Plasma Cutting Machine Market by Product Type (Single Flow, Dual Flow), Control (Manual, Mechanized), Configuration (2D, 3D, Tube/Section), End User (Manufacturing, Automotive, Industrial Construction, Electrical Equipment, Aerospace and Defense, and Others), and Region 2025-2033

Market Overview:

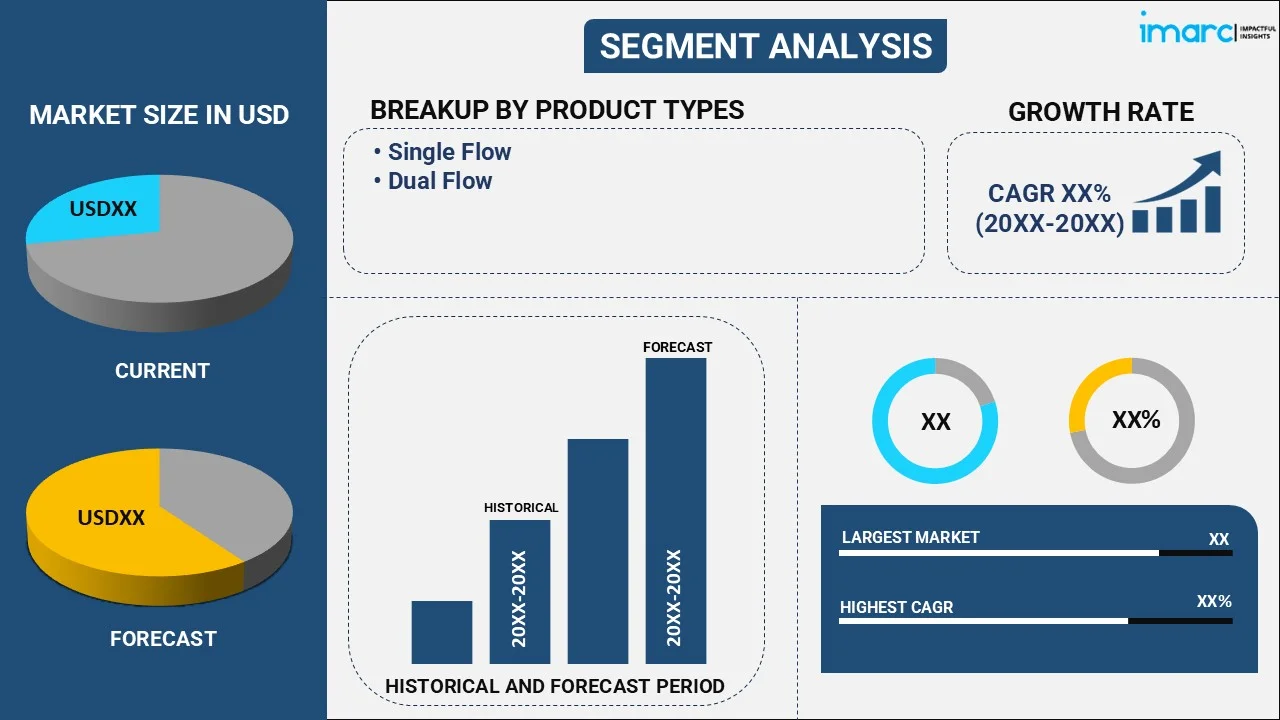

The global plasma cutting machine market size reached USD 1.44 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 2.14 Billion by 2033 exhibiting a growth rate (CAGR) of 4.25% during 2025-2033. The augmenting demand for metal cutting application across numerous industry verticals, the exponential growth in the aerospace industry, and growing construction industry represent some of the key factors driving the market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 1.44 Billion |

|

Market Forecast in 2033

|

USD 2.14 Billion |

| Market Growth Rate 2025-2033 | 4.25% |

Plasma cutting machine refers to a tool used in metalworking to cut through a variety of metals, including steel, aluminum, and copper. It works by creating an electrical arc that passes through a gas such as compressed air or nitrogen, creating a high-temperature plasma stream. This stream is directed toward melting and blowing away the material to create a clean and precise cut. Plasma cutting machines are commonly used in industries such as automotive, construction, and metal fabrication due to their ability to cut through thick materials quickly and with great precision. They can also be used for artistic and decorative purposes, allowing for intricate and detailed designs to be cut into metal surfaces. In recent years, plasma cutting machines have gained traction as they find applications across the automotive, construction, and manufacturing industries.

Plasma Cutting Machine Market Trends:

One of the primary factors driving the market is the ability of plasma cutting machines to handle thicker materials has led to their increased adoption rate. Other than this, as more individuals are interested in creating their own metalwork, including furniture, home decor, and artwork, these machines provide an efficient and affordable way for DIY enthusiasts, to cut and shape metal according to their desired designs. Besides this, the increasing adoption of renewable energy sources, such as wind turbines and solar panels, is escalating the demand for plasma cutting machines. These machines are used to cut and shape the metal components used in renewable energy infrastructure, which is positively influencing the market growth. In line with this, plasma cutting machines are used extensively in the aerospace industry for cutting and shaping metal parts for aircraft and spacecraft. Apart from these factors, these machines are widely used in the construction industry, to cut and shape metal beams and other structural components used in building construction, thereby propelling the market growth. Furthermore, the growing demand for customized metal products represents another growth-inducing factor since plasma cutting machines are used to produce highly customized metal products with complex designs and shapes. Furthermore, the advancements in technology have led to the development of more efficient and accurate plasma cutting machines, such as the introduction of computer numerical control (CNC) and automated systems have increased the efficiency and productivity of plasma cutting machines. Moreover, the increasing focus on safety and environmental regulations accelerated the sales of plasma cutting machines. They produce minimal waste and do not emit harmful gases or fumes, making them a safe and eco-friendly cutting option.

Key Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global plasma cutting machine market, along with forecasts at the global, regional, and country levels from 2025-2033. Our report has categorized the market based on product type, control, configuration, and end user.

Product Type Insights:

- Single Flow

- Dual Flow

- Shielded

- Unshielded

The report has provided a detailed breakup and analysis of the plasma cutting machine market based on the product type. This includes single flow and dual flow (shielded and unshielded). According to the report, single flow represented the largest segment.

Control Insights:

- Manual

- Mechanized

A detailed breakup and analysis of the plasma cutting machine market based on the control has also been provided in the report. This includes manual and mechanized. According to the report, mechanized accounted for the largest market share.

Configuration Insights:

- 2D

- 3D

- Tube/Section

The report has provided a detailed breakup and analysis of the plasma cutting machine market based on the configuration. This includes 2D, 3D, and tube/section. According to the report, 2D represented the largest segment.

End User Insights:

- Manufacturing

- Automotive

- Industrial Construction

- Electrical Equipment

- Aerospace and Defense

- Others

A detailed breakup and analysis of the plasma cutting machine market based on the end user has also been provided in the report. This includes manufacturing, automotive, industrial construction, electrical equipment, aerospace and defense, and others. According to the report, automotive accounted for the majority of the market share.

Regional Insights:

- North America

- United States

- Canada

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

The report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, Asia-Pacific was the largest market for plasma cutting machine. Some of the factors driving the Asia Pacific plasma cutting machine market included industrialization and infrastructure development, rising demand for automotive and construction industries, etc.

Competitive Landscape:

The report has also provided a comprehensive analysis of the competitive landscape in the global plasma cutting machine market. Competitive analysis such as market structure, market share by key players, player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided. Some of the companies covered include Ajan Elektronik, Automated Cutting Machinery Inc., C&G Systems Corporation, ESAB Corporation, Esprit Automation Ltd., Haco, Hornet Cutting Systems, Hypertherm Inc., Kjellberg Finsterwalde (Kjellberg-Holding GmbH), Komatsu Industries Corp. (Komatsu Limited), Messer Cutting Systems GmbH, SICK AG (Sick Holding GmbH), etc. Kindly note that this only represents a partial list of companies, and the complete list has been provided in the report.

Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Product Types Covered |

|

| Controls Covered | Manual, Mechanized |

| Configurations Covered | 2D, 3D, Tube/Section |

| End Users Covered | Manufacturing, Automotive, Industrial Construction, Electrical Equipment, Aerospace and Defense, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Ajan Elektronik, Automated Cutting Machinery Inc., C&G Systems Corporation, ESAB Corporation, Esprit Automation Ltd., Haco, Hornet Cutting Systems, Hypertherm Inc., Kjellberg Finsterwalde (Kjellberg-Holding GmbH), Komatsu Industries Corp. (Komatsu Limited), Messer Cutting Systems GmbH, SICK AG (Sick Holding GmbH), etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the plasma cutting machine market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the global plasma cutting machine market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the plasma cutting machine industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The plasma cutting machine market was valued at USD 1.44 Billion in 2024.

The plasma cutting machine market is projected to exhibit a CAGR of 4.25% during 2025-2033, reaching a value of USD 2.14 Billion by 2033.

The expansion of infrastructure projects and rising industrial automation are contributing to the market growth, as companies are seeking advanced equipment to improve productivity and reduce operational costs. Increasing adoption of computer numerical control (CNC) plasma cutters enhances precision and repeatability, encouraging more businesses to invest in these machines. Small and medium enterprises (SMEs) also benefit from portable and cost-effective plasma cutters, expanding the market across different scales of operation.

Asia-Pacific currently dominates the plasma cutting machine market in 2024, driven by rapid industrialization and increasing infrastructure advancements in nations, such as India and Japan. The area benefits from a large user base, lower production costs, and increasing investments in automation and metal fabrication.

Some of the major players in the plasma cutting machine market include Ajan Elektronik, Automated Cutting Machinery Inc, C&G Systems Corporation, ESAB Corporation, Esprit Automation Ltd, Haco, Hornet Cutting Systems, Hypertherm Inc., Kjellberg Finsterwalde (Kjellberg-Holding GmbH), Komatsu Industries Corp. (Komatsu Limited), Messer Cutting Systems GmbH, SICK AG (Sick Holding GmbH), etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)