Relishing the Taste of Potato Flakes: A Cost Model Analysis

What is Potato Flakes?

Potato flakes are a highly adaptable food ingredient created by processing cooked potatoes into thin, dehydrated slices.

Key Applications Across Industries:

They are often used in soups, snacks, baked goods, and fast meals and are well-known for their usefulness, taste, and simplicity of usage. These flakes provide a reliable and effective option for home cooking, foodservice, and commercial food production while preserving the natural flavour, texture, and nutritional value of fresh potatoes. They are indispensable in a variety of culinary applications due to their lengthy shelf life, lightweight design, and easy rehydration method. Their ability to be used in a variety of recipes, from thickened stews to crispy coatings, further solidifies their position as a basic component of the world's food industry. '

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global potato flakes market reached US$ 7.70 Billion in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 7.0% from 2025 to 2033, reaching a projected size of US$ 14.04 Billion by 2033. A number of factors contribute to the global market for potato flakes. Time-saving culinary solutions are becoming more and more popular, which is consistent with their status as a practical and adaptable ingredient.

Their appeal among health-conscious consumers has increased due to their gluten-free status and suitability for plant-based diets. Environmental problems have also been addressed by continuous advancements in drying methods and the use of extra potatoes, which have improved sustainability and decreased food waste. In emerging economies, where urban lifestyles and disposable incomes are changing eating patterns, the market also benefits from the increasing use of potato flakes. The market for potato flakes is expected to increase steadily as producers concentrate on eco-friendly production methods and product variety, providing promising prospects for the food sector.

Case Study on Cost Model of Potato Flakes Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale potato flakes manufacturing plant in Thailand.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 8,000 tons of potato flakes.

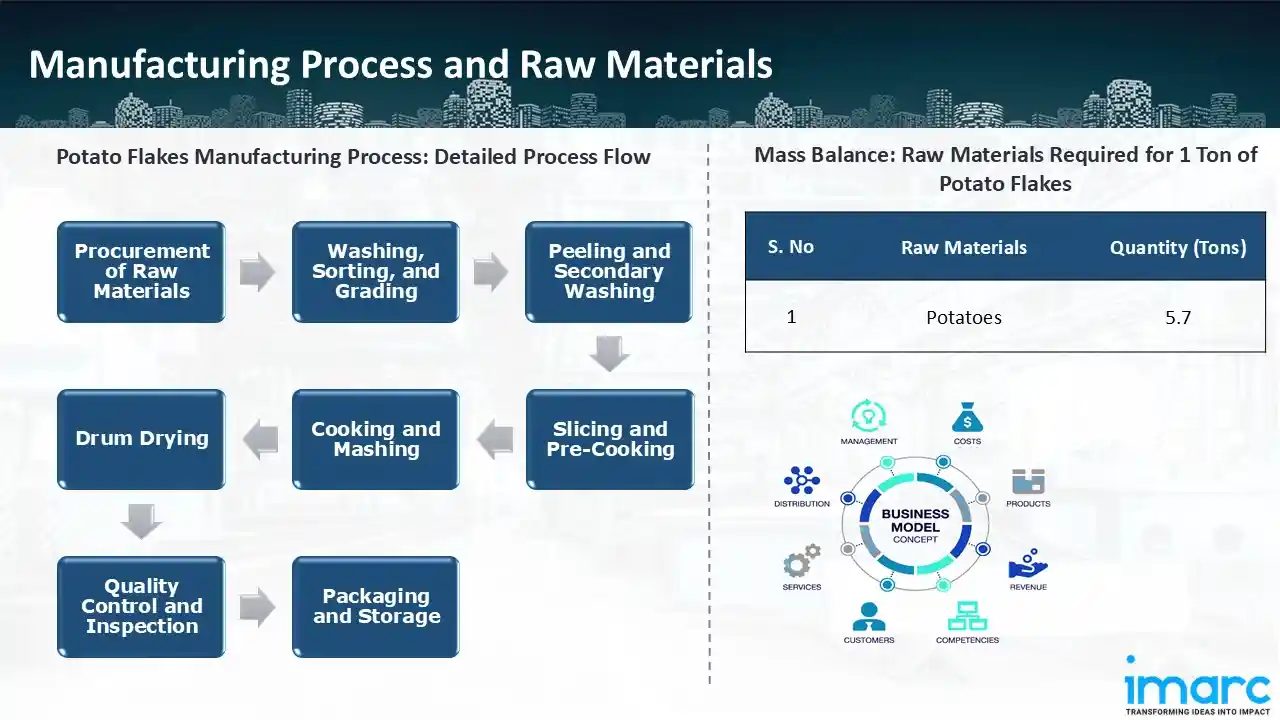

Manufacturing Process: Purchasing raw materials, such as premium potatoes from farms, is the first step in making potato flakes. To ensure consistency in size and quality, these potatoes are further cleaned, sorted, and graded to get rid of dirt, stones, and damaged parts. To get rid of the outer skin and any leftover contaminants, the potatoes are next peeled and given a second washing. To soften them and get them ready for processing, they are first peeled, then cut and boiled in advance. After the potatoes have been partially boiled, they are mashed to a smooth, lump-free consistency. In order to eliminate moisture while maintaining texture and flavour, the mashed potatoes are spread out in thin layers and dried using a drum drying technique. The potato flakes undergo quality control and inspection after drying, to make sure they fulfil industry standards. Lastly, the flakes are packaged and kept in a controlled environment to preserve freshness and increase shelf life.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the potato flakes manufacturing plant is potatoes. To produce 1 ton of potato flakes, we require 5.7 tons of good quality potatoes.

List of Machinery:

The following equipment was required for the proposed plant:

- Spiral elevator

- Complete Washing Destone and Steam Peeling system

- Potato brush peeling machine

- Roller Picking line

- Screw Lifting machine

- Chips Cutting machine

- Rinsing elevator machine

- Screw Blanching machine

- Screw Cooling machine

- Screw Hopper Elevator

- Double Screw Cooking machine and Potato masher

- Additives mixing tank

- Complete Drum Drying line (2)

- Fine powder crushing and collecting and dedusting system

- Automatic weighing packing and sealing machine

- Gas heated 6T steam boiler

- Mixer

- Feeding machine

- Automatic feeder

- Extruder

- Cutter

- Collecting conveyor

- Frying machine

- Cooling line

- Diverter conveyor

- Vibration distribution machine

- Seasoning machine

- Finished products conveyor

- Packing machine

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

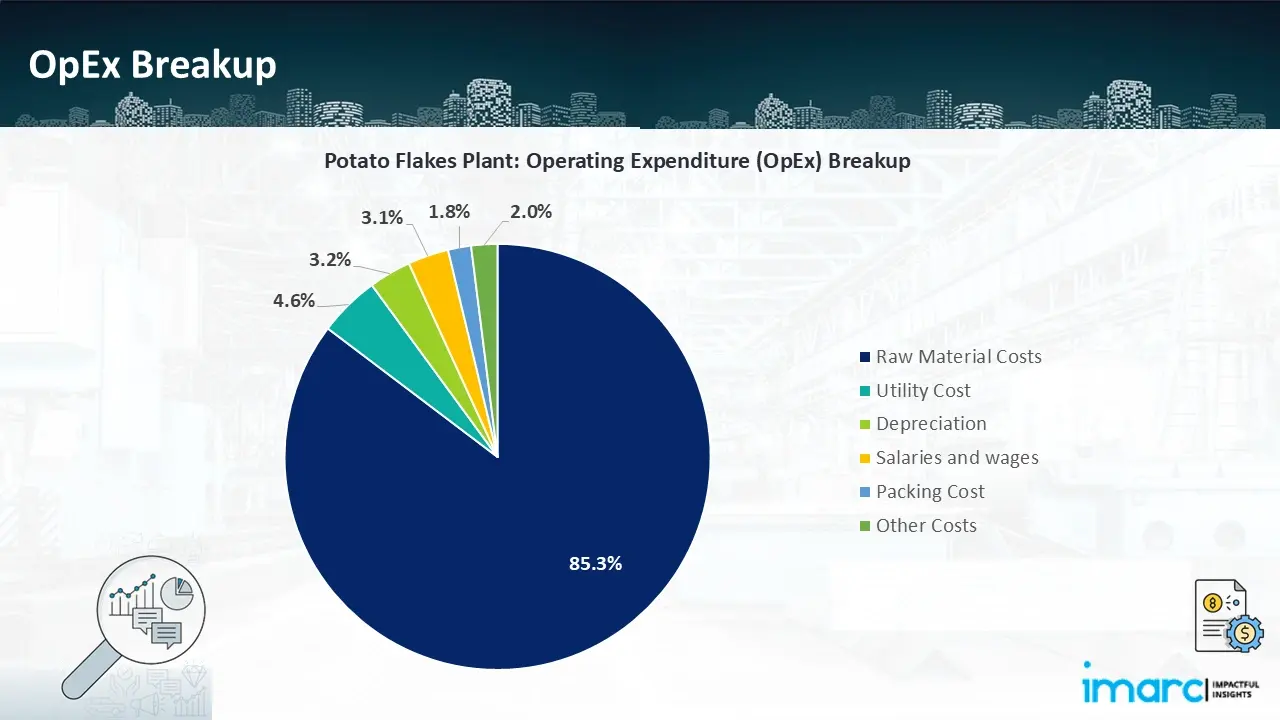

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

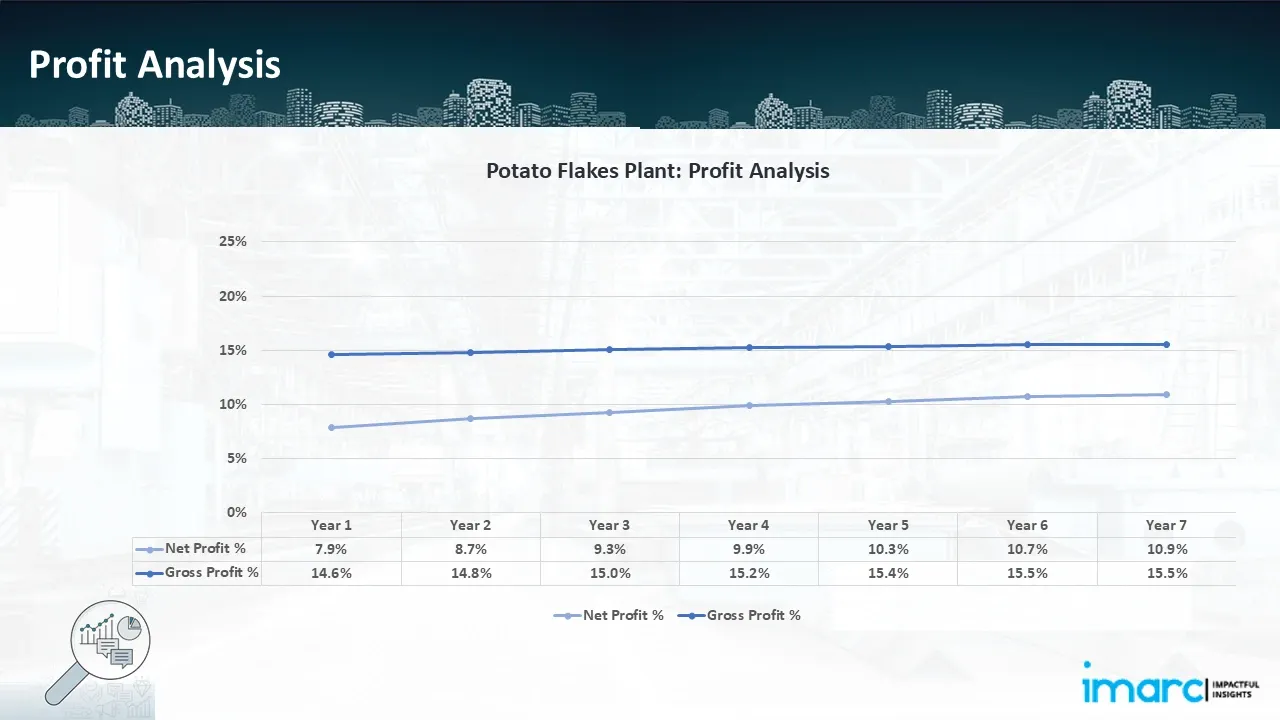

- Profitability Analysis Year on Year Basis: The proposed potato flakes plant, with an annual capacity of 8,000 tons of potato flakes, achieved an impressive revenue of USD 10.5 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Gross profit margins improved from 14.6% to 15.5% during the period, and net profit margins rise from 7.9% to 10.9%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our potato flakes manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 8,000 tons of potato flakes annually. Our commitment to offering precise, client-cantered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In January 2025, the opening of GreenFay Farm Foods' new, high-capacity facility for producing potato flakes has been announced. This cutting-edge plant, which has an amazing production capacity of 2,200 kg per hour, firmly establishes the company as one of the biggest producers of potato flakes in India. In order to satisfy the rising demands of the Indian and international markets, the expansion guarantees a steady supply of premium potato flakes.

- In March 2024, HyFun Foods plans to build three new potato processing facilities in Gujarat with an investment of 850 crore. In order to meet the growing demand for frozen potato products in both domestic and international markets, this expansion attempts to increase manufacturing capacity. The investment is in line with the expanding processed food industry and rising convenience food consumption in India.

- In January 2024, the Emsland Group announced expanding production with Emlichheim location boosting production capacity in order to retain and grow its market position while satisfying the growing demand for year-round, premium potato flakes. At the start of January 2024, the project officially began. The production line will be put into service at the beginning of the 2027 potato campaign.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104