Assessing the Financial Viability of a Gelatin Powder Manufacturing Plant: A Cost Model Study

What is Gelatin Powder?

Collagen in the connective tissues, bone, and skin of cows and pigs contains gelatin. A common method for creating this colourless, odourless animal protein is to boil ligaments, tendons, and skin in water.

Key Applications Across Industries:

Its outstanding physical characteristics include low viscosity, dispersion stability, high affinity, and dispersibility. In the food and beverage business, it is a widely used food additive. It is also used to make skin care and personal care products since the amino acids it contains aid to improve the look of skin and hair. Due to its exceptional water-binding and emulsifying qualities, gelatin is widely used in the global pharmaceutical and cosmetics industries.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global gelatin market size reached 4,70,970 Tons in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 1.3% from 2025 to 2033, reaching a projected volume of 5,36,020 Tons by 2033.

The global gelatin market is primarily driven by the rising demand for nutritional foods and beverages. Moreover, the escalating demand for gelatin in bakeries and confectionaries as a thickening and gelling agent is positively influencing market growth. Apart from this, the rising use of gelatin in cosmetics and personal care products, as it helps strengthen nails and hair, boost metabolism, and fight wrinkles, has catalyzed market growth. Additionally, there has been a rise in the use of gelatin for producing hard capsules and softgels. In line with this, the increasing customer preference for clean-label products owing to rising health consciousness is another major growth-inducing factor. Besides this, the rising applications of gelatin in paper and silver halide emulsion coatings have augmented the product demand.

Case Study on Cost Model of Gelatin Powder Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale gelatin powder manufacturing plant in Khalifa Economic Zone Abu Dhabi, UAE.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 3,000 Tons of gelatin powder per year.

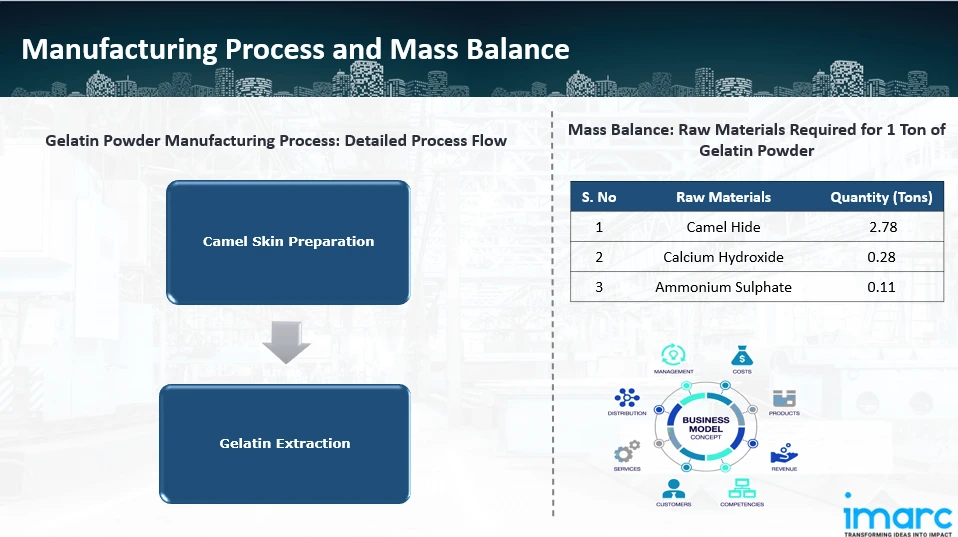

Manufacturing Process: The manufacturing process of gelatin from camel skin/hide involves camel skin preparation and gelatin extraction. First, healthy camels killed at three years old are used to make fresh camel skin, which has a pH of about 4.5 and is sent straight to the production facility. The skin is thoroughly cleaned with distilled water upon arrival to the plant, and any exposed meat is removed. Skins were limed with 10% (w/v) calcium hydroxide for 48 hours at room temperature, rinsed with water, neutralised with 4% (w/v) ammonium sulphate, and extracted with distilled water 1:3 (w/v) at 75 °C for three hours and 90 °C for two hours after the skin preparation procedure. After filtering, the collected gelatin was centrifuged at 30 °C for 5 minutes. The supernatant was dried at 60 °C for 24 h.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the gelatin powder manufacturing plant include camel hide, calcium hydroxide, and ammonium sulphate. To produce 1 ton of gelatin powder, around 2.78 ton of camel hide, 0.28 ton of calcium hydroxide, and 0.11 ton of ammonium sulphate are required.

List of Machinery

The following equipment was required for the proposed plant:

- Rotary di-shear skin cutter

- U type washing and neutralization units

- Extraction units

- Boiling extraction unit

- Clarification unit

- Cotton plate filter

- Cotton cake washing and pressing system

- Special ion exchanger for gelatine purification

- UF unit

- Three-effect falling film evaporator

- Flash steam sterilization unit

- Drying and dehumidifying system

- Milling machine

- Mixing machine

- Packing machine

- Buffering tanks for skin

- Process water heating and supplying system

- Storage tank for gelatine solution

- Buffering tank

- Storage tank for concentrated gelatine

- Buffering tank for concentrated gelatine

- Recycling tank for gelatine solution

- CIP system for gelatine extraction workshop

- Sanitary piping system for extraction workshop

- PLC/DCS control system for extraction workshop

- Waste Water Treatment Plant (WWTP) - Capacity: 500 Tons/Day

- Boiler - Capacity: 100 Tons/Day

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

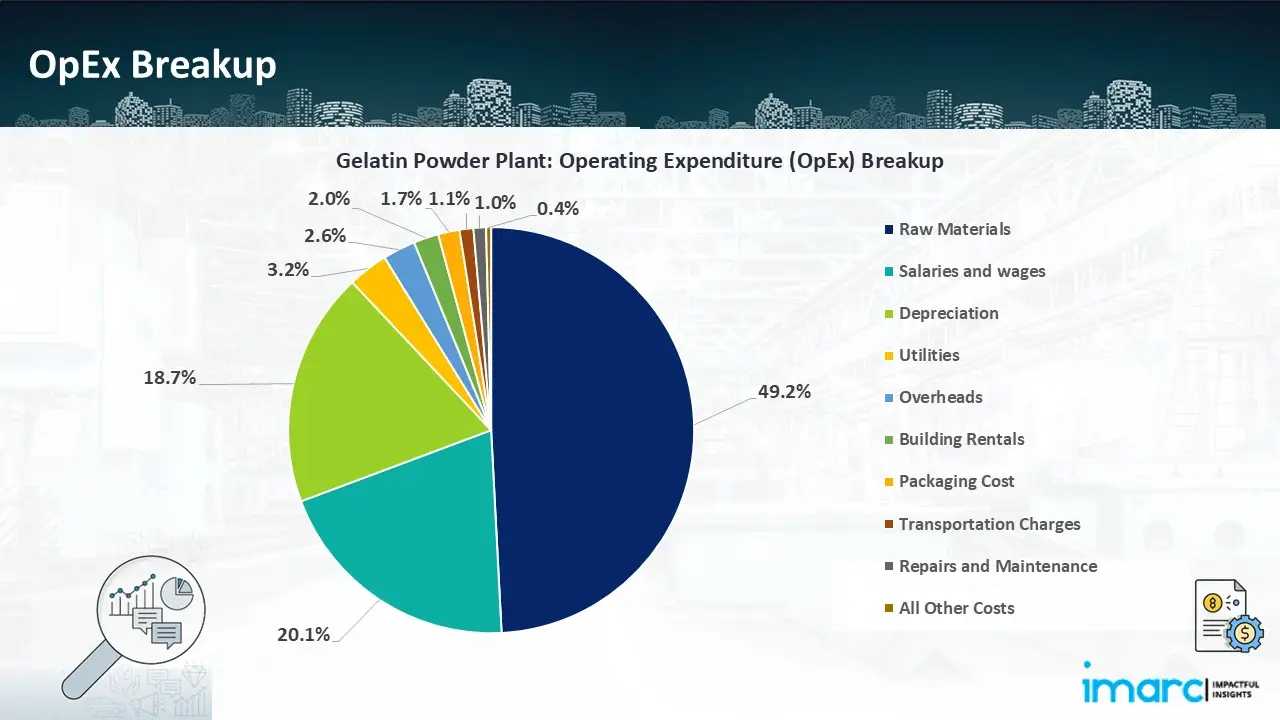

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

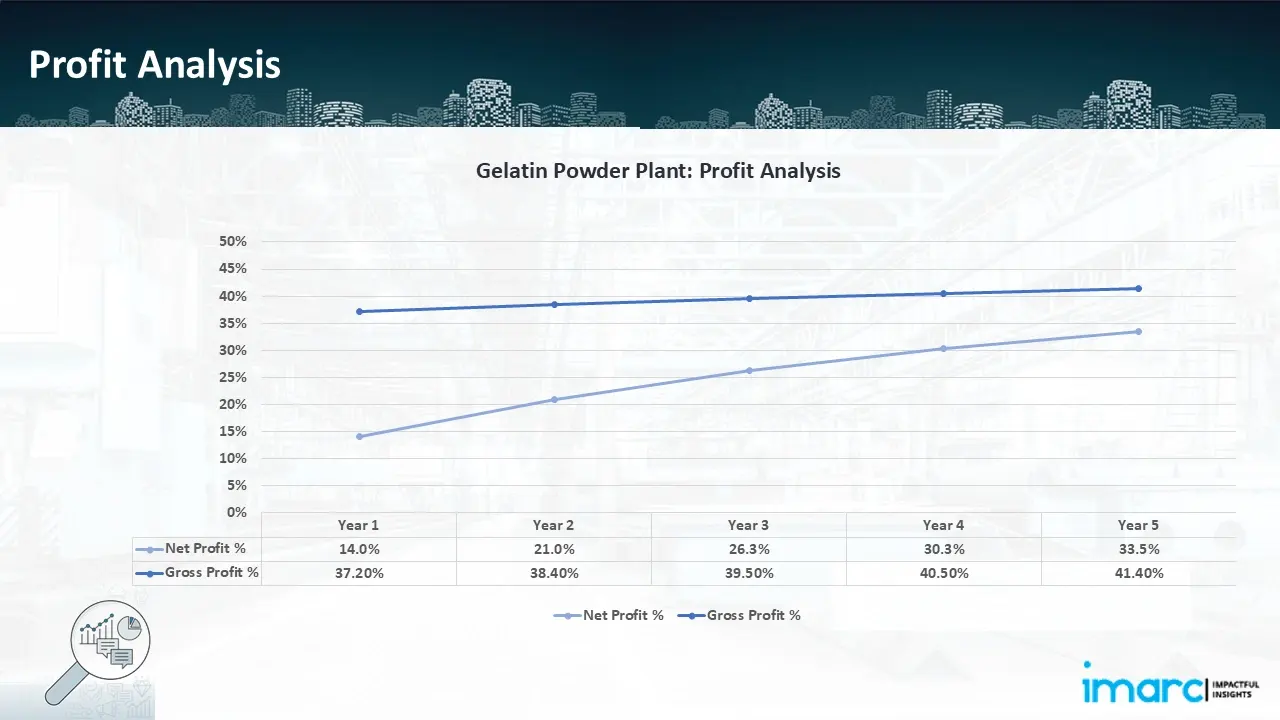

- Profitability Analysis Year on Year Basis: The proposed gelatin powder plant, with a capacity of 3,000 tons gelatin powder per year, achieved an impressive revenue of US$ 11.91 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit improved from 37.2% to 41.4%, and net profit rise from 14.0% to 33.5%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our gelatin powder manufacturing plant's financial model was meticulously created to satisfy the client's needs. Including capital expenditures, manufacturing processes, raw materials, and operating costs, it provided a thorough analysis of production costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 3,000 tonnes of gelatin powder annually. Our commitment to offering precise, client-centered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In June 2024, researchers at the ATLAS Institute at the University of Colorado Boulder think they may have solutions for using natural, biodegradable materials like gelatin to significantly reduce waste and provide recyclable fibres for apparel and other textiles. As consumers throw away clothes and other textiles, sometimes after just a few uses, the textile industry—which currently contributes significantly to landfill waste—may undergo a significant change.

- In May 2024, Nitta Gelatin launched a INR 200-crore expansion project In Kochi. The facility in Kakkanad hosted the groundbreaking ceremony for Nitta Gelatin India Limited's (NGIL) collagen peptide expansion project. The Kerala State Industrial Development Corporation and Nitta Gelatin of Japan have partnered to form NGIL. An investment of INR 200 crore is needed for the expansion project.

- In March 2023, GELITA has introduced a fast-setting gelatin that makes it possible to produce fortified gummies in a revolutionary way. The new gelatin, which goes by the name CONFIXX, makes it possible to produce gummies without starch that have a sensory profile that was previously only possible with a starch-based manufacturing procedure.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104