Saudi Arabia Smart Factory Market Report by Field Devices (Industrial Sensors, Industrial Robots, Industrial Network, Industrial 3D Printers, Machine Vision Systems), Technology (Product Lifecycle Management (PLM), Human Machine Interface (HMI), Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), Distributed Control Systems (DCS), Industrial Control System, and Others), End Use Industry (Pharmaceuticals, Food and Beverages, Chemical, Oil and Gas, Automotive and Transportation, Semiconductor and Electronics, Aerospace and Defense, and Others), and Region 2026-2034

Market Overview:

Saudi Arabia smart factory market size reached USD 2.1 Billion in 2025. Looking forward, IMARC Group expects the market to reach USD 4.4 Billion by 2034, exhibiting a growth rate (CAGR) of 8.36% during 2026-2034. The growing demand for increased efficiency and productivity through automation, coupled with the increasing focus of key players to enhance supply chain management, is primarily driving the market growth.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 2.1 Billion |

| Market Forecast in 2034 | USD 4.4 Billion |

| Market Growth Rate (2026-2034) | 8.36% |

A smart factory represents a state-of-the-art manufacturing facility that employs advanced technologies and automation systems to streamline production processes, boost efficiency, and elevate overall operational performance. This innovative manufacturing environment harnesses cutting-edge technologies such as the Internet of Things (IoT), artificial intelligence (AI), robotics, data analytics, and cloud computing to establish a highly interconnected and intelligent ecosystem. In the smart factory setting, machines and equipment are outfitted with sensors and linked to a central network, enabling real-time data collection and analysis. This capability facilitates predictive maintenance, early identification of issues, and proactive decision-making to minimize downtime and enhance productivity. Automation assumes a pivotal role, with machines and robots precisely and swiftly executing repetitive tasks, allowing human workers to concentrate on more intricate and strategic activities.

Saudi Arabia Smart Factory Market Trends:

The smart factory market in Saudi Arabia is experiencing significant growth, propelled by the country's commitment to technological advancement and its vision for a diversified and innovative industrial landscape. A smart factory, characterized by its utilization of cutting-edge technologies and automation systems, has become a key focus in the country's pursuit of enhancing manufacturing efficiency and competitiveness. The integration of these technologies allows for real-time data collection and analysis, fostering predictive maintenance and proactive decision-making to optimize productivity. Additionally, the implementation of sensors and central networks facilitates seamless communication, enhancing overall operational performance, thereby acting as another significant . The benefits of smart factories are particularly appealing to industries in Saudi Arabia, such as manufacturing, petrochemicals, and automotive. Increased productivity, cost reduction, improved product quality, enhanced worker safety, and greater flexibility in responding to market demands are among the advantages contributing to the adoption of smart manufacturing practices. Collaborations between the government, technology providers, and local industries are likely to drive investments in smart manufacturing, positioning Saudi Arabia as a regional leader in the adoption of advanced industrial technologies. This, in turn, is expected to fuel the market growth over the forecasted period.

Saudi Arabia Smart Factory Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2026-2034. Our report has categorized the market based on field devices, technology, and end use industry.

Field Devices Insights:

- Industrial Sensors

- Industrial Robots

- Industrial Network

- Industrial 3D Printers

- Machine Vision Systems

The report has provided a detailed breakup and analysis of the market based on the field devices. This includes industrial sensors, industrial robots, industrial network, industrial 3D printers, and machine vision systems.

Technology Insights:

- Product Lifecycle Management (PLM)

- Human Machine Interface (HMI)

- Enterprise Resource Planning (ERP)

- Manufacturing Execution Systems (MES)

- Distributed Control Systems (DCS)

- Industrial Control System

- Others

A detailed breakup and analysis of the market based on the technology have also been provided in the report. This includes product lifecycle management (PLM), human machine interface (HMI), enterprise resource planning (ERP), manufacturing execution systems (MES), distributed control systems (DCS), industrial control system, and others.

End Use Industry Insights:

- Pharmaceuticals

- Food and Beverages

- Chemical

- Oil and Gas

- Automotive and Transportation

- Semiconductor and Electronics

- Aerospace and Defense

- Others

The report has provided a detailed breakup and analysis of the market based on the end use industry. This includes pharmaceuticals, food and beverages, chemical, oil and gas, automotive and transportation, semiconductor and electronics, aerospace and defense, and others.

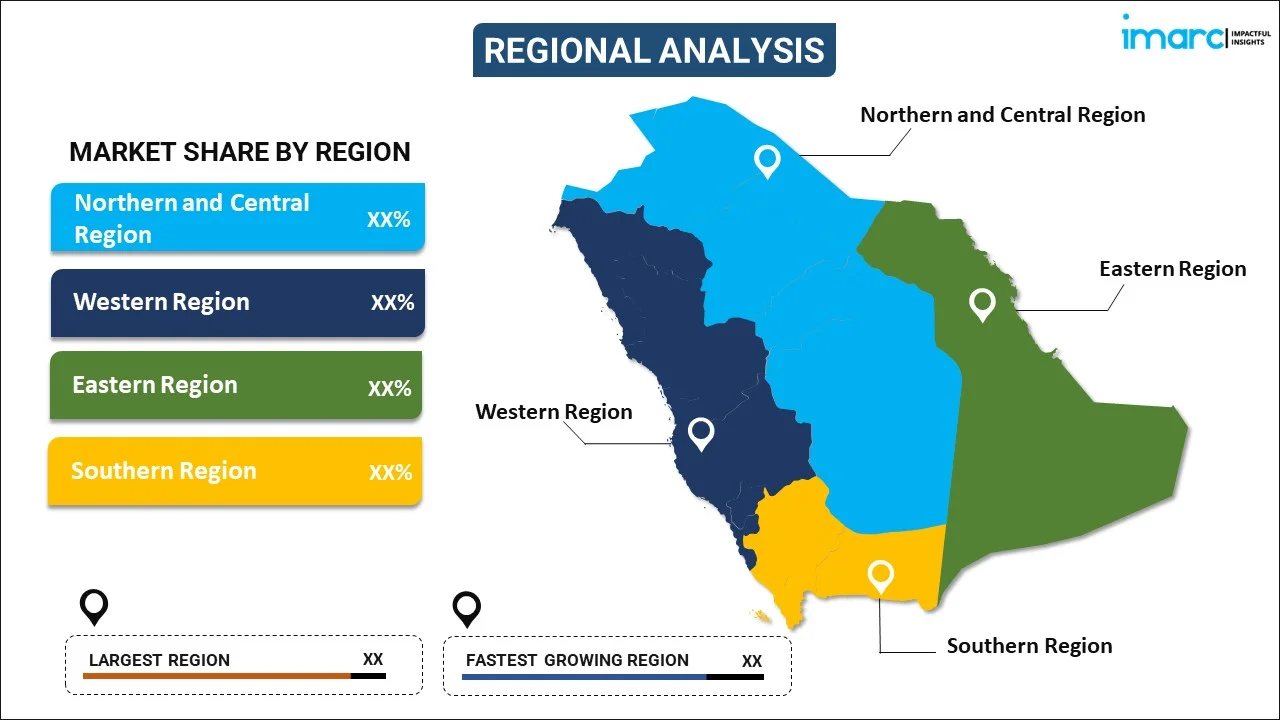

Regional Insights:

- Northern and Central Region

- Western Region

- Eastern Region

- Southern Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Northern and Central Region, Western Region, Eastern Region, and Southern Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Saudi Arabia Smart Factory Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Field Devices Covered | Industrial Sensors, Industrial Robots, Industrial Network, Industrial 3D Printers, Machine Vision Systems |

| Technologies Covered | Product Lifecycle Management (PLM), Human Machine Interface (HMI), Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), Distributed Control Systems (DCS), Industrial Control System, Others |

| End Use Industries Covered | Pharmaceuticals, Food and Beverages, Chemical, Oil and Gas, Automotive and Transportation, Semiconductor and Electronics, Aerospace and Defense, Others |

| Regions Covered | Northern and Central Region, Western Region, Eastern Region, Southern Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Saudi Arabia smart factory market performed so far and how will it perform in the coming years?

- What has been the impact of COVID-19 on the Saudi Arabia smart factory market?

- What is the breakup of the Saudi Arabia smart factory market on the basis of field devices?

- What is the breakup of the Saudi Arabia smart factory market on the basis of technology?

- What is the breakup of the Saudi Arabia smart factory market on the basis of end use industry?

- What are the various stages in the value chain of the Saudi Arabia smart factory market?

- What are the key driving factors and challenges in the Saudi Arabia smart factory?

- What is the structure of the Saudi Arabia smart factory market and who are the key players?

- What is the degree of competition in the Saudi Arabia smart factory market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Saudi Arabia smart factory market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Saudi Arabia smart factory market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Saudi Arabia smart factory industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)