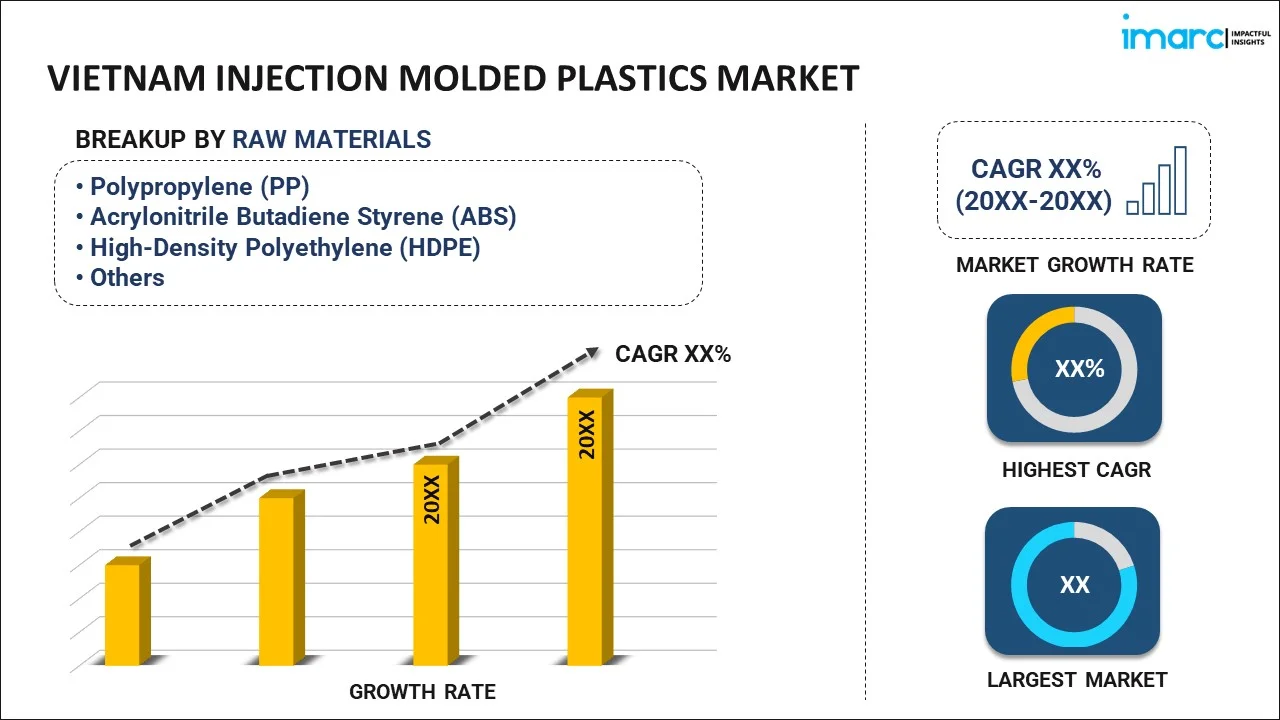

Vietnam Injection Molded Plastics Market Report by Raw Material (Polypropylene (PP), Acrylonitrile Butadiene Styrene (ABS), High-Density Polyethylene (HDPE), Polystyrene (PS), and Others), Application (Packaging, Consumables and Electronics, Automotive and Transportation, Building and Construction, Medical, and Others), and Region 2025-2033

Market Overview:

Vietnam injection molded plastics market size reached USD 1,258.8 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 1,703.7 Million by 2033, exhibiting a growth rate (CAGR) of 3.42% during 2025-2033. The increasing product adoption in the automotive industry, the rising product demand in the packaging industry, the growing product utilization in medical devices, and the rapid advancements in plastic materials and additives are some of the factors propelling the market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 1,258.8 Million |

| Market Forecast in 2033 | USD 1,703.7 Million |

| Market Growth Rate (2025-2033) | 3.42% |

Injection molded plastics refer to a manufacturing process wherein molten plastic is injected into a mold cavity, taking on the shape and dimensions of the mold as it cools and solidifies. This highly versatile and efficient technique is widely used across industries for the mass production of intricate and precise plastic components. The process begins with the feeding of plastic pellets into a heated barrel, where they are melted into a viscous state. A reciprocating screw within the barrel then injects the molten plastic into a mold cavity under high pressure. The mold, typically composed of two halves, defines the final shape of the product. Once injected, the plastic is allowed to cool and solidify, conforming precisely to the contours of the mold. The resulting plastic parts can range from small and intricate components to larger and more complex structures. Injection molding offers several advantages, including high production efficiency, consistent part quality, and the ability to produce large volumes economically. It is a preferred method for manufacturing a diverse array of products, such as automotive components, packaging materials, medical devices, consumer electronics, and household items. The process is known for its capability to produce detailed and uniform parts with tight tolerances, making it integral to industries requiring mass production of high-quality plastic components. Moreover, injection molding supports the use of various plastic materials, allowing manufacturers to choose materials that align with specific performance requirements, including durability, flexibility, and resistance to heat or chemicals. These plastics represent a cornerstone of modern manufacturing, contributing to the production of a vast array of everyday products and industrial components.

Vietnam Injection Molded Plastics Market Trends:

The market in Vietnam is majorly driven by the increasing demand across diverse sectors. One of the primary drivers is the expanding automotive industry in Vietnam, where these plastics find extensive use in the production of lightweight and durable components for vehicles. As the automotive sector continues to grow, the demand for precision-engineered plastic parts rises, contributing significantly to the market growth. The packaging industry, closely linked to the expanding e-commerce and food and beverage sectors, represents another driving force. The need for efficient and cost-effective packaging solutions has led to an increased reliance on these plastics for manufacturing containers, closures, and packaging components. Moreover, Vietnam's growing healthcare sector is contributing to the demand for injection-molded plastics in the production of medical devices and components. The precision, biocompatibility, and sterilization capabilities of these plastics make them crucial in the manufacturing of disposable medical products, thus boosting the market. Besides, consumer electronics and appliances also play a pivotal role in driving the market. The demand for aesthetically pleasing, lightweight, and durable casings, enclosures, and components in these industries leads to an expanded application of injection molding technology. As Vietnam continues to attract foreign direct investment (FDI), the market benefits from increased industrial activities and the adoption of advanced manufacturing technologies. Advancements in material technology contribute significantly to market growth, providing manufacturers with a broader range of plastic materials and additives that enhance performance, durability, and sustainability. The cost-effectiveness and design flexibility offered by injection molding further attract industries seeking high-volume production of intricately designed plastic parts, propelling the market.

Vietnam Injection Molded Plastics Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2025-2033. Our report has categorized the market based on raw material and application.

Raw Material Insights:

- Polypropylene (PP)

- Acrylonitrile Butadiene Styrene (ABS)

- High-Density Polyethylene (HDPE)

- Polystyrene (PS)

- Others

The report has provided a detailed breakup and analysis of the market based on the raw material. This includes polypropylene (PP), acrylonitrile butadiene styrene (ABS), high-density polyethylene (HDPE), polystyrene (PS), and others.

Application Insights:

- Packaging

- Consumables and Electronics

- Automotive and Transportation

- Building and Construction

- Medical

- Others

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes packaging, consumables and electronics, automotive and transportation, building and construction, medical, and others.

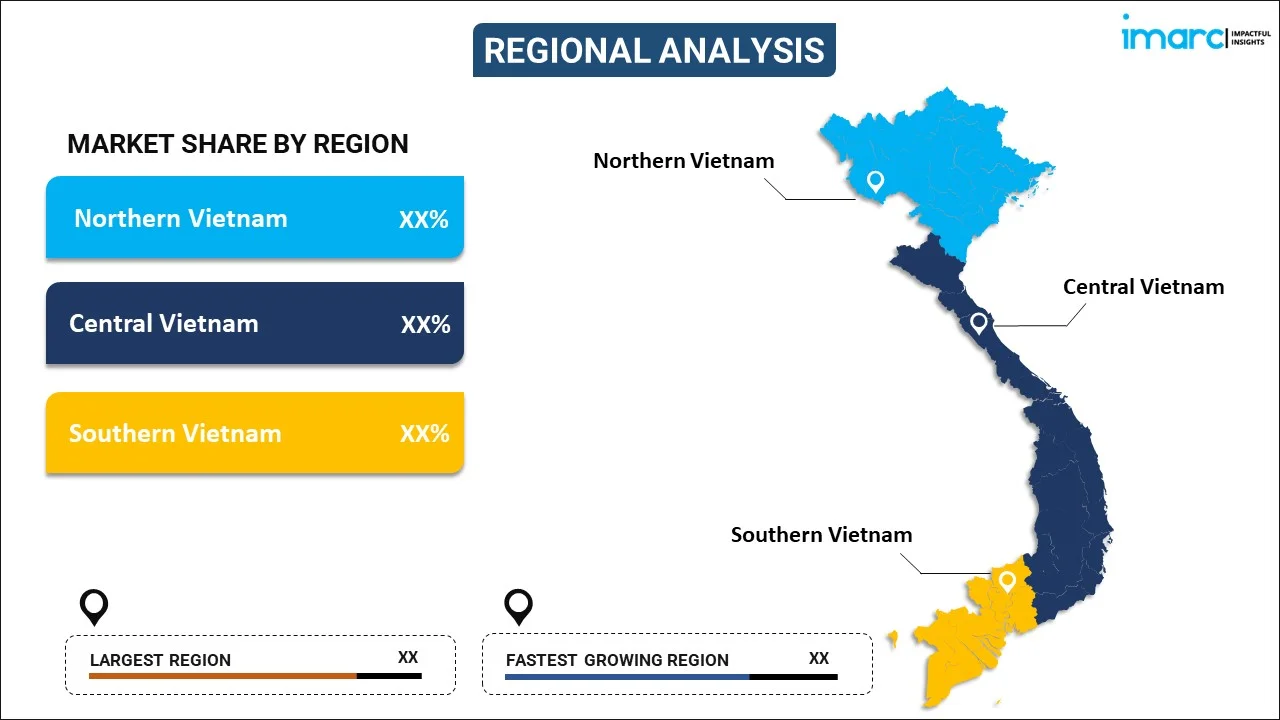

Regional Insights:

- Northern Vietnam

- Central Vietnam

- Southern Vietnam

The report has also provided a comprehensive analysis of all the major regional markets, which include Northern Vietnam, Central Vietnam, and Southern Vietnam.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Vietnam Injection Molded Plastics Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical and Forecast Trends, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Raw Materials Covered | Polypropylene (PP), Acrylonitrile Butadiene Styrene (ABS), High-Density Polyethylene (HDPE), Polystyrene (PS), Others |

| Applications Covered | Packaging, Consumables and Electronics, Automotive and Transportation, Building and Construction, Medical, Others |

| Regions Covered | Northern Vietnam, Central Vietnam, Southern Vietnam |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Vietnam injection molded plastics market performed so far and how will it perform in the coming years?

- What is the breakup of the Vietnam injection molded plastics market on the basis of raw material?

- What is the breakup of the Vietnam injection molded plastics market on the basis of application?

- What are the various stages in the value chain of the Vietnam injection molded plastics market?

- What are the key driving factors and challenges in the Vietnam injection molded plastics?

- What is the structure of the Vietnam injection molded plastics market and who are the key players?

- What is the degree of competition in the Vietnam injection molded plastics market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Vietnam injection molded plastics market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Vietnam injection molded plastics market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Vietnam injection molded plastics industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)