South Korea Metal Stamping Market Report by Material (Steel, Aluminum, Copper, and Others), Press Type (Mechanical Press, Hydraulic Press, Servo Press), Process (Blanking, Embossing, Bending, Coining, Deep Drawing, Flanging, and Others), Application (Automotive, Industrial Machinery, Consumer Electronics, Aerospace, Electrical and Electronics, Healthcare, Defense, Telecommunications, and Others), and Region 2025-2033

Market Overview:

South Korea metal stamping market size reached USD 26.7 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 36.8 Billion by 2033, exhibiting a growth rate (CAGR) of 3.65% during 2025-2033. The growing demand for energy-efficient and eco-friendly metal components and continuous investments in R&D activities represent some of the key factors driving the market growth.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033 |

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 26.7 Billion |

| Market Forecast in 2033 | USD 36.8 Billion |

| Market Growth Rate 2025-2033 | 3.65% |

Metal stamping stands as a versatile manufacturing method that shapes, cuts, and forms metal sheets into diverse and intricate designs and components. The process entails positioning the metal sheet between a die and a punch, applying pressure to achieve the desired shape or cutout. The advantages of metal stamping include rapid production, cost-effectiveness, and consistent precision. It finds extensive application in sectors such as automotive, aerospace, electronics, and appliances, where components like brackets, clips, panels, and connectors are manufactured. The process accommodates various metals, such as steel, aluminum, and copper, offering flexibility for a range of applications. Additionally, advancements in stamping technology, including progressive and transfer stamping methods, have enhanced efficiency and precision. In the realm of modern manufacturing, metal stamping remains a crucial technique for mass-producing high-quality metal parts, underscoring its significance in the production landscape.

South Korea Metal Stamping Market Trends:

The South Korea metal stamping market stands as a pivotal player in the nation's manufacturing landscape, showcasing versatility and efficiency in the production of intricate metal components. The fundamental procedure involves placing a metal sheet between a die and a punch, with pressure applied to create the desired shape or cutout. The South Korea metal stamping market offers numerous advantages, including high production speed, cost-effectiveness, and consistent precision. These attributes make it an indispensable technique for mass-producing components like brackets, clips, panels, and connectors, which are integral to the functioning of various products in diverse industries. Additionally, technological advancements in metal stamping, particularly through progressive and transfer stamping methods, have further elevated efficiency and accuracy in the manufacturing process. As South Korea continues to be a hub for advanced manufacturing technologies, the metal stamping market is poised for sustained growth. Furthermore, its role in producing high-quality, precision-engineered metal parts aligns with the country's commitment to innovation and excellence in manufacturing, which is acting as another significant growth-inducing factor. The South Korea metal stamping market will remain at the forefront of modern manufacturing practices in the coming years.

South Korea Metal Stamping Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2025-2033. Our report has categorized the market based on material, press type, process, and application.

Material Insights:

- Steel

- Aluminum

- Copper

- Others

The report has provided a detailed breakup and analysis of the market based on the material. This includes steel, aluminum, copper, and others.

Press Type Insights:

- Mechanical Press

- Hydraulic Press

- Servo Press

A detailed breakup and analysis of the market based on the press type have also been provided in the report. This includes mechanical press, hydraulic press, and servo press.

Process Insights:

- Blanking

- Embossing

- Bending

- Coining

- Deep Drawing

- Flanging

- Others

The report has provided a detailed breakup and analysis of the market based on the process. This includes blanking, embossing, bending, coining, deep drawing, flanging, and others.

Application Insights:

- Automotive

- Industrial Machinery

- Consumer Electronics

- Aerospace

- Electrical and Electronics

- Healthcare

- Defense

- Telecommunications

- Others

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes automotive, industrial machinery, consumer electronics, aerospace, electrical and electronics, healthcare, defense, telecommunications, and others.

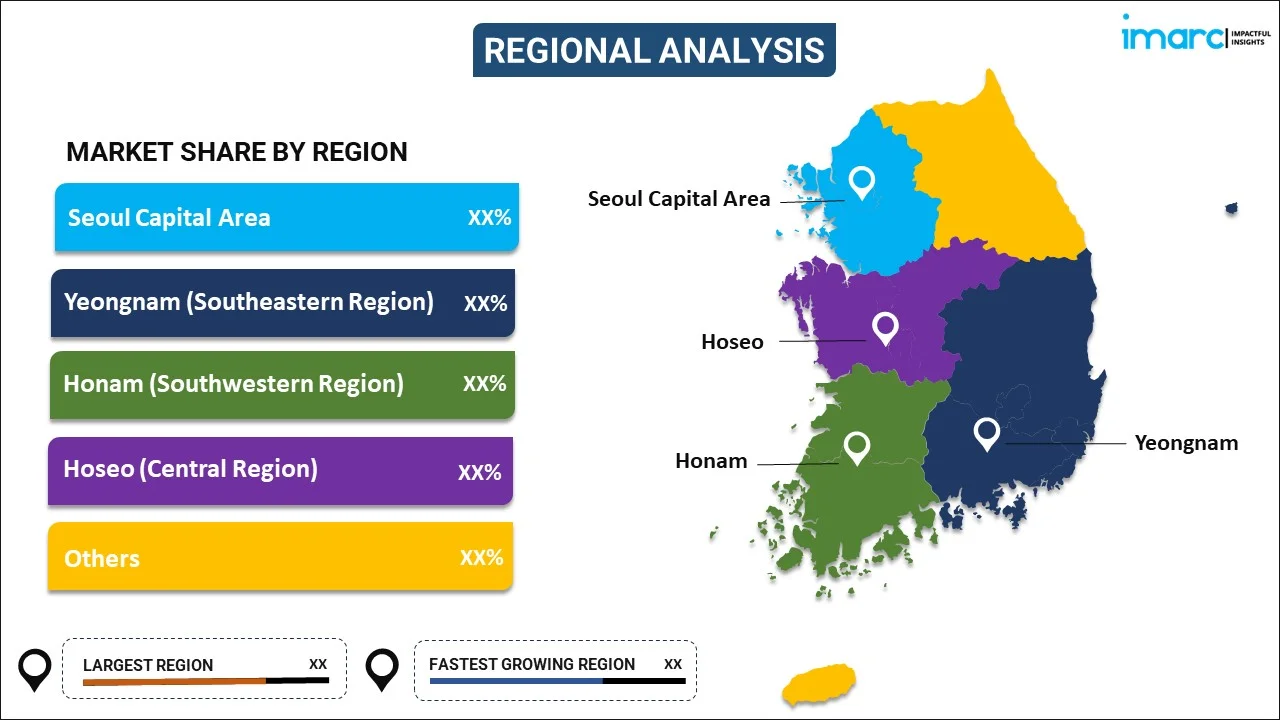

Regional Insights:

- Seoul Capital Area

- Yeongnam (Southeastern Region)

- Honam (Southwestern Region)

- Hoseo (Central Region)

- Others

The report has also provided a comprehensive analysis of all the major regional markets, which include Seoul Capital Area, Yeongnam (Southeastern Region), Honam (Southwestern Region), Hoseo (Central Region), and Others.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape in the market. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

South Korea Metal Stamping Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Materials Covered | Steel, Aluminum, Copper, Others |

| Press Types Covered | Mechanical Press, Hydraulic Press, Servo Press |

| Processes Covered | Blanking, Embossing, Bending, Coining, Deep Drawing, Flanging, Others |

| Applications Covered | Automotive, Industrial Machinery, Consumer Electronics, Aerospace, Electrical and Electronics, Healthcare, Defense, Telecommunications, Others |

| Regions Covered | Seoul Capital Area, Yeongnam (Southeastern Region), Honam (Southwestern Region), Hoseo (Central Region), Others |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the South Korea metal stamping market performed so far and how will it perform in the coming years?

- What has been the impact of COVID-19 on the South Korea metal stamping market?

- What is the breakup of the South Korea metal stamping market on the basis of material?

- What is the breakup of the South Korea metal stamping market on the basis of press type?

- What is the breakup of the South Korea metal stamping market on the basis of process?

- What is the breakup of the South Korea metal stamping market on the basis of application?

- What are the various stages in the value chain of the South Korea metal stamping market?

- What are the key driving factors and challenges in the South Korea metal stamping?

- What is the structure of the South Korea metal stamping market and who are the key players?

- What is the degree of competition in the South Korea metal stamping market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the South Korea metal stamping market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the South Korea metal stamping market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the South Korea metal stamping industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)