The Convenience of Instant Coffee: A Cost Modeling Approach Aiming Manufacturing Efficiency

What is Instant Coffee?

Instant coffee is a quick and easy-to-brew coffee beverage that is produced by brewing coffee beans into a liquid that concentrates and evaporates into powder or grain form.

Key Applications Across Industries:

It rapidly dissolves in hot water, so it's highly sought after by customers demanding fast and easy coffee brewing. It has a long storage life and is inexpensive, making it popular in homes, offices, and food service establishments. It is fueled by urbanization, hectic lifestyles, and growing demand for convenience drinks.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global instant coffee market reached US$ 14.7 Billion in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 4.5% from 2025 to 2033, reaching a projected size of US$ 21.9 Billion by 2033. The market for instant coffee is fueled by convenience, price, and changing consumer lifestyles.

With increased urbanization and busy lifestyles, demand for speedy, easy-to-make drinks has led to instant coffee being a popular option. Its long shelf life and lower price point in comparison to freshly brewed coffee are additional advantages. Expansion of coffee consumption in developing markets, particularly in the Asia-Pacific region, is another major driver. Furthermore, premium instant coffee innovations, organic types, and flavors appeal to young and health-conscious consumers. Growing demand for instant coffee in hotels, offices, and vending machines is also fueling market expansion. Furthermore, increasing e-commerce growth and aggressive marketing efforts by major players have enhanced availability, driving sales worldwide. Sustainability trends like packaging that is environmentally friendly and fair-trade sourcing are also impacting buying behavior. Overall, the market for instant coffee is expected to grow steadily, stimulated by shifting consumer trends and freeze-drying and spray-drying technology advancements.

Case Study on Cost Model of Instant Coffee Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale instant coffee manufacturing plant in Jeddah Industrial City 3, Saudi Arabia.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 307 tons of instant coffee.

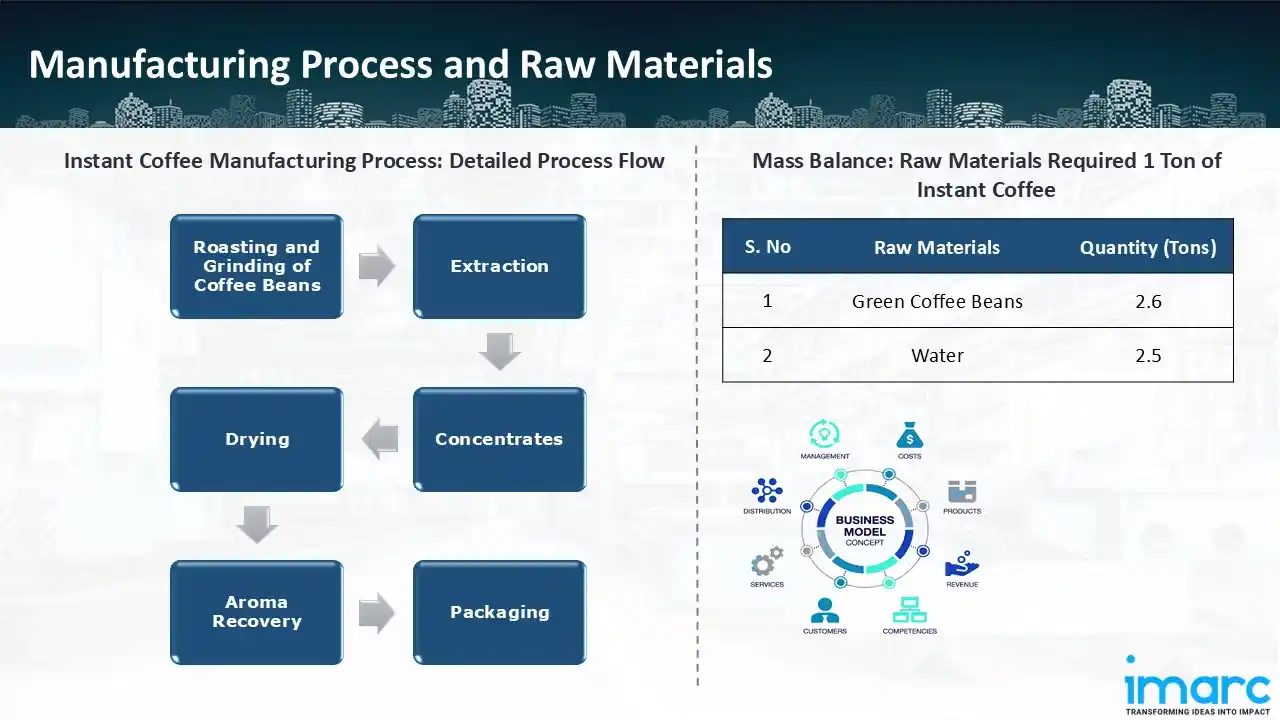

Manufacturing Process: Several crucial steps are involved in the production of instant coffee to guarantee efficiency, quality, and consistency. Depending on the desired roast profile, which affects flavour and aroma, green coffee beans are first roasted for 7 to 20 minutes at 180 to 250°C. To maximise extraction, the roasted beans are subsequently ground into fine to medium-sized particles. A concentrated solution of 25–35% coffee solids is created during the extraction stage by passing hot water (80–90°C) over powdered coffee in an insulated extractor, which dissolves soluble components. Then, employing vacuum concentration—where water evaporates under lower pressure—this extract is concentrated to 30–33%. The coffee is next dried by either freeze-drying, which retains flavour and aroma by freezing the extract and sublimating the ice under vacuum, or spray-drying, which atomises the liquid into a hot air stream to create a fine powder. scent recovery methods like desorption and adsorption are utilized to replenish lost volatile components because drying can lessen scent. To guarantee freshness, convenience, and product integrity, the instant coffee is next packaged using automated filling, sealing, and labelling machinery into jars, pouches, sachets, or single-serve sticks. This methodical procedure improves productivity while preserving the taste, aroma, and quality of instant coffee for consumers everywhere.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the instant coffee manufacturing plant largely include green coffee beans and water. To produce 1 ton of instant coffee, we require 2.6 tons of green coffee beans, and 2.5 tons of water.

List of Machinery:

The following equipment was required for the proposed plant:

- Neuhaus Neotec Hot Air Roasting Section

- Neuhaus Neotec Grinding system and R&G coffee silos, transport system

- DEVEX DV-12 High End Extract Preparation Section,

- ROBUSTADEVEX CRT Continuous Radiation Tray Freeze Drying Section,

- Spare Part Package

- Tanks and Platforms

- Evaporator with MVR instead of 2 x TVR

- Spent Press, Press Water Tank, Decanter to remove Solids from Press Water

- Oiling Dosing Unit for Freeze Dried Coffee1N

- Tray Washing Machine for Freeze Dryer1N/

- Mixer

- HTS4 C

- CVS

- CV100+DV10

- FB300

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

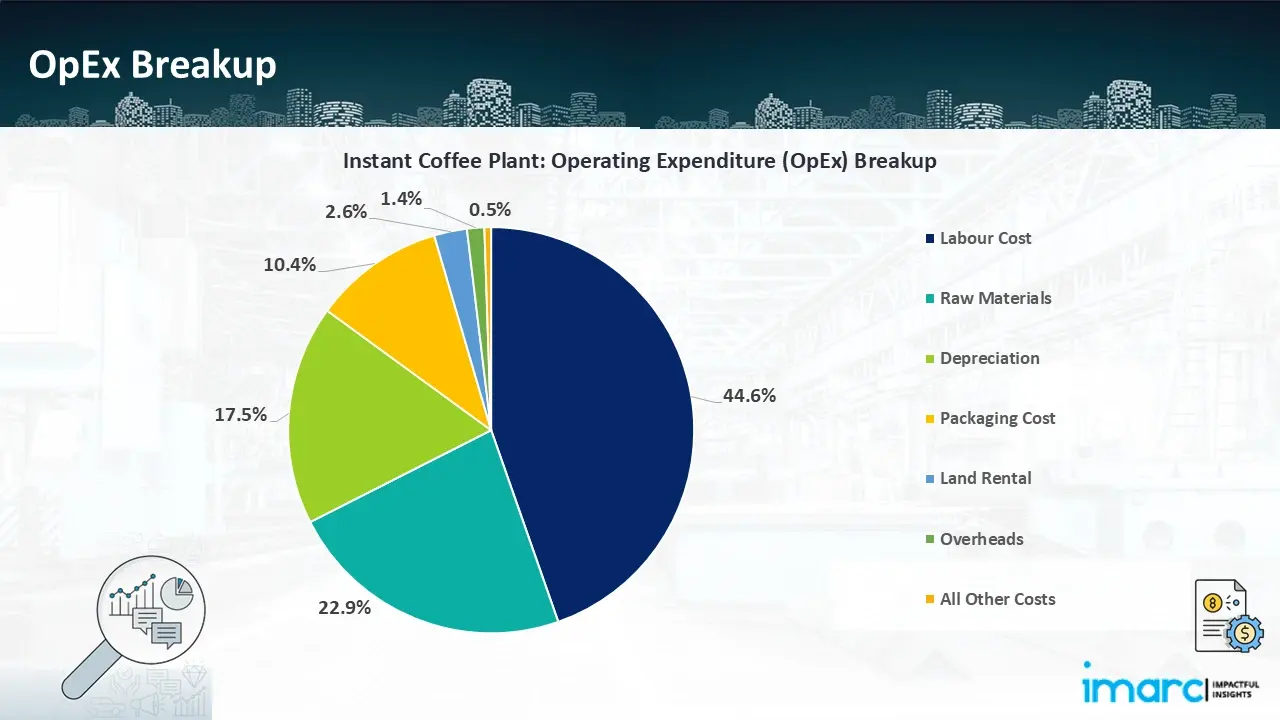

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

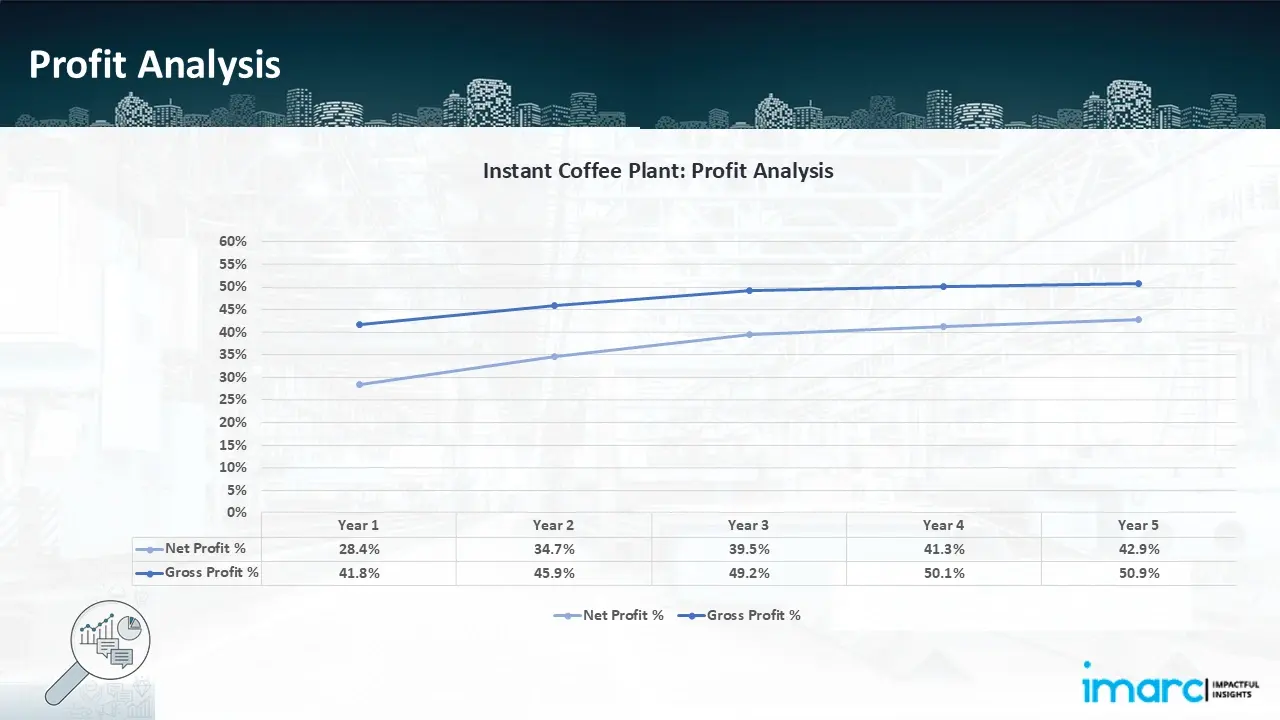

- Profitability Analysis Year on Year Basis: The proposed instant coffee plant, with an annual capacity of 307 tons of instant coffee, achieved an impressive revenue of US$ 6.11 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit improved from 41.8% to 50.9%, and net profit rise from 28.4% to 42.9%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our instant coffee manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 307 tons of instant coffee annually. Our commitment to offering precise, client-cantered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In February 2025, Starbucks Coffee At Home unveiled the new Starbucks Crema Collection Premium Instant, a decadent and inventive coffee line that coffee enthusiasts may enjoy hot or cold at home. Salted Caramel, Madagascar Vanilla, and Molten Chocolate are the three flavours that the Starbucks Crema Collection Premium Instant is available in the United States.

- In November 2024, Nestlé has introduced its newest coffee innovation, a new soluble coffee line that can be utilized for both hot and cold drinking. The range, launched under the brand Nescafé Classic, is offered in two natural flavors: hazelnut and caramel. Nestle coffee experts managed to produce a new soluble coffee that dissolves perfectly in both hot and cold water due to their experience of innovation. Presently, Central and Eastern Europe is able to buy the products.

- In July 2024, ITC launched two new SUNBEAN coffee namely Instant Coffee (100% Coffee) and Filter Coffee (70% Coffee 30% Chicory), both expertly curated by skilled baristas and crafted by ITC's master blenders.

- In February 2024, Hindustan Unilever Limited (HUL) added a new line of flavoured coffee in vanilla, caramel, or hazelnut to its Bru Gold portfolio. By increasing user numbers, generating additional occasions for consumption, and elevating its offering, the corporation hopes to propel growth.

- In January 2024, JDE Peet's said it has successfully acquired the Brazilian coffee and tea company from JAV Group after initially announcing the deal on July 24, 2023.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104