Roll Slitting Machines Market Size, Share, Trends and Forecast by Type, Material, Operation, and Region, 2025-2033

Roll Slitting Machines Market Size and Share:

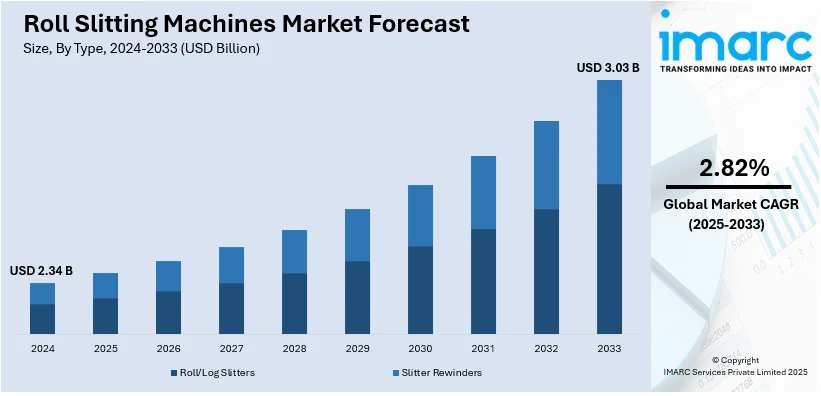

The global roll slitting machines market size was valued at USD 2.34 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 3.03 Billion by 2033, exhibiting a CAGR of 2.82% during 2025-2033. Asia-Pacific currently dominates the market, holding a significant market share of over 35.0% in 2024. The roll slitting machines market share across the region is driven by rising demand in packaging, automotive, and textiles industries, technological advancements in machine efficiency, increased automation, growing need for precision cutting, and expansion of manufacturing capabilities globally.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 2.34 Billion |

| Market Forecast in 2033 | USD 3.03 Billion |

| Market Growth Rate (2025-2033) | 2.82% |

The roll slitting machines market growth is experiencing great upsurge owing to the growing needs for precision cuts from the industrial packaging textile, and metals. These roll slitting machines enable the manufacturer to perform accurate and high-quality cuts that minimize wastage of raw materials while enhancing their operational efficiencies. Production time is reduced, and superior quality of products is easily desired by industries; therefore, the demand for advanced slitting technology will go up. Also, the booming e-commerce has significantly increased the demand for flexible packaging solutions and, therefore, the market increased width for this. Moreover, with technological advancements and perks like automation, digitalization, and improved blade technologies, slitting machine performance is also enhanced, making it more cost-effective and versatile. In addition, the focus on sustainability and eco-friendly packaging adds to the demand of waste minimization machines in emerging markets boosting the development of this market further.

To get more information on this market, Request Sample

The United States stands out as a key market disruptor, driven by its advanced manufacturing capabilities and high demand for precision cutting solutions. The US has an industrial framework that consists of packaging, automotive, textiles, and metal industries. The innovation and adoption of advanced slitting technologies are driven primarily by this diversified industrial base. Moreover, it is rending further market disruptions because of its shift towards automation and digitalization in manufacturing; such preference by businesses can be observed in efficiency, cost reduction, and quality control. Furthermore, the flourishing e-commerce industry in the US increases the need for roll slitting machines due to the ever-growing need for flexible, sustainable packaging. Their-sustainable approach and established infrastructure make the US a leading country with respect to global trends and future shaping of the market within the roll slitting machines.

Roll Slitting Machines Market Trends:

Automation and smart technology integration

One of the prominent trends in the roll slitting machines market is the integration of automation and smart technologies. According to reports, 40% of manufacturers prioritize smart manufacturing technologies, such as AI and automation, for digital transformation. To maximize efficiency, minimize labor costs, and enhance accuracy, manufacturers have preferred using automated roll slitting machines. These machines are equipped with advanced sensors, robotics, and real-time data analytics to provide optimum production process parameters, predictive maintenance, and maximum machine performance. Smart technology also gives manufacturers the ability to remotely monitor operations, ensuring minimum downtime and reduced human error. With an increasing demand for faster production rates and more accurate slitting, automation is expected to grow faster, thereby boosting roll slitting machines market demand.

Demand for customization and flexibility

Demand for customized solutions suiting the needs of different industries is another emerging trend for growth in the roll slitting machines market. Since different industries- textile, packaging, and metals- have different requirements in terms of cutting precision and types of material, manufacturers are now designing machines that can be flexible enough to handle a variety of materials, thicknesses, and sizes. These allow organizations to meet the changing demand of the market as well as enhance the efficiency of operations. Roll slitting machines are increasingly coming with some kind of adjustable settings, which enable an end-user to make several slitting patterns according to many different applications, thus pushing the demand for more flexible and versatile machines into the market.

Sustainability and waste reduction

Sustainability is now a major factor in the market of roll slitting machines because industries are interested to cut down waste and promote environmental practices. According to a UNEP report, the direct cost of waste management was USD 252 Billion in 2020, which rises till USD 361 Billion when externalities are being included. Rising environment consciousness due to regulations has compelled manufacturers to develop slitting machines that reduce waste material generated during the cutting operation. New blade technologies and efficient cutting methods ensure that materials are better utilized, cutting down production costs and minimizing environmental impacts. Additionally, many industries are opting for recyclable and biodegradable types of packaging, thus creating additional demand for roll slitting machines that have the feature of sharp cutting techniques, thereby providing a positive roll slitting machines market outlook for sustainable production processes.

Roll Slitting Machines Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global roll slitting machines market, along with forecasts at the global, regional, and country levels from 2025-2033. The market has been categorized based on type, material, and operation.

Analysis by Type:

- Roll/Log Slitters

- Slitter Rewinders

Slitter Rewinders stand as the largest component in 2024, holding around 64.7% of the market. Slitter rewinders, with their versatile machine functions and importance in various industries, remain the largest type segment in this market. These machines slit wide rolls of material into narrower widths and rewind the slit rolls into uniform rolls for further processing. The slitter rewinder finds its application in industries like packaging, paper, film, textiles, and metals, where precision cutting and high-speed performance are a must. Due to its ability to slit a variety of materials, including paper, plastic films, and foils, the slitter rewinder gives an extra advantage to the manufacturer. With advanced features like automatic tension control, precision slitting, and user-oriented interfaces, slitter rewinders have emerged as the machine of choice for manufacturers searching for maximum productivity at the lowest possible price. This versatility and efficiency have kept slitter rewinders the dominant segment in the roll slitting machines market.

Analysis by Material:

- Paper

- Polymers

- Foil

- Others

Polymers leads the market share in 2024. Polymers represent the major material segment for the roll slitting machines market, given their applicability in various sectors such as packaging, automotive, electronics, and textiles. Most common polymers such as polyethylene, polypropylene, and PVC are usually processed in roll slitting machines because of their adaptability, low weight, and economic pricing. Imminently, polymer films and laminates are abundantly requested for the manufacturing of robust, flexible, and safe packaging materials in the packaging industry. The growth of the e-commerce sector has further pushed up demand for polymer-based packaging, thereby increasing demand for roll slitting machines. Moreover, due to their adjustable thickness and range of material properties, polymers can easily be customized and thus are preferred for a variety of slitting applications. With a wide range of application and an even greater acceptance across industries, polymers will always lead the charge in keeping the roll slitting machines market growth steady.

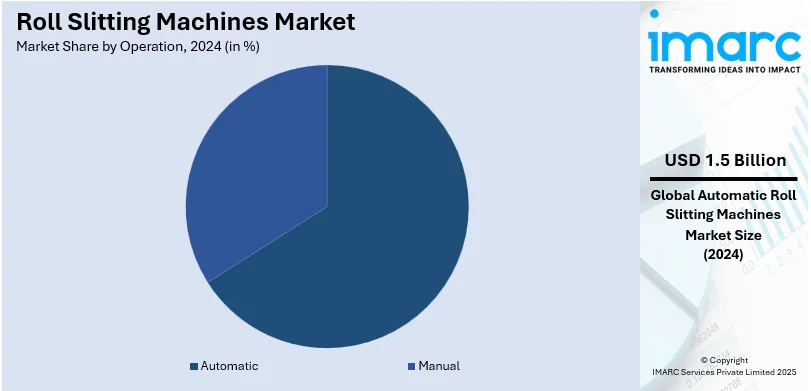

Analysis by Operation:

- Automatic

- Manual

Automatic leads the market with around 65.8% of market share in 2024. The market is dominated by automatic roll slitting machines, driven by demand for higher efficiency, precision, and lower labor costs. The machines utilize modern automation technologies for quicker and more accurate slitting with lower human intervention. Automatic roll slitters are thereby productive, as they reduce setup time, consistency in cuts, and errors, which is very important in industries like packaging, textiles, and metal processing, where the highest quality production is required. Features such as automatic tension control, digital interfacing, and real-time monitoring also increase operational efficiency. As manufacturers strive to reduce costs while improving throughput, the demand for automatic models of slitting machines continues to increase. This trend looks to continue to dominate the market, as industries continue to look for ways to enhance operations and increase output in a competitive environment.

Regional Analysis:

- North America

- United States

- Canada

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

In 2024, Asia-Pacific accounted for the largest market share of over 35.0%. Asia Pacific is the leading regional segment in the roll slitting machines market, stimulated by rapid industrialization and an increasing manufacturing base in countries such as China, India, Japan, and South Korea. The demand for roll slitting machines is fueled by the key industries of packaging, textiles, automotive, and electronics. With Asia Pacific being a production hub, the need for high-efficiency precision slitting solutions has seen an enormous growth very recently. Furthermore, the increasing growth of e-commerce in the region has generated a requirement for flexible packaging, which will further support the growth of the market. The region also enjoys the benefits of low-cost manufacturing and massive production facilities, thus allowing accessibility to roll slitting machines. With the rapid advent of automation and technological advancement, Asia Pacific is expected to continue commanding its position as a front-line player in the global roll slitting market.

Key Regional Takeaways:

United States Roll Slitting Machines Market Analysis

In 2024, the United States accounted for over 84.20% of the roll slitting machines market in North America. Rising demand for flexible packaging in the food & beverage, pharmaceuticals, and e-commerce industries is driving the U.S. roll slitting machines market. Sustainability mandates and changing consumer preferences are accelerating the trend toward eco-friendliness in packaging, which in turn leads to demand for advanced slitting solutions. Technological developments, such as automation and AI-driven slitting systems, allow for greater operational efficiency while minimizing material wastage, further encouraging adoption. In 2024, the U.S. e-commerce market was worth USD 1,087.54 Billion and is anticipated to reach USD 2,083.97 Billion by 2033, growing at a CAGR of 6.8% during the period 2025-2033, further emphasizing the growing need for efficient and scalable packaging solutions. The growth of e-commerce necessitates demand for high-speed precision slitting machines to cater to the increasing packaging requirements. With the growing demand for composites and laminates being utilized in the automotive and aerospace sectors, accurate slitting is required. The solutions thus assist in bringing down labor costs and further push for efficient production, which is bringing motivation for manufacturers to invest in automated AI slitting technologies. The presence of key industry participants focused on innovation and R&D ensures competitive intensity in the market, while the increase in the adoption of energy-efficient and smart slitting machines propels the long-term growth of the market.

Asia Pacific Roll Slitting Machines Market Analysis

The growth of the APAC roll slitting machines market is mainly propelled by rapid industrialization, growing manufacturing sectors, and an increasing demand for flexible packaging. Rampant production in food processing, electronics, and textiles in China, India, and Japan translates into increasing adoption. The South-East Asia flexible packaging market is forecasted to grow at a CAGR of 4.7% over the period of 2024-2032, which signifies the growing demand in the region for sustainable and efficient packaging solutions. Government initiatives that encourage industrial automation and smart manufacturing help bolster market growth. The boom in demand for high-speed, precision slitting machines is fueled by the increased activity in the e-commerce and logistics sectors. Moreover, sustainability trends endorsing recyclable and biodegradable materials further enhance the demand for advanced slitting technologies. The high labor costs typical of developed APAC markets with well-established economies endorse investments in automation. Market growth is further supported by the presence of key industry players alongside continuous technological advancements in AI-based slitting systems that improve efficiencies and promote savings in operational costs.

Europe Roll Slitting Machines Market Analysis

The European market for roll slitting machines is driven by tough regulations on sustainability which requires the manufacturers to acquire advanced slitting technologies that minimize any kind of waste. In addition, the rise in demand from the food & beverage industry, upon pharmaceutical and personal care that require specialized and flexible packaging continues to fuel demand in the market. Increasing automation of the cutting, using AI and IoT-enabled systems will also boost efficiency and accuracy. Reports show that 29% of EU enterprises had used IoT devices in 2021, primarily for securing their premises. This reflects the growing trend of the region towards smart technology. Other areas where slitting is in high demand are the automotive and aerospace as they need high-precision slitting of composites and technical textiles. On the other hand, the advent of e-commerce gives rise to the more growing need for efficient packaging solutions and thus drives demand for high-speed slitting machines. The manufacturers have spent their time and energy on optimizing their cost, energy consumption in the system, and meeting regulatory requirements. Strong centrally based infrastructures, skilled labor, and an ongoing R&D investment strategy thus underpin the market and position Europe as an emerging player in advanced slitting technology.

Latin America Roll Slitting Machines Market Analysis

The Latin American roll slitting machines market is driven by rising industrialization, growing demand for flexible packaging, and expanding food & beverage and pharmaceutical sectors. The region’s pharmaceutical excipients market reached USD 582.79 Million in 2024 and is projected to reach USD 1,136.19 Million by 2033, growing at a CAGR of 7.4% during 2025-2033, highlighting increasing pharmaceutical production. The rise of e-commerce and logistics further fuels demand for efficient packaging solutions. Countries like Brazil and Mexico are investing in advanced machinery to enhance production efficiency. Sustainability trends and automation adoption continue to shape market growth, supporting long-term expansion.

Middle East and Africa Roll Slitting Machines Market Analysis

The Middle East roll slitting machines market is driven by rising demand for flexible packaging in food, pharmaceutical, and e-commerce sectors. Saudi Arabia’s food packaging market reached USD 1,741.4 Million in 2024 and is projected to reach USD 2,552.5 Million by 2033, growing at a CAGR of 4.25% during 2025-2033, reflecting increasing packaging needs. The adoption of automation and AI-driven slitting technologies enhances efficiency and reduces material waste. Growing industrialization, coupled with government initiatives supporting manufacturing advancements, further fuels market expansion. Key players are investing in sustainable and high-speed slitting solutions to meet evolving industry demands.

Competitive Landscape:

Key players in the roll slitting machines market are making significant efforts to drive growth and innovation by focusing on advanced technology, customization, and expanding their global reach. Leading manufacturers are investing in research and development to incorporate automation, smart technology, and real-time monitoring into their machines, enhancing performance, precision, and efficiency. For instance, the integration of Internet of Things (IoT) solutions allows for predictive maintenance, reducing downtime and increasing machine reliability. Several companies are also emphasizing the importance of sustainability, designing machines that reduce material waste and promote eco-friendly production processes. Customization is another key focus, as manufacturers strive to offer flexible machines that can accommodate a wide range of materials, thicknesses, and sizes, meeting the diverse needs of industries like packaging, textiles, and metal processing. To expand their market share, major players are increasing their global footprint through strategic partnerships, acquisitions, and establishing production facilities in emerging markets. Additionally, companies are enhancing after-sales services and customer support to foster long-term relationships with clients, ensuring operational efficiency and satisfaction. These efforts collectively drive the roll slitting machines market by responding to industry demands for more efficient, cost-effective, and sustainable production solutions while keeping pace with technological advancements.

The report provides a comprehensive analysis of the competitive landscape in the roll slitting machines market with detailed profiles of all major companies, including:

- ALS Limited

- ASHE Converting Equipment

- Comexi Group

- Ghezzi & Annoni

- Kampf GmbH

- LIDEM Construcciones Mecánicas S.L

- OTEMAN

- Ribamatic Roll Slitters, SL

- Rosenthal Manufacturing Co. Inc.

- SOMA

- Svegea of Sweden AB

Latest News and Developments:

- September 2024: HCI has launched the FSL-TR1300 turret rewind slitting machine, designed for automated slitting and rewinding. It features automatic splicing, roll changing, core positioning, and a roll unloading system to enhance productivity and minimize downtime. The HMI system with a color touch screen ensures ease of use and consistent product quality.

- September 2024: Re:Build’s automation team collaborated with Re:Build Oribi to develop advanced roll slitting and composite converting equipment, enhancing CFRTP production efficiency. The TPX system enables precise tape slitting and pre-stacking, supporting industries like aerospace, automotive, and energy.

- July 2024: Jota Machinery upgraded its plotter paper roll slitter rewinder to the third-generation frame-type slitting machine, featuring a pneumatic slitting blade and a maximum speed of 500m/min.

Roll Slitting Machines Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | Roll/Log Slitters, Slitter Rewinders |

| Materials Covered | Paper, Polymers, Foil, Others |

| Operations Covered | Automatic, Manual |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | ALS Limited, ASHE Converting Equipment, Comexi Group, Ghezzi & Annoni, Kampf GmbH, LIDEM Construcciones Mecánicas S.L, OTEMAN, Ribamatic Roll Slitters, SL, Rosenthal Manufacturing Co. Inc., SOMA, Svegea of Sweden AB, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the roll slitting machines market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the global roll slitting machines market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the roll slitting machines industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The roll slitting machines market was valued at USD 2.34 Billion in 2024.

The roll slitting machines market is projected to exhibit a CAGR of 2.82% during 2025-2033.

The roll slitting machines market is driven by increasing demand for precision cutting, rising e-commerce, and the need for flexible packaging solutions. Technological advancements, including automation and smart features, enhance machine efficiency. Additionally, industries seeking cost-effective production, waste reduction, and customization fuel the growing adoption of roll slitting machines.

Asia Pacific currently dominates the market driven by rapid industrialization, particularly in China and India along with an increased demand from packaging, textiles, and automotive industries, alongside the region’s expanding e-commerce sector.

Some of the major players in the roll slitting machines market include ALS Limited, ASHE Converting Equipment, Comexi Group, Ghezzi & Annoni, Kampf GmbH, LIDEM Construcciones Mecánicas S.L, OTEMAN, Ribamatic Roll Slitters, SL, Rosenthal Manufacturing Co. Inc., SOMA and Svegea of Sweden AB.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)