Cost Dynamics of Glucose Syrup and Sorbitol Syrup Production: A Comprehensive Cost Model

What is Glucose Syrup and Sorbitol Syrup?

Glucose syrup and sorbitol syrup are versatile sweeteners widely used across the food and beverage industry. Their ability to enhance texture, retain moisture, and extend shelf life makes them essential ingredients in confectionery, bakery, dairy, and beverage products.

Key Applications Across Industries:

Beyond their functional benefits, these syrups contribute to taste enhancement and product stability, catering to consumer preferences for smooth, consistent formulations. With applications extending to pharmaceuticals and industrial uses, glucose and sorbitol syrups play a crucial role in multiple sectors. As demand for processed foods, beverages, and sustainable sweetener alternatives rises, the global market continues to expand, serving food manufacturers, pharmaceutical companies, and industrial users alike.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global glucose syrup and sorbitol syrup market reached US$ 2.4 Billion in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 3.0% from 2025 to 2033, reaching a projected size of US$ 3.1 Billion by 2033.

The global market for glucose syrup and sorbitol syrup is driven by several key factors. The rising demand for processed and convenience foods has significantly boosted market growth, particularly in regions with strong food and beverage industries. Their essential role as sweeteners, thickeners, and moisture retainers in confectionery, bakery, and dairy products further supports expansion. Additionally, the growing preference for natural and functional ingredients in health-conscious consumer segments has fuelled demand. Advancements in production technologies, including enzymatic hydrolysis and refining techniques, have enhanced product quality, stability, and sustainability. As the food and beverage industry continues evolving with shifting dietary trends and increasing demand for clean-label ingredients, glucose syrup and sorbitol syrup remain crucial components in meeting modern formulation needs.

Case Study on Cost Model of Glucose Syrup and Sorbitol Syrup Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale glucose syrup and sorbitol syrup manufacturing plant in Mexico.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with a production capacity of 99 tons glucose syrup per day and 113 tons sorbitol syrup per day.

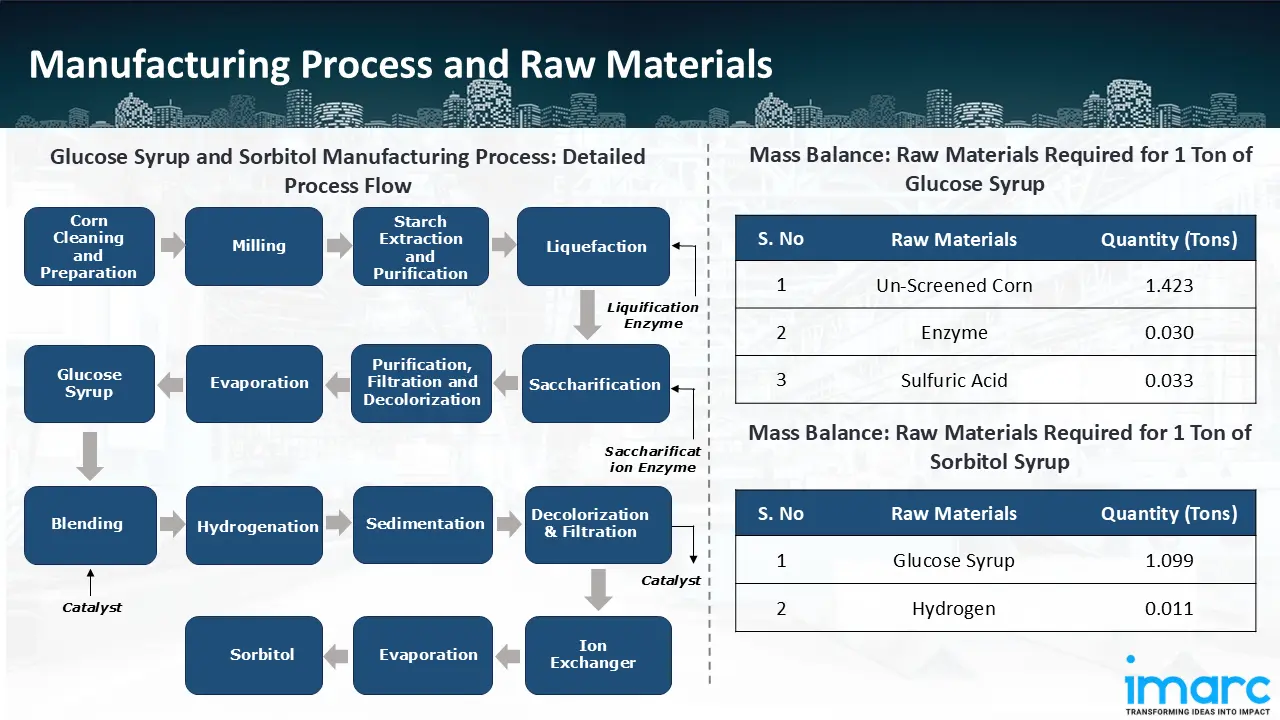

Manufacturing Process: The production of glucose syrup begins with cleaning and steeping corn kernels to remove impurities and soften them for milling. During wet milling, the kernels are ground to separate starch from fiber, protein, and germ, ensuring efficient extraction. The starch slurry is then purified through centrifugation and washed to remove residual components. In liquefaction, alpha-amylase enzymes break the starch into dextrins, which are further converted into glucose through saccharification using glucoamylase. The glucose solution then undergoes purification, filtration, and evaporation, increasing its concentration before final filtration and packaging for distribution in food, pharmaceuticals, and industrial applications. For sorbitol production, glucose syrup is blended and stabilized before undergoing hydrogenation in a reactor, where hydrogen gas converts dextrose into sorbitol. The crude sorbitol is transferred to a settling tank for sedimentation, followed by filtration and decolorization using activated carbon. Further ion exchange removes impurities before evaporation concentrates the solution to meet product standards. The final filtration and packaging ensure a high-purity sorbitol product suitable for various applications.

Mass Balance and Raw Material Required: To produce 1 ton of glucose syrup, we require 1.423 tons un-screened corn, 0.030 tons enzyme, and 0.033 tons sulfuric acid; and to produce 1 ton of sorbitol syrup, we require 1.099 tons glucose syrup and 0.011 tons hydrogen.

List of Machinery: The following equipment was required for the proposed plant:

- Corn Strach Production Line

- Glucose Syrup Production Line

- Sorbitol Syrup Production Line

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

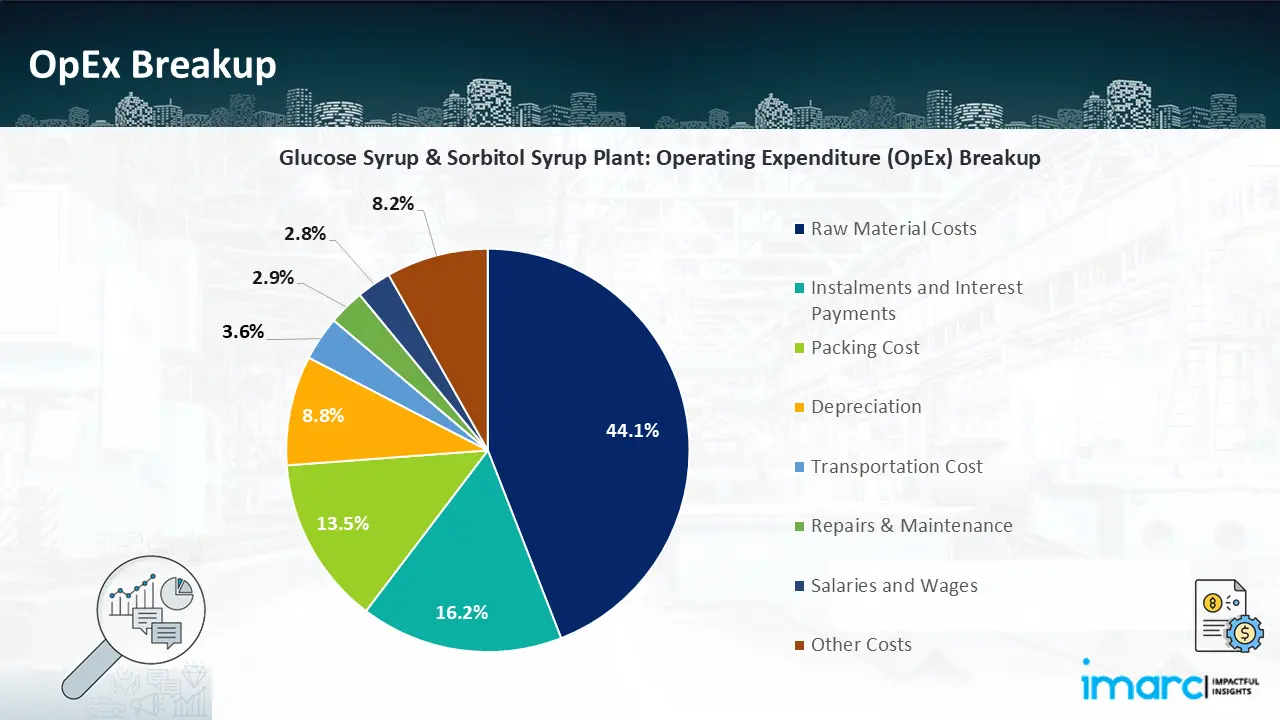

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

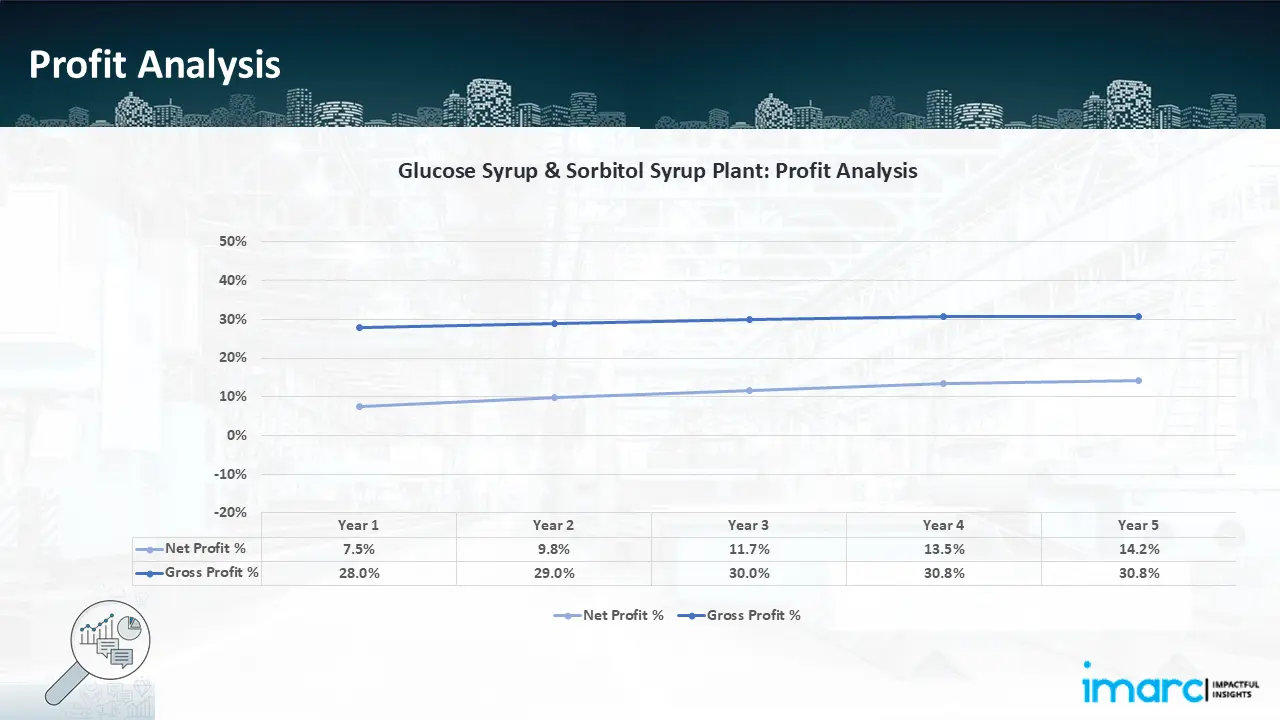

- Profitability Analysis Year on Year Basis: The proposed glucose syrup & sorbitol syrup plant, with a capacity of 99 tons glucose syrup per day and 113 tons sorbitol syrup per day, achieved an impressive revenue of USD 43.6 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 28.0% to 30.8%, and net profit rise from 7.5% to 14.2%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the glucose syrup and sorbitol syrup manufacturing plant was meticulously designed to meet the client’s objectives. It offered a detailed analysis of production costs, covering raw materials, manufacturing processes, capital expenditures, and operational costs. Tailored to the specific requirement of producing 99 tons glucose syrup per day and 113 tons sorbitol syrup per day, the model highlights key cost drivers and forecasts profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This detailed financial model provides the client with valuable insights for strategic decision-making, reflecting our dedication to delivering accurate, client-centred solutions that support the long-term success of large-scale manufacturing projects.

Latest News and Developments:

- In October 2024, Green Plains Inc. announced the successful continuous manufacture of dextrose syrups at the first commercial Clean Sugar TechnologyTM (CSTTM) deployment in Shenandoah, Iowa. With the help of this novel method created by Fluid Quip Technologies, dextrose, and glucose sorbitol syrups can be produced with up to 40% less carbon intensity than traditional substitutes. A major step toward sustainable manufacturing in the sector, these low-carbon ingredients are intended for use in bio-based materials, renewable chemicals, and food and beverage compositions.

- In September 2022, Cargill, Inc., a major player in the glucose syrup industry, announced a USD 50 million investment to construct a sustainable sorbitol syrup refinery in Fort Dodge, Iowa, U.S. The plant is expected to reduce CO2 emissions by nearly 50% compared to traditional sorbitol syrup production methods, aligning with Cargill’s sustainability commitments. The facility is scheduled for completion before 2025, reinforcing the company’s focus on environmentally responsible manufacturing practices.

- In September 2022, Ingredion, Inc., a leading global provider of ingredient solutions, inaugurated a new specialty starch plant in China. The facility was established to enhance the global food and beverage supply chain while also supporting local farmers by ensuring a steady demand for raw materials. This expansion reflects Ingredion’s commitment to innovation, supply chain resilience, and sustainable ingredient sourcing in the growing Asian market.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104