South East Asia Engineering Plastics Market Size, Share, Trends and Forecast by Resin Type, End Use Industry, and Country, 2025-2033

Market Overview:

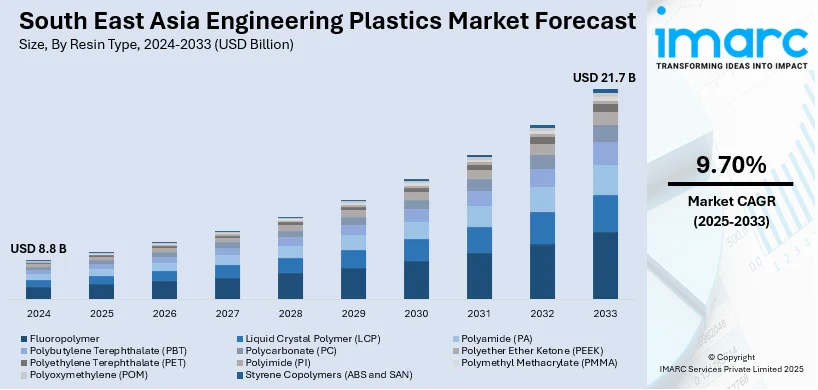

South East Asia engineering plastics market size reached USD 8.8 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 21.7 Billion by 2033, exhibiting a growth rate (CAGR) of 9.70% during 2025-2033. The emerging trend of using materials that have the ability to meet stringent performance requirements in terms of strength, resilience, and resistance to heat is primarily catalyzing the regional market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 8.8 Billion |

|

Market Forecast in 2033

|

USD 21.7 Billion |

| Market Growth Rate 2025-2033 | 9.70% |

Engineering plastics are a category of plastic materials that exhibit superior mechanical or thermal properties when compared to commonly produced plastics. They serve as a viable substitute for metals and ceramics due to their lightweight nature. These plastics demonstrate exceptional load capacity, thermal stability, mechanical strength, and durability. Variants of engineering plastics include widely used types like polycarbonates (PC), polyamides (PA), nylon 6, acrylonitrile butadiene styrene (ABS), and polysulphone (PSU). In recent times, the adoption of engineering plastics has increased significantly, finding extensive application in the manufacturing of dashboard trims, car bumpers, ski boots, optical discs, and helmets. Their popularity stems from their advantageous properties, making them a preferred choice in various industries for applications where strength, durability, and resistance to heat are crucial considerations.

To get more information on this market, Request Sample

South East Asia Engineering Plastics Market Trends:

The South East Asia engineering plastics market is experiencing remarkable growth, underlining the region's increasing reliance on advanced materials in various industries. Spanning countries like Indonesia, Malaysia, Thailand, Vietnam, and the Philippines, this market is characterized by a rising demand for engineering plastics owing to their superior mechanical and thermal properties compared to conventional plastics. Besides this, the automotive industry is a significant contributor to the South East Asia engineering plastics market, with applications ranging from dashboard trims to car bumpers. The lightweight nature of engineering plastics contributes to fuel efficiency and offers improved design flexibility. Additionally, these materials find use in diverse sectors, including consumer goods, electronics, and industrial machinery. In recent years, there has been a surge in the adoption of engineering plastics in South East Asia for various applications such as ski boots, optical discs, and helmets. Furthermore, the South East Asia engineering plastics market is dynamic, with both local and international players contributing to its expansion. The growing emphasis on lightweight and high-performance materials, coupled with advancements in manufacturing technologies, positions engineering plastics as integral components in the region's industrial and manufacturing landscape, which is expected to fuel the market growth over the forecasted period.

South East Asia Engineering Plastics Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the regional and country levels for 2025-2033. Our report has categorized the market based on resin type and end use industry.

Resin Type Insights:

- Fluoropolymer

- Ethylenetetrafluoroethylene (ETFE)

- Fluorinated Ethylene-Propylene (FEP)

- Polytetrafluoroethylene (PTFE)

- Polyvinylfluoride (PVF)

- Polyvinylidene Fluoride (PVDF)

- Others

- Liquid Crystal Polymer (LCP)

- Polyamide (PA)

- Aramid

- Polyamide (PA) 6

- Polyamide (PA) 66

- Polyphthalamide

- Polybutylene Terephthalate (PBT)

- Polycarbonate (PC)

- Polyether Ether Ketone (PEEK)

- Polyethylene Terephthalate (PET)

- Polyimide (PI)

- Polymethyl Methacrylate (PMMA)

- Polyoxymethylene (POM)

- Styrene Copolymers (ABS and SAN)

The report has provided a detailed breakup and analysis of the market based on the resin type. This includes fluoropolymer (ethylenetetrafluoroethylene (ETFE), fluorinated ethylene-propylene (FEP), polytetrafluoroethylene (PTFE), polyvinylfluoride (PVF), polyvinylidene fluoride (PVDF), and others), liquid crystal polymer (LCP), polyamide (PA) (aramid, polyamide (PA) 6, polyamide (PA) 66, and polyphthalamide), polybutylene terephthalate (PBT), polycarbonate (PC), polyether ether ketone (PEEK), polyethylene terephthalate (PET), polyimide (PI), polymethyl methacrylate (PMMA), polyoxymethylene (POM), and styrene copolymers (ABS and SAN).

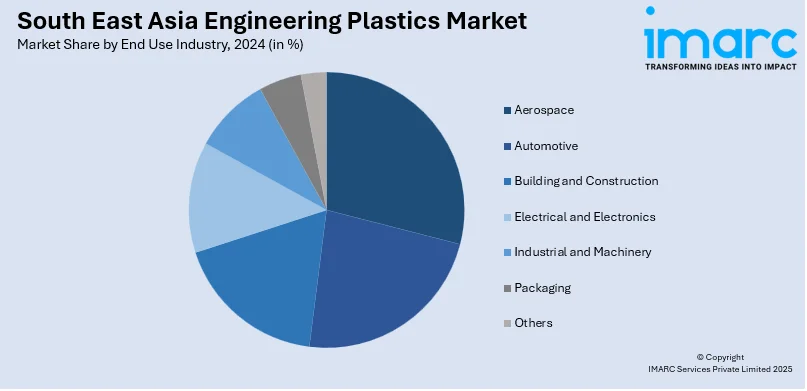

End Use Industry Insights:

- Aerospace

- Automotive

- Building and Construction

- Electrical and Electronics

- Industrial and Machinery

- Packaging

- Others

A detailed breakup and analysis of the market based on the end use industry have also been provided in the report. This includes aerospace, automotive, building and construction, electrical and electronics, industrial and machinery, packaging, and others.

Country Insights:

- Indonesia

- Thailand

- Singapore

- Philippines

- Vietnam

- Malaysia

- Others

The report has also provided a comprehensive analysis of all the major regional markets, which include Indonesia, Thailand, Singapore, Philippines, Vietnam, Malaysia, and Others.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

South East Asia Engineering Plastics Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical and Forecast Trends, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Resin Types Covered |

|

| End Use Industries Covered | Aerospace, Automotive, Building and Construction, Electrical and Electronics, Industrial and Machinery, Packaging, Others |

| Countries Covered | Indonesia, Thailand, Singapore, Philippines, Vietnam, Malaysia, Others |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the South East Asia engineering plastics market performed so far and how will it perform in the coming years?

- What is the breakup of the South East Asia engineering plastics market on the basis of resin type?

- What is the breakup of the South East Asia engineering plastics market on the basis of end use industry?

- What are the various stages in the value chain of the South East Asia engineering plastics market?

- What are the key driving factors and challenges in the South East Asia engineering plastics?

- What is the structure of the South East Asia engineering plastics market and who are the key players?

- What is the degree of competition in the South East Asia engineering plastics market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the South East Asia engineering plastics market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the South East Asia engineering plastics market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the South East Asia engineering plastics industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)