South East Asia Machine Tools Market Size, Share, Trends and Forecast by Tool Type, Technology Type, End Use Industry, and Country, 2025-2033

Market Overview:

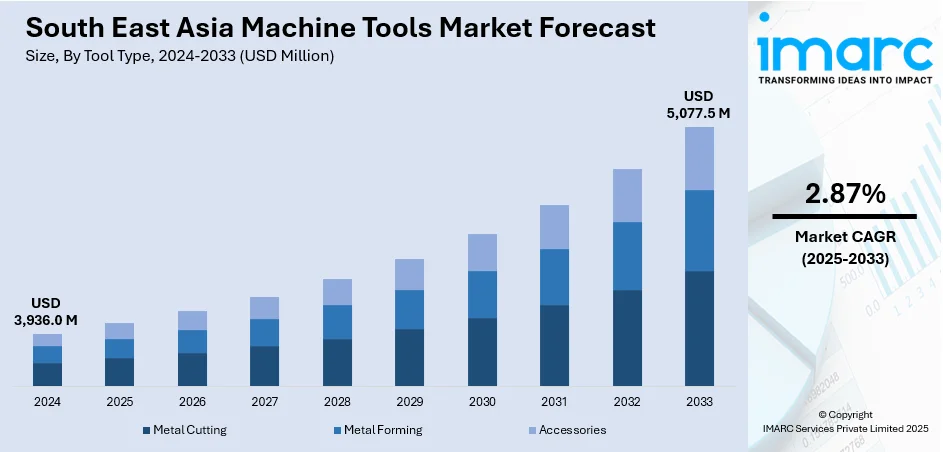

The South East Asia machine tools market size reached USD 3,936.0 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 5,077.5 Million by 2033, exhibiting a growth rate (CAGR) of 2.87% during 2025-2033. The emerging technological advancements, the significant expansion in aerospace and medical device manufacturing, and the widespread adoption of machine tools in the manufacturing sector represent some of the key factors contributing to the market growth.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 3,936.0 Million |

|

Market Forecast in 2033

|

USD 5,077.5 Million |

| Market Growth Rate 2025-2033 | 2.87% |

Machine tools refer to power-driven devices designed for cutting, shaping, or forming metal or other materials. They are typically used in industrial settings and workshops for tasks such as drilling, turning, milling, grinding, and more. They are fundamental devices used in manufacturing and machining processes, shaping and producing precision components and parts used in various industries, including automotive, aerospace, electronics, and construction. There are several categories of machine tools, each tailored to specific machining processes, including turning, milling, drilling, grinding, and electrical discharge machines. Additionally, turning machines rotate a workpiece while a cutting tool removes material to invent cylindrical shapes, including lathes and screw machines, while milling machines use rotary cutters to eliminate material from a workpiece's surface, creating flat or irregularly shaped objects. For instance, drilling machines are designed for creating holes in materials including drill presses and CNC drilling machines. Moreover, grinding machines are used to achieve high-precision surface finishes and tight tolerances by removing small amounts of material through abrasion, while electrical discharge machines (EDM) employ electrical discharges to cut, shape, and drill materials that are typically difficult to machine using conventional methods. These tools are integral to the world of engineering and manufacturing, facilitating the creation of intricate and accurately dimensioned products.

To get more information on this market, Request Sample

South East Asia Machine Tools Market Trends:

The market is primarily driven by the emerging technological advancements. In addition, machine tools are becoming more advanced, efficient, and precise, which is escalating the demand from various industries, including automotive, aerospace, and electronics, requiring highly accurate and automated machinery to meet their production needs, thus contributing to market growth. Moreover, the widespread adoption of Industry 4.0 principles, focusing on the integration of automation, data exchange, and smart technologies, has had a profound impact on the machine tools market, representing another major growth-inducing factor. Also, manufacturers are investing in computer numerical control (CNC) machines and robotic systems, leading to higher productivity, reduced labor costs, and improved quality control, thus augmenting market growth. Besides this, the growing manufacturing sector is driven by increasing consumer demand, urbanization, and economic expansion, which is escalating the demand for machine tools to support mass production and precision engineering, thus accelerating the market growth. Along with this, the growing aerospace and medical device manufacturing requires intricate and highly precise components, resulting in the adoption of machine tools to produce these components with the required accuracy, further propelling the market growth. Furthermore, several industries are demanding more customized and flexible production capabilities, while modern machine tools are offering greater flexibility, allowing manufacturers to quickly adapt to changing market demands, thus creating a positive market outlook.

South East Asia Machine Tools Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the regional and country levels for 2025-2033. Our report has categorized the market based on tool type, technology type, and end use industry.

Tool Type Insights:

- Metal Cutting

- Machining Centers

- Turning Machines

- Grinding Machines

- Milling Machines

- Eroding Machines

- Others

- Metal Forming

- Bending Machines

- Presses

- Punching Machines

- Others

- Accessories

The report has provided a detailed breakup and analysis of the market based on the tool type. This includes metal cutting (machining centers, turning machines, grinding machines, milling machines, eroding machines, and others), metal forming (bending machines, presses, punching machines, and others), and accessories.

Technology Type Insights:

- Conventional

- CNC (Computerized Numerical Control)

A detailed breakup and analysis of the market based on the technology type have also been provided in the report. This includes conventional and CNC (computerized numerical control).

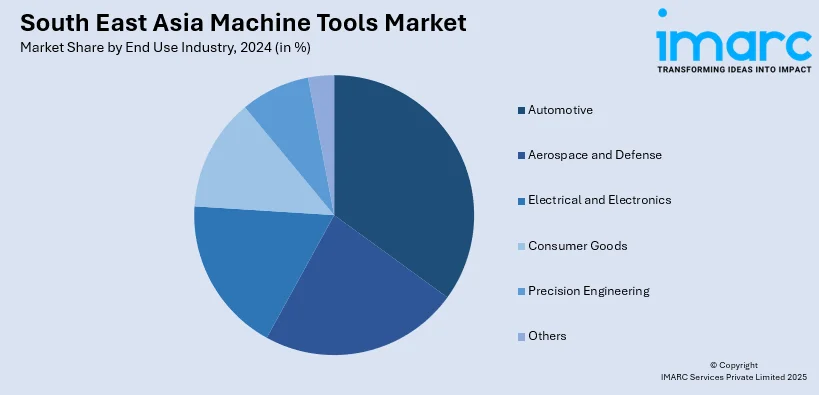

End Use Industry Insights:

- Automotive

- Aerospace and Defense

- Electrical and Electronics

- Consumer Goods

- Precision Engineering

- Others

The report has provided a detailed breakup and analysis of the market based on the end use industry. This includes automotive, aerospace and defense, electrical and electronics, consumer goods, precision engineering, and others.

Country Insights:

- Indonesia

- Thailand

- Singapore

- Philippines

- Vietnam

- Malaysia

- Others

The report has also provided a comprehensive analysis of all the major regional markets, which include Indonesia, Thailand, Singapore, Philippines, Vietnam, Malaysia, and Others.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape in the market. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

South East Asia Machine Tools Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Tool Types Covered |

|

| Technology Types Covered | Conventional, CNC (Computerized Numerical Control) |

| End Use Industries Covered | Automotive, Aerospace and Defense, Electrical and Electronics, Consumer Goods, Precision Engineering, Others |

| Countries Covered | Indonesia, Thailand, Singapore, Philippines, Vietnam, Malaysia, Others |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the South East Asia machine tools market performed so far and how will it perform in the coming years?

- What is the breakup of the South East Asia machine tools market on the basis of tool type?

- What is the breakup of the South East Asia machine tools market on the basis of technology type?

- What is the breakup of the South East Asia machine tools market on the basis of end use industry?

- What are the various stages in the value chain of the South East Asia machine tools market?

- What are the key driving factors and challenges in the South East Asia machine tools?

- What is the structure of the South East Asia machine tools market and who are the key players?

- What is the degree of competition in the South East Asia machine tools market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the South East Asia machine tools market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the South East Asia machine tools market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the South East Asia machine tools industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)