Precision Ball Screw Market Report by Type (Ground Precision Ball Screw, Rolled Precision Ball Screw), Application (Semiconductor, Medical, Laboratory, and Others), and Region 2026-2034

Market Overview:

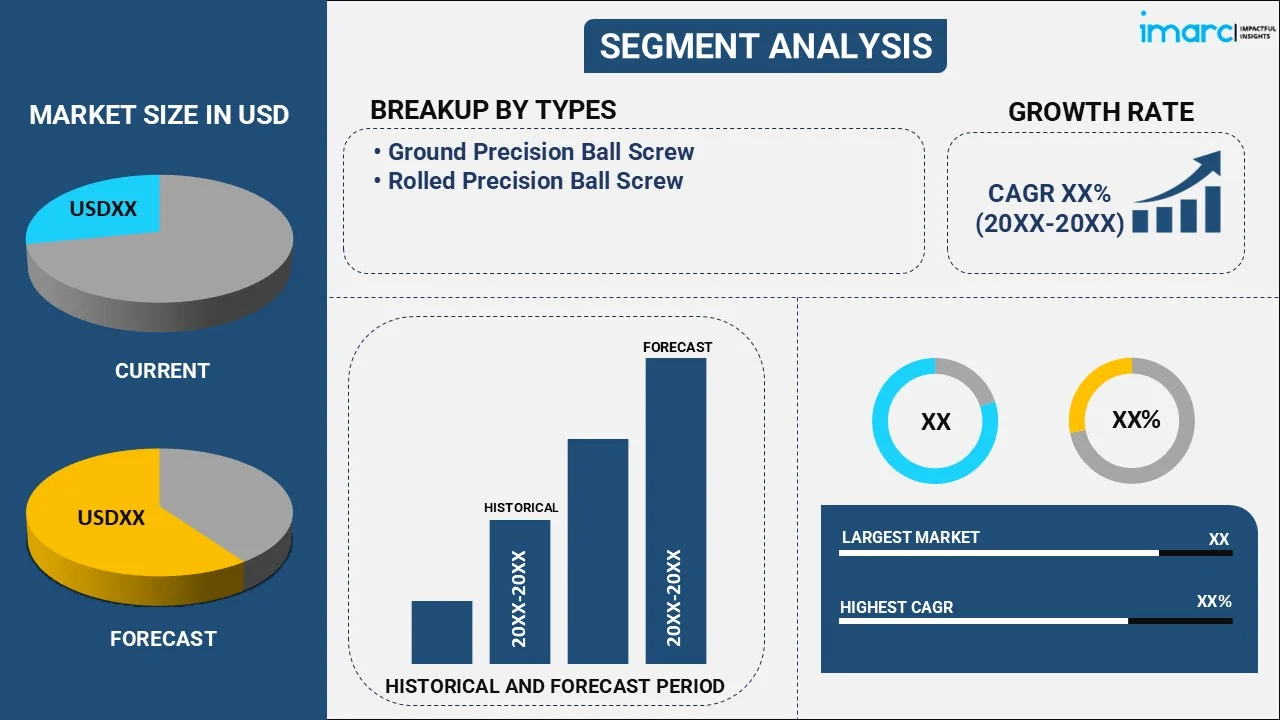

The global precision ball screw market size reached USD 1.7 Billion in 2025. Looking forward, IMARC Group expects the market to reach USD 2.5 Billion by 2034, exhibiting a growth rate (CAG R) of 4.10% during 2026-2034. The increasing automation and adoption of advanced manufacturing technologies, enhancing focus on energy efficiency and electromechanical systems, rapid industrialization in emerging economies, and escalating demand for high-precision manufacturing in industries are some of the major factors propelling the market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034 |

|

Historical Years

|

2020-2025

|

|

Market Size in 2025

|

USD 1.7 Billion |

|

Market Forecast in 2034

|

USD 2.5 Billion |

| Market Growth Rate 2026-2034 | 4.10% |

A precision ball screw is a mechanical component used in various industries to convert rotational motion into linear motion with high accuracy and efficiency. It consists of a screw shaft with precision-ground threads and ball bearings housed in a nut. As the shaft rotates, the balls circulate within the nut, reducing friction and enabling smooth linear movement. This design minimizes backlash and provides precise positioning, making it ideal for applications demanding precise motion control, such as CNC machines, robotics, aerospace, and medical equipment. The precision ball screw's ability to enhance performance and reliability has made it a critical component in modern precision engineering.

To get more information on this market Request Sample

The global precision ball screw market is driven by the increasing automation and adoption of advanced manufacturing technologies across industries such as automotive, aerospace, electronics, and healthcare. Precision ball screws play a crucial role in these applications, offering superior accuracy and repeatability in the movement of components. Moreover, the growing focus on energy efficiency in industrial processes is encouraging the replacement of conventional hydraulic and pneumatic systems with electric actuators, where precision ball screws find extensive use, creating a favorable outlook for market expansion. In addition to this, rapid industrialization in emerging economies is boosting the demand for machine tools and industrial machinery, thereby contributing to the surging demand for precision ball screws. Furthermore, consistent technological advancements, such as the development of miniature ball screws for smaller devices and the integration of smart features, are propelling the market growth. Besides this, as industries prioritize improved productivity, reduced downtime, and enhanced product quality, the global precision ball screw market is poised to experience considerable growth.

Precision Ball Screw Market Trends/Drivers:

Increasing automation and advanced manufacturing technologies

The rise in automation across various industries is a significant driving force behind the precision ball screw market's growth. As industries seek to improve productivity, efficiency, and quality, the demand for precision motion control systems is on the rise. Moreover, precision ball screw finds extensive usage in automated processes, including computer numerical control (CNC) machines, robotics, and industrial automation systems, where precise positioning and movement control are essential. Additionally, the adoption of advanced manufacturing technologies, including additive manufacturing, smart manufacturing, and industry 4.0 initiatives, is further fueling the product demand to ensure optimal performance and reliability in modern manufacturing processes.

Rising focus on energy efficiency and electromechanical systems

The rising emphasis on energy efficiency and sustainability is encouraging industries to transition from conventional hydraulic and pneumatic systems to electric actuators driven by precision ball screws. Compared to traditional systems, precision ball screws offer higher efficiency and reduced energy consumption. This shift is particularly prominent in industries such as automotive, aerospace, and industrial machinery, where energy-efficient solutions are essential to meet regulatory requirements and reduce operational costs. In addition to this, the use of electric actuators with precision ball screws also results in quieter operation, reduced maintenance, and improved overall system performance, making them an attractive choice for various applications.

Rapid industrialization and infrastructure development

Rapid industrialization in emerging economies is generating substantial demand for machine tools, industrial machinery, and automation solutions, driving the growth of the precision ball screw market. Besides this, developing countries are witnessing a surge in manufacturing activities and infrastructure projects, leading to increased investments in equipment and machinery that require precision motion control. Precision ball screws play a vital role in critical applications, such as metal cutting, milling, and assembly processes. Furthermore, the growth of industries like electronics, healthcare, and consumer goods in these regions is contributing to the demand for precision ball screws in various applications, ranging from semiconductor manufacturing to medical equipment.

Precision Ball Screw Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global precision ball screw market report, along with forecasts at the global, regional and country levels from 2026-2034. Our report has categorized the market based on type and application.

Breakup by Type:

To get detailed segment analysis of this market Request Sample

- Ground Precision Ball Screw

- Rolled Precision Ball Screw

Ground precision ball screw dominates the market

The report has provided a detailed breakup and analysis of the market based on the type. This includes ground precision ball screw and rolled precision ball screw. According to the report, ground precision ball screw represented the largest segment.

The growing need for high-precision and reliable motion control solutions in industries, such as aerospace, defense, and semiconductor manufacturing, is driving the adoption of ground precision ball screws. Moreover, the increasing trend towards miniaturization and compact designs in various applications, such as medical devices, electronics, and automotive systems, necessitates the use of smaller yet highly accurate ground precision ball screws, thereby contributing to the market's growth. In addition to this, the shift towards automation and the deployment of advanced robotics in manufacturing processes that require precision motion control components, such as ground ball screws, to ensure smooth and precise movement, improving overall productivity and efficiency, is aiding in market expansion. Furthermore, as industries continue to explore cutting-edge technologies and demand superior equipment performance, ground precision ball screws become a crucial enabler for achieving enhanced product quality and operational excellence.

Breakup by Application:

- Semiconductor

- Medical

- Laboratory

- Others

Semiconductor holds the largest share in the market

A detailed breakup and analysis of the market based on the application has also been provided in the report. This includes semiconductor, medical, laboratory, and others. According to the report, semiconductors accounted for the largest market share.

As the semiconductor industry advances towards smaller and more complex electronic components, there is a surging need for high precision manufacturing processes, creating a positive market outlook. Besides this, the growing use of precision ball screws ensures precise and accurate positioning of wafers, masks, and other critical components during lithography, wafer handling, and inspection processes, which, in turn, is strengthening the market growth. Moreover, with the rising demand for consumer electronics, automotive electronics, and the Internet of Things (IoT) devices, semiconductor manufacturers are under pressure to increase production capacity while maintaining superior product quality. Precision ball screws offer reliable motion control, minimizing errors and enabling higher throughput, thereby supporting the semiconductor industry's efforts to meet market demands efficiently. Furthermore, the trend towards three dimensions (3D) integration and advanced packaging technologies in semiconductors require precise alignment and assembly processes, making precision ball screws indispensable in achieving reliable and robust connections for these intricate devices.

Breakup by Region:

To get more information on the regional analysis of this market Request Sample

- North America

- United States

- Canada

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

Asia Pacific exhibits a clear dominance, accounting for the largest precision ball screw market share

The report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, Asia Pacific accounted for the largest market share.

The demand for precision ball screws in the Asia Pacific region is propelled by rapid industrialization and economic growth in countries such as China, India, and Japan. Besides this, increased investments in manufacturing and automation industries are spurring the demand for precision motion control systems. As these economies expand their industrial base and technology sectors, there is a greater need for precision ball screws in various applications, including CNC machines, robotics, and semiconductor manufacturing equipment, which, in turn, is aiding in market expansion. Moreover, the region's burgeoning automotive industry, along with the rising popularity of electric vehicles (EVs), is fueling the demand for precision engineering components to enhance manufacturing efficiency and produce high-quality automotive products. Furthermore, the growing focus on renewable energy and infrastructure development in Asia Pacific fuels the demand for precision ball screws in wind turbines, solar panel manufacturing, and construction machinery, where accurate motion control is essential for optimal performance and energy efficiency.

Competitive Landscape:

The global precision ball screw market is characterized by a highly competitive landscape with several prominent players vying for market share. Established companies dominate the market with their extensive product portfolios, widespread geographical presence, and long-standing industry experience. These key players continuously focus on research and development (R&D) to innovate and introduce advanced precision ball screw solutions that cater to diverse industry needs. Moreover, strategic partnerships, mergers, and acquisitions are commonly utilized strategies to strengthen their market reach and technological capabilities. The market is also witnessing the presence of numerous regional and niche manufacturers, particularly in emerging economies. These companies often target specific industries and applications, offering specialized precision ball screws tailored to their customer's requirements.

The report has provided a comprehensive analysis of the competitive landscape in the market. Detailed profiles of all major companies have also been provided. Some of the key players in the market include:

- Hiwin Corporation

- Koyo Machinery USA Inc.

- KSS Co. Ltd.

- KURODA Precision Industries Ltd.

- Nidec Corporation

- NSK Ltd.

- PMI Group (Precision Motion Industries Inc.)

- Robert Bosch GmbH

- TBI Motion Technology Co. Ltd.

- THK Co. Ltd.

- Tsubaki Nakashima Co. Ltd.

Recent Developments:

- In July 2020, THK Co. Ltd. introduced two novel additions to its ball spline product line: LFK-X and LFH-X. These innovative products facilitate efficient utilization of space and contribute to a more streamlined design.

- In June 2022, NSK Ltd. unveiled a new advancement in technology aimed at significantly extending the lifespan of ball screws employed in high-load drive applications. This innovative technology is anticipated to generate increased revenue, driven by the growing transition of industrial machinery manufacturers towards electric designs.

- In November 2022, HIWIN Corporation announced the launch of FB Series Ball Splines featuring enhanced precision and flexibility in handling tasks, offering combined stroke and rotation capabilities.

Precision Ball Screw Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical and Forecast Trends, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Types Covered | Ground Precision Ball Screw, Rolled Precision Ball Screw |

| Applications Covered | Semiconductor, Medical, Laboratory, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Hiwin Corporation, Koyo Machinery USA Inc., KSS Co. Ltd., KURODA Precision Industries Ltd., Nidec Corporation, NSK Ltd., PMI Group (Precision Motion Industries Inc.), Robert Bosch GmbH, TBI Motion Technology Co. Ltd., THK Co. Ltd., Tsubaki Nakashima Co. Ltd. etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the precision ball screw market from 2020-2034.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the global precision ball screw market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the precision ball screw industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The global precision ball screw market was valued at USD 1.7 Billion in 2025.

We expect the global precision ball screw market to exhibit a CAGR of 4.10% during 2026-2034.

The extensive utilization of precision ball screws in material handling, manufacturing plants, construction works, machinery repair shops, etc., for enhanced load capacity and positioning accuracy is primarily driving the global precision ball screw market.

The sudden outbreak of the COVID-19 pandemic had led to the implementation of stringent lockdown regulations across several nations, resulting in temporary closure of numerous end-use industries, thereby negatively impacting the demand for precision ball screws.

Based on the type, the global precision ball screw market has been segmented into ground precision ball screw and rolled precision ball screw. Currently, ground precision ball screw represents the largest market share.

Based on the application, the global precision ball screw market can be bifurcated into semiconductor, medical, laboratory, and others. Among these, semiconductor accounts for the majority of the total market share.

On a regional level, the market has been classified into North America, Europe, Asia-Pacific, Middle East and Africa, and Latin America, where Asia-Pacific currently dominates the global market.

Some of the major players in the global precision ball screw market include Hiwin Corporation, Koyo Machinery USA Inc., KSS Co. Ltd., KURODA Precision Industries Ltd., Nidec Corporation, NSK Ltd., PMI Group (Precision Motion Industries Inc.), Robert Bosch GmbH, TBI Motion Technology Co. Ltd., THK Co. Ltd., and Tsubaki Nakashima Co. Ltd.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)