Manufacturing Predictive Analytics Market Size, Share, Trends and Forecast by Component, Deployment Model, Application, End Use Industry, and Region, 2025-2033

Manufacturing Predictive Analytics Market Size and Share Statistics:

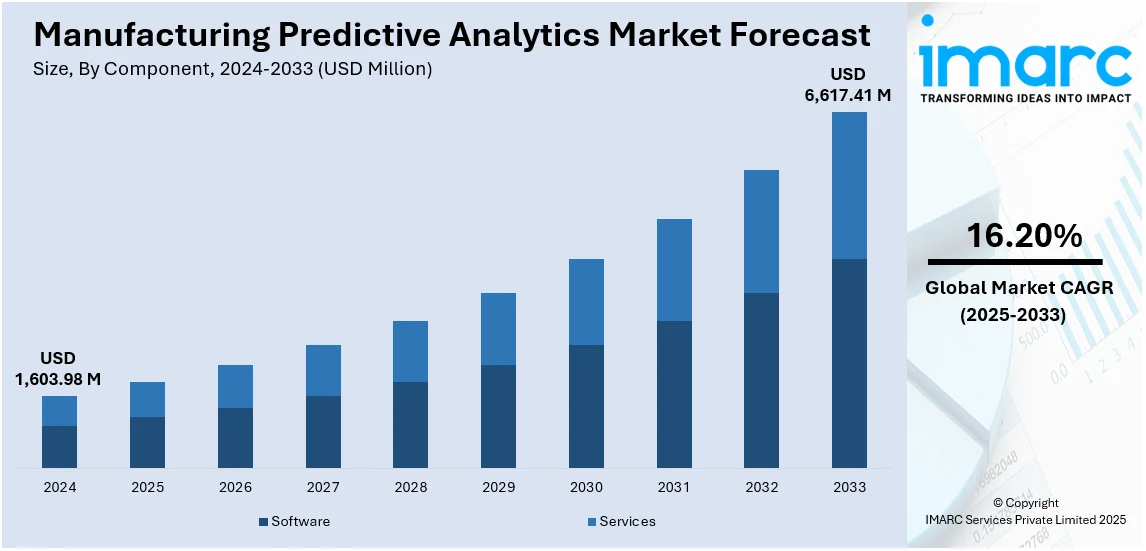

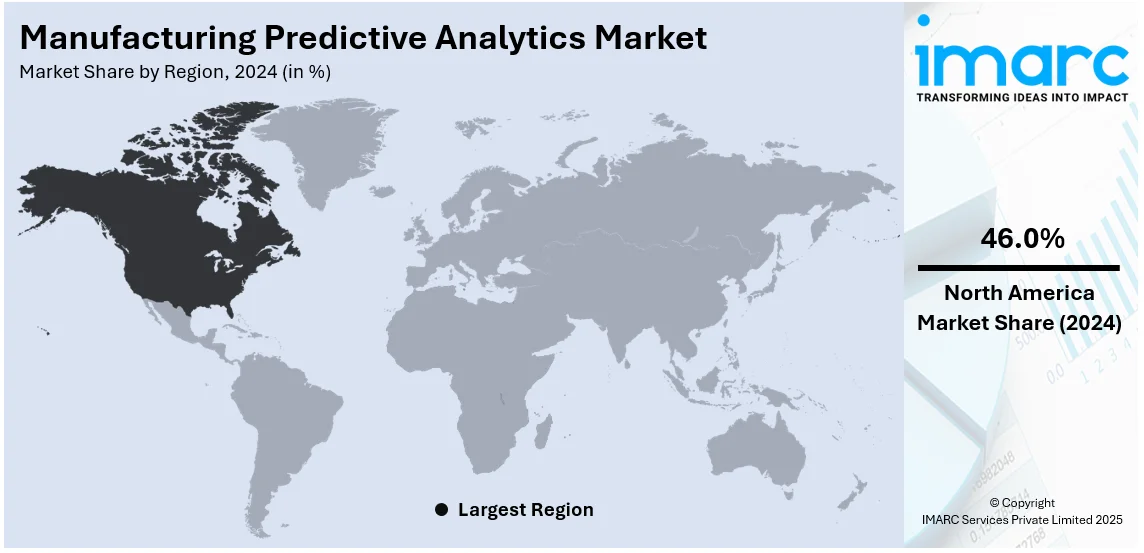

The global manufacturing predictive analytics market size was valued at USD 1,603.98 Million in 2024. Looking forward, IMARC Group estimates the market to reach USD 6,617.41 Million by 2033, exhibiting a CAGR of 16.20% from 2025-2033. North America currently dominates the market, holding a market share of over 46.0% in 2024. The manufacturing predictive analytics market share is expanding, driven by increasing adoption of Industry 4.0, rising demand for operational efficiency, advancements in artificial intelligence (AI), big data and machine learning (ML), heightened concentration on predictive maintenance, and the need for data-driven decision-making in manufacturing processes.

|

Report Attribute

|

Key Statistics |

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033 |

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 1,603.98 Million |

|

Market Forecast in 2033

|

USD 6,617.41 Million |

| Market Growth Rate (2025-2033) | 16.20% |

The rapid digitization of the manufacturing industry in different parts of the world is one of the main reasons driving the market. In addition to this, the growing need for smart and scalable factory solutions is giving a push to the growth of the market. Manufacturing predictive analytics utilizes statistical tools and various data points to enhance product quality, gain insight into market trends, and perform preventive maintenance. This is due to the fact that with increased demand for proper remote monitoring solutions, the market is growing. Various technological improvements like the addition of manufacturing technologies with artificial intelligence (AI), big data and machine learning (ML) solutions, are offering a favorable manufacturing predictive analytics market outlook.

There are many reasons why the United States has emerged as a key contributor to the manufacturing predictive analytics. One of the most influential trends in the US market is the increasing employment of AI and ML. This allows manufacturers to analyze large datasets, identify patterns, and make accurate predictions regarding machine performance, product quality, and supply chain disruptions. AI-powered predictive analytics is used in predictive maintenance and reduces unplanned downtime, thereby optimizing the equipment's lifespan. The manufacturers are finding greater uses of AI algorithms in gaining real-time information in their production processes to result in efficiency improvement with cost savings. As AI and ML models advance, so will their application to predictive analytics solutions in improving the growth of the market. According to the IMARC Group, the US AI market is projected to reach USD 97,084.2 Million by 2032.

Manufacturing Predictive Analytics Market Trends:

Advancements in ML and AI

Machine learning (ML) and artificial intelligence (AI) technologies form the backbone of growth in predictive analytics in the manufacturing sector. These technologies empower manufacturers to process large volumes of operational data, enabling them to identify patterns and predict potential equipment failures. AI-driven predictive models can help manufacturers adjust construction schedules, cut downtime, and recover overall operational efficiency. As the algorithms advance, therefore, so does the precision of the prediction, and indeed more in maintenance costs, as well as enhanced asset management. In April 2024, the Japanese government awarded USD 470 Million in tender to five companies for developing an AI supercomputer, as per an industry report. This is expected to accelerate the pace of AI and ML applications, making Japan a leader in AI-driven manufacturing innovations. The development of AI supercomputers will likely enhance predictive analytics capabilities across industries, boost productivity, improve decision-making, and offer a more sustainable approach to manufacturing processes. These advancements are expected to significantly contribute to the continued growth of the AI-powered predictive analytics market within the manufacturing sector.

Internet of Things (IoT) and Sensor Integration

IoT has transformed the manufacturing industry by enabling the delivery of real-time data through sensors embedded in equipment, machines, and production lines, thereby impelling the manufacturing predictive analytics market growth. The key relevance for this kind of information for predictive analytics will enable the tracking of health at machine levels for potential breakdown prediction prior to breakdown occurrence. Manufacturers will improve the operational efficiency of equipment through decision-making capabilities made easier through the timely availability of actionable insights via IoT devices. The effectiveness of IoT-driven predictive maintenance in ensuring asset lifecycles without increasing instances of unplanned downtime and maintaining an overall precision advantage will increase its usage further. Such reduction in downtime would increase the production efficiency but at the same time reduce costs considerably. It makes IoT a major growth driver for the manufacturing industry. With the uptake of IoT technologies, manufacturers position themselves to optimize their operations, minimize the costs associated with maintenance, and boost productivity as a whole. In 2024, Guidewheel introduced Scout, a new product designed to help manufacturers predict maintenance needs and detect spontaneous warning signals of problems before they result in machine downtime or failures.

Cloud Computing and Big Data

Both cloud computing and big data technologies are critical elements that make the success of predictive analytics in manufacturing a reality. They allow manufacturers to collect, store, and process huge data sets that come from multiple sources. Advanced analytics and insights are supported by such technologies, which can help manufacturers do better things in optimizing their operations and decision-making. This means scaling up analytics capabilities and access to high-powered computational resources through the use of cloud infrastructure to gain insights cost-effectively and more effectively. Canada's Prime Minister revealed, according to reports, a planned investment of USD 1.77 Billion for the development of artificial intelligence in the country for April 2024. Such strategic investment will further accelerate growth in manufacturing industry sectors, along with other industry sectors, as AI capabilities grow stronger. The future of AI development will bring improved tools for predictive analytics, making automation and efficiency better for companies in the manufacturing industry. That way, it could be an excellent investment in developing the manufacturing industry because it is going to push such companies into incorporating AI-driven predictive maintenance, chain optimization, and production forecasting as techniques that boost the industry toward faster digital changeover.

Manufacturing Predictive Analytics Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global manufacturing predictive analytics market, along with forecast at the global, regional, and country levels from 2025-2033. The market has been categorized based on component, deployment model, application, and end use industry.

Analysis by Component:

- Software

- Services

Software leads the market. The software segment is an important part of the market, which includes advanced analytics platforms, AI-driven machine learning models, and data visualization tools. Predictive analytics software enables manufacturers to process huge quantities of historical and real-time information to produce actionable insights that enhance production efficiency, minimize downtime, and boost supply chain management, thereby driving the manufacturing predictive analytics market demand. Market growth has been boosted by an increasing adoption of cloud-based analytics solutions, as it allows manufacturers to access predictive insights from anywhere remote with seamless integration into existing enterprise systems, for example, Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES). As industrial automation and smart factory concepts increasingly grow, the demand for sophisticated predictive analytics software solutions is expected to be huge.

Analysis by Deployment Model:

- Cloud-based

- On-premises

On-premises leads the market. The on-premises deployment model remains a preferred choice for large manufacturing enterprises that require greater control over their data, security, and compliance requirements. On-premises predictive analytics solutions are hosted within a company’s own information technology (IT) infrastructure, ensuring data sovereignty and minimizing reliance on third-party cloud service providers. This model is particularly advantageous for manufacturers operating in highly regulated industries, such as aerospace, defense, and pharmaceuticals, where data security and privacy concerns are paramount. Additionally, on-premises solutions offer enhanced customization and integration capabilities, allowing manufacturers to tailor analytics models to their specific operational needs. However, the high initial investment in hardware, software, and IT infrastructure, along with ongoing maintenance costs, may pose challenges for smaller manufacturers. Despite these cost considerations, on-premises predictive analytics continues to be a viable option for enterprises prioritizing data control and long-term strategic investments in digital transformation.

Analysis by Application:

- Demand Forecasting

- Machinery Inspection and Maintenance

- Product Development

- Supply Chain Management

- Others

Demand forecasting is a critical application of predictive analytics in the manufacturing sector, enabling companies to anticipate market trends, consumer preferences, and production requirements. By leveraging historical sales data, economic indicators, and external factors such as seasonality and geopolitical events, manufacturers can optimize inventory levels, reduce waste, and prevent stock shortages or overproduction. Predictive analytics models help businesses adjust their production schedules in real time, ensuring alignment with fluctuating demand patterns.

Predictive analytics is vital for machinery inspection and maintenance, enabling manufacturers to identify possible equipment failures ahead of time. Conventional maintenance approaches, like reactive or planned maintenance, frequently lead to avoidable downtime and increased expenses. Predictive maintenance systems employ IoT sensors, real-time data analysis, and AI-based algorithms to oversee machine performance, identify irregularities, and forecast component breakdowns. This proactive strategy decreases unexpected downtime, prolongs equipment longevity, and lessens operational interruptions.

Predictive analytics is transforming product development by enabling manufacturers to analyze customer feedback, market trends, and production data to enhance innovation and design. By leveraging data-driven insights, manufacturers can identify consumer preferences, predict product performance, and optimize material usage. This results in reduced development cycles, lower production costs, and improved product quality.

Supply chain management is one of the most impactful applications of predictive analytics in manufacturing, helping companies mitigate risks, improve logistics, and enhance overall efficiency. By analyzing data from multiple sources, including supplier performance, transportation networks, and market conditions, predictive analytics provides manufacturers with actionable insights to optimize inventory levels, reduce lead times, and minimize disruptions.

Analysis by End Use Industry:

- Semiconductor and Electronics

- Energy and Power

- Pharmaceutical

- Automobile

- Heavy Metal and Machine Manufacturing

- Others

The semiconductor and electronics industry is a major adopter of predictive analytics, utilizing advanced data modeling to optimize manufacturing processes, improve yield rates, and enhance quality control. Given the high precision required in semiconductor fabrication, predictive analytics helps identify defects in microchips and electronic components before they become critical issues. Additionally, predictive maintenance is widely used in this sector to minimize downtime of highly sophisticated and expensive manufacturing equipment.

The energy and power sector relies heavily on predictive analytics to optimize operations, improve asset management, and enhance energy efficiency. In manufacturing facilities, predictive analytics is used to monitor power consumption patterns, identify inefficiencies, and implement energy-saving strategies. Additionally, energy-intensive industries use predictive maintenance to ensure the reliability of turbines, generators, and other critical infrastructure, reducing unplanned downtime and maintenance costs.

In the pharmaceutical industry, predictive analytics is revolutionizing manufacturing by optimizing production processes, ensuring regulatory compliance, and improving drug quality. By analyzing data from production lines, predictive models can detect potential deviations that may lead to defective batches, thereby reducing waste and improving efficiency. Additionally, predictive analytics plays a key role in supply chain management by forecasting demand for pharmaceutical products, ensuring the timely availability of raw materials, and reducing the risk of shortages.

The automotive industry is experiencing a digital transformation, with predictive analytics playing a crucial role in production optimization, predictive maintenance, and supply chain efficiency. Automotive manufacturers use predictive analytics to monitor assembly line performance, reduce production bottlenecks, and ensure high-quality manufacturing. Additionally, predictive maintenance is widely adopted to prevent unexpected breakdowns in robotic manufacturing systems and machinery.

Heavy metal and machine manufacturing companies are leveraging predictive analytics to improve production efficiency, reduce downtime, and enhance equipment reliability. This industry relies on large-scale machinery that requires continuous monitoring and maintenance to avoid costly disruptions. Predictive maintenance solutions analyze real-time sensor data for identifying early signs of wear and tear, facilitating manufacturers to schedule maintenance proactively and minimize unexpected failures.

Regional Analysis:

- North America

- United States

- Canada

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

In 2024, North America accounted for the largest market share of over 46.0%. One of the most significant trends in the North American market is the increasing use of AI and ML technologies. These tools allow manufacturers to process extensive amounts of historical and real-time data to predict machine failures, optimize production processes, and enhance product quality. AI-driven predictive analytics models continuously learn from data patterns, improving accuracy and efficiency over time. The proliferation of Industrial IoT (IIoT) is another major driver of predictive analytics adoption in North America. IIoT connects manufacturing equipment, sensors, and systems, generating large volumes of real-time data. Predictive maintenance is among the most significant uses of predictive analytics within the manufacturing sector. Conventional maintenance approaches like reactive and preventive maintenance frequently lead to elevated maintenance expenses and unexpected downtime. Predictive analytics tackles these issues by examining equipment performance data to identify early indicators of potential failures. This proactive strategy enables manufacturers to plan maintenance tasks prior to failures happening, thereby increasing the longevity of equipment and lowering repair expenses. In 2024, Environics Analytics (EA) unveiled a number of new improvements to its MobileScapes product line. For the first time ever globally, EA's data scientists have successfully merged SDK data from GPS-enabled applications with cellular network location data to assess human movement. It will emphasize EA's stance in delivering the most precise and extensive mobile movement data for use in marketing and business applications across Canada.

Manufacturing Predictive Analytics Market Regional Takeaways:

United States Manufacturing Predictive Analytics Market Analysis

The United States hold 85.70% share in North America. According to S&P Global, in December 2024, the sale of passenger cars in the US was 3.2 Million SAAR. Therefore, the growing trend in the automobile industry serves as a crucial aspect of boosting the manufacturing predictive analytics market in the United States. As the automotive sector is continuing to evolve because of improvements in EVs and autonomous driving technology, manufacturers are increasingly adopting predictive analytics to optimize production, reduce costs, and improve efficiency. Predictive analytics will enable the automobile manufacturing companies to predict their demand, manage supply chain disruptions, and ensure consistent quality through predictive maintenance and real-time data monitoring. With advanced algorithms and machine learning, manufacturers can optimize schedules, reduce downtime, and boost OEE. In fact, since the U.S. automotive market continues upwardly, predictive analytics will be significantly important for car manufacturers to ensure sustainability in being competitive, upgrading processes, and maintaining a growth volume of new autos.

Europe Manufacturing Predictive Analytics Market Analysis

Europe's semiconductor industry is a significant growth driver for the manufacturing predictive analytics market in the region, accounting for approximately Euro 51 Billion (USD 53.2 Billion) in 2022 and 9.3% of the global market share, as per an industry report. The semiconductor sector is highly complex and requires precise and efficient manufacturing processes to meet global demand. The increased demand for semiconductors has posed stiff challenges in optimizing production while minimizing waste with the applied highest standards of quality in production. Manufacturers in Europe are now using predictive analytics to enable them to streamline supply chains, optimize demand forecasting, and prevent downtime due to machine breakdowns. Predictive maintenance and real-time data analysis efficiently utilize resources for better overall productivity by reducing waste and improving product quality. With the strong position Europe has in the semiconductor industry and the increasing interest in digital transformation, the adoption of predictive analytics should accelerate significantly, which will make the manufacturing sector grow significantly while improving competitiveness in the global market.

Asia Pacific Manufacturing Predictive Analytics Market Analysis

According to an industry report, Asia-Pacific's pharmaceutical market is also expected to grow at 4.2% CAGR during 2022-2027 in the region and China and Japan would lead the market. This is one of the important growth drivers for the manufacturing predictive analytics in the Asian region. The expanded pharmaceutical industry in Asia-Pacific increases the demand for the advanced manufacturing solutions related to the streamlining of the production processes with efficiency and product quality. Predictive analytics is a crucial element in the optimization of production lines, demand forecasting, and the identification of risks in the manufacturing process. In countries like China and Japan, where pharmaceutical manufacturing is growing rapidly, it is important to integrate quality control, predictive maintenance, and supply chain optimization solutions for enhancing the operational performance of the manufacturing system. Predictive analytics allows manufacturers to predict equipment failures, minimize downtime, and reduce operational costs, thus ensuring the timely production of pharmaceutical products. With the growth of the pharmaceutical market, demand for predictive analytics in manufacturing will grow more significantly, forcing innovation and enhancing competitiveness in the region.

Latin America Manufacturing Predictive Analytics Market Analysis

Electric vehicles in Latin America is a fast-emerging focus that is driving the adoption of manufacturing predictive analytics. As per an industry report, the Brazilian government reduced the tax on electric vehicles, cutting the rates from 30% to 15% starting January 2024, and this is going to speed up the adoption of electric vehicles in the region. Additionally, large firms such as General Motors and Volkswagen are investing much, and GM is opening a new production line in São Paulo, which it announced in March 2023 to support the increased demand for electric vehicles. With EV production increasing, manufacturers are employing predictive analytics for optimizing production lines, reducing downtime, and managing supply chains more effectively. Predictive tools allow companies to track the health of their equipment, predict demand, and enhance their operational efficiency. The rise in EV manufacturing in Latin America requires advanced analytics solutions to streamline production, minimize costs, and maximize throughput. It makes predictive analytics the most important tool for improving manufacturing capabilities, hence further boosting growth in this sector in the region.

Middle East and Africa Manufacturing Predictive Analytics Market Analysis

A fast-evolving electric vehicle market in the Middle East and Africa (MEA) region is expected to grow to USD 54 Billion by 2035, as per an industry report. This market will be one of the primary growth drivers for the manufacturing predictive analytics market in the region, as manufacturers increase the scale of electric vehicle production and turn towards predictive analytics for more efficient and performing production lines. Predictive analytics optimizes manufacturing processes, reduces downtime, and improves the quality of EV components, such as batteries and motors, by predicting potential failures before they occur. In addition, the increasing demand for EVs is driving supply chain management advancements, with predictive analytics allowing manufacturers to predict demand, streamline inventory management, and reduce operational costs. Escalating productions of EVs, the growth of IoT and AI in manufacturing process, and wider adoption of predictive analytics are driving the region's growth. As the growth in the MEA is driven by the expanding EV market, the MEA manufacturing industry is more reliant on predictive analytics for cost reduction, operational efficiency, and innovation.

Top Manufacturing Predictive Analytics Companies:

A primary approach adopted by leading companies is the integration of advanced technologies such as ML, IoT and AI into their predictive analytics solutions. For instance, IBM Corporation launched the watsonx.data in 2023, which and spontaneously connect to data, prokaryote trustworthy insights, and lower data warehouse expenses. Optimized for every type of data analytics and AI workloads, watsonx.data amalgamates the simplicity of a data lake with the functionality of a data warehouse, assisting companies to scale data analytics and AI from anywhere. Moreover, to broaden their market reach and enhance solution offerings, key players are actively engaging in strategic partnerships and collaborations. These alliances enable companies to combine expertise, share resources, and deliver comprehensive solutions tailored to the diverse requirements of manufacturers. Mergers and acquisitions (M&A) are prevalent strategies among major players aiming to strengthen their market position and expand their technological capabilities. By acquiring companies with specialized expertise, larger firms can enhance their product portfolios and access innovative technologies.

The report provides a comprehensive analysis of the competitive landscape in the manufacturing predictive analytics market with detailed profiles of all major companies, including:

- Alteryx Inc.

- BRIDGEi2i Analytics

- Cisco Systems Inc.

- Civis Analytics

- FICO

- International Business Machines Corporation

- Microsoft Corporation

- Oracle Corporation

- RapidMiner Inc.

- SAP SE

- SAS Institute Inc.

- TIBCO Software Inc.

Latest News and Developments:

- May 2023: TEKsystems Global Services launched TEKsystems AMPGSTM Modern Manufacturing Analytics, a pre-configured solution for the Manufacturing Data Cloud by Snowflake. This partnership enables manufacturers across various industries to unlock valuable industrial data, driving digital transformation.

- May 2023: Rootstock Software launched the Spring '23 Release, a comprehensive analytics solution specifically designed for manufacturing called Enterprise Insights. With five modules — sales, spend, inventory, manufacturing, and financial analytics - the platform has been engineered to improve an organization's operation and financial decisions.

- February 2023: AVEVA launched the new version of its AVEVA Predictive Analytics software for the predictive monitoring of industrial assets, including in the oil and gas, power, chemicals, mining, and manufacturing industries. The new release will help operators enhance asset reliability, improve workforce productivity, and sustain a more effective environment.

- June 2024: EthonAI unveiled its Manufacturing Analytics Systems (MAS), which is a set of interoperating software applications intended to address the toughest problems that manufacturers are confronted. It assists manufacturers in achieving operational excellence in several use cases, including quality control, root cause analysis, and material flow analysis.

Manufacturing Predictive Analytics Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Components Covered | Software, Services |

| Deployment Modes Covered | Cloud-based, On-premises |

| Applications Covered | Demand Forecasting, Machinery Inspection and Maintenance, Product Development, Supply Chain Management, Others |

| End Use Industries Covered | Semiconductor and Electronics, Energy and Power, Pharmaceutical, Automobile, Heavy Metal and Machine Manufacturing, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Alteryx Inc., BRIDGEi2i Analytics, Cisco Systems Inc., Civis Analytics, FICO, International Business Machines Corporation, Microsoft Corporation, Oracle Corporation, RapidMiner Inc., SAP SE, SAS Institute Inc. and TIBCO Software Inc., etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the manufacturing predictive analytics market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the global manufacturing predictive analytics market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the manufacturing predictive analytics industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The manufacturing predictive analytics market was valued at USD 1,603.98 Million in 2024.

The manufacturing predictive analytics market is projected to exhibit a CAGR of 16.20% during 2025-2033, reaching a value of USD 6,617.41 Million by 2033.

The manufacturing predictive analytics market is driven by the increasing adoption of Industry 4.0, rising demand for operational efficiency, advancements in AI, big data, and ML, growing focus on predictive maintenance, and the need for data-driven decision-making to enhancing the production, reducing downtime, and enhance overall supply chain management.

North America currently dominates the manufacturing predictive analytics market, accounting for a share of 46.0%, driven by advanced industrial automation, strong AI adoption, high investment in smart factories, and robust IoT integration.

Some of the major players in the manufacturing predictive analytics market include Alteryx Inc., BRIDGEi2i Analytics, Cisco Systems Inc., Civis Analytics, FICO, International Business Machines Corporation, Microsoft Corporation, Oracle Corporation, RapidMiner Inc., SAP SE, SAS Institute Inc. and TIBCO Software Inc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)