PVC Stabilizers Market Size, Share, Trends and Forecast by Type, Form, Application, End Use Industry, and Region, 2025-2033

PVC Stabilizers Market Size and Share:

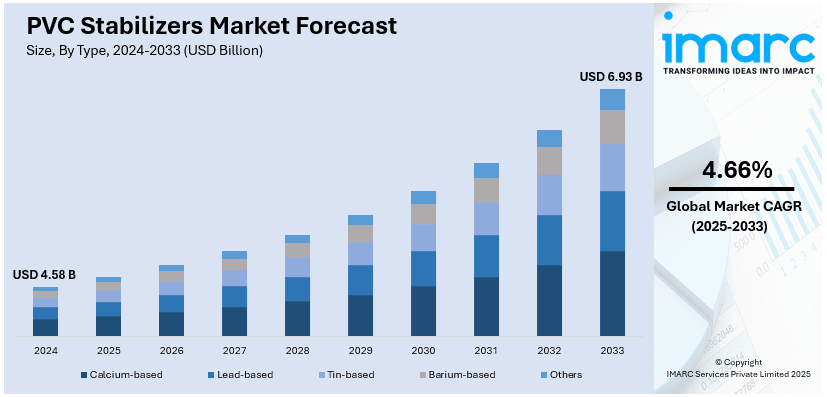

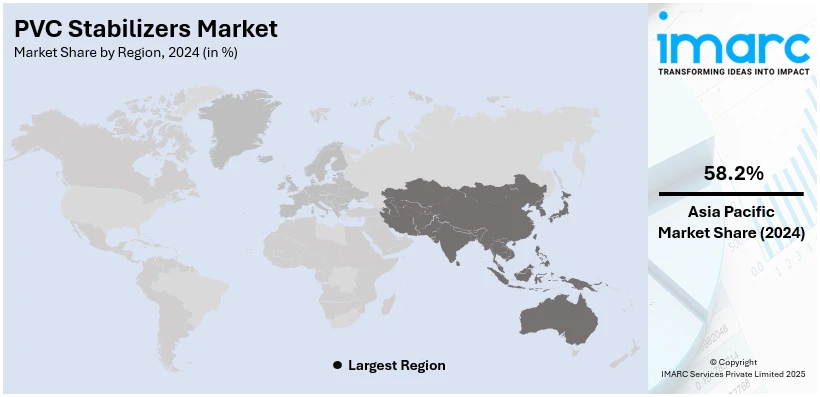

The global PVC stabilizers market size was valued at USD 4.58 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 6.93 Billion by 2033, exhibiting a CAGR of 4.66% during 2025-2033. Asia Pacific currently dominates the market, holding a significant market share of over 58.2% in 2024. This dominance is driven by rapid industrialization, growing infrastructure development, and an increasing demand for PVC-based products across various industries.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 4.58 Billion |

| Market Forecast in 2033 | USD 6.93 Billion |

| Market Growth Rate 2025-2033 | 4.66% |

The major driver of the PVC stabilizers market growth is the increased demand for polyvinyl chloride (PVC) due to its application in construction and infrastructure projects. PVC is adopted for various applications such as pipes, flooring, windows, and doors owing to its cost-effective price, versatility, and longevity. In turn, as urbanization and infrastructure development are expected to fare better worldwide, especially in emerging economies, the demand for superior-quality PVC material just becomes so much greater. PVC stabilizers significantly improve the life and performance of PVC products via protection from degradation due to heat and UV exposure. For instance, in September 2024, Westlake Global Compounds and Westlake Dimex announced the launch of the "Choose Pink" PVC recycling program at Houston Methodist, collecting post-patient PVC items like nasal cannulas, masks, and tubing for recycling. This growing demand for durable and sustainable building materials directly drives the PVC stabilizers market.

To get more information on this market, Request Sample

The United States is a key player in the PVC stabilizers market, driven by the robust demand for PVC products across various industries, including construction, automotive, and packaging. The country’s growing infrastructure development and renovation activities contribute significantly to the increasing consumption of PVC in applications, such as pipes, siding, flooring, and windows. This represents one of the key PVC stabilizers market trends. For instance, in August 2024, Formosa Plastics announced a major expansion of its Baton Rouge PVC plant, boosting capacity to meet customer demand, creating local job opportunities, and contributing to regional economic growth. PVC stabilizers are essential in enhancing the durability and performance of these products, especially in outdoor environments exposed to UV rays and heat. With a strong manufacturing base, advancements in technology, and increasing focus on sustainability, the U.S. continues to serve as a major market for PVC stabilizers.

PVC Stabilizers Market Trends:

Emphasis on Health and Safety Regulations

Stringent regulatory norms concerning health and safety are influencing the PVC stabilizer industry, as outlined in the European Chemicals Agency's guidelines. The focus on minimizing toxic additives in PVC manufacturing is driving the adoption of safer stabilizers, which are compliant with international standards. The European Union's Regulation (EU) 2023/293 mandates that lead content in PVC polymers and copolymers be reduced to less than 0.1% by November 2024. This demand for compliant stabilizers is reflected in a growing market share for non-toxic alternatives, expected to witness a substantial CAGR in the coming years. Regulatory compliance is also spurring innovation in stabilizer formulations that meet both safety and performance criteria.

Significant Innovations in Material Science

Innovations in the field of material science are unlocking new potential for PVC stabilizers. The U.S. Bureau of Labor Statistics forecasts that the job opportunities for materials engineers will rise by 5% from 2022 to 2032. Such trends have fueled this growing demand. High-performance stabilizers that offer improved thermal resistance and durability are now under development, with several already on the market. This innovation surge is motivated by industrial needs for more resilient, long-lasting PVC products in sectors like construction, healthcare, and automotive. Cutting-edge research is opening doors for stabilizers that can offer enhanced material characteristics while being cost-effective, thereby meeting the dual objectives of quality and affordability while facilitating the PVC stabilizers market demand.

Mergers and Collaborations

The PVC stabilizer market is currently undergoing a phase of consolidations and strategic partnerships, as key players look to strengthen their market position and enhance their technological capabilities. These strategic alliances are crucial in driving innovation and improving the efficiency of stabilizer formulations. By combining their expertise, companies can accelerate the development of new, high-performance stabilizers that meet the growing demand for environmentally friendly and sustainable products. For instance, in November 2023, Baerlocher India announced the launch of a new facility in Madhya Pradesh to produce sustainable additives like calcium-based PVC stabilizers, reflecting the industry's move towards eco-friendly solutions. Additionally, these partnerships allow for better resource utilization, access to new markets, and the ability to offer a wider range of PVC stabilizers to cater to various industry needs. These movements are shaping the future growth of the market.

PVC Stabilizers Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global PVC stabilizers market, along with forecast at the global, regional, and country levels from 2025-2033. The market has been categorized based on type, form, application, and ed use industry.

Analysis by Type:

- Calcium-based

- Lead-based

- Tin-based

- Barium-based

- Others

Lead-based leads the market with around 44.0% of the PVC stabilizers market share in 2024. Lead and its compounds are playing a nuanced role in various industries, posing challenges that involve risk assessment, toxicity, and environmental impact. These elements are featuring prominently in a range of applications, from batteries and paints to radiation shielding, due to their attributes such as high density and malleability. Traditionally used in PVC stabilizers, lead-based are available in multiple forms like ingots, sheets, or powders, lead allows manufacturers to create products that fulfill specific industrial needs, from energy storage to X-ray attenuation. However, advances in environmental science are continuously highlighting the adverse health and ecological effects of lead exposure. This emerging understanding is pushing research toward the development of safer alternatives and remediation technologies. This shift is enabling more responsible handling and usage of lead, aiming to minimize environmental contamination and health risks.

Analysis by Form:

- Powder

- Granules

- Pastilles

- Flakes

- Liquid

Powder leads the market with around 41.8% of the market share in 2024. In the PVC (Polyvinyl Chloride) stabilizer market, powder form is a commonly used and versatile presentation of stabilizers. PVC stabilizers are essential additives used to prevent the degradation of PVC due to heat, light, and other environmental factors. Powdered PVC stabilizers are versatile and can be used in various PVC processing methods, including extrusion, injection molding, and calendering. This versatility makes them suitable for a wide range of applications. Powdered stabilizers are relatively easy to handle and incorporate into PVC formulations. They can be accurately measured and mixed with PVC resin and other additives during the compounding process.

Analysis by Application:

- Pipes and Fittings

- Window Profiles

- Rigid and Semi-rigid Films

- Wires and Cables

- Coatings and Flooring

- Others

Pipes and fittings leads the market with around 34.5% of market share in 2024. PVC (Polyvinyl Chloride) stabilizers play a crucial role in the production of PVC pipes and fittings. These stabilizers are essential additives that protect PVC materials from degradation caused by heat, light, and other environmental factors during processing, use, and exposure to outdoor conditions. PVC is inherently susceptible to thermal and photochemical degradation. PVC stabilizers are added during the compounding process to stabilize the PVC resin, ensuring the final products maintain their structural integrity and performance. PVC pipes and fittings are often exposed to elevated temperatures, especially in outdoor applications. Heat stabilizers in PVC formulations prevent thermal degradation, maintaining the mechanical strength and dimensional stability of the products.

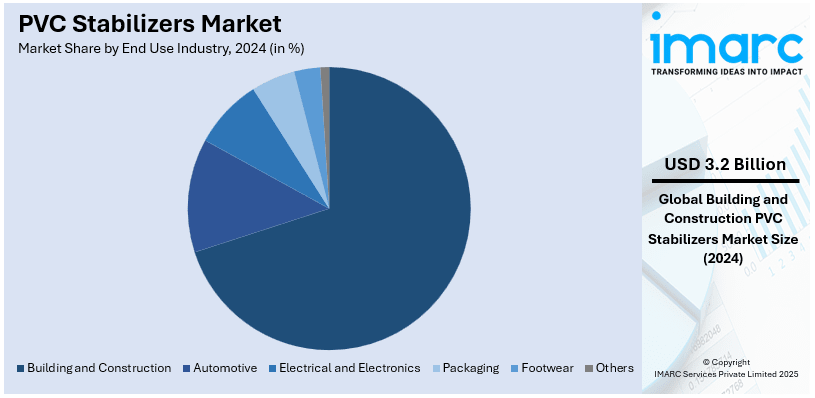

Analysis by End Use Industry:

- Building and Construction

- Automotive

- Electrical and Electronics

- Packaging

- Footwear

- Others

Building and construction leads the market with around 70.4% of market share in 2024. The building and construction industry is a significant end-use sector in the PVC (Polyvinyl Chloride) stabilizers market. PVC is widely used in construction for various applications, including pipes, profiles, cables, roofing, flooring, windows, and doors. PVC stabilizers are essential additives in this industry to ensure the durability, performance, and longevity of PVC-based building and construction materials. PVC is a versatile material extensively used in the construction industry. It is employed in the manufacturing of PVC pipes, profiles (such as window and door frames), cables, cladding, and roofing materials. PVC is susceptible to degradation when exposed to environmental factors such as heat, UV radiation, and chemicals. PVC stabilizers are added to PVC formulations to prevent degradation and maintain the structural and mechanical integrity of building materials.

Regional Analysis

- North America

- United States

- Canada

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

In 2024, Asia Pacific accounted for the largest market share of over 58.2%. The Asia Pacific region is witnessing a significant surge in the demand for PVC stabilizers, driven primarily by the burgeoning construction and automotive industries. Moreover, the rising disposable incomes and rapid urbanization in the region is necessitating advanced materials for sustainable development, fostering the market growth of PVC stabilizers. In addition to this, technological innovations in the field of polymer science are fostering the development of next-generation PVC stabilizers in the Asia Pacific region. Besides this, online platforms require packaging materials that are both durable and lightweight, attributes enhanced by the inclusion of efficient PVC stabilizers. This demand for robust packaging material is contributing significantly to the market's expansion in the region. Regulatory landscapes in Asia Pacific countries are increasingly emphasizing environmental sustainability. This trend is catalyzing a shift towards eco-friendly PVC stabilizers that comply with emerging regulations on hazardous substances which is creating a positive market outlook. Other factors such as R&D activities and the expansion of e-commerce platforms are driving the growth of the market across the region.

Key Regional Takeaways:

United States PVC Stabilizers Market Analysis

US accounts for 86.6% share of the market in North America. A considerable demand in construction, automotive, and packaging segments has been noted to drive growth in the PVC stabilizers market in the United States. In 2023, the U.S. Census Bureau reported an overall construction expenditure of about USD 2 trillion, which contributed to the hike in demand for PVC applications such as pipes, profiles, and fittings. Significantly, the car industry also boosts demand, wherein the U.S. produced some 10.6 million cars in 2023, according to CEIC data, of which PVC stabilizers are part of interior as well as outer car components, while stricter norms for environmental policies are forcing such manufacturers to employ non-toxic and ecofriendly stabilizers mainly calcium-zinc and organic type. PMC Group and Baerlocher USA are the prime market players focused on innovation for compliance with changes in safety aspects. Steady market growth is ensured with the expansion of domestic production capacity and technological progress, making the U.S. a leader in the PVC stabilizers industry.

North America PVC Stabilizers Market Analysis

The North America PVC stabilizers market is experiencing steady growth driven by increasing demand for polyvinyl chloride (PVC) across various industries, including construction, automotive, and packaging. For instance, in January 2025, the North America PVC stabilizers market is projected to grow annually by 2.9%, reaching $527.4 million by 2030, driven by increasing PVC demand in industries like construction, automotive, packaging, and electronics. The need for PVC stabilizers, which enhance the stability and durability of PVC products, is fueled by stricter environmental regulations and growing sustainability concerns. The market is further supported by innovations in stabilizer formulations that improve thermal and UV stability, which are essential for PVC applications exposed to outdoor conditions. The United States holds the largest market share, supported by a well-established manufacturing base and significant demand from end-use industries. Additionally, growing adoption of eco-friendly stabilizers is reshaping the market, with key manufacturers focusing on developing non-toxic and biodegradable solutions to meet regulatory requirements and consumer preferences.

Europe PVC Stabilizers Market Analysis

The PVC stabilizers market in Europe is growing with increasing regulation over lead-based stabilizers and with demand for eco-friendly alternatives. The European Union saw an overall increase of 3.2% in the total construction output for 2023, which supports the demand for PVC products in building applications. The automotive sector is also crucial, as electric vehicles make up 22.7% of new EU car registrations in 2023, according to ACEA, driving demand for stabilizers in lightweight plastic components. Major players like Baerlocher and Reagens are investing in sustainable stabilizer solutions in order to comply with REACH regulations. Bio-based and tin-free stabilizers are part of the transition toward Europe's sustainability goals, thus ensuring long-term market expansion.

Asia Pacific PVC Stabilizers Market Analysis

The Asia Pacific PVC stabilizers market is expanding swiftly with strong industrial and construction activities. In 2023, China's National Bureau of Statistics pointed out that infrastructure investment in the country escalated by 5.6%, which further strengthened the need for PVC in pipes, cables, and window profiles. In turn, the construction sector in India, estimated to be at USD 738 billion in 2023 (as per reports), is also fueling PVC stabilizer consumption. Another critical driver is the automotive industry. China produced more than 27 million vehicles in 2023, according to the China Association of Automobile Manufacturers (CAAM). Environmental awareness is also causing a shift towards calcium-zinc and organic stabilizers. Players like Songwon and Adeka are expanding their footprint, as regional production facilities are being exploited to cater to increasing demand. Government initiatives on local manufacturing, and strict rules on heavy metals, accelerate market further.

Latin America PVC Stabilizers Market Analysis

The PVC stabilizers market in Latin America is expanding, supported by construction, packaging, and regulatory shifts. Brazil's construction sector increased 2.8% in 2023, which the Brazilian Construction Industry Chamber reported to boost the demand for PVC-based materials. The automotive market is also changing in the region. Mexico alone produced over 3.5 million vehicles in 2023, according to the Mexican Association of the Automotive Industry (AMIA), thus requiring stabilizers in automotive interiors and wiring applications. Government regulations on lead stabilizers are driving a shift towards non-toxic alternatives. Chemson and Baerlocher are among companies capitalizing on this shift, investing in sustainable stabilizer solutions. It is also gaining market share with more foreign investments into local manufacturing that ensure stable supply and cost efficiency for regional industries.

Middle East and Africa PVC Stabilizers Market Analysis

The Middle East and Africa PVC stabilizers market is growing steadily, mainly due to infrastructure and urbanization projects. As per the UAE government figures, the country committed AED 4.25 billion, or approximately USD 1.16 billion, to healthcare infrastructure in 2022, which increased the use of PVC-based medical products requiring stabilizers. Saudi Arabia's Vision 2030 initiative is driving major construction projects, with USD 1.1 trillion in infrastructure investments planned, according to the Ministry of Investment. The African market is also growing, with South Africa leading in PVC pipe and cable production. Increasing environmental concerns are pushing regional manufacturers to adopt lead-free stabilizers. This can be done through partnering with local companies and meeting regulatory requirements by giant global players like Arkema and BASF, thereby making PVC more environmentally friendly in its solution form for increasing demand.

Competitive Landscape:

While current conditions in the PVC stabilizers market show a moderate rate of growth, leading companies in the sector are executing strategic initiatives, suggesting a robust future trajectory. These prominent entities are diversifying their chemical formulations to meet varying industry requirements, thereby strengthening their market positioning. Partnerships with end-user industries like construction and automotive are also being pursued to broaden application avenues for PVC stabilizers. Significant investment is being channeled into research and development by these key players, with an emphasis on creating environmentally compliant and high-performance stabilizers. These research efforts aim to replace traditional, toxic elements in PVC stabilizers with greener alternatives, aligning with global sustainability goals. Advances such as these are central to meeting the increasingly stringent regulatory frameworks being enacted worldwide. Operational efficiencies are also being honed. Focused efforts to streamline supply chains and incorporate advanced production methodologies are enabling these leaders to manufacture top-tier, cost-effective PVC stabilizers. For instance, in December 2024, Clariant announced the commencement of construction of a second production line in Cangzhou, China, for its multifunctional Nylostab S-EED additive. The line, in partnership with Beijing Tiangang, aims to enhance process stability and productivity. Such operational advancements are critical in an industry where margins can be slim and the demand for high-quality, consistent products is paramount. The competitive landscape of the PVC stabilizers market is evolving rapidly. New entrants, armed with innovative technologies, are challenging the status quo, while existing market leaders are looking to fortify their market share through strategic mergers and acquisitions.

The report provides a comprehensive analysis of the competitive landscape in the PVC stabilizers market with detailed profiles of all major companies, including:

- Adeka Corporation

- Akdeniz Chemson

- Baerlocher GmbH

- Clariant AG

- Goldstab Organics Pvt. Ltd

- KD Chem Co., Ltd.

- Reagens SPA

- SONGWON Industrial Group

- Sun Ace Kakoh (Pte.) Ltd.

- Valtris Specialty Chemicals Limited

- Waldies Co. Ltd

Recent Developments:

- January 2025: SONGWON Industrial Group has added Altek International FZE as its distributor of premium PVC stabilizers in the Middle East in January 2025. This collaboration is aimed at the increasing demand in the region for sustainable PVC solutions, driven by urbanization and construction growth.

- March 2024: Valtris Specialty Chemicals appointed Barentz as its distribution channel partner in the U.S. and Canada. Barentz will represent Valtris's Mixed Metal Stabilizers, Biocides, Vulcabond™ bonding agents, and Santicizer® products for the PVC, CASE, and lubricant markets in these two countries.

- May 2023: Arkema is accelerating its decarbonization targets and gaining SBTi validation for its 1.5°c trajectory by 2030.

- December 2022: Valtris Specialty Chemicals announced that it would complement its digital commerce capabilities to offer better visibility and access to the full range of sites in the plasticizer area.

- December 2021: Final agreement inked by Reagens and Evans Chemetics, wholly owned subsidiary of Bruno Bock, with Reagens USA acquiring Evans Chemetics Thioester Business consisting of the Evanstab® family of secondary antioxidants products.

PVC Stabilizers Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Types Covered | Calcium-based, Lead-based, Tin-based, Barium-based, Others |

| Forms Covered | Powder, Granules, Pastilles, Flakes, Liquid |

| Applications Covered | Pipes and Fittings, Window Profiles, Rigid and Semi-rigid Films, Wires and Cables, Coatings and Flooring, Others |

| End Use Industries Covered | Building and Construction, Automotive, Electrical and Electronics, Packaging, Footwear, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Adeka Corporation, Akdeniz Chemson, Baerlocher GmbH, Clariant AG, Goldstab Organics Pvt. Ltd, KD Chem Co., Ltd., Reagens SPA, SONGWON Industrial Group, Sun Ace Kakoh (Pte.) Ltd., Valtris Specialty Chemicals Limited, Waldies Co. Ltd, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the PVC stabilizers market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the global PVC stabilizers market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the PVC stabilizers industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The PVC stabilizers market was valued at USD 4.58 Billion in 2024.

IMARC estimates the PVC stabilizers market to reach USD 6.93 Billion by 2033, exhibiting a CAGR of 4.66% during 2025-2033.

Key factors driving the PVC stabilizers market include increasing demand for PVC in construction, automotive, packaging, and electrical industries. Growing environmental regulations, the need for enhanced product durability, and innovations in stabilizer formulations to improve UV and thermal stability further contribute to market expansion. Sustainability trends also play a significant role.

Asia Pacific currently dominates the market with 58.2% share. This region benefits from robust industrial growth, particularly in construction, automotive, and packaging sectors. The increasing demand for PVC products in these industries fuels the demand for stabilizers.

Some of the major players in the PVC stabilizers market include Adeka Corporation, Akdeniz Chemson, Baerlocher GmbH, Clariant AG, Goldstab Organics Pvt. Ltd, KD Chem Co., Ltd., Reagens SPA, SONGWON Industrial Group, Sun Ace Kakoh (Pte.) Ltd., Valtris Specialty Chemicals Limited, Waldies Co. Ltd, etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)