Areca Nut Cost Model: Comprehensive Profitability Analysis

What is Areca Nut?

The areca nut, or betel nut, is the seed of the areca palm (Areca catechu), a tropical palm mainly grown in South and Southeast Asia. It is one of the oldest described masticatories, chewing historically with betel leaf and lime for its mild stimulant effect.

Key Applications Across Industries:

The nut is oval, fibrous, and high in alkaloids like arecoline, which is responsible for the typical flavor and psychoactive effects. Top producers are India, Bangladesh, Sri Lanka, Indonesia, Myanmar, Thailand, and China, with India dominating in both output and consumption. Areca nuts are mainly categorized into two forms white areca nuts, which are sun-dried mature nuts, and red areca nuts, obtained by boiling and chopping unripe fruits. Aside from traditional mastication, the areca nut is used differently in industrial and cultural purposes. It finds greater use in making ayurvedic remedies, natural dyes, mouth fresheners, and tannins, with increasing use in cosmetics and traditional ceremonies throughout Asia and the Pacific. The increasing emphasis on sustainable cultivation practices and rural wealth generation has further encouraged areca nut farming.

What the Expert Says: Market Overview & Growth Drivers

In spite of controversies surrounding its health implications, the areca nut is still a major cash crop, sustaining millions of small farmers and contributing importantly to local economies. The global areca nut market reached a value of USD 12.28 Billion in 2024. According to IMARC Group, the market is projected to reach USD 20.06 Billion by 2033, at a projected CAGR of 5.2% during 2025-2033.

Global market demand for areca nuts is driven by a mix of cultural, economic, and industrial forces. One of the major drivers is the deep-rooted cultural value of areca nut consumption in Asian-Pacific countries, especially India, Bangladesh, and Indonesia, where betel nut chewing is an established social and traditional habit. Increased global numbers of South Asian diaspora have also increased international demand, particularly in the Middle East, the United States, and Europe, opening new export markets. Also, the growing consumption of areca nut in value-added products like pan masala, supari, mouth fresheners, and herbal preparations is leading to market growth. The use of the nut in pharmaceuticals and nutraceuticals, due to its antioxidant and antimicrobial activity, has developed new industry segments. Also, government policies supporting agroforestry and rural livelihoods in producing countries have consolidated cultivation and supply chains. Technological improvements in processing, drying, and grading methods have enhanced product quality, shelf life, and export competitiveness. The increasing global trade liberalization and e-commerce distribution channels are also facilitating small and medium producers to reach international markets. Cumulatively, these trends continue to drive the global areca nut market, with Asia-Pacific remaining its leading production and consumption base.

Case Study on Cost Model of Areca Nut Processing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale areca nut processing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed areca nut processing plant in India. This plant is designed to process 1,200 tons of areca nut annually.

Processing Flow: Areca nut processing is a multi-step operation for transforming fresh nuts from areca palm trees (Areca catechu) into saleable products that have a better quality, longer shelf life, and improved flavor. It starts with harvesting, usually when the fruits have become yellow or orange in color, which means they are mature. The nuts are picked by hand and dehusked to remove the fibrous outer covering of the shell and reveal the inner seed. Following dehusking, the nuts are washed and graded according to size, color, and degree of ripeness, as these determine the end-product variety, predominantly white areca nut or red areca nut. In the processing of white areca nut, the dehusked nuts are briefly boiled and then dried under sun or by mechanical means for a number of days until the moisture content falls below 10%. This drying process is essential to stop the growth of fungal organisms and harden the nuts for long-term storage. Red areca nut processing involves boiling unripe fruits with husk for several hours, which improves color and flavor, then peeling, cutting, and drying to meet the desired texture. After drying, the nuts are graded and polished with sieves and polishing drums to achieve an even texture and shiny appearance. Some of the processors also flavor, roast, or coat the nuts to be used in pan masala or mouth fresheners. The finished nuts are then packed in moisture-proof materials for sale in the country or exportation. Every processing stage ensures areca nuts retain their unique quality, flavor, and shelf life for international markets.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

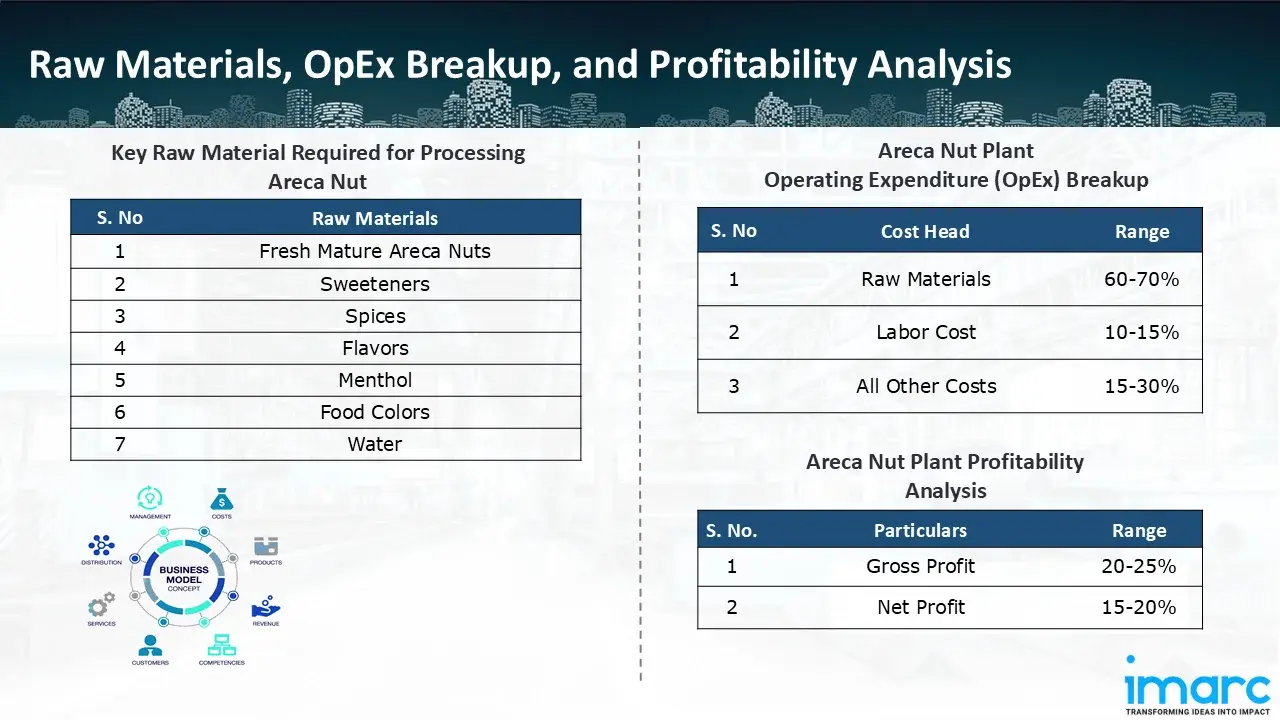

The basic raw materials required for areca nut processing include:

- Fresh Mature Areca Nuts

- Sweeteners

- Spices

- Flavors

- Menthol

- Food Colors

- Water

Machineries Required:

- Dehusking Machine

- Boiling Vessel / Steam Boiler

- Drying System (Solar / Hot Air Dryer)

- Cutting & Slicing Machine

- Polishing Machine

- Grading Machine

- Coating Machine (Optional)

- Packaging Machine

- Sealing Machine

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a processing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a processing plant effectively. Opex in a processing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a processing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a areca nut processing plant ranges between 60-70%, labor cost ranges between 10% to 15%, and all other costs ranges between 15-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-25%, and net profit lie between the range of 15-20% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the areca nut processing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, processing, capital expenditure, and operational expenses. By addressing the specific requirements of processing 1,200 tons of areca nuts annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale processing ventures.

Latest News and Developments:

- In September 2025, the inter-state cooperative organisation Campco is set to benefit areca nut farmers by transitioning to the production of organic fertiliser. Moving forward, Campco is planning to produce organic fertilisers and planned to purchase 18 acres in Hiriyur, Chitradurga, for this purpose.

- In June 2025, Mizoram government is setting up areca nut processing units in the districts of Kolasib and Mamit. This initiative, funded by the North Eastern Council (NEC), aims to enhance value addition for cash crops, create employment opportunities, and strengthen the state's agricultural economy.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the processing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish processing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104