Breakdown of Production Cost of Inedible Beef Tallow Manufacturing Plant: A Cost Model Approach

What is Inedible Beef Tallow?

Inedible beef tallow, a byproduct of the meat processing industry, is derived from beef suet and serves various industrial and commercial purposes. This versatile substance undergoes rendering, a process that separates the fat from solid components.

Key Applications Across Industries:

Inedible beef tallow's primary application is in animal feed, as it provides essential fats and energy for livestock, particularly in pet food and livestock supplements. Additionally, it finds use in the cosmetics and personal care industry, contributing to the production of candles, soaps, and skin-care products. The historical use of tallow in candle-making is notable, as it produces long-lasting, clean-burning candles.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global inedible beef tallow market volume stood at 9.07 Million Tons in 2024, growing at a CAGR of 3.1% from 2019 to 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 3.8% from 2025 to 2033, reaching a projected volume of 12.84 Million Tons by 2033.

The market for inedible beef tallow is driven by its many industrial uses, especially un animal feed, oleochemicals, and biofuels. The usage of beef tallow as an affordable and renewable feedstock has expanded due to the growing demand for sustainable biodiesel. Market expansion is also fuelled by the expanding oleochemical sector, which manufactures fatty acids, soaps, and lubricants. The growing use in pet food and animal feed, where it improves palatability and energy content, is another important factor. Because tallow is used in tanning and lubricants, the growing leather and chemical industries also increase demand. Moreover, strict waste management laws promote the use of tallow and other animal byproducts. Inedible beef tallow is becoming more popular across a variety of industries due to rising demand for affordable and environmentally friendly substitutes, which will guarantee consistent market expansion.

Case Study on Cost Model of Inedible Beef Tallow Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale inedible beef tallow manufacturing plant in Biloxi, Mississippi, United States.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with a production capacity of 60 tons of inedible beef tallow per day.

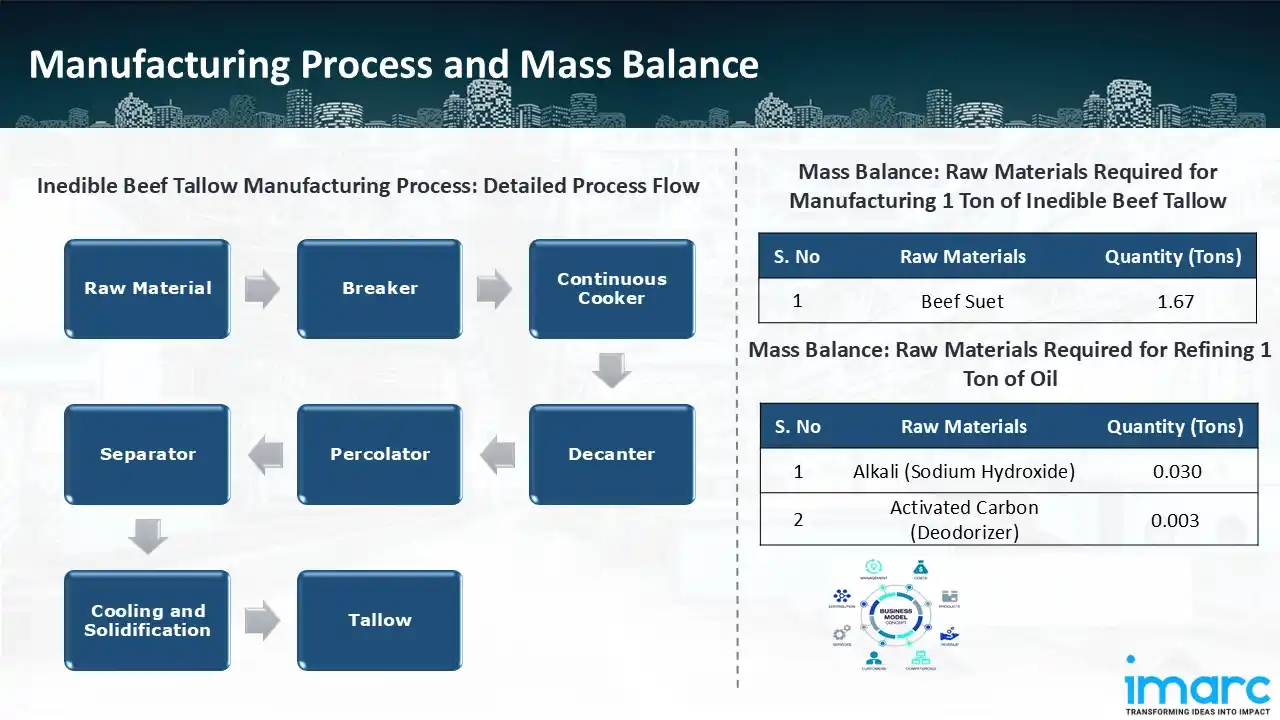

Manufacturing Process: The first step in making inedible beef tallow is gathering raw animal fat from butcher shops or meat processing plants. Connective tissues, contaminants, and tiny meat remnants are frequently present in this raw fat. The rendering process is made more efficient by utilising grinders or breakers to split the fat into tiny pieces for easier processing. The broken-down fat is next heated in the continuous cooker to a temperature over its melting point but below the levels of degradation. This regulated heating process creates a liquid combination by separating the fat from the water content and connective structures. The mixture is run through a centrifuge or decanter after the cooking procedure is finished. Tallow floats on top of this apparatus, which uses density differences to separate liquid fat from water and other contaminants. Heavy pollutants sink to the bottom. The tallow is further purified by percolation, which lets it pass through a filtration system that removes any residues or solid particles that may still be present. Lastly, a separator is used to remove any remaining particles from the tallow, guaranteeing maximum purity. After being cleansed, the inedible beef tallow can be used to make biodiesel, animal feed, oleochemicals, and other industrial processes, which increases its market demand and broad utility.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the inedible beef tallow manufacturing plant include beef suet, alkali (sodium hydroxide) and activated carbon. To manufacture 1 ton of inedible beef tallows, we require 1.67 tons of beef suet. To refine 1 ton of tallow oil, 0.030 tons of sodium hydroxide and 0.003 tons of activated carbon is required.

List of Machinery:

The following equipment was required for the proposed plant:

- Chain Plate Elevator

- Frozen Beef Tallow Crusher

- Chain Plate Elevator

- Shaftless Screw Conveyor

- Melting Tank

- Catcher

- Oil-Residue Separate Scraper Conveyor

- Oil-Residue Mixing Tank

- Feeding Pot

- Screw Oil Press Machine

- Oil Residue Scraper

- Air Compressor

- Vibrating Leaf Filter

- Condenser

- Liquefied Water Collection Tank

- Water Injection Pump

- Separate Water Tank

- Fiberglass Cooling Tower

- Roots Vacuum Pump

- Water Pump

- "Circulating Water Pump For

- Cooling Tower"

- Cooling Water Circulating Pump

- Press Cake Screw Conveyor

- Chain Type Bucket Elevator

- Cake Output Screw Conveyor

- Power Distribution Cabinet

- Installation Materials

- Salting Out Tank

- Refinery Tank

- High Level Alkali Tank

- High Level Water Tank

- Oil Viewer

- Soap Stock Pump

- Crude Oil Pump

- Clay Feeding Tank

- Bleaching Tank

- Catcher

- Vibrating Vertical Leaf Filter

- Bleached Clean Oil Tank

- Bleached Dirty Oil Tan

- Splash Oil Catcher

- Safety Filter

- Steam Superheater

- Filter Plate Washing Pool

- Air Storage Tank

- Air Compressor

- Water Jet Pump

- Steam Distributor

- Heater

- Deaerator

- Deaerator Extraction Pump

- Oil/Oil Heat Exchanger

- Heat Conduction Oil Heater

- Cooler

- Feeding Type High Efficient Deodorizing Tower

- Fatty Acid Catching Tower

- Four-Stage Steam Jet Pump

- Deodorization Oil Pump

- Fatty Acid Circulating Tank

- Fatty Acid Cooler

- Fatty Acid Circulating Pump

- Product Oil Storage Tank

- Product Oil Pump

- Polishing Filter

- Water Distributor

- Steam Distributor

- Citric Acid Tank

- Citric Acid Quantitative Pump

- Static Mixer

- Heat Conduction Oil Furnace (Whole Set)

- Power Distribution Cabinet

- Cooling Tower

- Indirect Water-Cooling Tower

- Supply Water Pump

- Supply Water Pump

- Circulating Water Pump

- Hoist (Lifting Device)

- Deaerator Material Level Control

- Deodorizing Tower Material Level Control

- Liquid Level Alarm Device

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

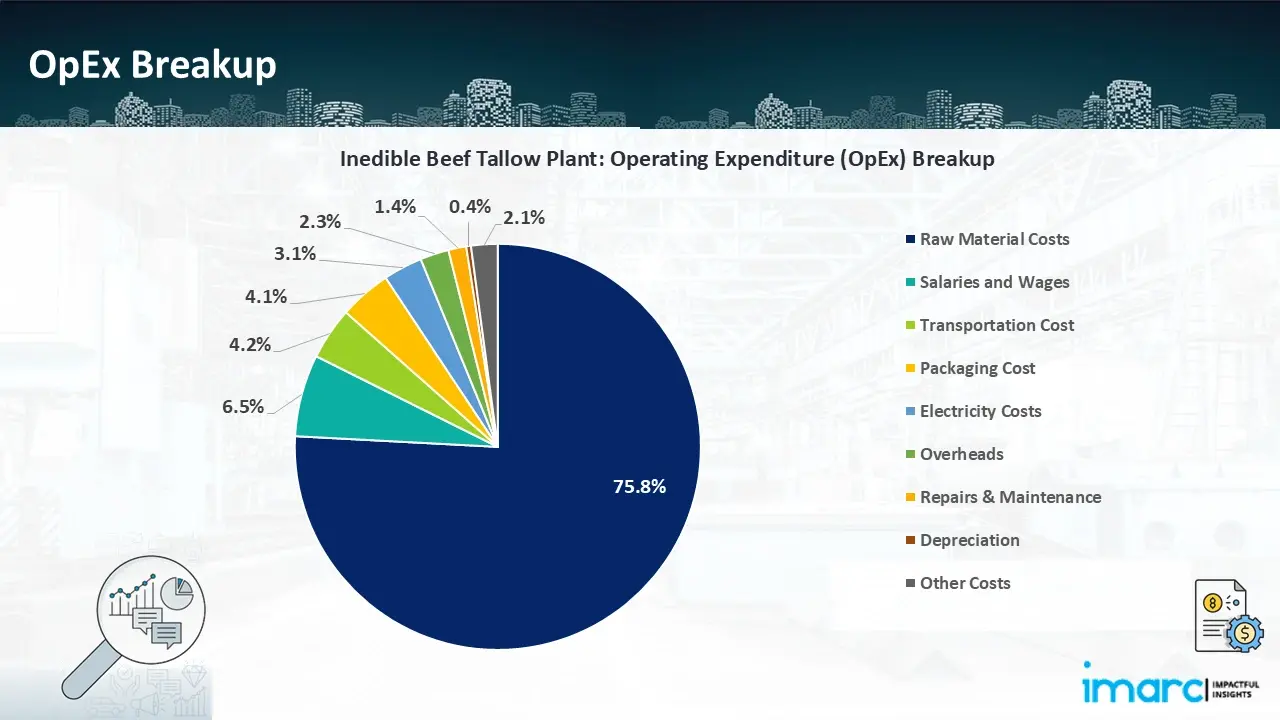

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

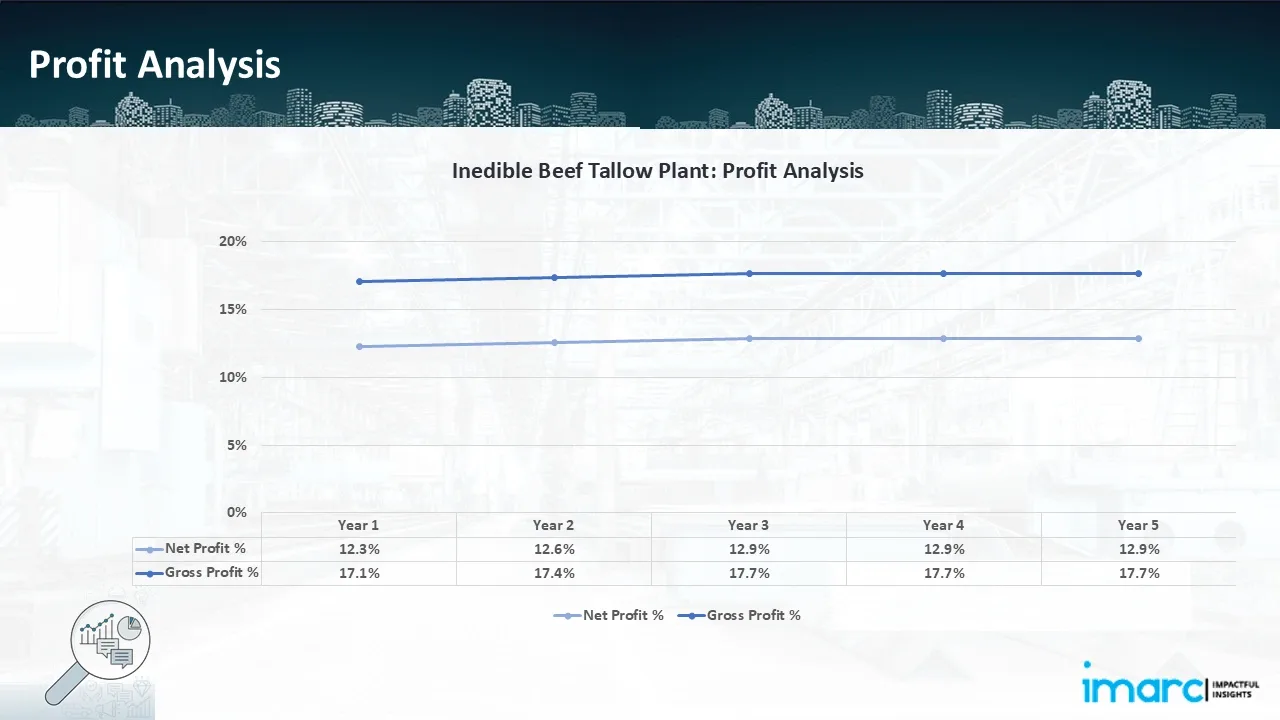

- Profitability Analysis Year on Year Basis: The proposed inedible beef tallow plant, with a capacity of 60 tons of inedible beef tallow per day, achieved an impressive revenue of US$ 26.8 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit slightly improved from 17.1% to 17.7%, and net profit rise from 12.3% to 12.9%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our inedible beef tallow manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 60 tons of inedible beef tallow per day. Our commitment to offering precise, client-cantered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In January 2025, Steak 'n Shake declared that by February 2025, all of their famous shoestring fries will be fried in beef tallow. The manufacturer claims that the alteration is intended to improve quality and taste. The action comes after seed oils have come under increasing fire for being connected by some to diseases like inflammation and obesity.

- In December 2024, GrainCorp, Australia's biggest tallow exporter, marks its 100th anniversary as the market for biodiesel declines.

- In February 2024, tallow exports hit a record high of over $1 Billion during the 2022–2023 fiscal year, according to the Department of Agriculture in Australia. This is a result of the growing biofuels sector.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104