Multihead Weighers Market Size, Share, Trends and Forecast by Machine Type, Number of Heads, Technology, End User, and Region, 2025-2033

Multihead Weighers Market Size and Share:

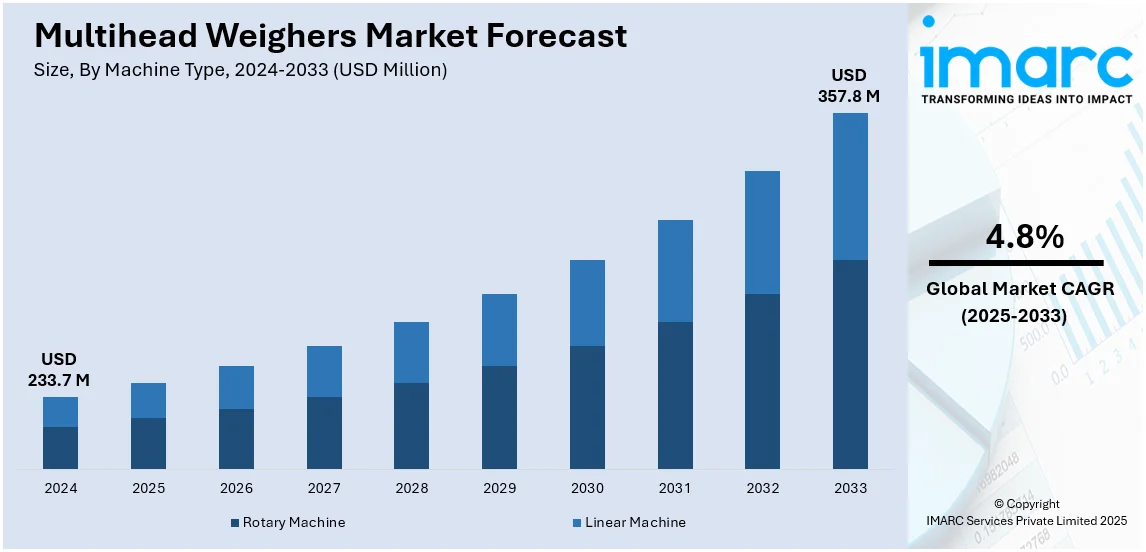

The global multihead weighers market size was valued at USD 233.7 Million in 2024. Looking forward, IMARC Group estimates the market to reach USD 357.8 Million by 2033, exhibiting a CAGR of 4.8% from 2025-2033. North America currently dominates the market, holding a market share of over 34% in 2024. The increasing demand for automated packaging solutions, the growing consumer expectations for convenience and product quality, and the emerging technological advancements in multihead weighers are some of the major factors propelling the market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 233.7 Million |

| Market Forecast in 2033 | USD 357.8 Million |

| Market Growth Rate (2025-2033) | 4.8% |

The multihead weighers market growth is driven by the increasing automation in food, pharmaceutical, and packaging industries. Growing demand for precision, speed, and efficiency in bulk weighing and packaging is driving manufacturers to adopt advanced multihead weighers that reduce product giveaway and optimize portion control. The shift toward sustainable and flexible packaging solutions, particularly in snacks, frozen foods, and ready-to-eat meals, is further fueling the market. Additionally, rising labor costs and hygiene regulations are accelerating the adoption of automated weighing solutions that enhance efficiency while ensuring compliance with food safety standards.

In the United States, demand for multihead weighers is increasing due to the expansion of packaged food, e-commerce, and direct-to-consumer markets. For instance, as per industry reports, the estimated U.S. retail e-commerce sales for Q4 2024 reached USD 352.9 Billion, reflecting a 22.1% increase (±0.9) compared to Q3 2024. The need for energy-efficient, high-speed weighing systems is growing as manufacturers seek to improve product consistency and reduce operational costs, contributing to multihead weighers market demand. Furthermore, FDA regulations on food safety further drive the adoption of hygienic, easy-to-clean weighing systems, ensuring compliance while maintaining efficiency.

Multihead Weighers Market Trends:

Increasing demand for automated packaging solutions

The growing demand for automated packaging solutions is driving the growth of the multihead weighers market. According to India Brand Equity Foundation, FDI inflows in the Paper and Pulp industry totalled USD 1.73 Billion from April 2000 to June 2024, highlighting investor confidence in India's packaging landscape. In addition, numerous organizations are striving for greater efficiency and productivity in their packaging processes, turning to advanced technologies such as multihead weighers. These machines offer high-speed and accurate weighing capabilities, ensuring precise and consistent product measurements by automating the weighing and packaging tasks, multihead weighers enable manufacturers to streamline their operations, reduce human error, and enhance productivity, contributing to multihead weighers market growth. Furthermore, automated packaging solutions save time and labor costs, enabling companies to meet the increasing consumer demand for efficient and timely product delivery. As a result, the demand for multihead weighers is expected to continue rising as industries embrace automation as a means to optimize their packaging processes.

The growing consumer expectations for convenience and product quality

The evolving consumer expectations for convenience and product quality are also driving the growth of the multihead weighers market. Additionally, consumers are preferring demand accurately weighed and packaged products that offer consistent quality and portion sizes, multihead weighers, with their precise weighing capabilities, are well-suited to meet these expectations contributing to the market growth. Moreover, the widespread adoption of multihead weighers in the food and beverage (F&B) industry to control portions, ensure consistent and accurate measurements, enhancing product quality and customer satisfaction represents another major multihead weighers market trends growth-inducing factor. According to Trade Promotion Council of India, the food processing sector has received around Rs 7,126 crore (USD 857.7 Million) worth of investments by the end of 2023 under the Production Linked Incentive (PLI) scheme for food processing. Furthermore, these machines enable manufacturers to customize packaging sizes, catering to the growing demand for individual-sized or convenience-oriented products.

The emerging technological advancements

These advancements have improved the capabilities and functionalities of multihead weighers, making them more versatile, efficient, and adaptable to various industries needs. In addition, the integration of advanced software algorithms and machine learning (ML) is enhancing the accuracy and speed of multihead weighers contributing to the market growth. According to reports, global investment in AI technologies will reach USD 200 Billion by 2025, further influencing the multihead weighers market outlook as AI-driven solutions continue to improve precision and automation in weighing systems. These machines utilize sophisticated algorithms to analyze weight data and make precise calculations, ensuring accurate product measurements. Moreover, the incorporation of robotic systems and packaging machinery improved multihead weighers by combining multihead weighers with robotic arms or conveyor systems, manufacturers can achieve seamless automation and integration within their production lines representing another major growth-inducing factor. This integration enables efficient product handling, precise weighing, and synchronized packaging operations. Furthermore, the development of user-friendly interfaces and connectivity features in multihead weighers, equipped with intuitive touchscreens and user interfaces that simplify machine operation and control, providing real-time data visualization, monitoring, and adjustment options, allowing operators to efficiently manage the weighing process is influencing the market growth.

Multihead Weighers Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global multihead weighers market, along with forecast at the global, regional, and country levels from 2025-2033. The market has been categorized based on machine type, number of heads, technology, and end-user.

Analysis by Machine Type:

- Rotary Machine

- Linear Machine

Rotatory machine stand as the largest machine type in 2024, holding around 64.8% of the market. Rotary multihead weighers are widely utilized in the packaging industry and are known for their high-speed weighing capabilities. These machines consist of a rotating circular disc with multiple weighing heads attached to it each weighing head independently measures the product weight and transfers it to a central control system for calculation and packaging. Moreover, rotary machines are ideal for applications that require high throughput and continuous operation in industries such as snacks, confectionery, and dry goods, where a large quantity of small-sized products needs to be weighed and packed rapidly influencing the market growth.

Analysis by Number of Heads:

- Up To 10 Heads

- 11 Heads To 15 Heads

- 16 Heads To 20 Heads

- Above 20 Heads

Up to 10 heads lead the multihead weighers market share in 2024, catering to industries with moderate production volumes and products that do not require high-speed weighing. These weighers provide accurate portioning, reducing product giveaway while maintaining consistency. Their compact design and cost-effectiveness make them ideal for small to medium-scale manufacturers seeking automation without excessive investment. They are widely adopted in packaging snacks, confectionery, small bakery items, dried fruits, tea leaves, spices, and hardware components. Their versatility, ease of maintenance, and adaptability to various packaging formats contribute to continued market growth across multiple industries.

Analysis by Technology:

- Gravity Technology

- Centrifugal Technology

- Vibration Technology

- Others

Gravity technology leads the market in 2024, offering efficient, precise, and cost-effective weighing solutions across various industries. The market is categorized by technology, with gravity-based systems utilizing natural gravitational force to measure and distribute products with high accuracy. These weighers incorporate individual weighing buckets, which ensure consistent portioning by releasing products into packaging containers based on preset weight parameters. They are widely used in dry, free-flowing products such as grains, cereals, coffee, snacks, and seeds, minimizing manual intervention and improving operational efficiency in food processing and packaging facilities.

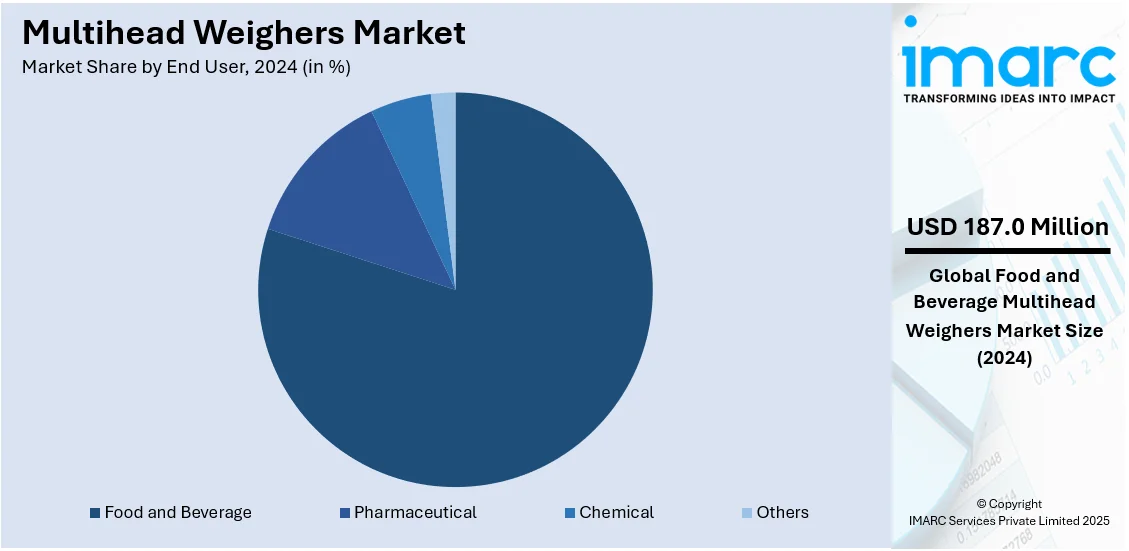

Analysis by End User:

- Food and Beverage

- Pharmaceutical

- Chemical

- Others

Food and beverages lead the market with around 80.0% of market share in 2024. The food and beverage (F&B) industry is one of the primary end users of multihead weighers. They find extensive applications in weighing and packaging food products such as snacks, cereals, confectionery, frozen foods, and fresh produce. Moreover, multihead weighers in the food and beverage sector ensure precise portioning, consistent packaging, and adherence to quality standards representing another major growth-inducing factor.

Regional Analysis:

- North America

- United States

- Canada

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

In 2024, North America accounted for the largest multihead weighers market share of over 34%, driven by the expansion of the food, pharmaceutical, and packaging industries. The United States and Canada lead in adopting high-speed, automated weighing solutions to improve efficiency and compliance with strict FDA and food safety regulations. Moreover, increasing demand for pre-packaged and ready-to-eat foods has accelerated the use of advanced multihead weighers in processing and packaging facilities. Companies prioritize energy-efficient, IoT-enabled models to enhance product consistency and reduce operational costs. Additionally, technological advancements, strong distribution networks, and investments in automation further strengthen North America’s position as the leading regional market.

Key Regional Takeaways:

United States Multihead Weighers Market Analysis

In 2024, United States accounted for 79.80% of the market share in North America. United States experiences a rising demand for multihead weighers, fuelled by the growing chemical industry, which requires precise and efficient weighing solutions for bulk materials, powders, and granules. According to International Trade Administration, the U.S. chemical manufacturing industry total FDI in the industry was USD 766.7 Billion in 2023. As chemical manufacturers seek to enhance productivity and minimize material wastage, multihead weighers are increasingly integrated into automated production lines to ensure accuracy and consistency. The need for compliance with stringent quality control standards and safety regulations further accelerates the adoption of these systems, ensuring uniformity in packaging and reducing contamination risks. Advanced weighing solutions contribute to operational efficiency by optimizing material flow and reducing downtime in high-speed manufacturing environments. The emphasis on sustainable manufacturing practices also supports the integration of multihead weighers, as they enable precise material dispensing and minimize product loss. Rising investments in industrial automation and technological advancements in weighing systems contribute to increased efficiency, cost-effectiveness, and operational scalability. With chemical production expanding to meet increasing demand across various sectors, the requirement for multihead weighers continues to grow, reinforcing their role in automated material handling and packaging.

Europe Multihead Weighers Market Analysis

Europe experiences increasing multihead weighers adoption, driven by growing packaging requirements due to the expanding food and beverages sector. According to reports, in 2020, there were 291,000 enterprises in the EU processing food and beverages. As food safety regulations become more stringent, precise weighing solutions are crucial in ensuring accurate portioning, minimizing waste, and maintaining product quality. The rising preference for pre-packaged food items and ready-to-eat meals has led to a higher demand for efficient, high-speed weighing systems that can handle diverse product types, including fresh produce, snacks, and bakery items. Multihead weighers enhance productivity by optimizing packaging efficiency, reducing product giveaway, and improving consistency across production batches. The shift toward sustainable packaging practices also accelerates the integration of advanced weighing solutions, as they contribute to minimizing excess packaging material. With food and beverages companies prioritizing automation to streamline operations and meet evolving consumer demands, multihead weighers are increasingly incorporated into production lines.

Asia Pacific Multihead Weighers Market Analysis

Asia-Pacific is witnessing a surge in multihead weighers adoption, primarily due to the growing pharmaceutical sector, where precise measurement and accurate dosing are essential for ensuring compliance with stringent quality control regulations. According to India Brand Equity Foundation, the cumulative FDI equity inflow in the drugs and pharmaceuticals industry is USD 22.52 Billion during the period April 2000-March 2024, almost 3.4% of the total inflow received across sectors. As pharmaceutical manufacturing scales up to meet rising demand, companies integrate automated weighing solutions to enhance efficiency, minimize human error, and maintain product consistency. The increasing production of tablets, capsules, and powders necessitates advanced multihead weighers that offer high-speed operation while maintaining precision. These systems play a crucial role in optimizing packaging processes, improving product safety, and ensuring uniformity in pharmaceutical formulations. The rapid expansion of the pharmaceutical industry, coupled with growing investments in automated manufacturing solutions, supports the widespread adoption of multihead weighers across production facilities. Regulatory requirements for strict weight accuracy and traceability further drive demand, encouraging manufacturers to integrate advanced weighing solutions into their packaging lines.

Latin America Multihead Weighers Market Analysis

Latin America is witnessing a growing demand for multihead weighers, supported by the increasing need for automated packaging solutions due to the expanding online e-commerce sector. According to reports, the Latin America market currently boasts over 300 Million digital buyers. As online shopping continues to grow, businesses prioritize efficiency in packaging to meet high-volume order fulfillment requirements. Multihead weighers play a vital role in ensuring precise portioning and minimizing packaging errors, leading to improved customer satisfaction and reduced operational costs. The shift toward faster and more automated packaging lines encourages manufacturers to adopt advanced weighing solutions that enhance productivity while maintaining accuracy. With logistics networks expanding to accommodate rising ecommerce transactions, efficient packaging becomes essential for streamlining supply chains. Multihead weighers contribute to cost-effective packaging operations by reducing material wastage and optimizing packaging speeds.

Middle East and Africa Multihead Weighers Market Analysis

Middle East and Africa are experiencing increasing multihead weighers adoption, facilitated by integration with robotic systems and packaging machinery, enhancing automation and efficiency within production lines due to the growing logistics sector. According to reports, logistics in the Middle East is booming as GCC countries leverage their strategic location, with 30% of global trade passing through the Red Sea and Gulf of Aden, driving further expansion and diversification in the sector. The need for high-speed, accurate weighing solutions is rising as logistics companies seek to streamline packaging processes and improve operational reliability. Multihead weighers enable seamless integration with automated material handling systems, ensuring faster packaging cycles while maintaining precision. The ability to handle diverse product types further supports their adoption in logistics-driven industries. As businesses focus on reducing manual intervention and optimizing throughput, the demand for automated weighing solutions continues to increase.

Competitive Landscape:

The multihead weighers market is highly competitive, driven by technological advancements and increasing automation in food, pharmaceutical, and packaging industries. Leading manufacturers focus on high-speed, precision weighing solutions that enhance efficiency and reduce waste. Companies are investing in intelligent software integration, IoT connectivity, and hygienic designs to meet evolving regulatory standards and operational demands. For instance, in January 2024, Guangdong TOUPACK Intelligent Equipment, announced a successful launch of a new product in an event attended by industry experts, partners, and professionals. They demonstrated their latest intelligent weighing innovation to advance precision and automation in the sector. The market is characterized by continuous product innovation, strategic mergers, and global expansion efforts to strengthen distribution networks. Furthermore, rising demand for customizable, energy-efficient models is pushing manufacturers to develop versatile, cost-effective solutions, ensuring a competitive edge in this rapidly evolving industry.

The report provides a comprehensive analysis of the competitive landscape in the multihead weighers market with detailed profiles of all major companies, including:

- Comek S.r.l.

- Dm Packaging Group S.r.l.

- Emrich Packaging Machinery Pty Ltd

- Grupo Exaktapack S.L.

- Ilapak International S.A. (IMA – Industria Macchine Automatiche S.p.A.)

- Ishida Co. Ltd.

- Laurijsen WeegAutomaten

- Marel hf.

- MULTIPOND Wägetechnik GmbH

- MultiWeigh GmbH

- NVenia LLC (Duravant LLC)

- P.F.M. S.P.A.

- Yamato Scale Co. Ltd.

Latest News and Developments:

- October 2024: Harpak-ULMA and Cabinplant have partnered to enhance North American food packaging with advanced multihead weighers, reducing waste and improving efficiency. Cabinplant’s precision weighing systems ensure accurate portioning for fresh, frozen, and delicate foods while integrating seamlessly with various packaging formats. This collaboration helps food producers cut product giveaway, lower labor costs, and boost sustainability in high-speed operations.

- September 2024: Wierzejki, one of Poland’s largest meat manufacturers, has enhanced its dumpling production with an Ishida multihead weigher, boosting throughput and efficiency. The Ishida CCW-RVE-214W-1S-30-WP replaced manual packing, cutting labor needs and reducing product giveaway from 5% to under 2%. This investment achieved a payback period of 18 months, significantly improving cost savings and precision.

- August 2024: IMA Group, through its newly established IMA Sarong, finalized the acquisition of Sarong’s Packaging Machinery and Packaging Materials divisions in Reggiolo, Italy. This move strengthens IMA’s expertise in advanced packaging technologies, including multihead weighers for precise product weighing. The acquisition enhances IMA’s capabilities in pharmaceutical and food packaging, offering innovative solutions to global markets.

- March 2024: Ishida Europe expanded its footprint in Africa by acquiring National Packaging Systems (NPS), a South African packaging equipment manufacturer. This acquisition reinforces Ishida’s position in the region, enhancing its offerings in high-performance multihead weighers for food and non-food industries. By leveraging NPS’s local expertise, Ishida aims to deliver advanced weighing and packaging solutions tailored to African market needs.

- June 2024: Marel inaugurated its state-of-the-art Global Distribution Center (GDC) in Eindhoven to optimize its worldwide logistics and service operations. The facility enhances Marel’s ability to distribute food processing equipment, including high precision multihead weighers, to customers more efficiently. With improved inventory management and faster delivery times, the GDC supports Marel’s mission to enhance automation in food processing.

Multihead Weighers Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Machine Types Covered | Rotary Machine, Linear Machine |

| Number of Heads Covered | Up To 10 Heads, 11 Heads To 15 Heads, 16 Heads To 20 Heads, Above 20 Heads |

| Technologies Covered | Gravity Technology, Centrifugal Technology, Vibration Technology, Others |

| End Users Covered | Food and Beverage, Pharmaceutical, Chemical, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Comek S.r.l., Dm Packaging Group S.r.l., Emrich Packaging Machinery Pty Ltd, Grupo Exaktapack S.L., Ilapak International S.A. (IMA – Industria Macchine Automatiche S.p.A.), Ishida Co. Ltd., Laurijsen WeegAutomaten, Marel hf., MULTIPOND Wägetechnik GmbH, MultiWeigh GmbH, NVenia LLC (Duravant LLC), P.F.M. S.P.A., Yamato Scale Co. Ltd, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the multihead weighers market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the global multihead weighers market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the multihead weighers industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The multihead weighers market was valued at USD 233.7 Million in 2024.

IMARC estimates the global multihead weighers market to reach USD 357.8 Million in 2033, exhibiting a CAGR of 4.8% during 2025-2033.

The factors driving the multihead weighers market include increasing demand for automation in food processing, the need for high-precision weighing solutions, rising consumer preferences for packaged goods, and advancements in technology that enhance weighing speed, accuracy, and efficiency, improving overall production processes.

North America currently dominates the market, holding a market share of over 34% in 2024. This growth is propelled by advanced manufacturing technologies, a strong food processing industry, and a growing demand for automation. The region's focus on high-quality standards and innovation further supports its dominance in the market segment.

Some of the major players in the multihead weighers market include Comek S.r.l., Dm Packaging Group S.r.l., Emrich Packaging Machinery Pty Ltd, Grupo Exaktapack S.L., Ilapak International S.A. (IMA – Industria Macchine Automatiche S.p.A.), Ishida Co. Ltd., Laurijsen WeegAutomaten, Marel hf., MULTIPOND Wägetechnik GmbH, MultiWeigh GmbH, NVenia LLC (Duravant LLC), P.F.M. S.P.A., Yamato Scale Co. Ltd, etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)