Saudi Arabia IoT in Manufacturing Market Size, Share, Trends, and Forecast by Software, Connectivity, Services, Application, End User Vertical, and Region, 2026-2034

Saudi Arabia IoT in Manufacturing Market Overview:

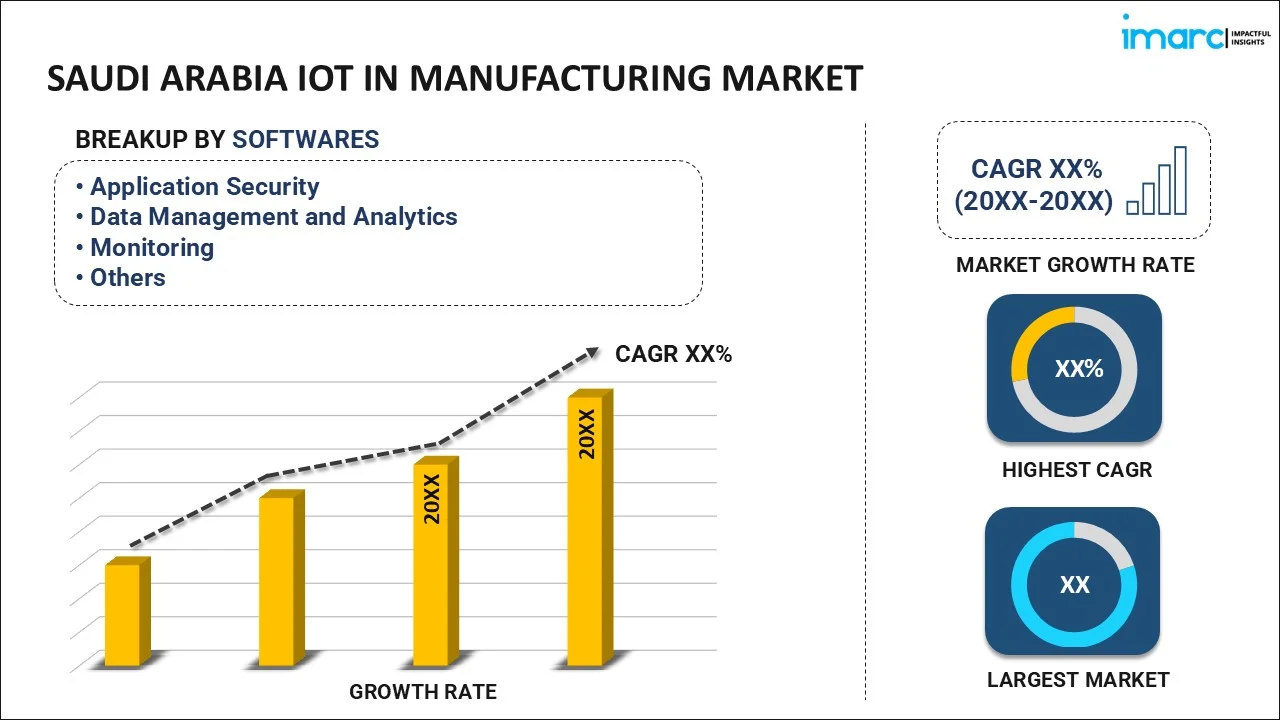

The Saudi Arabia IoT in manufacturing market size reached USD 708.0 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 2,594.5 Million by 2034, exhibiting a growth rate (CAGR) of 15.52% during 2026-2034. The market is experiencing significant growth, propelled by strategic government partnerships and the widespread adoption of advanced industry 4.0 technologies, which are driving greater efficiency, predictive maintenance, and streamlined processes within the industrial landscape.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 708.0 Million |

| Market Forecast in 2034 | USD 2,594.5 Million |

| Market Growth Rate (2026-2034) | 15.52% |

Saudi Arabia IoT in Manufacturing Market Trends:

Integration of IoT with Advanced Robotics and Automation

Saudi Arabia’s manufacturing sector is advancing through the integration of IoT with robotics and automation. For instance, according to industry reports, the Kingdom plans to make 15% of its public transport and 25% of goods transport vehicles autonomous by 2030, reflecting its commitment to advance autonomous technologies. Moreover, in 2023, Saudi Arabia launched a trial for Dhahaina (Smart), its first autonomous electric vehicle, to boost awareness and adoption of autonomous vehicle (AV) technology. Within manufacturing, IoT-enabled robots streamline critical tasks like assembly, quality inspection, and logistics, allowing manufacturers to boost productivity and maintain precision. Through IoT connectivity, robotic systems receive real-time data, enabling intelligent decision-making and rapid response to process requirements. This blend of automation and IoT is setting a benchmark in operational efficiency and scalability, reinforcing the country's move towards an automated and smart manufacturing environment that aligns with global standards.

Adoption of Industry 4.0 for Smart Manufacturing

The manufacturing sector in Saudi Arabia is swiftly adapting Industry 4.0 concepts through the integration of IoT technologies that are transforming the traditional factories into highly responsive and data-driven establishments. The IoT-enabled devices connect the machines in production lines without any limitations, allowing real-time data to flow in, enabling immediate adjustments, optimizing processes, and enhancing quality. Smart manufacturing not only minimizes wastes but also substantializes productive input, creating a new threshold for operational excellence that the industrial landscape within the Kingdom can measure against. Government initiatives coupled with private-sector investments in IoT technologies are hastening this change, signifying a shift to a digitally-driven industrial landscape. For instance, according to industry reports, in 2024, the government introduced an initiative of a $1.2 billion program to enhance the digital skills of 100,000 students by 2030, underscoring the long-term commitment to a digitally proficient workforce. Strategic investments from both the public and private sectors further accelerate this transition, with a strong focus on building robust supply chains and logistics networks that are essential to sustaining competitive growth. By embedding advanced digital capabilities within key sectors like manufacturing, trade, and retail, Saudi Arabia is positioning its industries for resilience, efficiency, and increased competitiveness in a technology-driven global economy.

Enhanced Focus on Cybersecurity in IoT Deployments

As IoT adoption in manufacturing grows, Saudi Arabian companies are prioritizing cybersecurity to safeguard sensitive industrial data and systems. For instance, according to industry reports, the Saudi Arabia cybersecurity market is projected to reach US$ 10.5 Billion by 2032, thereby reflecting the strong emphasis on securing digital infrastructure. Additionally, the interconnected nature of IoT devices, which continuously share valuable operational data, heightens the risk of cyber threats within the sector. Consequently, manufacturers are investing in advanced security frameworks and protocols to protect IoT networks. Cybersecurity has become a pivotal aspect of IoT strategy, with firms adopting solutions that prevent unauthorized access and protect against data breaches. This proactive focus on cybersecurity is essential for building resilience and trust in Saudi Arabia’s IoT-enabled manufacturing landscape, laying a secure foundation for its ongoing digital transformation.

Saudi Arabia IoT in Manufacturing Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the region level for 2026-2034. Our report has categorized the market based on software, connectivity, services, application, and end user vertical.

Software Insights:

- Application Security

- Data Management and Analytics

- Monitoring

- Network Management

- Others

The report has provided a detailed breakup and analysis of the market based on the software. This includes application security, data management and analytics, monitoring, network management, and others.

Connectivity Insights:

- Satellite Network

- Cellular Network

- RFID

- NFC

- Wi-Fi

- Others

A detailed breakup and analysis of the market based on the connectivity have also been provided in the report. This includes satellite network, cellular network, RFID, NFC, wi-fi, and others.

Services Insights:

- Professional

- System Integration and Deployment

- Managed

- Others

A detailed breakup and analysis of the market based on the services have also been provided in the report. This includes professional, system integration and deployment, managed, and others.

Application Insights:

- Process Optimization

- Predictive Maintenance

- Asset Management

- Workforce Management

- Emergency and Incident Management

- Logistics and Supply Chain Management

- Inventory Management

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes process optimization, predictive maintenance, asset management, workforce management, emergency and incident management, logistics and supply chain management, and inventory management.

End User Vertical Insights:

- Automotive

- Food and Agriculture Equipment

- Industrial Equipment

- Electronics and Communication Equipment

- Chemicals and Materials Equipment

- Others

A detailed breakup and analysis of the market based on the end user vertical have also been provided in the report. This includes automotive, food and agriculture equipment, industrial equipment, electronics and communication equipment, chemicals and materials equipment, and others.

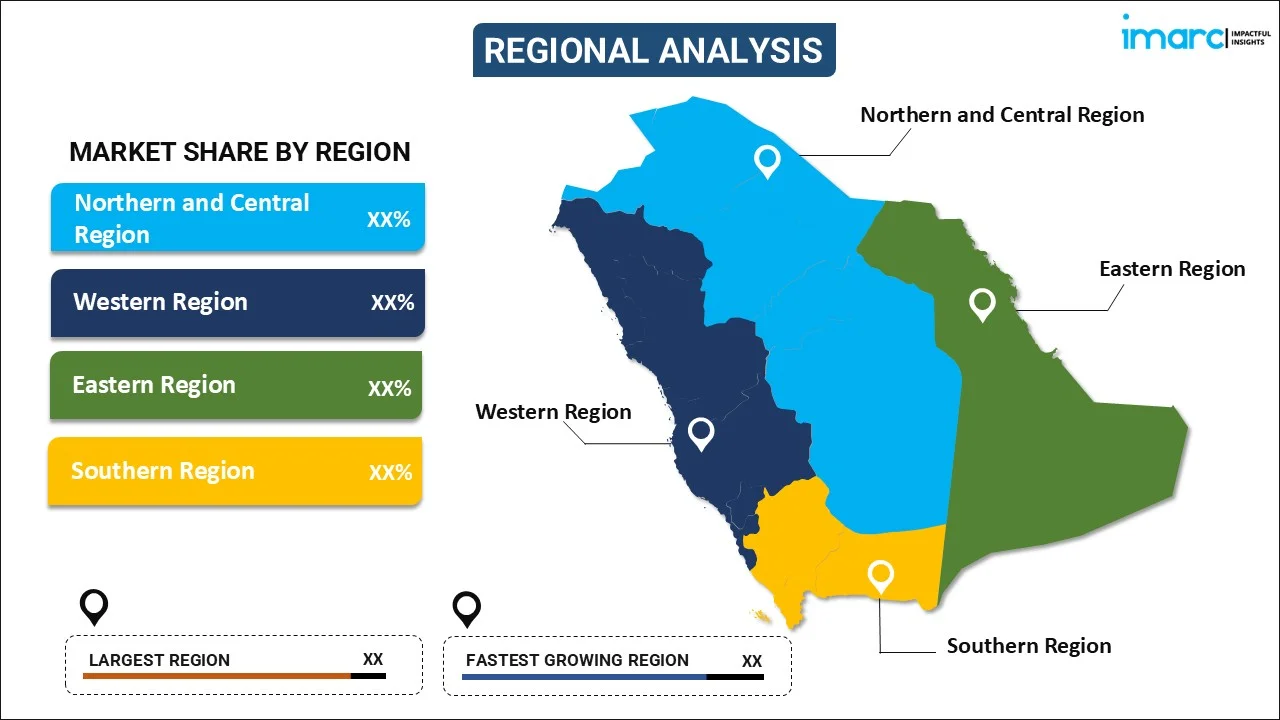

Regional Insights:

- Northern and Central Region

- Western Region

- Eastern Region

- Southern Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Northern and Central Region, Western Region, Eastern Region, and Southern Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Saudi Arabia IoT in Manufacturing Market News:

- In 2023, the Schneider Electric announced partnership with IoT Squared, a joint venture by Saudi Arabia's Public Investment Fund (PIF) and STC (Saudi Telecom Company), to drive advancements in energy management and industrial automation. The agreement boosts R&D and supports Saudi Arabia's digital transformation goals, aiming to harness IoT to tackle industry challenges and drive sustainable, tech-driven growth in key sectors.

Saudi Arabia IoT in Manufacturing Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Softwares Covered | Application Security, Data Management and Analytics, Monitoring, Network Management, Others. |

| Connectivities Covered | Satellite Network, Cellular Network, RFID, NFC, Wi-Fi, Others |

| Services Covered | Professional, System Integration and Deployment, Managed, Others |

| Applications Covered | Process Optimization, Predictive Maintenance, Asset Management, Workforce Management, Emergency and Incident Management, Logistics and Supply Chain Management, Inventory Management |

| End User Verticals Covered | Automotive, Food and Agriculture Equipment, Industrial Equipment, Electronics and Communication Equipment, Chemicals and Materials Equipment, Others |

| Regions Covered | Northern and Central Region, Western Region, Eastern Region, Southern Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Saudi Arabia IoT in manufacturing market performed so far and how will it perform in the coming years?

- What is the breakup of the Saudi Arabia IoT in manufacturing market on the basis of software?

- What is the breakup of the Saudi Arabia IoT in manufacturing market on the basis of connectivity?

- What is the breakup of the Saudi Arabia IoT in manufacturing market on the basis of services?

- What is the breakup of the Saudi Arabia IoT in manufacturing market on the basis of application?

- What is the breakup of the Saudi Arabia IoT in manufacturing market on the basis of end user vertical?

- What is the breakup of the Saudi Arabia IoT in manufacturing market on the basis of region?

- What are the various stages in the value chain of the Saudi Arabia IoT in manufacturing market?

- What are the key driving factors and challenges in the Saudi Arabia IoT in manufacturing?

- What is the structure of the Saudi Arabia IoT in manufacturing market and who are the key players?

- What is the degree of competition in the Saudi Arabia IoT in manufacturing market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Saudi Arabia IoT in manufacturing market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Saudi Arabia IoT in manufacturing market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Saudi Arabia IoT in manufacturing industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)