Sweet Success: A Financial Model for Mango Juice and Pulp Plants

What is Mango Pulp and Juice?

Mango pulp is the thick, smooth, and semi-liquid product yielded by crushing or pulping ripened mangoes. It is the inner flesh of the mango fruit extracted, without the skin and seeds.

Key Applications Across Industries:

Mango pulp is widely utilized as a base for many food items, including mango juice, nectar, drinks, smoothies, ice creams, desserts, and as a topping for pancakes or yogurt. Mango juice is a cool drink prepared from ripe mangoes' juice. To make mango juice, the ripe mangoes are normally peeled, pitted, and the flesh of the mango is squeezed to get the pulp. The pulp is further treated to remove the juice from any remaining fibers or solids.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global mango pulp and juice market reached US$ 1.93 Billion in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 5.7% from 2025 to 2033, reaching a projected size of US$ 3.22 Billion by 2033. The market for mango pulp and juice is influenced by a number of major drivers.

Increased demand for natural and healthy drinks from consumers is fueling sales, with mango-based drinks being high in vitamins and antioxidants. Urbanization and lifestyle changes are driving higher consumption of easy-to-consume, ready-to-drink juices. The growth in the food & beverage industry is also pushing demand for mango pulp in processed foods, dairy, and confectionery. Market expansion is supported further by export possibilities based on strong global demand from the Middle East, Europe, and the U.S. In addition, increased food processing and preservation technology provides improved product shelf life and quality. Support by the government of agro-processing and expanded mango production in targeted areas underlines supply. Finally, increased disposable incomes and premiumization trends drive demand for value-added, organic, and high-quality mango products. These factors in combination are responsible for the consistent growth of the mango pulp and juice market.

Case Study on Cost Model of Mango Pulp and Juice Manufacturing Plant

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale mango pulp and juice manufacturing plant in Puerto Rico.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with an annually production capacity of 1,680 tons of mango pulp and 3,600 tons mango juice.

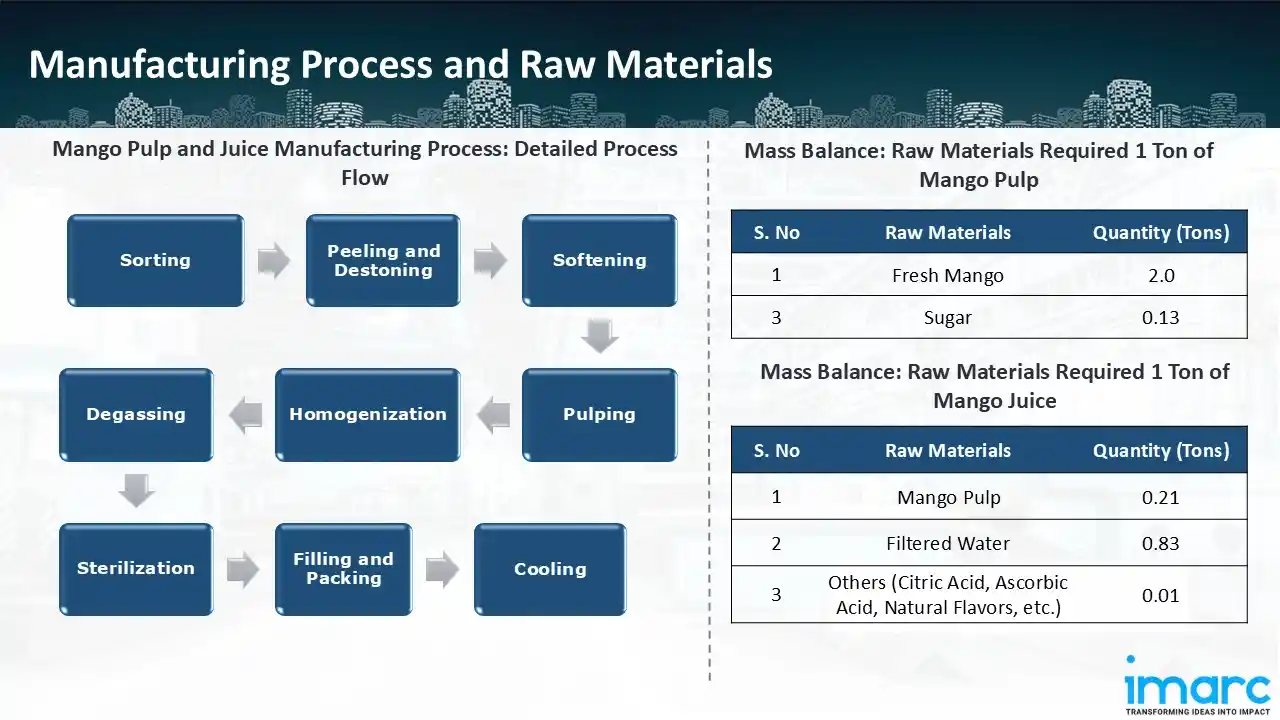

Manufacturing Process: The production of Mango Pulp and Juice starts with the use of quality raw materials such as soybeans, wheat, and salt. The soybeans are washed thoroughly and steamed, while the wheat is roasted and ground. The ingredients are then blended in equal quantities before being mixed with a brine of saltwater, which acts as a preservative. Koji mold is added to the mixture, which triggers enzymatic activity that hydrolyzes proteins into umami-rich amino acids, creating a mash called "moromi." The moromi is fermented and aged for a few months, during which enzymes, yeast, and bacteria create the characteristic taste and smell of Mango Pulp and Juice. After aging, the moromi is pressure-filtered to obtain raw Mango Pulp and Juice liquid. The liquid that is extracted is then subjected to heat treatment for sterilization, which improves its color, aroma, and flavor. The purified Mango Pulp and Juice is then pumped into the filling section, where glass bottles are filled by automated machinery. A capping machine caps the bottles, followed by labeling for brand recognition. Lastly, the packaged bottles are loaded into carton boxes manually or by a carton-filling machine, ready for distribution. This highly controlled production method secures the quality and consistency of the Mango Pulp and Juice, rendering it as a popular condiment for both classic and contemporary cuisines.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the mango pulp manufacturing plant largely include fresh mango and sugar. The primary raw materials utilized in the mango juice manufacturing plant largely include mango pulp, filtered water, and other raw materials. To produce 1 ton of mango pulp, we require 2 tons of fresh mango, and 0.13 tons of sugar. To produce 1 ton of mango juice, we require 0.21 tons of mango pulp, 0.83 tons of filtered water, and 0.01 tons of other raw materials.

List of Machinery:

The following equipment was required for the proposed plant:

- Conveyor Belt

- Brush Type Washing Machine

- Roller Sorting Belt

- Bubble Washing Machine

- Roller Air Dryer

- Plate Elevator

- Mango peeling and kernel removing machine

- Rotor Pump

- Mango Pulp Making Machine

- Storage Tank

- Refiner

- Mixing Tank

- UHT Tube in tube sterilize

- Single head bag in drum aseptic filling machining control system

- Vacuum Bag Packaging

- Homogenization Machine

- Tube Sterilization Machine

- Final Product Tank

- Sugar Cooking Pot

- Juice Pump

- Duplex Filter

- 3 in 1 Filling Machine

- Spraying pasteurization tunnel

- Air Drying Machine

- Labeling & Printing Machine

- Shrinking Film Packing Machine

- Control panel

- Pipe and valve

- Cable, bridge, trough, threading pipe

- Steam Boiler

- CIP Cleaning System

- CIP Return Pump

- Water Treatment System

- Cooling Tower

- Air Compressor Couple

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

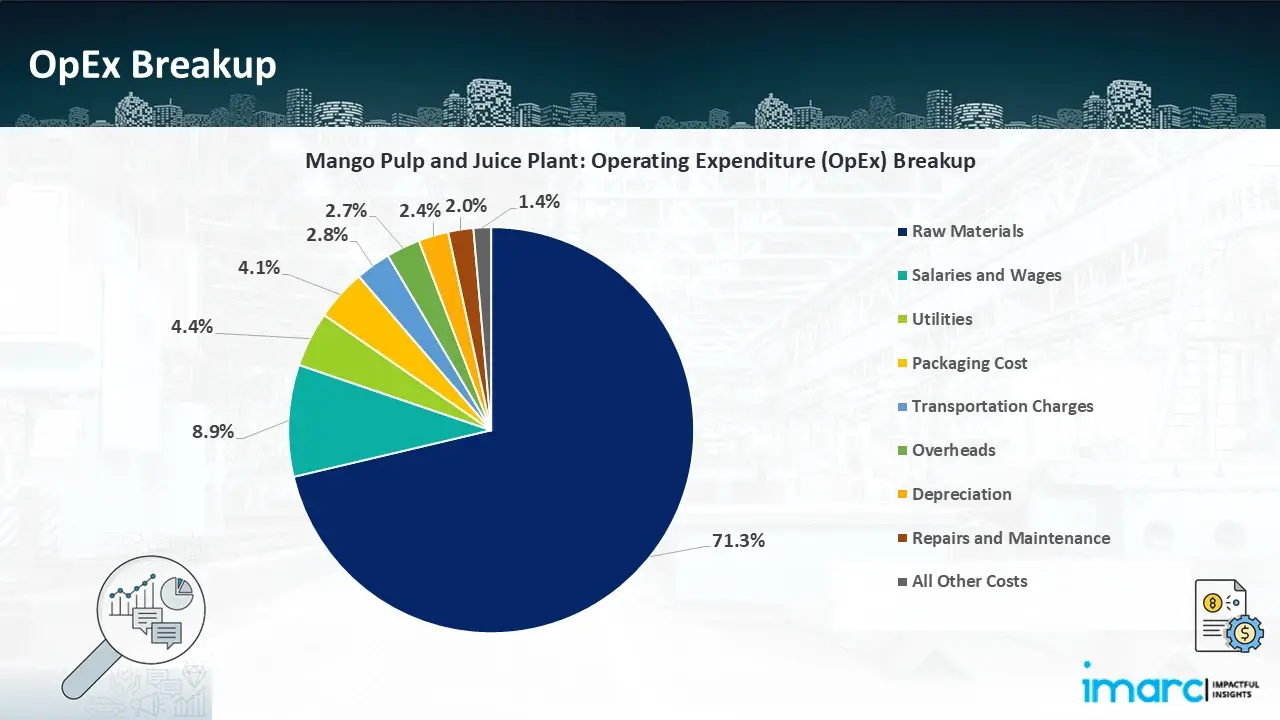

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

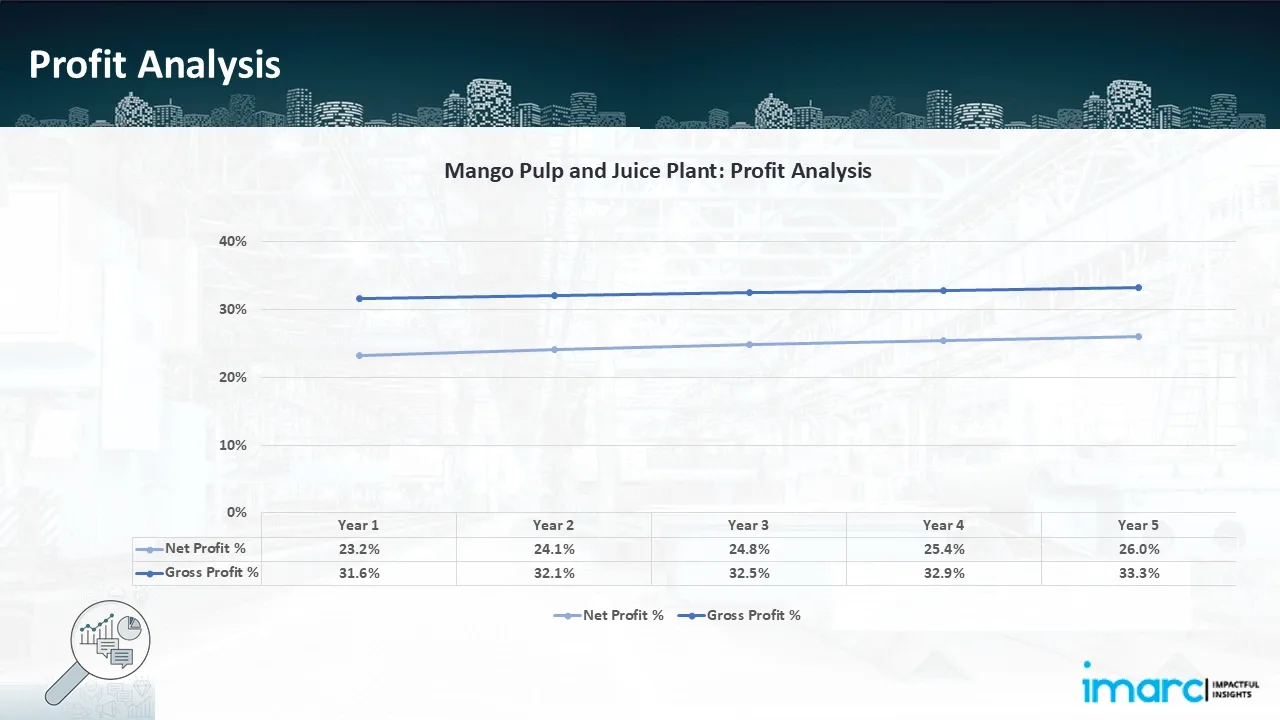

- Profitability Analysis Year on Year Basis: The proposed mango pulp and juice plant, with an annual capacity of 1,680 tons of mango pulp and 3,600 tons of mango juice, achieved an impressive revenue of US$ 8.96 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 31.6% to 33.3% by year 5, and net profit rise from 23.2% to 26.0%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our mango pulp and juice manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 1,680 tons of mango pulp and 3,600 tons mango juice annually. Our commitment to offering precise, client-cantered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In September 2023, Fresca Juices, launched Fresca Gold Aam ka Ras. in its 200 ml aseptic pack for just Rs. 20.

- In May 2023, ITC Ltd.'s Sunfeast introduces the World of Smoothies' in Reliance stores with fresh new flavors, such as - Mango, Strawberry, Litchi and Peach-Pineapple. Its Mango Smoothie with Mango Chunks are made using delectable mango pulp it features mango chunks, so it is just right for summer.

- In March 2023, Naturals, the well-known ice cream company, has introduced their own "Amrakhand" ice cream, a festive flavour. This delicious flavour, which is enhanced with the goodness of mango pulp, elaichi, sugar, and milk, was inspired by two well-known Maharashtrian sweets, Amrakhand and Shrikhand.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104