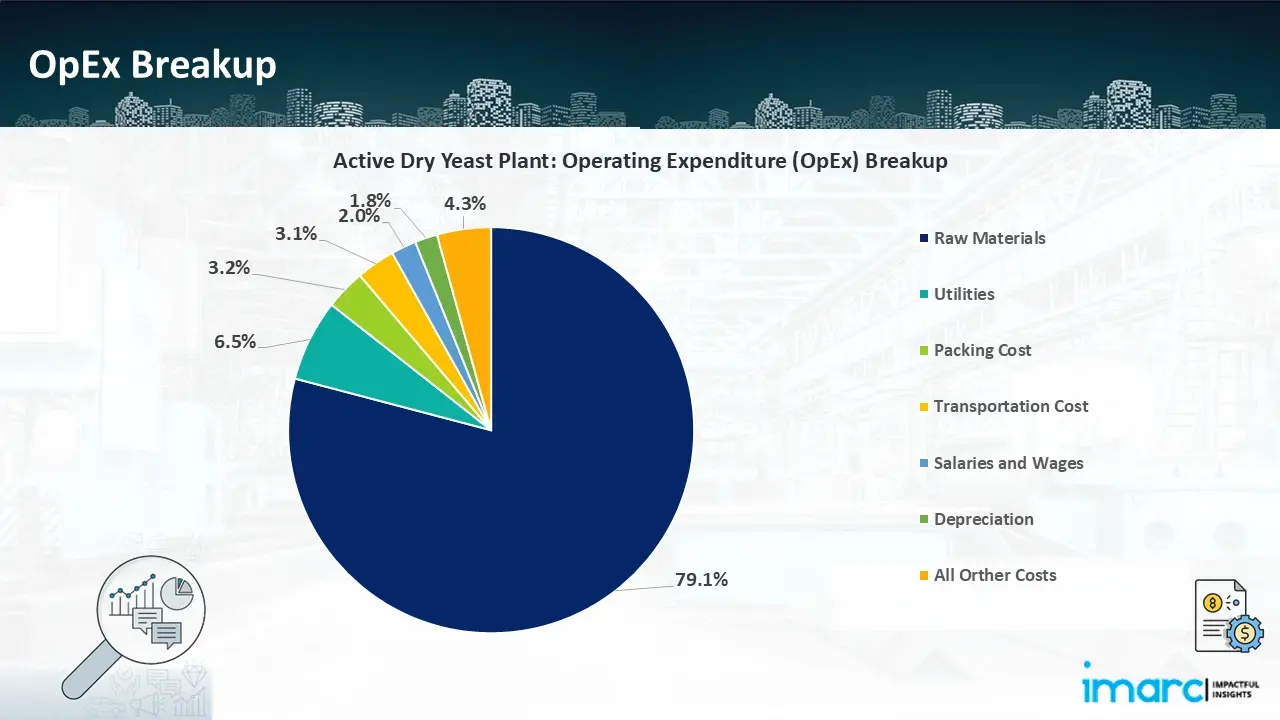

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

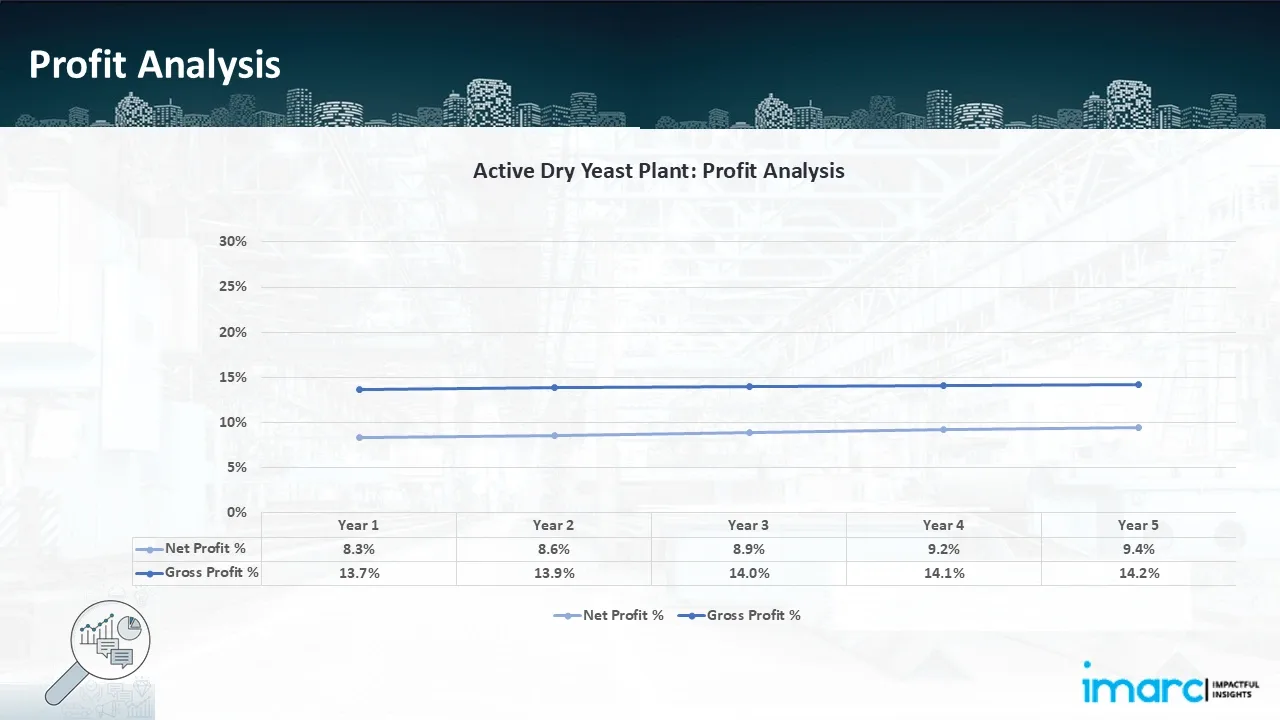

- Profitability Analysis Year on Year Basis: The proposed active dry yeast plant, with a capacity of 20 tons active dry yeast per day, achieved an impressive revenue of US$ 14.28 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit improved from 13.7% to 14.2%, and net profit rise from 8.3% to 9.4%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our active dry yeast manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 20 tonnes of active dry yeast per day. Our commitment to offering precise, client-centered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In October 2024, Lesaffre, a French yeast manufacturer, became the company's largest stakeholder after purchasing a 70% share in Biorigin, a manufacturer of yeast products for human and animal nutrition. Lesaffre's production procedures, logistics, and customer services are expected to be enhanced by the acquisition. It will improve its yeast derivative component solutions by utilising Biorigin's capabilities, particularly those in pet food.

- In August 2024, one of the top companies in the US craft brewing liquid yeast industry, Omega Yeast Labs LLC, was purchased by AB Mauri North America. This strategic move aims to strengthen AB Mauri's specialty yeast business for craft beer by combining its global technology with Omega Yeast's high-quality liquid yeast production.

- In June 2024, Lesaffre, a major leader in fermentation and microorganisms worldwide regarding its yeast extract business, announced the completion of a deal with dsm-firmenich, a top developer in nutrition, health, and beauty. Lesaffre demonstrates its dedication to expansion and innovation in the market for savoury ingredients with this acquisition.

- In February 2023, White Labs has added dry yeast to its fermentation line, enhancing its current liquid yeast products. With a longer shelf life, simpler storage, and worldwide accessibility for fermenters and brewers, this change improves brewing versatility. White Labs now serves both commercial and homebrewing needs, putting the company in a competitive position in the dry yeast industry.

- In September 2022, Angel Yeast, a global yeast manufacturer announced that it has created its latest dry yeast product, Premium Dry Yeast, to solve many of the baking problems of today at Bakery China 2022, the biggest event in the world that caters to the whole value chain for the bakery and confectionery industry.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104