United States Caustic Soda Market Size, Share, Trends and Forecast by Product Type, Manufacturing Process, Grade, Application, and Region, 2025-2033

United States Caustic Soda Market Size and Share:

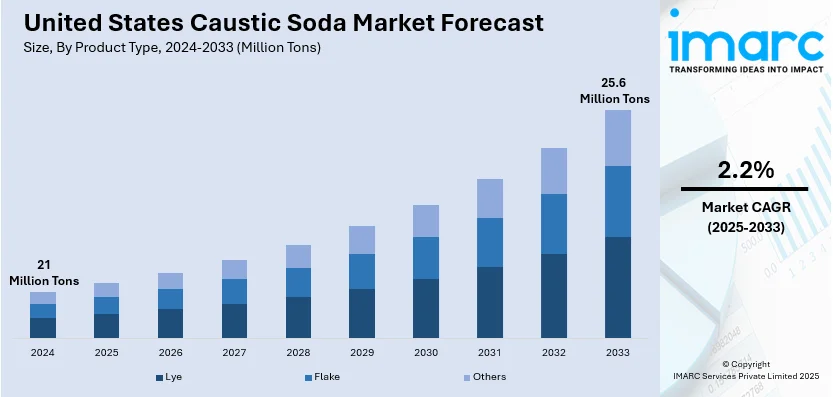

The United States caustic soda market size was valued at 21 Million Tons in 2024. Looking forward, IMARC Group estimates the market to reach 25.6 Million Tons by 2033, exhibiting a CAGR of 2.2% from 2025-2033. The US market is driven by the growing utilization of caustic soda in the preparation of fibers and fabrics to remove impurities, along with increasing demand for specialized chemical formulations in key industries.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | 21 Million Tons |

| Market Forecast in 2033 | 25.6 Million Tons |

| Market Growth Rate (2025-2033) | 2.2% |

With the increasing significance of wastewater treatment in municipal and industrial sectors, the need for caustic soda, utilized in water purification and treatment, is growing. Caustic soda is used to reduce the hardness of water. In combination with other substances, caustic soda assists in precipitating these minerals, rendering the water more appropriate for both domestic and industrial purposes. Additionally, the rising application of caustic soda to eliminate harmful materials such as heavy metals, suspended solids, and organic contaminants from water is further bolstering market expansion. Caustic soda is also efficient in decomposing pollutants in wastewater, including oils, fats, and greases. With the United States striving for improved water management and more stringent wastewater regulations, caustic soda is becoming essential.

Technological advancements are making caustic soda production more efficient and cost-effective. Improvements in electrolytic cell technology are encouraging the development of more energy-efficient methods to produce caustic soda and minimize production costs. This is increasing the supply of caustic soda, which is catalyzing its demand across various industries. Moreover, advancements in automation and smart monitoring systems are also improving the operational efficiency of caustic soda applications. These technologies allow for precise dosage and better control in processes like chemical manufacturing, where caustic soda is used to synthesize products and neutralize acids. Enhanced precision reduces waste, increases productivity, and ensures that caustic soda is utilized effectively, further driving its demand.

United States Caustic Soda Market Trends:

Rising demand for aluminum

With the growing demand for aluminum in sectors such as automotive, construction, and packaging, there is a rising need for alumina refining and, consequently, caustic soda. Caustic soda is extensively utilized in aluminum manufacturing for multiple purposes, such as cleaning, etching, and refining aluminum products. The process of extracting alumina involves using caustic soda to dissolve bauxite and isolate alumina from contaminants. In addition to this, the rising use of anodized aluminum in architecture, automotive, and consumer electronics is boosting the need for caustic soda to create a long-lasting and corrosion-resistant oxide layer. The effective application of caustic soda during refining and extrusion aids in minimizing waste and enhancing the environmental impact of aluminum manufacturing. As per the IMARC Group’s report, the aluminum extrusion market in the United States is expected to show a growth rate (CAGR) of 4.02% between 2024-2032.

Advancements in the textile industry

The rapid improvements in the textile industry, which needs caustic soda for the dyeing and finishing of fabrics, is impelling the market growth. Caustic soda assists in the preparation of fibers and fabrics by removing impurities, which enhances the quality of the final product. It is essential in the bleaching process of cotton and other fibers. In textile manufacturing, caustic soda is used in a process called mercerizing, which involves treating cotton fabric with a caustic soda solution. This process increases the fabric’s strength, luster, and dye affinity, making it more desirable for high-quality textile products. Caustic soda is used in eco-friendly textile processing, such as waterless dyeing technologies and more efficient cleaning methods to reduce water consumption and chemical waste. The data published on the website of the IMARC Group shows that the United States textile market is expected to exhibit a growth rate (CAGR) of 2.8% during 2024-2032.

Increasing utilization of specialty chemicals

The rising demand for specialty chemicals in industries like electronics and automotive and is propelling the market growth. Caustic soda is extensively used in the production of specialty chemicals, such as synthetic fibers, plastics, resins, surfactants, and adhesives. It acts as a reactant in processes like the production of chlorine and sodium hydroxide, which are fundamental to manufacturing several chemicals. The increasing utilization of specialty chemicals in manufacturing cleaning agents, detergents, and industrial cleaners, is further fueling the market growth. Moreover, caustic soda is required in specialized formulations of chemicals in industries like pharmaceuticals and cosmetics, and food processing, which is catalyzing its demand. The IMARC Group’s report predicted that the United States specialty chemicals market will exhibit a growth rate (CAGR) of 3.12% during 2024-2032.

United States Caustic Soda Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the United States caustic soda market, along with forecasts at the country and regional levels from 2025-2033. The market has been categorized based on product type, manufacturing process, grade, and application.

Analysis by Product Type:

- Lye

- Flake

- Others

Lye is caustic soda in its liquid form and is quite flexible and accessible for use in many applications. It is used in manufacturing, such as paper products, water treatment, and chemical production. Being highly soluble, it fosters using it in operations that would require heavy industrialized processes. Its reliability and flexibility make it more suitable for large industrial users who need the substance for their businesses.

Flake caustic soda is preferred for its easy storage and transportation and long shelf life. It is used mostly by small-scale industries in areas with less infrastructure. When accurate dosing is the requirement, flake caustic soda is used. It comes in solid form, hence minimizing spillage risks. It also increases safety and efficiency for industries working in different environments.

Analysis by Manufacturing Process:

- Membrane Cell

- Diaphragm Cell

- Others

The membrane cell process is known for being energy efficient and eco friendly. It separates brine and water through a selective membrane and provides high-purity caustic soda. This is of high quality and cost-effective.

The diaphragm cell offers advantages such as lower production costs and simplicity. This process uses a porous diaphragm in separating chlorine and caustic soda during electrolysis, which makes it suitable for applications that do not demand ultra-high purity, such as textiles, pulp and paper, and general industrial cleaning.

Analysis by Grade:

- Reagent Grade

- Industrial Grade

- Pharmaceutical Grade

- Others

Reagent-grade caustic soda is highly pure and used in precise laboratory and research and development (R&D) activities. It ensures minimal impurities, which makes it indispensable in scientific studies and specialized industrial processes. It can maintain stability under controlled conditions, and hence reduce variability in outcomes.

Industrial-grade caustic is cost-effective and suitable for large-scale processes that don’t require ultra-high purity. It acts as a precursor or reagent in producing various chemicals like plastics, solvents, and bleach. It is employed across sectors like textiles, paper production, and water treatment.

Pharmaceutical-grade caustic soda is essential for producing medicines, sanitizers, and medical-grade cleaning agents. It is highly pure, which enhances its compliance with stringent health and safety standards. It is used in the preparation of excipients, active pharmaceutical ingredients (APIs), and sterilization processes.

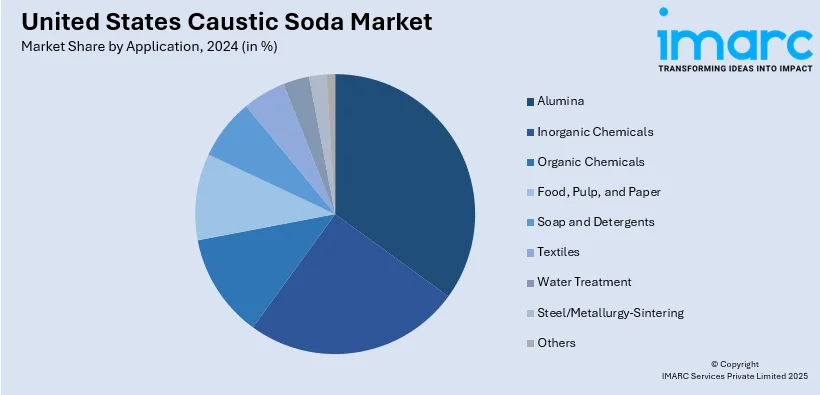

Analysis by Application:

- Alumina

- Inorganic Chemicals

- Organic Chemicals

- Food, Pulp, and Paper

- Soap and Detergents

- Textiles

- Water Treatment

- Steel/Metallurgy-Sintering

- Others

In the US caustic soda market, alumina refining is a significant application. Caustic soda is employed in the extraction of alumina from bauxite ore. The extrusion process requires aluminum to be as clean as possible to ensure the production of high-quality and defect-free products.

Caustic soda is essential in the production of various inorganic chemicals, such as sodium carbonate, sodium hydroxide, and sodium hypochlorite. These chemicals are used to synthesize other compounds and to treat wastewater. Cleaning agents and disinfectants, which require caustic soda in the manufacturing process, are in high demand in the United States.

In the US, caustic soda is employed to manufacture organic chemicals like plastics, solvents, and agrochemicals. It is used in processes like saponification and alkylation to produce key raw materials. It finds applications in industries like automotive, packaging, and agriculture, where it acts as a sustainable and environmental friendly solution.

The food, paper, and pulp industries account for a significant portion of the US caustic soda market due to their essential use in key manufacturing processes. In food processing, caustic soda aids in peeling, refining oils, and producing ingredients. In the paper industry, it’s crucial for pulping wood and bleaching. They rely on caustic soda for efficient and cost-effective production.

Caustic soda is used in the saponification process to create soap and detergent formulations as well as remove dirt and stains. The strength and type of soap can be adjusted by modifying the proportions of caustic soda and oils, which allows manufacturers to create a wide range of products from soft to hard soaps.

In the textile industry, caustic soda is used for processes like dyeing, bleaching, and fabric finishing. It assists in removing impurities from raw fibers to enable better dye absorption and fabric quality. Sustainability efforts in textile production also promote the use of caustic soda for eco-friendly treatments.

Caustic soda is important in water treatment, mainly in neutralizing acidic water and treating wastewater. It is used in the removal of heavy metals and cleaning water for municipal, industrial, and agricultural purposes. This segment benefits from growing environmental regulations and investments in water infrastructure.

In the steel and metallurgy industry, caustic soda is used in sintering and refining processes. It aids in removing impurities from metals, which ensures the production of high-quality steel and other metals. As the need for advanced and durable metals rises, caustic soda remains a key ingredient in steel production.

Regional Analysis:

- Northeast

- Midwest

- South

- West

In the Northeast region, caustic soda can be easily accessed through ports and efficient distribution networks. The numbers of chemical and paper manufacturers are also on the rise. New York and Boston are the hubs for industries that use caustic soda for water treatment and in textiles. As there is a high population in the region, the demand for caustic soda is on the rise.

The Midwest is a key player in the market owing to its thriving manufacturing and agricultural sectors. States like Ohio, Illinois, and Michigan use caustic soda in processes like chemical synthesis, soap production, and crop protection. As raw materials are highly available here with logistical ease, the Midwest remains a significant contributor to the market.

The South dominates the United States market because of the well-established chemical and petrochemical industries. Texas and Louisiana host numerous production facilities to encourage the use of caustic soda in applications like oil refining and plastics. The region’s access to the Gulf Coast facilitates efficient import and export activities.

Caustic soda finds applications in mining, agriculture, and water treatment in the West. The California and Nevada states utilize it for gold mining, crop production, and water maintenance. The region also benefits from environmental initiatives requiring effective wastewater treatment solutions.

Competitive Landscape:

Key players in the United States are contributing to market growth through innovation, expansion, and meeting the diverse demands of various industries. Major chemical manufacturers are investing heavily to increase production capacity and ensure a reliable supply of caustic soda for critical sectors, such as water treatment, aluminum production, textiles, and pulp and paper. They are placing bets focus on improving membrane cell technology to enhance production efficiency and reduce environmental impact. These companies are adopting sustainable practices to align with eco-friendly trends, which make production processes more energy-efficient and aid in reducing waste. By forming strategic partnerships and acquisitions, along with industrial expansions, key players are further solidifying their market presence. Key market players are also participating in various exhibitions. For example, in 2024, Westlake Corporation participated at the NPE 2024 held from 6 to 10th May in Florida to present its top-notch sustainable products. One of the major products presented by the company is GreenVin caustic soda, which is less carbon intensive.

The report provides a comprehensive analysis of the competitive landscape in the United States caustic soda market with detailed profiles of all major companies, including:

- Dow Inc.

- Occidental Petroleum Corporation

- Olin Corporation

- ProChem Inc.

- Westlake Corporation

Latest News and Developments:

- February 2024: American OxyChem, a subdivision of Occidental Petroleum Corporation announced the revival of its caustic soda and vinyl chloride monomer (VCM) production at its facility, located in Ingleside, Texas, USA. It strengthens the company's dedication to make industrial operations more reliable and efficient and enhance of production of vinyl products.

United States Caustic Soda Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million Tons |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Product Types Covered | Lye, Flake, Others |

| Manufacturing Processes Covered | Membrane Cell, Diaphragm Cell, Others |

| Grades Covered | Reagent Grade, Industrial Grade, Pharmaceutical Grade, Others |

| Applications Covered | Alumina, Inorganic Chemicals, Organic Chemicals, Food, Pulp, and Paper, Soap and Detergents, Textiles, Water Treatment, Steel/Metallurgy-Sintering, Others |

| Regions Covered | Northeast, Midwest, South, West |

| Companies Covered | Dow Inc., Occidental Petroleum Corporation, Olin Corporation, ProChem Inc., Westlake Corporation, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the United States caustic soda market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the United States caustic soda market.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the United States caustic soda industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

It is a white and odorless solid that is available in the form of flakes, pellets, or as a concentrated solution. It can dissolve oils, grease, and other substances, which makes it a vital component in many cleaning and chemical processes. It is widely used in various industrial applications, including soap and detergent manufacturing, water treatment, textile processing, and chemical synthesis.

The United States caustic soda market was valued at 21 Million Tons in 2024.

IMARC estimates the United States caustic soda market to exhibit a CAGR of 2.2% during 2025-2033.

The growing trend toward environmental friendly products, especially in the paper, textile, and cleaning industries, which require caustic soda, is positively influencing the market. Besides this, as the economy is rising, the demand for consumer products and industrial goods is increasing, both of which rely on caustic soda for production. Caustic soda is used in food processing, such as peeling fruits and vegetables and in cleaning food processing equipment, further bolstering the market growth.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)