Beer Cost Model: Profitability and Cost Breakdown

_11zon-(1).webp)

What is Beer?

Beer is one of the oldest and most popular alcoholic drinks in the world, made by the fermentation of cereal grains, usually barley, but also wheat, maize, or rice using yeast, hops, and water. The process of brewing turns these natural products into a drink that has intricate flavors, fizz, and a range of alcohol levels, usually 3% to 8% ABV. Hops add bitterness and flavor, with malted barley adding fermentable sugars and color.

Key Applications Across Industries:

Beer has developed in centuries from small-scale, craft brewing to an international industrialized market with identifiable styles including lagers, ales, stouts, and pilsners. Contemporary brewing utilizes sophisticated technologies such as automated fermentation management, filtration, and pasteurization to deliver consistent product quality and longer shelf life. Apart from being a recreational beverage, beer is also of great cultural and economic significance. It is a focal point for social events, festivities, and meals, as well as a backbone for massive-scale agricultural and industrial economies. The international brewing industry features giant multinational companies like Anheuser-Busch InBev, Heineken, and Carlsberg, together with a fast-emerging craft brewing sector which values creativity, local produce, and traditional brewing methods. Rising consumer demand for premium and flavored beers and sustainable brewing is redefining market trends. With shifting consumer taste to low-alcohol and non-alcoholic beverages, brewers are broadening portfolios to address evolving lifestyle and health trends. As a result, beer not only continues to be a beverage staple but also a demonstration of changing consumer behavior, craftsmanship, and global beverage innovation.

What the Expert Says: Market Overview & Growth Drivers

The global beer market reached a value of USD 686.3 Billion in 2024. According to IMARC Group, the market is projected to reach USD 802.9 Billion by 2033, at a projected CAGR of 1.8% during 2025-2033. The global beer industry is fueled by a mix of demographic, cultural, and economic elements that keep stimulating diversification and growth.

Rising demand for premium and craft beers due to consumers increasingly desiring products with unique flavors, authenticity, and local craftsmanship is among the major drivers. Increased middle-class population in developing economies, especially Asia-Pacific, Africa, and Latin America, has resulted in higher disposable incomes and increased alcoholic beverage consumption, leading to increased beer sales. The expansion of urbanization and hospitality industry, such as pubs, bars, and restaurants, also contributes largely to the growth of the market. The development of new flavors and brewing methods, e.g., fruit-flavored, gluten-free, or reduced-calorie beers, appeals to changing consumer preferences and health-oriented tastes. Additionally, the growing demand for low-alcohol and non-alcoholic beers is also driven by wellness movements and shifts in drinking culture, particularly among the young and in areas where alcohol is more strictly regulated. The industry also gains from the adoption of more sustainable brewing methods such as water-saving techniques, the use of renewable energy, and recyclable packaging, which resonate with sustainable consumers. E-commerce platforms and digital marketing further increase access, allowing breweries to find new consumers directly. Moreover, huge mergers and acquisitions of leading global brewers are consolidating distribution channels and broadening product ranges. Collectively, these elements are driving innovation, consumer interaction, and global access, setting the beer market on a trajectory of consistent growth amidst regional regulatory issues and changing consumption trends.

Case Study on Cost Model of Beer Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale beer manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed beer manufacturing plant in India. This plant is designed to produce 6,000,000 litres of beer annually.

Manufacturing Process: The production process of beer is a tightly controlled biochemical and mechanical process that transmutes cereal grains, mostly barley, into a tasty, carbonated alcoholic drink. The process starts in the malting phase, where grains of barley are water-soaked, permitted to sprout, and subsequently kiln-dried in order to stop germination. This step also triggers enzymes to transform the starches of the grain into fermentable sugars. The milled malted barley is subsequently milled to coarse grist, which allows for effective sugar extraction in the subsequent phase, mashing. During mashing, the milled malt is added to hot water in a mash tun, with enzymes breaking down starches further into maltose and other sugars to produce a sweet liquid called wort. The wort is filtered and transferred to a brew kettle, where it's boiled and hops are included. Hops provide bitterness, flavor, and serve as natural preservatives. Boiling kills off the wort and stabilizes its composition. Rapid cooling of the wort follows boiling to an appropriate temperature for fermentation. The cooled wort is then transferred to fermentation tanks, where yeast (most commonly Saccharomyces cerevisiae for ales or Saccharomyces pastorianus for lagers) is added. The yeast ferments sugars into alcohol and carbon dioxide over a period of several days or weeks depending on the type of beer. Once fermented, the beer is matured or conditioned to mature flavor and clarity. It is subsequently filtered, carbonated, and pasteurized (in most cases) and then filled into bottles, cans, or kegs. Every step enforced by accurate temperature, time, and ingredient regulation maintains the consistency, stability, and characteristic flavor profile of the beer.

Get a Tailored Feasibility Report for Your Project Request Sample

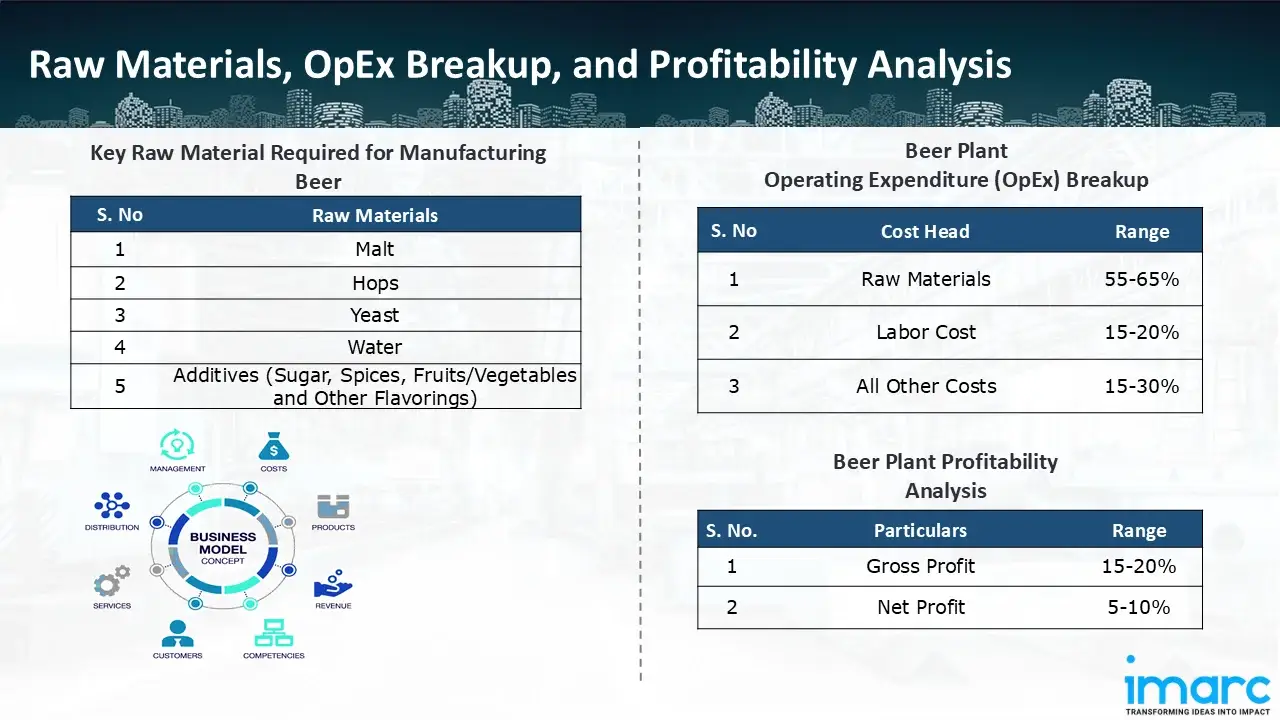

Raw Material Required:

The basic raw materials required for beer manufacturing include:

- Malt

- Hops

- Yeast

- Water

- Additives (Sugar, Spices, Fruits/Vegetables and Other Flavorings)

Machineries Required:

- Roller Mill

- Hammer Mill

- Mash Tun (Cylindrical / Conical Vessel, Jacketed for Heating)

- Agitator / Stirrer

- Lauter Tun with False Bottom

- Mash Filter Press

- Steam-Heated / Direct-Fired Kettle

- Wort Agitator

- Whirlpool Tank (Centrifugal Action)

- Pump Hot Wort Through Heat Exchanger

- Cold Water / Glycol

- Cool To 18–25°C For Ale

- 8–12°C For Lager

- Inline Aerator

- Oxygen Diffuser

- Cylindroconical Fermenters (Stainless Steel)

- Temperature Control Jackets

- Plate and Frame Filter

- Cartridge Filter

- Centrifuge

- Carbonation / Conditioning Tanks

- Bottle Filler (Gravity / Counter-Pressure)

- Can Filler

- Keg Filler

- Capping / Seaming Machine

- Water Treatment System (RO, Softener, Dechlorinator)

- CIP (Clean-In-Place) Systems for Tanks and Pipelines

- Pumps and Piping for Wort and Beer Transfer

- Sensors (Temperature, Pressure, Ph, Dissolved Oxygen and CO2 sensor)

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a beer manufacturing plant ranges between 55-65%, labor cost ranges between 15% to 20%, and all other costs ranges between 15-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the beer manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 6,000,000 litres of beer annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, Carlsberg India plans to invest more than Rs 400 crore in Bengal to expand its brewery in Dhanekhali, Hooghly, using a brownfield project. This is part of the multinational beer giant's plan to grow in India. This follows the announcement at World Food India 2025 that the firm and the Union Ministry of Food Processing Industries had signed a Memorandum of Understanding.

- In October 2024, Molson Coors has completed its 200,000-square-foot brewery expansion in Golden, Colorado. According to the corporation, this will ultimately save money and help lower carbon emissions.

- In January 2024, the global division of Asahi Group Holdings, Asahi Europe & International (AEI), announced the purchase of Octopi Brewing, a well-known contract beverage manufacturing and co-packing plant in Waunakee, Wisconsin.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104