South Korea Metal Casting Market Report by Process (Sand Casting, Gravity Casting, High-Pressure Die Casting (HPDC), Low-Pressure Die Casting (LPDC), and Others), Material Type (Cast Iron, Aluminum, Steel, Zinc, Magnesium, and Others), End Use (Automotive and Transportation, Equipment and Machine, Building and Construction, Aerospace and Military, and Others), and Region 2025-2033

Market Overview:

South Korea metal casting market size is projected to exhibit a growth rate (CAGR) of 5.7% during 2025-2033. The growing adoption of advanced technologies, along with the integration of 3D printing and additive manufacturing techniques, increasing emphasis on environment-friendly practices, and rising the exploration of eco-friendly alloys represent some of the key factors driving the market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Growth Rate (2025-2033) | 5.7% |

Metal casting refers to a versatile manufacturing procedure that involves the pouring of molten metal into a mold cavity to make a desired shape. It comprises sand casting, which involves creating mold from compact sand around a pattern and is suitable for ferrous and non-ferrous metals. It consists of investment casting or precision casting, which uses a wax pattern that is coated with a ceramic shell. It also includes die casting that is suitable for high-volume production of components with excellent dimensional accuracy. It involves heating metals beyond their melting points and pouring the molten material into the mold. It undergoes various finishing processes, including cleaning, cutting, and polishing, to get the desired surface finish and dimensional accuracy. Metal casting allows for the economical production of large quantities of components, making it a preferred method for industries requiring mass production. It enables the creation of intricate and complex shapes that may be challenging or costly to achieve through other manufacturing processes. It also accommodates a wide range of materials, including ferrous and non-ferrous alloys, providing manufacturers with flexibility in material selection based on their requirements. It is an eco-friendly process as scrap metal generated during casting can be recycled, contributing to sustainability and lowering the environmental impact of manufacturing processes.

South Korea Metal Casting Market Trends:

At present, the increasing adoption of advanced technologies, along with the integration of 3D printing and additive manufacturing techniques, enabling more complex and intricate designs with greater precision represents one of the crucial factors impelling the growth of the market in South Korea. This shift towards advanced manufacturing techniques not only enhances the efficiency of production but also opens doors to new possibilities in terms of product design and customization. Besides this, the rising emphasis on environment-friendly practices is encouraging manufacturers to invest in sustainable casting processes and materials in the country. This includes the exploration of eco-friendly alloys and the development of cleaner and more energy-efficient production methods. Companies are also adopting greener practices to reduce their environmental footprint, thereby influencing the overall direction of the metal casting industry in the country. In addition, the growing need for lightweight components to improve fuel efficiency and lower emissions is increasing the use of aluminum and other lightweight alloys in automotive casting applications. As the automotive industry is transitioning towards electric vehicles (EVs), metal casting companies are witnessing a rise in the demand for specialized components, such as those used in battery casings and electric motor housings. Apart from this, manufacturers are implementing advanced sensors, data analytics, and artificial intelligence (AI) to examine and optimize their casting processes in real time. This not only improves the overall quality of the cast components but also enhances operational efficiency.

South Korea Metal Casting Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2025-2033. Our report has categorized the market based on process, material type, and end use.

Process Insights:

- Sand Casting

- Gravity Casting

- High-Pressure Die Casting (HPDC)

- Low-Pressure Die Casting (LPDC)

- Others

The report has provided a detailed breakup and analysis of the market based on the process. This includes sand casting, gravity casting, high-pressure die casting (HPDC), low-pressure die casting (LPDC), and others.

Material Type Insights:

- Cast Iron

- Aluminum

- Steel

- Zinc

- Magnesium

- Others

A detailed breakup and analysis of the market based on the material type have also been provided in the report. This includes cast iron, aluminum, steel, zinc, magnesium, and others.

End Use Insights:

- Automotive and Transportation

- Equipment and Machine

- Building and Construction

- Aerospace and Military

- Others

The report has provided a detailed breakup and analysis of the market based on the end use. This includes automotive and transportation, equipment and machine, building and construction, aerospace and military, and others.

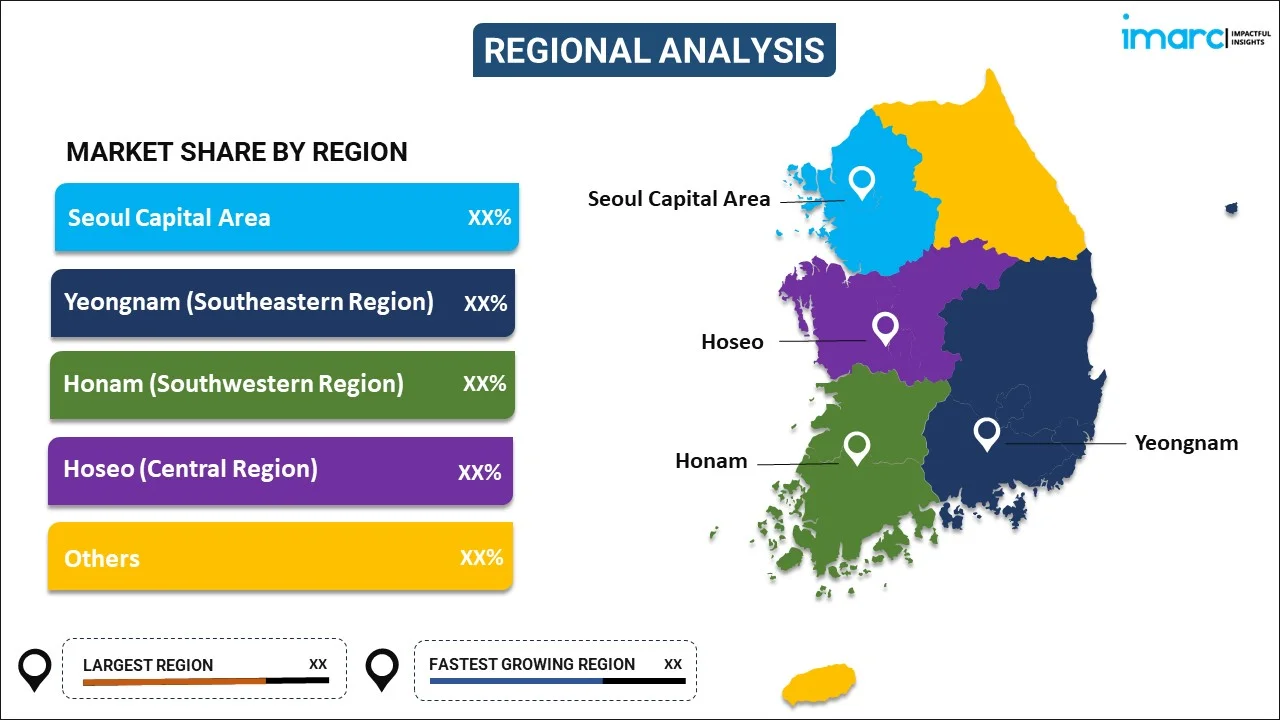

Regional Insights:

- Seoul Capital Area

- Yeongnam (Southeastern Region)

- Honam (Southwestern Region)

- Hoseo (Central Region)

- Others

The report has also provided a comprehensive analysis of all the major regional markets, which include Seoul Capital Area, Yeongnam (Southeastern Region), Honam (Southwestern Region), Hoseo (Central Region), and Others.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

South Korea Metal Casting Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical and Forecast Trends, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Processes Covered | Sand Casting, Gravity Casting, High-Pressure Die Casting (HPDC), Low-Pressure Die Casting (LPDC), Others |

| Material Types Covered | Cast Iron, Aluminum, Steel, Zinc, Magnesium, Others |

| End Uses Covered | Automotive and Transportation, Equipment and Machine, Building and Construction, Aerospace and Military, Others |

| Regions Covered | Seoul Capital Area, Yeongnam (Southeastern Region), Honam (Southwestern Region), Hoseo (Central Region), Others |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the South Korea metal casting market performed so far and how will it perform in the coming years?

- What has been the impact of COVID-19 on the South Korea metal casting market?

- What is the breakup of the South Korea metal casting market on the basis of process?

- What is the breakup of the South Korea metal casting market on the basis of material type?

- What is the breakup of the South Korea metal casting market on the basis of end use?

- What are the various stages in the value chain of the South Korea metal casting market?

- What are the key driving factors and challenges in the South Korea metal casting?

- What is the structure of the South Korea metal casting market and who are the key players?

- What is the degree of competition in the South Korea metal casting market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the South Korea metal casting market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the South Korea metal casting market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the South Korea metal casting industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)