Engineering Sustainability with Cross-Laminated Timber (CLT): A Data-Driven Cost Model

What is Cross-Laminated Timber (CLT)?

Cross-laminated timber (CLT), an engineered wood product, is renowned for its durability, strength, and adaptability in contemporary buildings. CLT provides a lightweight yet strong substitute for steel and concrete in structures with sustainable engineering.

Key Applications Across Industries:

Its layered structure adds to its integrity and makes it suitable for building anything from residential to commercial to high-rise buildings. Besides being aesthetically pleasing for eco-friendly building projects, CLT has very good fire resistance, thermal performance, and ease of installation. CLT changes the architectural sphere and instigates the development of new concepts for urban environments and shaping the future of sustainable construction.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global cross-laminated timber (CLT) market reached USD 1,899.7 Million in 2025. Looking ahead, the market is expected to grow at a CAGR of approximately 8.70% from 2026 to 2034, reaching a projected size of USD 4,175.1 Million by 2034. The global market for cross-laminated timber (CLT) is driven by several key factors.

The rising demand for sustainable and eco-friendly construction materials has significantly boosted its adoption, particularly in regions prioritizing green building initiatives. CLT’s structural strength, fire resistance, and energy efficiency make it an attractive alternative to traditional materials like concrete and steel. Increasing urbanization and the push for carbon-neutral construction have further fueled market expansion. Furthermore, CLT's efficiency is increasing due to developments in modular construction techniques and prefabrication, which have decreased construction time and cost of labors. Governments and regulatory bodies worldwide are supporting mass timber construction through incentives and updated building codes, further promoting its use. The growing emphasis on circular economy principles and sustainable forestry practices has reinforced CLT’s market appeal. With rapid advancements in construction technologies and a global shift towards greener infrastructure, CLT continues to play a crucial role in modern architecture and sustainable urban development.

Case Study on Cost Model of Cross-laminated Timber (CLT) Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale cross-laminated timber (CLT) manufacturing plant in Ireland.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with a production capacity of 166.7 cubic meters of cross-laminated timber (CLT) of each type per day.

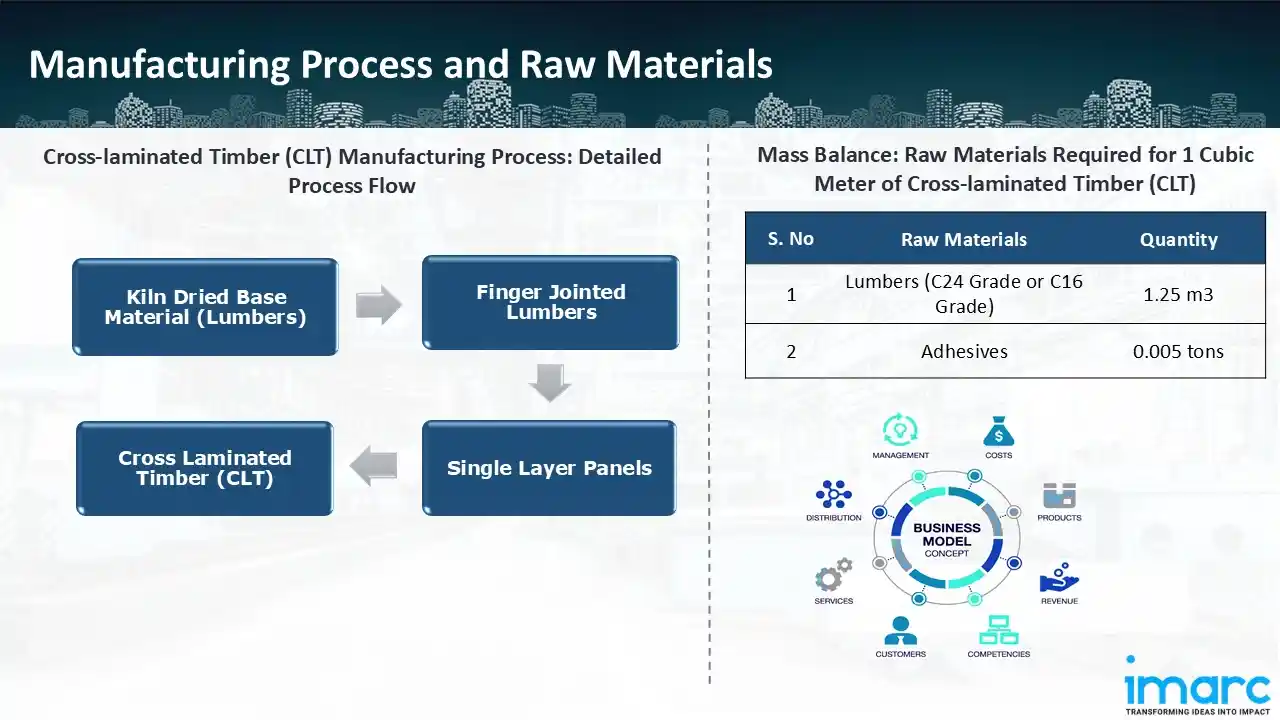

Manufacturing Process: The manufacturing process of Cross-Laminated Timber (CLT) begins with kiln-drying lumber to a moisture content of 12% ± 2%, preventing dimensional instability and surface cracking. The dried lumber is then finger-jointed, where defective sections are removed, and pieces are trimmed and shaped for precise alignment. Next, edge bonding and planing are performed using adhesives such as polyurethane (PUR), melamine urea formaldehyde (MUF), or phenol resorcinol formaldehyde (PRF) to create a solid panel. The glued layers are cross-laminated, meaning they are arranged perpendicularly (typically at 90°) to each other, forming a stable, high-strength structure. These layers are then compressed under hydraulic or vacuum presses, ensuring a firm bond. Once cured, the CLT panels undergo rigorous quality control tests, including bending strength, shear resistance, and delamination checks, to ensure structural reliability. After inspection, the panels are ready for distribution and application in construction, infrastructure, and sustainable building projects.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the cross-laminated timber (CLT) manufacturing plant include lumbers (C24 grade or C16 grade) and adhesives. To manufacture 1 cubic meter of cross-laminated timber (CLT), we require 1.25 cubic meter lumbers (C24 grade or C16 grade) and 0.005 tons adhesives.

List of Machinery:

The following equipment was required for the proposed plant:

- Cross Chain Conveyor for Packages

- Lift Table

- Roll Conveyor for Installation on the Lift Table

- Roll Conveyor for Package- Lifting

- Vacuum Destacking Device

- Scramble Device for Spacer Sticks

- Cross Chain Conveyor with Singling Device and Back Holders

- Turning Device

- Moisture Meter

- Marking Station with Flip Unit for Boards

- Chain Conveyor

- Conveyor for Wet Boards

- Roll Conveyor with Feeding Rolls

- Roll Conveyor with Pull off Left/Right

- Vertical Conveyor

- Cross Chain Conveyor with Singling Device and Back Holders

- Cross Chain Conveyor with Singling Device and Slide

- Cross Cutting Machine

- Waste Board Removal

- Belt Conveyor

- Pull off with Dog Strips and Aligning Roll Track

- Cross Chain Conveyor with Back Holders

- HS-Finger Joint Cutters Assembly

- Contact-Less Glue Applicator for Upright Joints H=80 Mm

- Glue Application Monitoring System

- Tool Crane

- Roll Conveyor with Pull Off Section

- Planer Machine

- Axis Positioning Control

- Driven Side Pressure Rolls - Adjustable with Motorized Drive

- Tool Crane with Crane Rail

- Roll Conveyor with Pull off Left/Right

- Cross Chain Conveyor with Lifting Bars for Cross Layers

- Cross Cutting Saw

- Waste Board Removal

- Pull off with Dog Strips and Aligning Roll Track

- Stacker

- Cross Chain Conveyor for Packages

- Vertical Conveyor for 4- Storage

- 4-Storey Storage

- Supporting Substructure for 4-Floor Storage

- Cross Chain Conveyor

- Flipper Station

- 4–Levels Lamellas Storage with Back Holders

- Glue Application Unit

- Pressing Unit

- Face Side Pressure Machine

- Automated Panel Cutting Machine

- Cross Chain Conveyor for CLT Plate

- Roll Conveyor- for Lifting Of CLT Plate

- Sanding Machine

- Assembling and Wiring of Machines

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

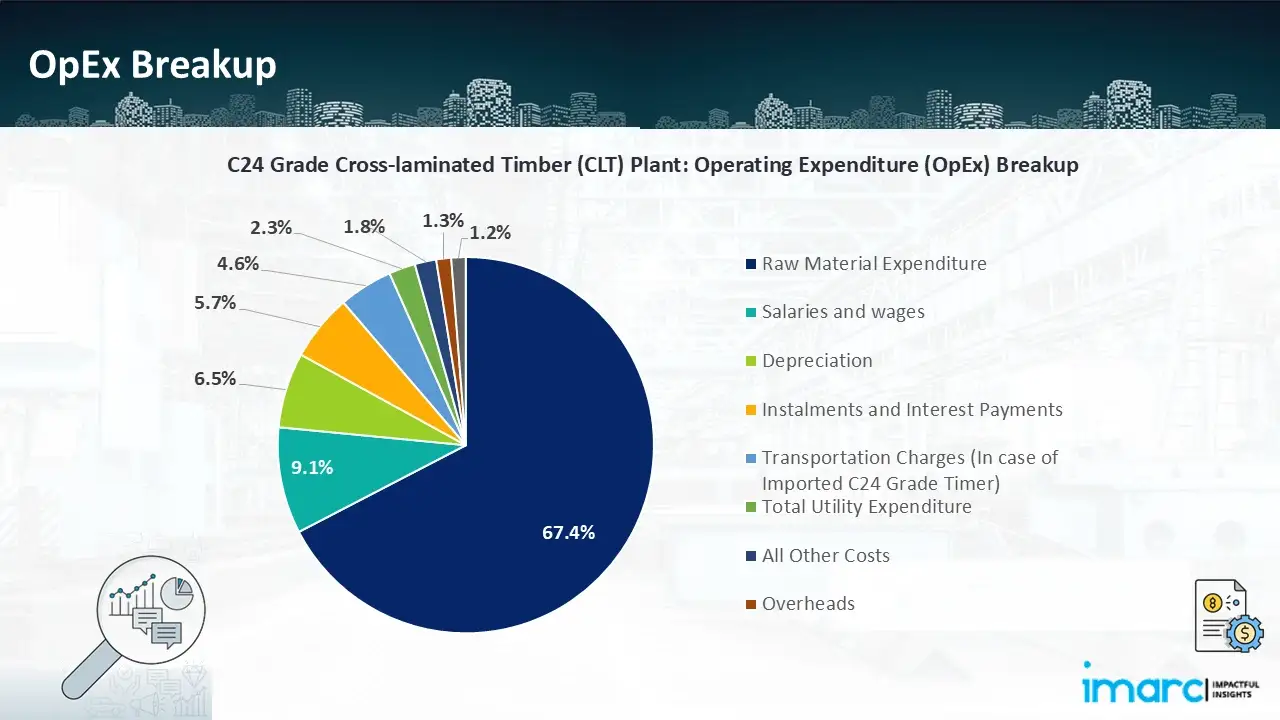

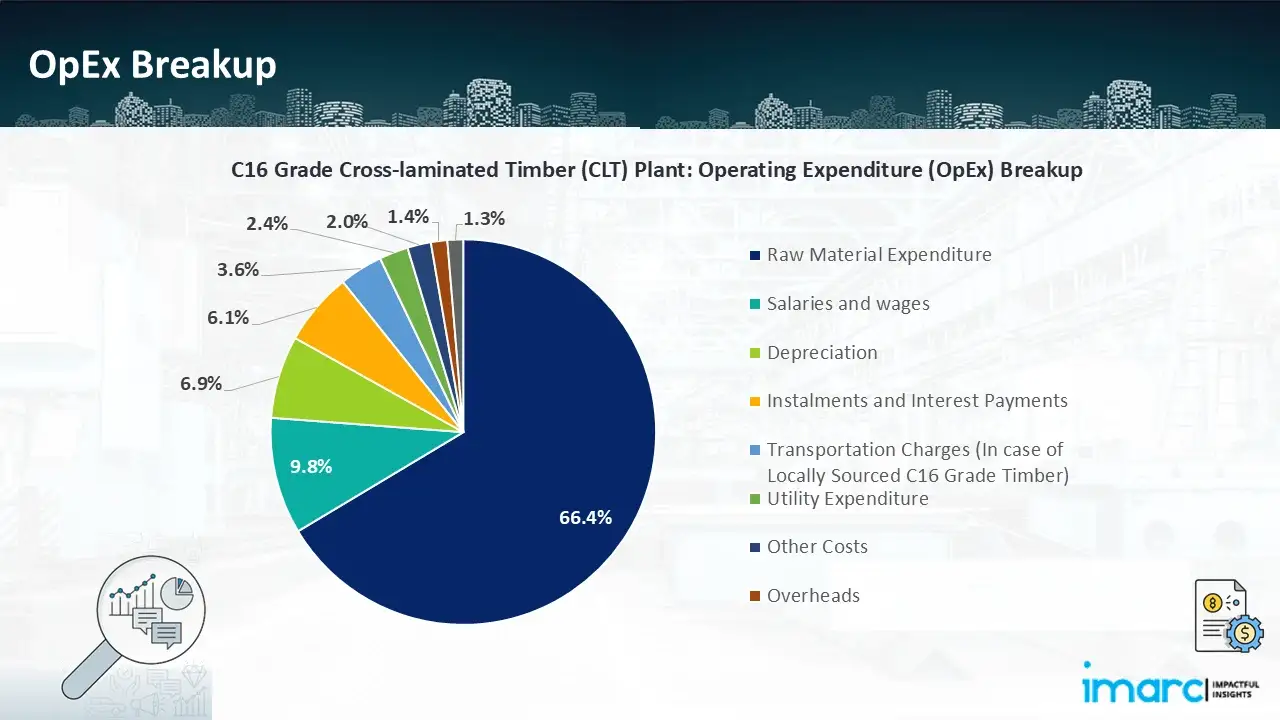

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

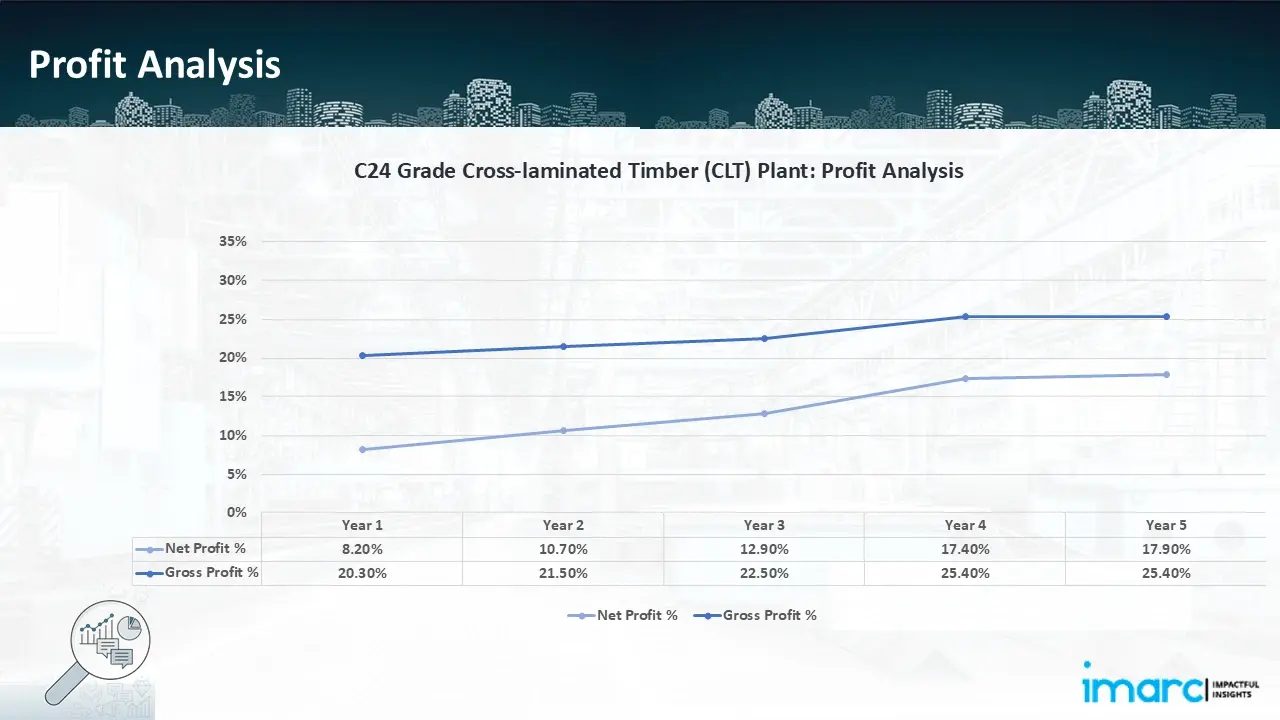

- Profitability Analysis Year on Year Basis: The proposed C24 grade cross-laminated timber (CLT) plant, with a capacity of 166.7 cubic meters of cross-laminated timber (CLT) per day, achieved an impressive revenue of Euro 16.3 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising till year 4 and stays the same in year 5. Gross profit margin improved from 20.3% to 25.4% throughout the years, and net profit went up from 8.2% to 17.9%, highlighting strong financial viability and profitability.

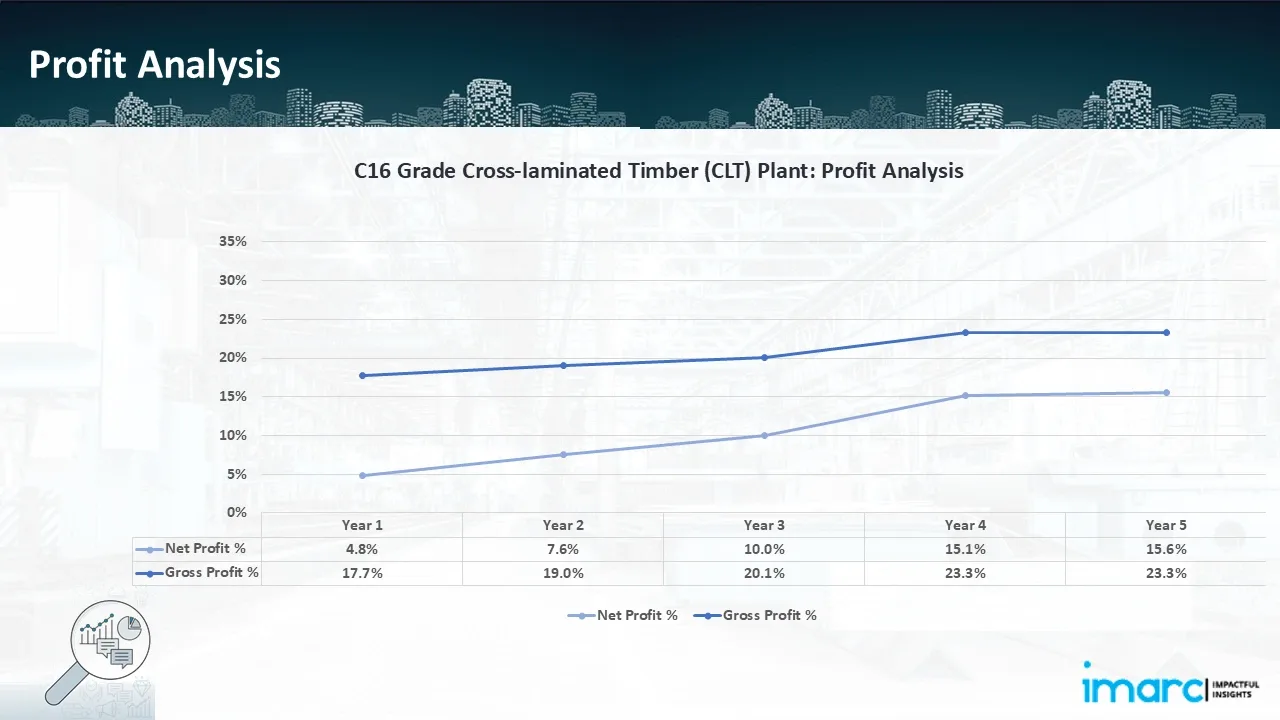

- Profitability Analysis Year on Year Basis: The proposed C16 grade cross-laminated timber (CLT) plant, with a capacity of 166.7 cubic meters of cross-laminated timber (CLT) per day, achieved an impressive revenue of Euro 14.7 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising till year 4 and stays the same in year 5. Gross profit margin improved from 17.7% to 23.3% throughout the years, and net profit went up from 4.8% to 15.6%, highlighting strong financial viability and profitability.

- Profitability Analysis Year on Year Basis: The proposed C16 grade cross-laminated timber (CLT) plant, with a capacity of 166.7 cubic meters of cross-laminated timber (CLT) per day, achieved an impressive revenue of Euro 14.67 Million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue reaching Euro 22.01 Million by year 5. Gross profit margins improve from 17.7% to 23.3%, and net profit margins rise from 4.8% to 15.6%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our cross-laminated timber (CLT) manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of manufacturing 166.7 cubic meters of cross-laminated timber (CLT) per day. Our commitment to offering precise, client-cantered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In February 2025, Construction of Göteborg Grand Central has begun in Gothenburg, Sweden, featuring a new station building within a newly developed district. Södra, in collaboration with Hybridge, is supplying 9,100 m² of cross-laminated timber (CLT) for structural components of the building, as confirmed by Södra.

- In February 2024, Schilliger Holz AG has commenced CLT production at its Volgelsheim plant, with an expected annual output of approximately 40,000 m². The panels produced by Schilliger Bois SAS are intended for distribution across the European market.

- In November 2024, Microsoft has developed a hybrid construction method incorporating CLT, reducing embodied carbon emissions by 35% compared to traditional steel structures. This innovation aligns with the company’s sustainability initiatives.

- In June 2023: Mercer Mass Timber, a subsidiary of Mercer International Inc., successfully acquired Structurlam Mass Timber Corporation and its subsidiaries. This acquisition enhances Mercer’s mass timber product offerings and increases its CLT production capacity, strengthening its support for timber construction projects.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104