Economic Assessment of Stone Paper Manufacturing: A Detailed Cost Model

What is Stone Paper?

Stone paper is an innovative, eco-friendly material gaining traction across various industries due to its durability, sustainability, and water resistance. Made primarily from calcium carbonate and resin, it offers a tree-free alternative to traditional paper, reducing deforestation and water consumption.

Key Applications Across Industries:

Its tear-resistant and smooth texture makes it ideal for printing, packaging, and stationery applications. Additionally, stone paper is recyclable, photodegradable, and highly resistant to moisture, making it suitable for outdoor and high-humidity environments. With growing environmental concerns and demand for sustainable packaging and printing solutions, stone paper is emerging as a key player in the global paper industry, attracting interest from publishers, packaging manufacturers, and eco-conscious brands.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global stone paper market reached USD 951.5 Million in 2025. Looking ahead, the market is expected to grow at a CAGR of approximately 3.19% from 2026 to 2034, reaching a projected size of USD 1,273.5 Million by 2034.

The global stone paper market is driven by several key factors. The increasing demand for sustainable and eco-friendly alternatives to traditional paper has significantly boosted market growth, particularly in regions with stringent environmental regulations. Stone paper’s durability, water resistance, and recyclability make it an attractive choice for various applications, including packaging, printing, and labelling. Additionally, its role in reducing deforestation and water consumption aligns with global sustainability goals, further driving adoption. Advancements in production technologies, including improved mineral-based formulations and energy-efficient manufacturing processes, have enhanced product quality, cost-effectiveness, and environmental impact. As industries and consumers shift toward greener solutions, stone paper continues to gain traction as a viable alternative, supporting sustainable packaging, publishing, and stationery markets worldwide.

Case Study on Cost Model of Stone Paper Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale stone paper manufacturing plant in Qatar.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with a production capacity of 16.67 tons per day.

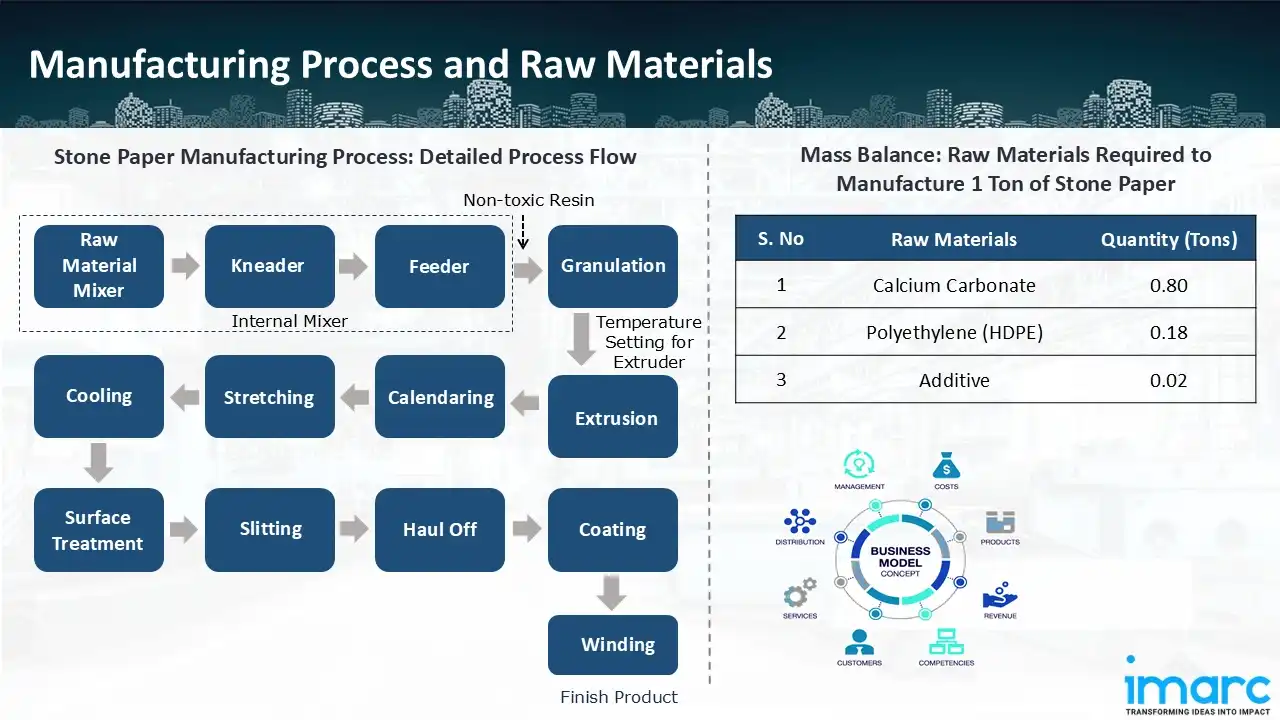

Manufacturing Process: Stone paper production involves pelletizing and extrusion processes. It begins with internal mixing, where raw materials, auxiliaries, and additives are blended in a high-temperature, high-pressure kneader to ensure uniform dispersion. The mixed material is then granulated into pellets, making it suitable for extrusion. During extrusion, the granules are fed into an extruder with a screw and barrel system, where they are heated to 160°C and combined with molten PE. The molten material is then extruded through an O-shaped die, forming a cylindrical tube. Compressed air blows this into a stable film bubble, which is calendared through a three-roller system to achieve the desired thickness. Next, the material undergoes stretching and cooling for structural stability. Surface treatment, such as corona treatment, improves ink adhesion for printing. Slitting trims the edges to customer specifications, followed by coating for enhanced durability. Finally, the stone paper is wound into rolls for various applications.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the stone paper manufacturing plant include calcium carbonate, polyethylene (HDPE) and additive. To produce 1 ton of stone paper, we require 0.80 tons calcium carbonate, 0.18 tons polyethylene (HDPE) and 0.02 tons additive.

List of Machinery:

The following equipment was required for the proposed plant:

- Weightless Automatic Metering and Feeding System

- Continuous Internal Mixer with Double Rotors

- Forced Feeding Device

- Single Screw Extruder

- Die Surface Hot Cutting Auxiliary System

- Feeder System

- Screw

- Gear Box

- Motor

- Die Head

- Automatic Air Supply and Stabilizer

- Traction Splint

- Thickness Gauge

- Winding Machine

- Rolling Machine

- Levelling Roll

- Corona

- Coating Die

- Oven

- Winding Machine

- Pure Water Making Equipment

- Dissolving Tank

- Stirred Tank

- Slitting Machine

- Cutting Machine

- Lab Test Machine

- Balance

- Oven

- High Temperature Furnace

- Whiteness and Opacity Meter

- Particle Size Analyzer

- Smoothness Tester

- Viscosity Meter

- Tensile Machine

- Hand Mixer

- Melt Indexer

- Hand-Held Thickness Gauge

- Table Thickness Gauge

- Small Electric Airsickness

- Small Coating Machine

- Stiffness Instrument

- Gloss Meter

- Hydrometer

- Gram Sampler

- Standard Pressure Roll

- Standard Cutter

- Analyze Computer and Label Printers

- Detection of Consumables

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

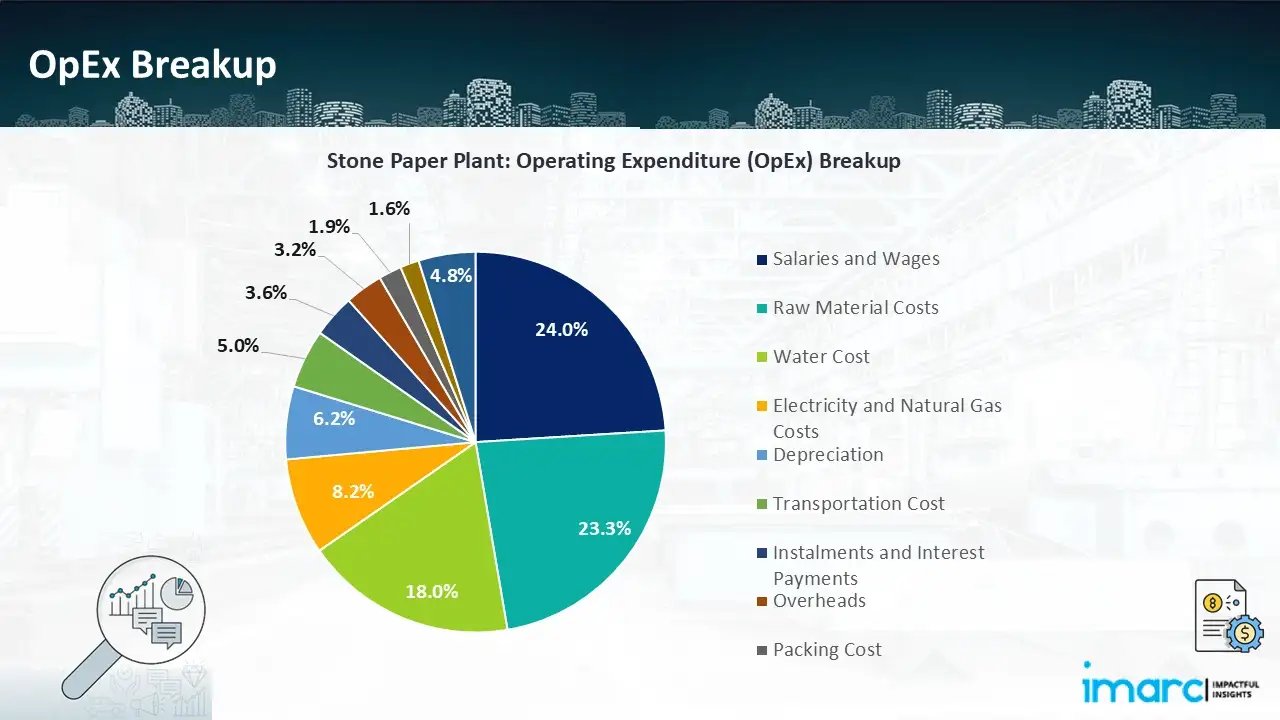

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

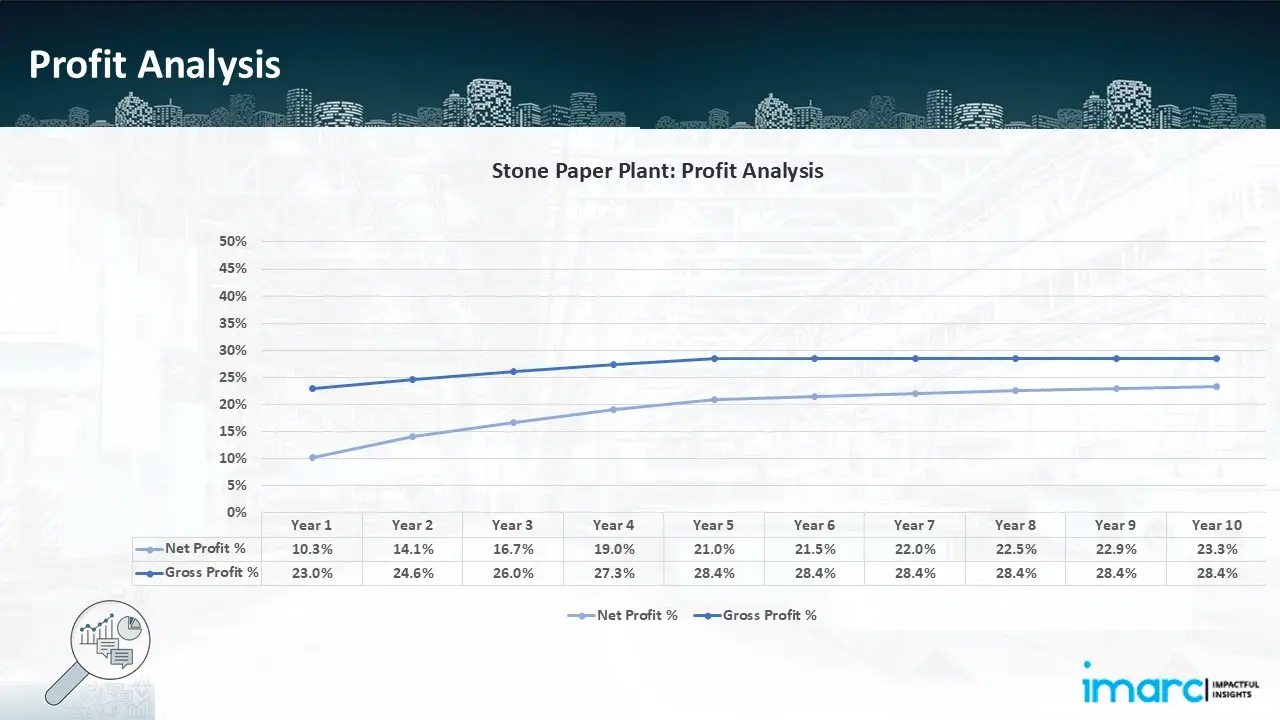

- Profitability Analysis Year on Year Basis: The proposed stone paper plant, with a capacity of 16.67 tons per day, achieved an impressive revenue of US$ 6.00 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Gross profit margin improved from 23.0% to 28.4% throughout the years, and net profit went up from 10.3% to 23.3%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our stone paper manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of manufacturing 16.67 tons of stone paper per day. Our commitment to offering precise, client-cantered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In October 2023, Shenzhen Stone Paper Enterprise Ltd. has unveiled its wholesale stone powder synthetic paper as a sustainable and flexible solution for vegetable packaging in the printing and packaging industry. The company highlights the exceptional durability of stone paper, making it ideal for packaging various vegetables while ensuring their protection during transportation and storage. Additionally, the use of non-toxic resin in its production ensures that no harmful chemicals come into contact with food items, maintaining both safety and freshness.

- In January 2023, Taiwan Longmeng Composite Materials Co., Ltd. responded to the growing e-commerce waste problem by developing a new recycling system for environmentally friendly packaging materials. The company reported that Taiwan’s online shopping sector consumes over 100 Million packing boxes and bags annually, generating approximately 18,000 tons of packaging waste. To combat this issue, they have introduced corrugated cardboard made from stone paper composite material. This innovation is particularly useful for cold-chain logistics, where traditional corrugated cardboard boxes can be replaced with stone-paper-based saury boxes, significantly reducing packaging waste.

- In December 2021, A KEMAS developed Limex Pellet, an injection-molding-grade material that is both highly recyclable and environmentally friendly. This advanced material aims to reduce greenhouse gas emissions while conserving critical natural resources. Limex Pellet offers a sustainable alternative to conventional plastic, reinforcing the company’s commitment to eco-friendly manufacturing solutions.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104