Undercarriage Systems Market Size, Share, Trends and Forecast by Type, Application, and Region, 2025-2033

Undercarriage Systems Market Size and Share:

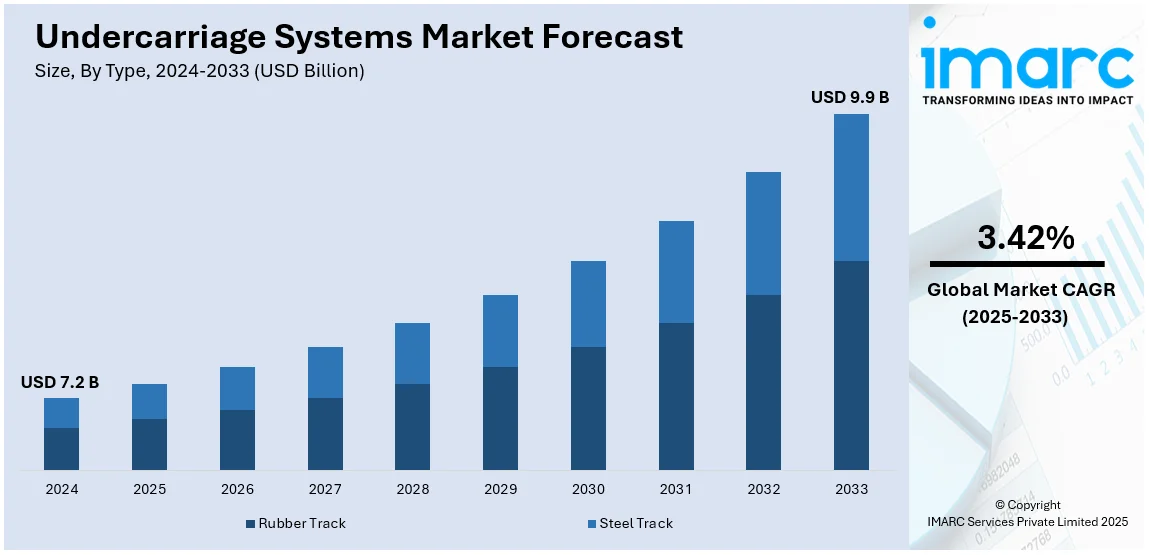

The global undercarriage systems market size was valued at USD 7.2 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 9.9 Billion by 2033, exhibiting a CAGR of 3.42% during 2025-2033. Asia-Pacific currently dominates the market, holding a significant market share of over 39.5% in 2024. The increasing number of mining and excavation activities, the growing investments in infrastructure development projects, such as road, railways, and urbanization initiatives, and the growing emphasis on fuel efficiency and environmental sustainability represent some of the key factors driving the undercarriage systems market share across the region.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 7.2 Billion |

|

Market Forecast in 2033

|

USD 9.9 Billion |

| Market Growth Rate (2025-2033) | 3.42% |

A major factor fueling the undercarriage systems market is the rising global demand for construction and mining machinery, driven by enhanced infrastructure growth and urban development. The boom in large construction projects, mostly in developing nations, is stimulating demand for heavy-duty and robust undercarriage systems with extended performance and durability of the machinery. According to industry reports, India construction industry is expected to reach USD 1.4 Trillion by 2047. Technological advancement with lighter materials and new designs also raises the system's life and productivity, increasing their attraction to end-users. Growth in mechanization of industries, along with greater investment in the maintenance of the fleet, will further support growth in the market. Additionally, the aftermarket undercarriage system market is expected to grow on account of replacement requirements, due to the wearing out of machinery in heavy-duty applications and sustained demand.

The United States stands out as a key market disruptor, driven by its robust product demand in the construction, agriculture, and mining industries. A high growth in residential, commercial, and transportation projects is significantly increasing the need for heavy equipment, which relies on durable and efficient undercarriage systems. Rearing trends for high advanced machinery in farms boosts productivity, giving undercarriage systems designed especially for tractors and harvesters additional boost to grow further. Maintenance of equipment for mining industries through an element called fleet management increases the adoption rate of products and components designed specifically for its requirement in such aftermarket. Therefore, undercarriage components suffer heavy wear, so their rapid replacement is observed. The advancement in technology, such as improved materials and innovative design, increases the durability and efficiency of the operation while attracting more investments.

Undercarriage Systems Market Trends:

Infrastructure development and urbanization

The main driving factor behind the growth of the undercarriage systems market is rapid global urbanization and increasing attention toward infrastructure development. As per the United Nations, 68% of the global population is expected to reside in urban areas by 2050. In Asia-Pacific, unprecedented growth is being experienced in urban centers of developing economies, and there has been an ever-increasing need for roads, bridges, residential complexes, and industrial facilities. Large-scale construction projects such as excavators, bulldozers, and loaders heavily rely on these robust undercarriage systems for proper operation. The need for smart cities and an updated, modernized infrastructure in developed countries also plays a role in the increased growth of the market. Undercarriage systems are essential for maintaining the stability and mobility of equipment on different terrains; therefore, such construction activities cannot be done without undercarriage systems. Furthermore, investments into public infrastructure projects, including transportation networks and energy facilities, by the government also increase the undercarriage systems market demand.

Technological advancements in materials and design

Advancements in material and design technologies have transformed the undercarriage systems market in a global arena by making more resilient, lightweight, and efficient products possible. Introductions in high-strength steel, composite materials, and wear-resistant alloys have substantially enhanced the service life and performance of undercarriage components such as tracks, rollers, and idlers. Designs, for instance, have taken the shape of modular undercarriage systems to allow for ease of replacement and maintenance, minimizing end-users' downtimes and expenses. Moreover, manufacturers are using CAD along with simulation tools to optimize undercarriage systems for various types of machinery and terrains, thereby enhancing adaptability and operational efficiency. All these technologies enhance the reliability of undercarriage systems and align with the ongoing need for sustainability by minimizing material waste during production and reducing energy consumption, further creating a positive undercarriage systems market outlook.

Growing adoption of mechanization in agriculture and mining

High growth potential of undercarriage systems can be seen from the increased application of mechanized equipment in agriculture and mining. The increase in agricultural activities for more productivity with the efficient utilization of resources has resulted in a higher acceptance of advanced machinery such as tractors, combines, and harvesters that have more requirements in terms of the robust undercarriage systems in varied, mostly challenging, and demanding terrains. Similarly, the global mining industry is growing as the demand for raw materials and minerals increases. This increases the use of heavy equipment like excavators, bulldozers, and drilling machines. Undercarriage systems play a crucial role in these applications, providing stability, mobility, and durability under extreme conditions. The aftermarket for replacement parts also grows due to the frequent wear and tear in such industries, thereby ensuring sustained demand for undercarriage systems. Emerging markets focus on mechanization further fueling the undercarriage systems market growth.

Undercarriage Systems Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global undercarriage systems market, along with forecasts at the global, regional, and country levels from 2025-2033. The market has been categorized based on type and application.

Analysis by Type:

- Rubber Track

- Steel Track

Steel track dominates the market, as they are more durable and stronger, with better performance in heavy-duty applications. These tracks are mainly used in construction, mining, and forestry equipment where machines have to work on rugged and uneven terrains. Steel tracks offer greater stability, traction, and load-bearing capacity compared to rubber alternatives, which makes them suitable for high-impact environments. Further, resistance to wear and performance even at extreme conditions enhance their large adoption. Also, longevity and low-cost efficiency in steel tracks will reinforce its position to become the undercarriage system market's biggest share.

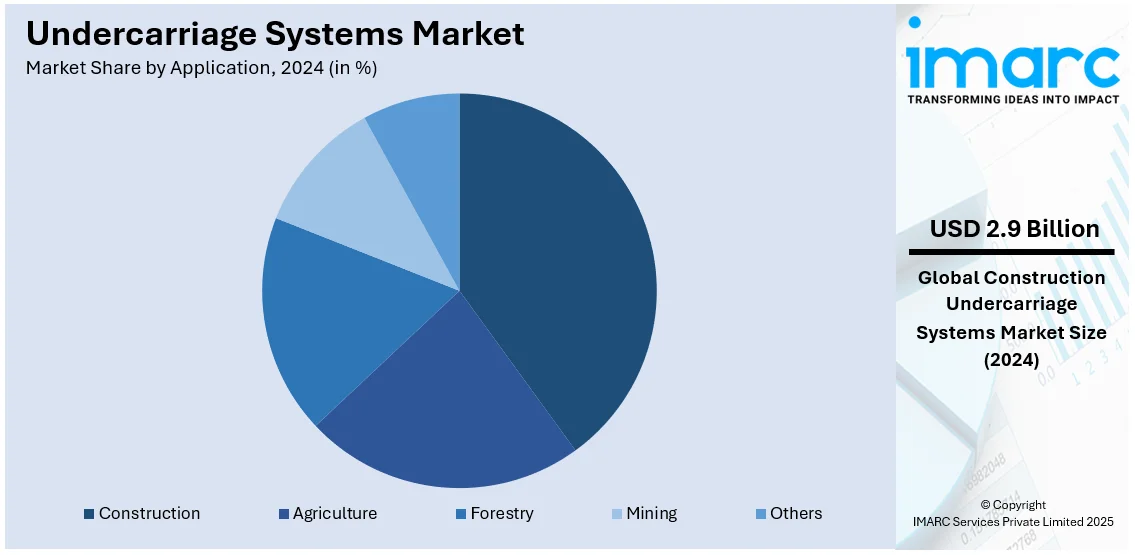

Analysis by Application:

- Agriculture

- Construction

- Forestry

- Mining

- Others

Construction holds maximum number of share, with over 40% of shareholding in 2024, majorly on account of extensive use in infrastructure development, urbanization, and large construction projects. Apparatus like excavators, bulldozers, and loaders rely majorly on heavy-duty undercarriage systems for optimal performance on varied terrain. An increase in the demand for roads and bridges, commercial as well as residential projects, especially in the developing economies, is a primary source of the demand for construction equipment. Besides this, government spending on public infrastructure and private sector initiatives in the real estate sectors boost the market further. The continuous undercarriage components replacement and maintenance of these machines also sustain the demand.

Regional Analysis:

- North America

- United States

- Canada

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Others

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

In 2024, Asia-Pacific accounted for the largest market share of over 39.5%, on account of fast-paced industrialization and infrastructure development within emerging economies of China, India, and countries in Southeast Asia. The reason is the steadily growing demand for heavy construction and mining machinery arising from large infrastructure projects and resource extraction. Finally, mechanized agriculture increases demand for robust undercarriage systems as well. Government investment in public infrastructure, combined with a massive manufacturing base of heavy equipment, makes Asia Pacific the prominent region, offering a constant need for reliable solutions under the chassis.

Key Regional Takeaways:

United States Undercarriage Systems Market Analysis

The United States undercarriage systems market is primarily driven by the rapid expansion of the construction and mining sectors, fueled by the increasing demand for infrastructure development and resource extraction. According to reports, as of 2024, approximately 555,045 people are employed in the mining industry in the US, highlighting the sector's significant contribution to the economy and its reliance on heavy machinery. The government’s infrastructure development initiatives, such as the Infrastructure Investment and Jobs Act, have further bolstered construction activities, which heightens the demand for durable undercarriage systems. Additionally, the shift toward automation and the integration of advanced technologies like telematics and condition monitoring is enhancing the performance and longevity of undercarriage components, stimulating market growth. The growing focus on fleet management and equipment uptime optimization drives manufacturers to innovate for improved durability and cost-efficiency. Moreover, the increasing use of construction equipment in renewable energy projects and the energy sector also plays a vital role in expanding the market. The availability of aftermarket services that ensure operational efficiency contributes to continued demand. Consequently, the US undercarriage systems market is expected to experience strong growth, supported by technological advancements, increased construction activity, and a robust mining sector.

Asia Pacific Undercarriage Systems Market Analysis

In the Asia-Pacific region, increasing urbanization and infrastructure development are key drivers of the undercarriage systems market. Emerging economies like China, India, and Southeast Asia are heavily investing in infrastructure projects, boosting demand for construction and mining equipment.As per industry reports, 16.3 million individuals were employed in small-scale mining across South Asia, including 12 million in India, whereas East Asia and the Pacific had 9.8 million, with 9 million located in China. . This underscores the vast scale of the mining sector, driving the need for durable undercarriage systems. Additionally, the adoption of advanced technologies, including telematics for fleet management, is enhancing the performance and longevity of undercarriage components. The rise of automation in construction equipment further emphasizes the demand for high-performance undercarriages. With significant investments in both infrastructure and industrial sectors, the APAC undercarriage systems market is poised for strong growth, driven by the expanding mining, construction, and agricultural industries.

Europe Undercarriage Systems Market Analysis

The undercarriage systems market in Europe is driven by the growing demand for construction equipment, especially in key sectors such as infrastructure development, mining, and agriculture. The European Union’s focus on sustainability and green infrastructure is accelerating the adoption of efficient machinery, leading to increased demand for high-performance undercarriage systems. Significantly, the European Climate Law establishes an interim goal to cut net greenhouse gas emissions by at least 55% by 2030, relative to 1990 levels, compelling businesses to focus on eco-friendly alternatives in their machinery. . As construction projects continue to expand, especially in urban regeneration and smart cities, there is a surge in the need for heavy-duty machinery that can operate efficiently in tough environments. Additionally, the trend toward fleet modernization, with companies investing in more advanced and sustainable equipment, further drives the market for durable undercarriage systems. The mining industry in Europe is also evolving, with an increasing demand for reliable undercarriage systems for mining machinery. Moreover, the region’s shift towards electric and hybrid construction equipment is stimulating innovations in undercarriage design. Consequently, these factors collectively fuel the demand for undercarriage systems across Europe.

Latin America Undercarriage Systems Market Analysis

Urbanization in Latin America is a significant driver of the undercarriage systems market. According to researches, urbanization in Latin American countries has reached around 80%, surpassing most other regions. This rapid urbanization leads to a surge in infrastructure projects, particularly in cities, boosting demand for construction equipment. Additionally, the growing mining sector in countries like Brazil and Chile further increases the need for durable undercarriage systems. The shift toward fleet modernization and the increasing focus on efficient equipment are also contributing factors to market growth. The demand for reliable undercarriage systems is thus expected to remain strong in the region.

Middle East and Africa Undercarriage Systems Market Analysis

The undercarriage systems market in the Middle East and Africa is driven by increased infrastructure development, particularly in the GCC countries and parts of sub-Saharan Africa. Urbanization is advancing rapidly in the region, with 64% of the population already urbanized, according to the World Bank. This growing urbanization accelerates demand for construction equipment and robust undercarriage systems. Additionally, large-scale construction and energy projects are further propelling market growth. The expanding mining industry in countries like South Africa also contributes to the need for durable undercarriage solutions. As automation and sustainable construction practices rise, the demand for advanced undercarriage systems will continue to grow.

Competitive Landscape:

The undercarriage systems market has key players that are making several strategic efforts to drive growth and enhance their competitive position. Many companies invest in R&D to innovate and improve their durability, performance, and efficiency on undercarriage systems. This encompasses the use of advanced materials like high strength steel, composites to increase longevity without raising the maintenance cost of end-users. Modular and customized undercarriage solutions with high adaptability for different machinery and terrains are being designed and developed by the manufacturers. They are also offering an expanded range of products with integrated solutions combining advanced undercarriage systems with cutting-edge fleet management technologies, enhancing the monitoring and maintenance capabilities.

The report provides a comprehensive analysis of the competitive landscape in the undercarriage systems market with detailed profiles of all major companies, including:

- Caterpillar Inc.

- DRB Holding Co. Ltd.

- Hitachi Construction Machinery Co. Ltd. (Hitachi Ltd.)

- Komatsu Ltd.

- RENOMAG spol. s r.o.

- thyssenKrupp AG

- VTS Track Solutions

Latest News and Developments:

- January 2025: KAGE Innovation has launched its Under-Hitch Tractor Undercarriage System, featuring front 3-point hitch technology. This adjustable system enhances compatibility with various tractor models, improving versatility in snow removal and other applications. Designed for professionals, it allows operators to use category 2 three-point hitch attachments at the front of the tractor, offering improved functionality, precision, and efficiency.

- July 2024: Volvo CE India facilitated the entry of two Korean undercarriage parts manufacturers, contributing to increased localization in the country. These manufacturers supplied parts to Volvo and also to other players in the market. Industry groups like ICEMA supported similar initiatives, including a delegation visit to Japan. Volvo CE’s launch of the EC210 excavator, with 70% local content, highlighted changes in India's supply chain.

- July 2024: HD Hyundai Construction Equipment North America has expanded its product line with the introduction of the Hyundai HD100 crawler dozer, featuring a 115-net-hp (86 kW) engine. This new addition broadens Hyundai’s earthmoving equipment offerings, which include wheel loaders, excavators, dump trucks, skid steers, and compact track loaders. The HD100 dozer’s design is optimized for heavy-duty undercarriage systems, further enhancing Hyundai’s capabilities in handling diverse material handling and construction tasks.

- January 2023: Felling Trailers, Inc. has launched its Low Pro Heavy Duty (LP HD) models, specifically designed to transport heavy construction equipment with wide undercarriages, such as excavators and dozers. The LP HD series accommodates equipment with an 8’-8.5’ track gauge, ensuring optimal weight distribution over the trailer for safe and efficient transport. Available in 25-ton (FT-50-3 LP HD, triple axle) and 30-ton (FT-60-4 LP HD, quad axle) configurations, the trailers feature robust structural components, making them ideal for handling heavy machinery with substantial undercarriage systems.

- December 2022: IAA, Inc. has added undercarriage photo services to its Inspection Services® platform, improving estimate accuracy by providing visibility into key components like the drivetrain, suspension, and engine. The service is also useful for inspecting electric vehicle batteries. Providers will receive 10 standard undercarriage images via IAA's CSAToday® system, available as part of any inspection or as a separate request.

Undercarriage Systems Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | Rubber Track, Steel Track |

| Applications Covered | Agriculture, Construction, Forestry, Mining, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Caterpillar Inc., DRB Holding Co. Ltd., Hitachi Construction Machinery Co. Ltd. (Hitachi Ltd.), Komatsu Ltd., RENOMAG spol. s r.o., thyssenKrupp AG, VTS Track Solutions, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the undercarriage systems market from 2019-2033.

- The undercarriage systems market research report provides the latest information on the market drivers, challenges, and opportunities in the global market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the undercarriage systems industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The undercarriage systems market was valued at USD 7.2 Billion in 2024.

The undercarriage systems market is projected to exhibit a CAGR of 3.42% during 2025-2033, reaching a value of USD 9.9 Billion by 2033.

Key factors driving the global undercarriage systems market include increasing infrastructure development, technological advancements in materials and design, and the growing adoption of mechanized equipment in construction, mining, and agriculture.

The Asia Pacific region is the largest in the worldwide undercarriage systems market, driven by its flourishing construction and agriculture sectors, swift infrastructure growth, and the presence of major equipment manufacturers.

Some of the major players in the undercarriage systems market include Caterpillar Inc., DRB Holding Co. Ltd., Hitachi Construction Machinery Co. Ltd. (Hitachi Ltd.), Komatsu Ltd., RENOMAG spol. s r.o., thyssenKrupp AG, VTS Track Solutions, etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)