Cost Modeling and Financial Viability of Yellow Phosphorus Manufacturing Plant: A Detailed Cost Model

What is Yellow Phosphorus?

Yellow phosphorus, a chemical element with the symbol P and atomic number 15, is a fascinating and essential element in the periodic table. This highly reactive nonmetal is widely known for its distinctive yellow appearance and its crucial role in various industrial applications.

Key Applications Across Industries:

Found in nature primarily as phosphates, yellow phosphorus is isolated through a complex process to ensure its purity and effectiveness. Its versatility allows it to be employed in the production of fertilizers, detergents, and even in the synthesis of organophosphorus compounds used in medicine and pesticides.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global yellow phosphorus market was valued at US$ 4.4 Billion in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 3.4% from 2025 to 2033, reaching a projected value of US$ 5.9 Billion by 2033. It has a wide range of benefits and uses. First, it transformed fire-starting through its contribution to the manufacturing of safety matches.

It is also an essential part of phosphoric acid, which is used in food additives, detergents, and fertilisers. Yellow phosphorus is used to make a variety of industrial compounds that improve safety and protection, including insecticides and flame retardants. It is employed for semiconductor doping in the electronics sector. Additionally, it is essential to smoke grenades in the military. Its many uses, ranging from technology to agriculture, make it an invaluable asset for improving many facets of contemporary life. Accordingly, the growth of the market is being aided by the development of e-commerce platforms and the accessibility of a large variety of goods. The market is expanding due to several other factors, including continuous research and development (R&D) efforts and advancements in formulations and delivery systems.

Case Study on Cost Model of Yellow Phosphorus Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale yellow phosphorus manufacturing plant in Tien Giang, Vietnam.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with production capacity of 100 tons of yellow phosphorus per day.

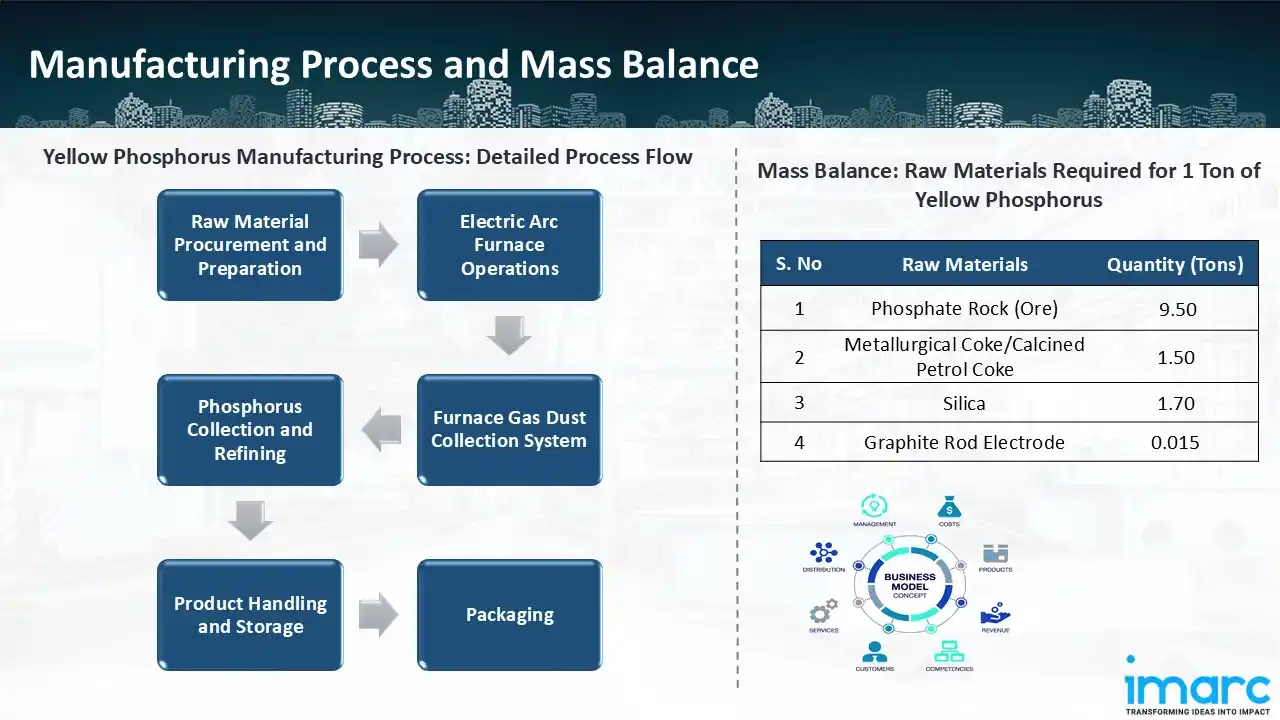

Manufacturing Process: The procurement and processing of raw materials, such as phosphate rock, coke, and silica, is the first step in the production of yellow phosphorus. To maximise the chemical reaction in the furnace, these components are precisely combined and crushed. A reduction reaction is facilitated by the high temperatures (over 1,200°C) in an electric arc furnace (EAF), where the combined raw materials are supplied. This procedure creates gaseous phosphorus by reducing phosphorus pentoxide (P2O5) from the phosphate rock with carbon from coke. Furnace gases are then discharged together with this phosphorus gas. The gaseous phosphorus is collected by a furnace gas dust collection device, which also filters out contaminants. Following controlled condensation, the gas is collected and processed into liquid yellow phosphorus. To eliminate any remaining contaminants, the liquid phosphorus must be cooled and purified throughout the phosphorus collection and refining process. This guarantees yellow phosphorus of superior purity appropriate for industrial use. To avoid oxidation and spontaneous combustion, the refined phosphorus is then sent to product handling and storage, where it is maintained in water or inert conditions. The substance is then delivered for use in fertilisers, chemicals, and other sectors after being packaged in specialised containers.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the Yellow Phosphorus manufacturing plant include phosphate rock (ore), metallurgical coke/calcined petrol coke, silica and graphite rod electrode. To produce 1 ton of yellow phosphorus, around 9.50 tons of phosphate rock (ore), 1.50 tons of metallurgical coke/calcined petrol coke, 1.70 tons of silica, and 0.015 tons of graphite rod electrode is required.

List of Machinery:

The following equipment was required for the proposed plant:

- Electrode Hydraulic Lifter

- Crane

- Electric Hoist

- Draught Fan

- Pumping Machinery

- Valves and Fittings

- Raw Material Belt Conveyor and Belt Scale

- Winch

- Furnace Opener

- Slagging System Equipment

- Other Standard Equipment

- Steam Boilers (Fueled by Yellow Phosphorus Tail Gas)

- Electric Furnace Steel Shell

- Feed Pipe

- Gas Scrubber and Air Conduit

- Storehouse

- Tail Gas Main Water Seal, Safety Water Seal and Air Feed Water Seal

- Phosphorus Tanks

- Yellow Phosphorus Refining Kettle

- Mud Phosphorus Refining Tank

- Mud Phosphorus Settling Tank

- Yellow Phosphorus Metering Tank

- Yellow Phosphorus Transit Tank and Crude Phosphorus Transit Tank

- Cooling Water Circulation Tank

- Condensate Tank and Rinse Return Tank

- Rinse Water High Level Tank

- Emergency Water Tank

- Yellow Phosphorus Packing Water Tank

- Pipes

- Other Incidental Facilities, etc.

- Carbon Bricks (Including Bottom and Wall Carbon Bricks)

- Carbon Tile Seam Paste

- Refractory Bricks, etc.

- Construction Cost

- Workshop Power Transformer

- Distribution Cabinets, Distribution Boxes, Operating Columns, etc.

- Electric Cables

- Cable Tray

- Other Materials (Including Line Pipe, Sporadic Steel, etc.)

- Furnace Transformers

- Short net system

- Desulphurization Tower

- Water Washing Tower

- Alkali Washing Tower

- Induced Draft Fan

- Cooling Tower

- Control System

- Cable & Cable Tray

- Other Materials

- Non-standard Equipment

- Standard Equipment

- Piping and Others

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

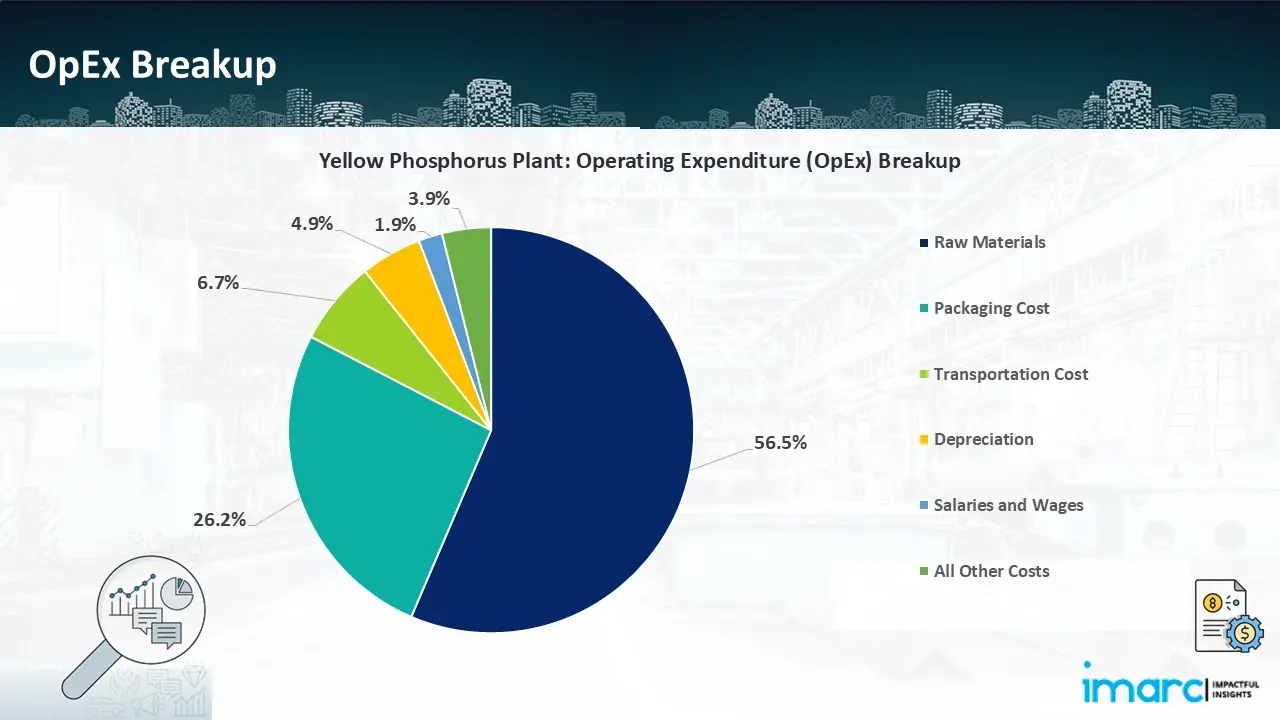

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

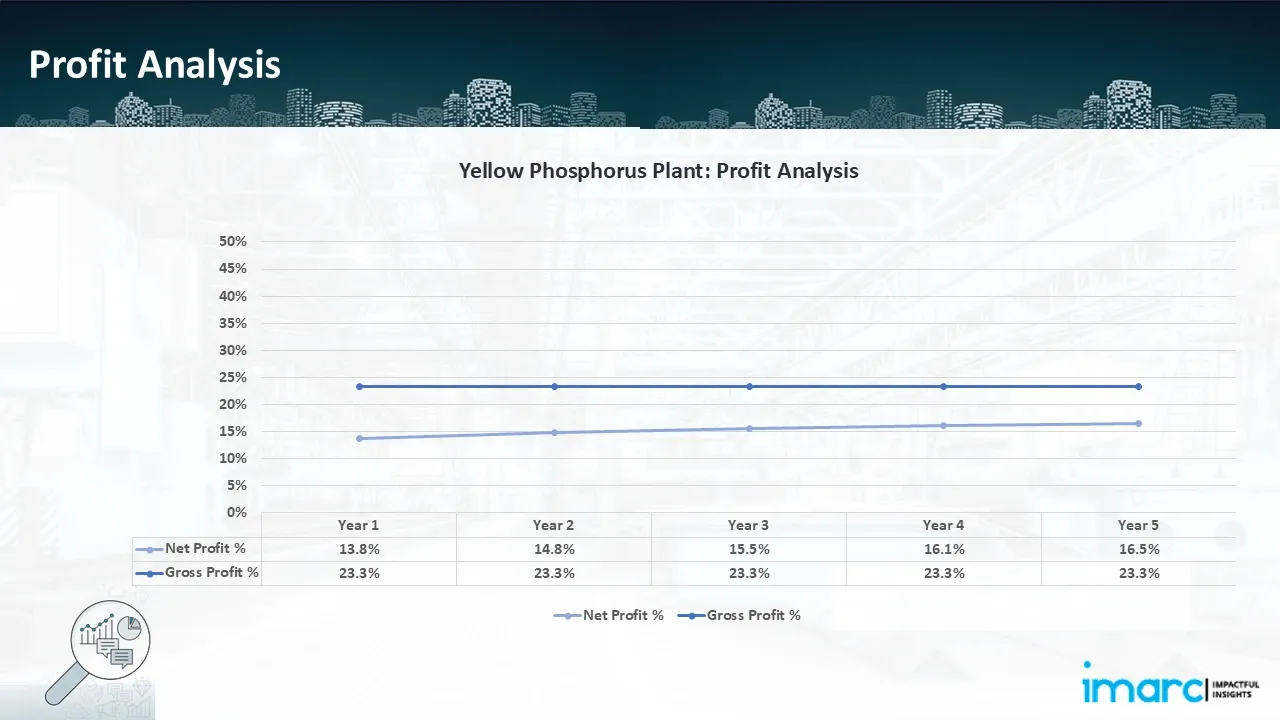

- Profitability Analysis Year on Year Basis: The proposed yellow phosphorus plant, with a capacity of 100 tons of yellow phosphorus per day, achieved an impressive revenue of US$ 106.42 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the years. Moreover, gross profit stood constant at 23.3% throughout the years, and net profit rise from 13.8% to 16.5%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our yellow phosphorus manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 100 tonnes of yellow phosphorus per day. Our commitment to offering precise, client-cantered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In November 2024, Mitsui Chemicals, Inc. declared that it has started working on the recycling technique needed to create high-purity phosphorus materials in Japan, in collaboration with Shimonoseki Mitsui Chemicals, Inc., its wholly owned subsidiary.

- In March 2024, Ðuc Giang Chemicals Group JSC (DGC) has revealed that it is looking to expand its production of yellow phosphorus through possible merger and acquisition (M&A) agreements. Within this year, DGC and Vietnam Apatite-Phosphorus Joint Stock Company (PAT) intend to unite.

- In January 2024, an inauguration ceremony was staged by Sichuan Huifenghe New Material Technology Co., Ltd., a subsidiary of Fuhua Tongda Chemical, China's primary glyphosate manufacturer, to restart the yearly 20,000-ton yellow phosphorus facility in China following the refurbishment of environmental and safety equipment.

- In October 2023, a joint research agreement between Sumitomo Corporation and Tohoku University aims to develop a new yellow phosphorus production technique and enable the commercial production of this raw material for semiconductors in Japan.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104