South East Asia 3D Printing Market Size, Share, Trends and Forecast by Technology, Process, Material, Offering, Application, End User, and Country, 2025-2033

Market Overview:

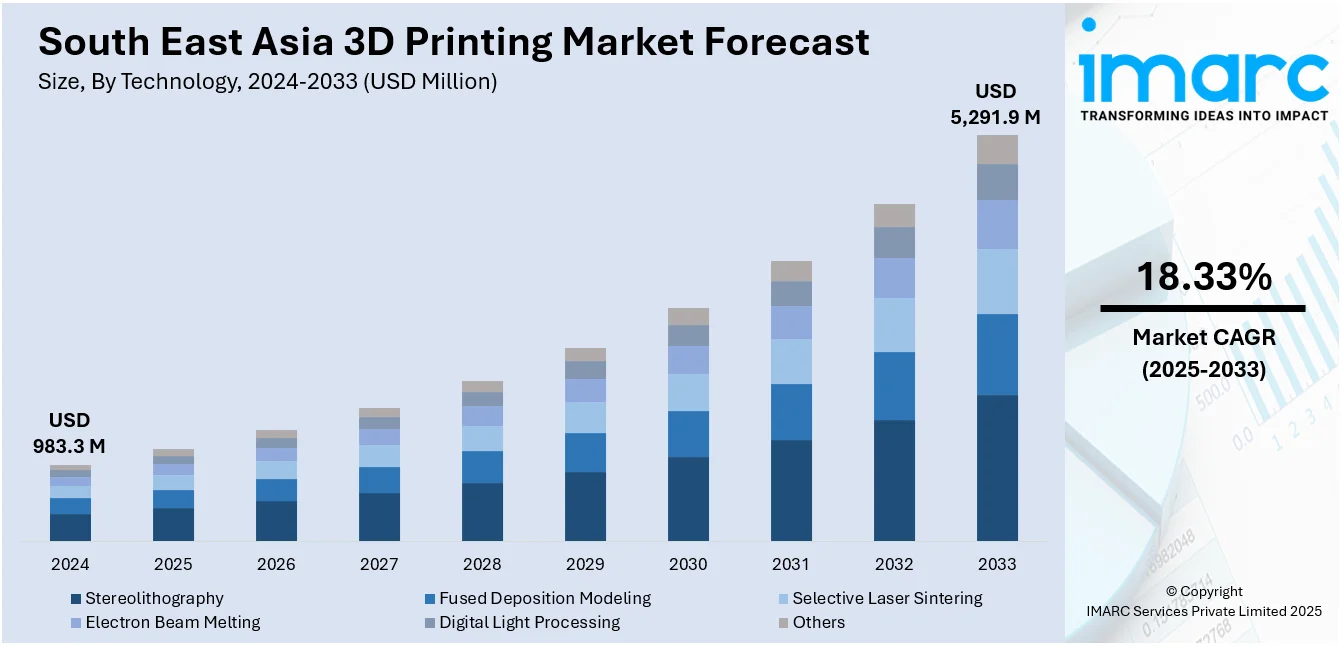

South East Asia 3D printing market size reached USD 983.3 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 5,291.9 Million by 2033, exhibiting a growth rate (CAGR) of 18.33% during 2025-2033. The increasing product applications across diverse industries, rising government initiatives and investments in technology hubs, heightened emphasis on manufacturing cost reductions, and escalating demand for customized consumer goods represent some of the key factors driving the market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 983.3 Million |

|

Market Forecast in 2033

|

USD 5,291.9 Million |

| Market Growth Rate 2025-2033 | 18.33% |

3D printing is a manufacturing process that creates three-dimensional objects from digital models. By laying down successive layers of material, this technology is able to produce complex shapes and designs with precision. This process, also known as additive manufacturing, begins with the creation of a 3D design using computer-aided design (CAD) software. Once the design is finalized, it is sliced into thin horizontal sections, which are then printed layer by layer to form the final object. Materials used in 3D printing vary, including plastics, resins, metals, and even biological substances. This versatility opens up a myriad of applications across industries, such as aerospace, automotive, healthcare, and consumer goods. It enables the production of prototypes and end use products faster and more cost-effectively than traditional manufacturing methods. 3D printing is transforming manufacturing processes by reducing waste, simplifying supply chains, and facilitating the customization of products. At present, 3D printing technology is advancing rapidly, contributing to significant innovations in product development and manufacturing.

To get more information on this market, Request Sample

South East Asia 3D Printing Market Trends:

The South East Asia 3D printing market is currently experiencing robust growth propelled by several key factors. The region is witnessing an increased adoption of 3D printing technologies across various industries due to its ability to reduce manufacturing costs, shorten production cycles, and enhance product customization, thus driving market growth. Moreover, governments of several South East Asian countries are actively promoting the adoption of Industry 4.0 technologies, with 3D printing being a critical component. Such favorable initiatives and extensive investments in technology hubs and innovation centers are fostering market growth. Additionally, the healthcare industry in South East Asia is leveraging 3D printing for the production of customized medical and dental implants, prosthetics, and surgical models. This is particularly significant in improving patient outcomes and is catalyzing the demand for 3D printing technologies in medical applications. In line with this, the increasing adoption of 3D printing in the automotive sector for the creation of complex parts and components is further fueling market growth. Besides this, the escalating demand for consumer electronics and personalized consumer goods is positively influencing market growth. The large and growing middle-class population in the South East Asia region creates a substantial market for customized products, which 3D printing can efficiently serve, thus accelerating product adoption rates. Furthermore, educational institutions in the region are increasingly incorporating 3D printing into their curricula, boosting the technology's exposure and acceptance. Along with this, the presence of numerous local startups and enterprises exploring the capabilities of 3D printing contributes to market growth, fueling innovation and competitiveness. Apart from this, supply chain disruptions, spurred by global events such as the coronavirus (COVID-19) pandemic, have also led companies in South East Asia to reconsider their manufacturing and production strategies, with many turning to 3D printing to enable more agile and resilient operations. This, coupled with ongoing advancements in 3D printing technologies, materials, and services that improve the accessibility and usability for manufacturers in the region, is providing a positive thrust to the market growth.

South East Asia 3D Printing Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the regional and country level for 2025-2033. Our report has categorized the market based on technology, process, material, offering, application, and end user.

Technology Insights:

- Stereolithography

- Fused Deposition Modeling

- Selective Laser Sintering

- Electron Beam Melting

- Digital Light Processing

- Others

The report has provided a detailed breakup and analysis of the market based on the technology. This includes cold stereolithography, fused deposition modeling, selective laser sintering, electron beam melting, digital light processing, and others.

Process Insights:

- Binder Jetting

- Directed Energy Deposition

- Material Extrusion

- Material Jetting

- Powder Bed Fusion

- Sheet Lamination

- Vat Photopolymerization

A detailed breakup and analysis of the market based on the process have also been provided in the report. This includes binder jetting, directed energy deposition, material extrusion, material jetting, powder bed fusion, sheet lamination, and vat photopolymerization.

Material Insights:

- Photopolymers

- Plastics

- Metals and Ceramics

- Others

The report has provided a detailed breakup and analysis of the market based on the material. This includes photopolymers, plastics, metals and ceramics, and others.

Offering Insights:

- Printer

- Material

- Software

- Service

A detailed breakup and analysis of the market based on the offering have also been provided in the report. This includes printer, material, software, and service.

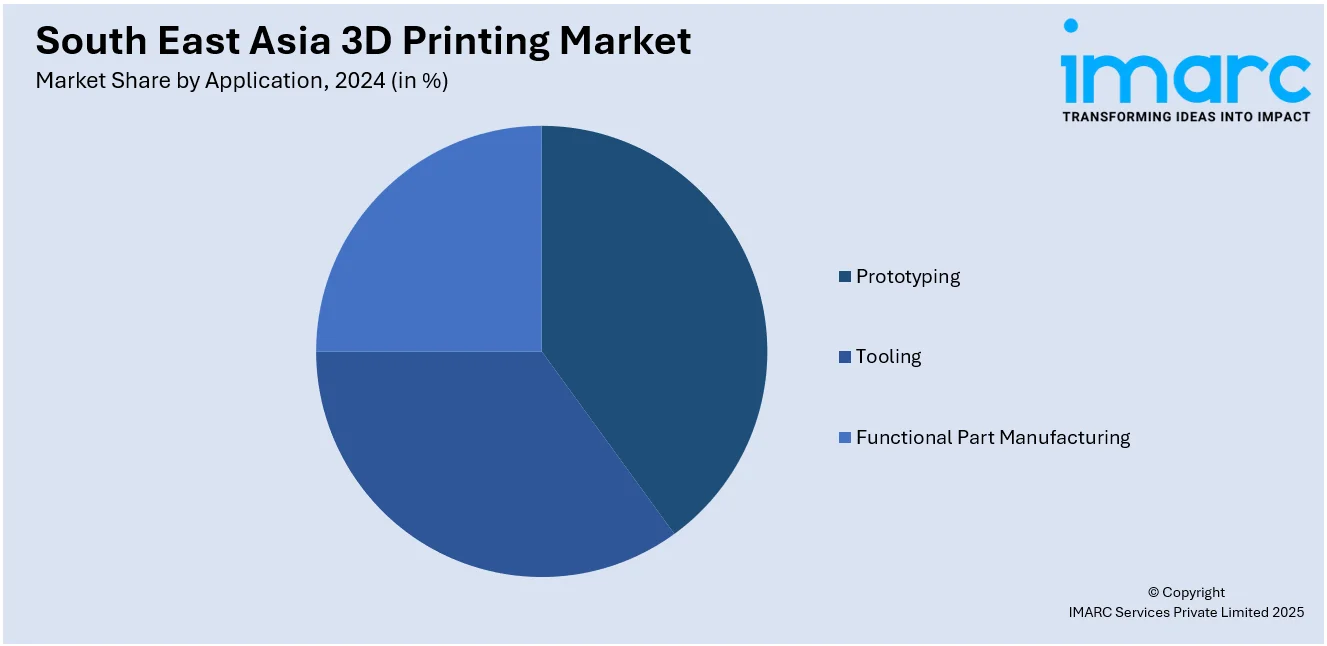

Application Insights:

- Prototyping

- Tooling

- Functional Part Manufacturing

The report has provided a detailed breakup and analysis of the market based on the application. This includes prototyping, tooling, and functional part manufacturing.

End User Insights:

- Consumer Products

- Machinery

- Healthcare

- Aerospace

- Automobile

- Others

A detailed breakup and analysis of the market based on the end user have also been provided in the report. This includes consumer products, machinery, healthcare, aerospace, automobile, and others.

Country Insights:

- Indonesia

- Thailand

- Singapore

- Philippines

- Vietnam

- Malaysia

- Others

The report has also provided a comprehensive analysis of all the major regional markets, which include Indonesia, Thailand, Singapore, Philippines, Vietnam, Malaysia, and Others.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

South East Asia 3D Printing Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical and Forecast Trends, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Technologies Covered | Stereolithography, Fused Deposition Modeling, Selective Laser Sintering, Electron Beam Melting, Digital Light Processing, Others |

| Processes Covered | Binder Jetting, Directed Energy Deposition, Material Extrusion, Material Jetting, Powder Bed Fusion, Sheet Lamination, Vat Photopolymerization |

| Materials Covered | Photopolymers, Plastics, Metals and Ceramics, Others |

| Offerings Covered | Printer, Material, Software, Service |

| Applications Covered | Prototyping, Tooling, Functional Part Manufacturing |

| End Users Covered | Consumer Products, Machinery, Healthcare, Aerospace, Automobile, Others |

| Countries Covered | Indonesia, Thailand, Singapore, Philippines, Vietnam, Malaysia, Others |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the South East Asia 3D printing market performed so far and how will it perform in the coming years?

- What is the breakup of the South East Asia 3D printing market on the basis of technology?

- What is the breakup of the South East Asia 3D printing market on the basis of process?

- What is the breakup of the South East Asia 3D printing market on the basis of material?

- What is the breakup of the South East Asia 3D printing market on the basis of offering?

- What is the breakup of the South East Asia 3D printing market on the basis of application?

- What is the breakup of the South East Asia 3D printing market on the basis of end user?

- What are the various stages in the value chain of the South East Asia 3D printing market?

- What are the key driving factors and challenges in the South East Asia 3D printing?

- What is the structure of the South East Asia 3D printing market and who are the key players?

- What is the degree of competition in the South East Asia 3D printing market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the South East Asia 3D printing market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the South East Asia 3D printing market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the South East Asia 3D printing industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)