Economic Feasibility and Cost Modelling of Titanium Sponge Manufacturing Plant: A Cost Model Approach

What is Titanium Sponge?

Titanium sponge is a highly porous, lightweight form of titanium metal produced through the Kroll process.

Key Applications Across Industries:

It is the major raw material in the production of titanium alloys in industrial, automotive, medical implant, and aerospace applications. For high-performance industries, titanium sponge is an indispensable component as it has a very high strength-to-weight ratio, is resistant to corrosion, and is biocompatible. It is prepared by reducing titanium tetrachloride (TiCl4) with magnesium, followed by purification and processing to produce titanium compounds that can be used.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global Titanium sponge market by volume was at 262.7 Thousand Tons in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 4.0% from 2025 to 2033, reaching a projected volume of 391.8 Thousand Tons by 2033.

The titanium sponge market is largely driven by growing demand from the aerospace, defense, and medical industries due to its exceptional strength-to-weight ratio and corrosion resistance. The need for high-performance titanium alloys is fueled by the growth of both military and commercial aircraft production as well as increased space exploration operations. Further supporting market expansion is the growing usage of titanium in medical implants due to its biocompatibility. Demand is being increased by the automotive industry's adoption of titanium for lightweight, fuel-efficient car components. Titanium is perfect for industrial applications in the chemical and marine industries because of its tolerance to hostile environments. Furthermore, market accessibility is being improved by government programs encouraging domestic titanium production as well as technological developments in extraction and refining procedures. The market is expanding because of the growing trend towards sustainability and titanium material recycling, which guarantees a consistent supply for a range of sectors.

Case Study on Cost Model of Titanium Sponge Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale titanium sponge manufacturing plant in Uzbekistan.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's set-up and operations. The proposed facility is designed with a production capacity of 100 tons of titanium sponge per day.

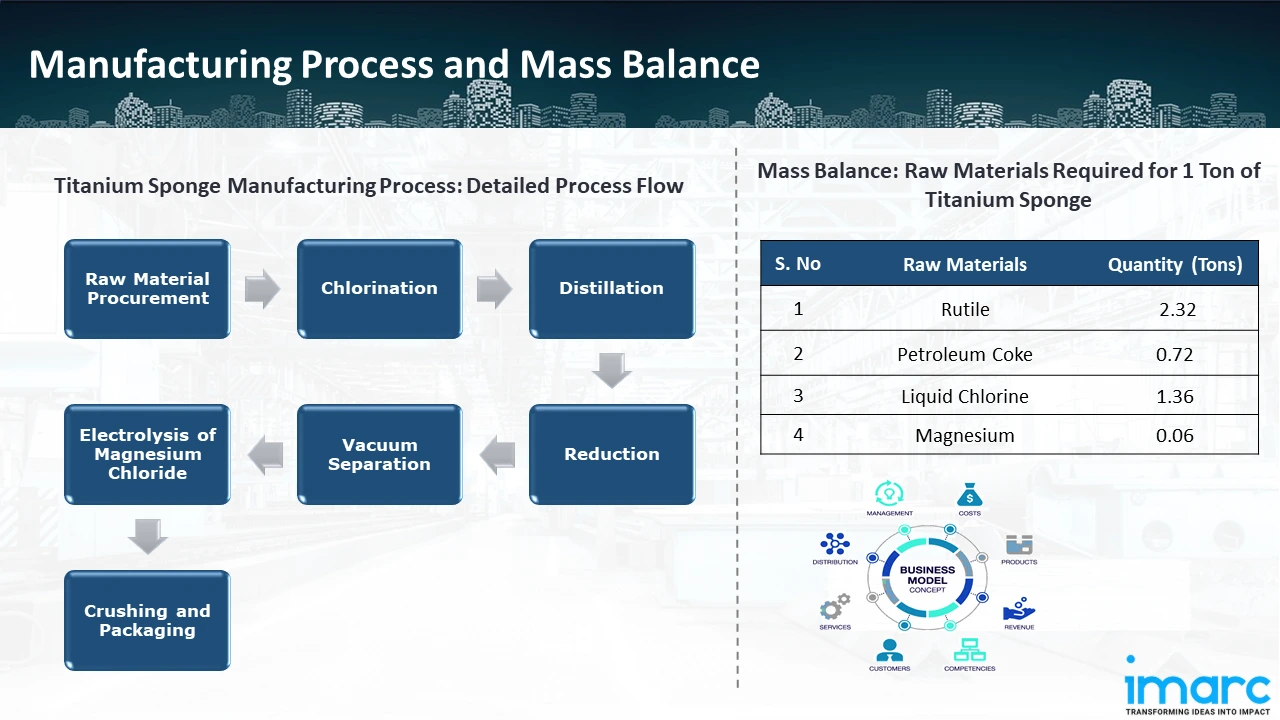

Manufacturing Process: Purchasing raw materials is the first step in making titanium sponge. Here, titanium ore, usually rutile or ilmenite, is found and processed for more refinement. The process of chlorination separates impurities like iron and other metals by reacting the ore with carbon and chlorine at high temperatures to create titanium tetrachloride (TiCl4). The TiCl4 is then purified by distillation, which guarantees that undesirable impurities and byproducts are eliminated. Following purification, the TiCl4 undergoes a reduction process in which it combines with molten magnesium in a closed reactor (Kroll process), creating titanium sponge, a porous titanium metal. This process also produces magnesium chloride as a byproduct. After reduction, the titanium sponge is vacuum separated to eliminate any remaining magnesium and magnesium chloride. The final product's purity is guaranteed by this procedure. The magnesium chloride is then subjected to electrolysis, where the resulting magnesium and chlorine are separated for further production and used again in a recycling process to ensure it has future uses. After that, the titanium sponge is crushed into various dimensions as the industrial needs require them and transported to the different industrial, aerospace, defense, and medical communities, where the final processing of other titanium sheets and ingots occurs and high-performance parts. To uphold industry standards and guarantee that the finished product satisfies requirements, quality control inspections are carried out at every stage of the process.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the titanium sponge manufacturing plant include rutile, petroleum coke, liquid chlorine and magnesium. To produce 1 ton of titanium sponge, around 2.32 tons of rutile, 0.72 tons of petroleum coke, 1.36 tons of liquid chlorine, and 0.06 tons of magnesium is required.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

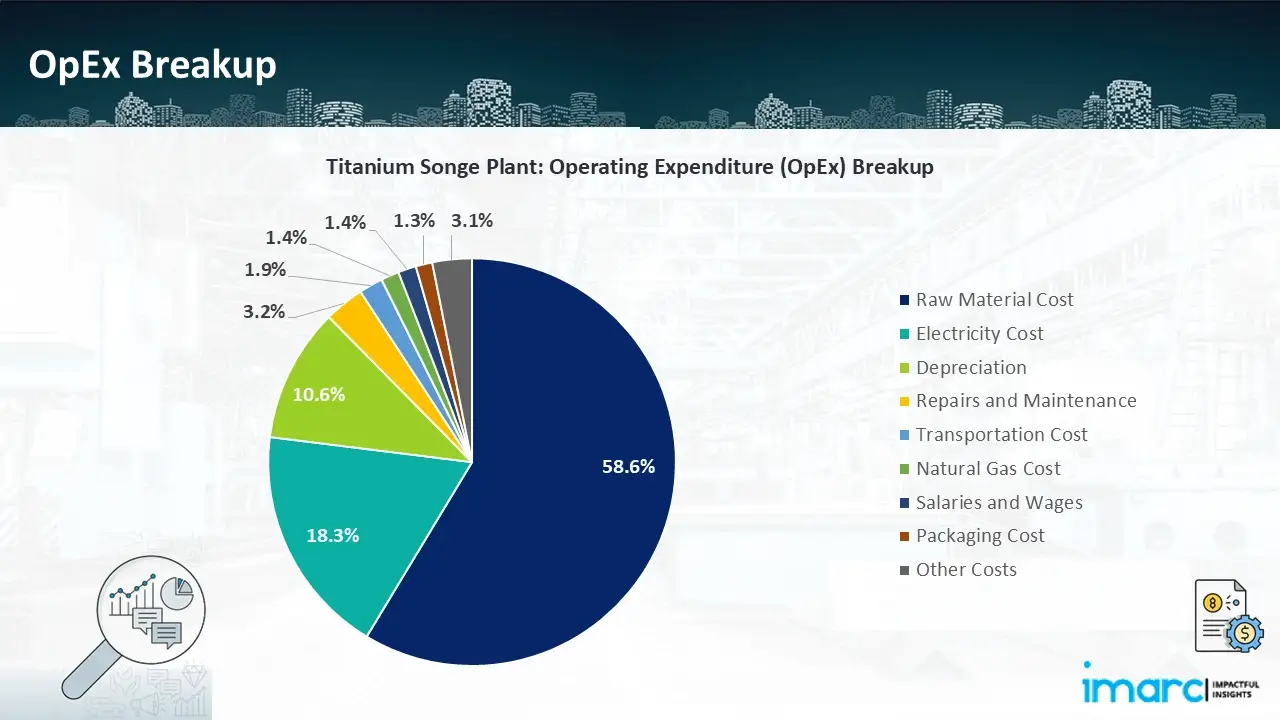

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

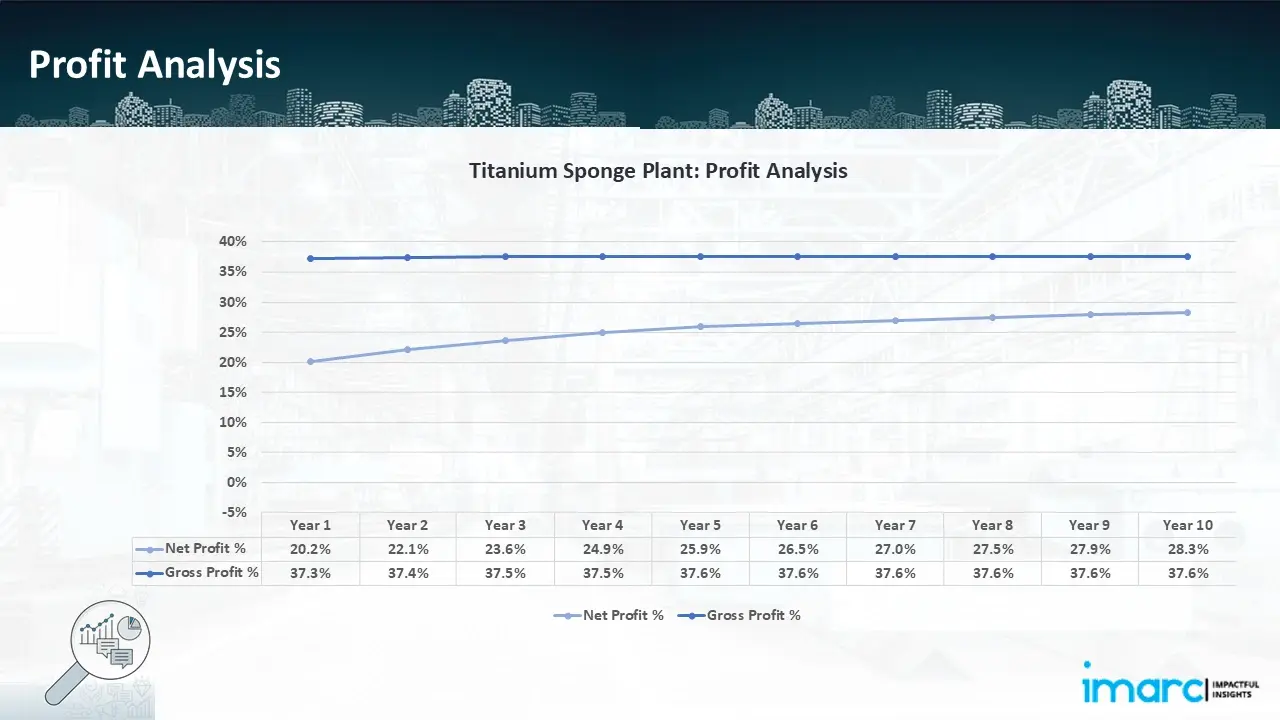

- Profitability Analysis Year on Year Basis: The proposed titanium sponge plant, with a capacity of 100 tons titanium sponge per day, achieved an impressive revenue of US$ 211.6 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising till year 5 and then remaining constant till year 10. Moreover, gross profit improved from 37.3% to 37.6%, and net profit rose from 20.2% to 28.3%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our titanium sponge manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 100 tonnes of titanium sponge per day. Our commitment to offering precise, client-cantered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In January 2025, PTC Industries and the Government of Odisha have signed a Memorandum of Understanding (MoU) to build a cutting-edge aerospace-grade titanium sponge production facility in the area.

- In May 2024, National Titanium's announced that its titanium sponge production project has reached full operational capacity. The company currently manufactures 80,000 Tonnes of titanium sponge annually (tpa), mostly for industrial, medicinal, and aerospace uses. By guaranteeing a steady supply to important businesses, this milestone solidifies its position in the titanium market.

- In May 2024, Osaka Titanium Technologies, a Japanese manufacturer, announced to increase the capacity of its titanium sponge due to increased demand from the aviation sector, which has resulted in increased sales and profits. In order to address the increasing demand for titanium sponge, it intends to invest ¥30 Billion (US$191 Million) to establish a new factory in the western city of Amagasaki, Japan. This will increase Amagasaki's capacity to produce titanium sponge from 40,000 t/yr to 50,000 t/yr.

- In December 2023, Xinjiang Xiangsheng New Material Technology Co., Ltd. plans to increase its titanium sponge production capacity by 30,000 Tonnes per annum (tpa), focusing on aviation-grade material. This expansion will raise the company's total capacity from the current 20,000 tpa to 50,000 tpa. Additionally, the project aims to produce byproducts such as 1,861.2 Tonnes of low-grade titanium sponge, 21,800 Tonnes of steel linear plates and castings, and 50,000 Tonnes of wearable steel balls annually.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104