Laser Marking Machine Market Size, Share, Trends and Forecast by Type, Application, and Region, 2025-2033

Laser Marking Machine Market Size and Share:

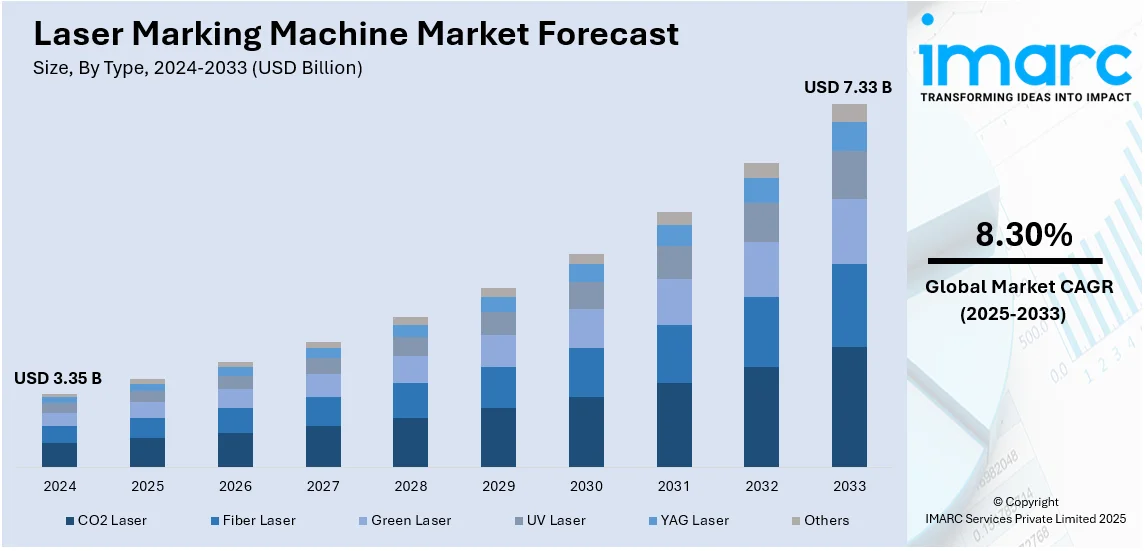

The global laser marking machine market size was valued at USD 3.35 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 7.33 Billion by 2033, exhibiting a CAGR of 8.30% from 2025-2033. Asia Pacific currently dominates the market, holding a market share of over 42.8% in 2024. The market is growing as industries seek high-precision marking solutions, better automation, and stricter product traceability. Innovations in fiber, CO₂, and green-laser technologies are making marking faster and more adaptable to different materials. Expanding product usage in automotive, aerospace, electronics, and medical devices is further driving the product demand, alongside sustainability efforts, thereby driving the laser marking machine market growth.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 3.35 Billion |

| Market Forecast in 2033 | USD 7.33 Billion |

| Market Growth Rate (2025-2033) | 8.30% |

The market for laser marking machines is growing because of the widespread adoption of industrial automation, stringent product traceability compliance, and growing demand in major manufacturing industries. Automotive, aerospace, electronics, and medical equipment industries need precise marking for identification, anti-counterfeiting, and regulatory requirements, thereby contributing to the market growth. Laser technology is more durable, precise, and efficient than conventional marking techniques, and hence it is the preferred option. Technological leaps in green-laser, CO₂, and fiber technologies enhance speed and versatility on various materials, further fueling the laser marking machines market demand. Expansion in the semiconductor market, spurred by increasing global electronic manufacturing, has heightened demand for accurate, non-contact marking technology. The transition to eco-friendly marking technology complements sustainability initiatives by minimizing chemical waste and energy usage.

In the United States, the laser marking machine market is expanding due to robust manufacturing capabilities, regulatory requirements for product authentication, and increasing investment in smart factories. The aerospace and defense sectors rely on laser marking for permanent, high-contrast identification on critical components, ensuring compliance with safety standards. Additionally, medical device manufacturers use laser marking for UDI (Unique Device Identification) labeling, boosting adoption. The rising demand for customized consumer products, including engraved electronics and jewelry, represents one of the key laser marking machine market trends. However, ongoing research into faster, more precise laser marking solutions is further shaping industry growth, with a focus on enhancing efficiency and material versatility. For instance, in December 2024, Videojet Technologies announced the launch of the 7920 UV laser marking system, designed to enhance reliability, flexibility, and ease of use in coding for consumer goods, pharmaceutical, and parts marking industries, featuring smart technology, high-speed marking, and remote connectivity.

Laser Marking Machine Market Trends:

Expansion of Industrial Automation and Market Growth

Rapid industrialization across the globe, along with increasing automation in the manufacturing sector, is one of the key factors driving the growth of the market. According to the Association for Advancing Automation, the Industrial Automation and Control Systems market is estimated at USD 46.4 Million in 2024 and is projected to grow at a CAGR of 10.3%, reaching USD 85.3 Million by 2030. Laser marking machines are widely used across various industries, such as automotive, electronics & semiconductor, medical, aerospace, machine tools, packaging, and construction, for premium-quality custom marking and engraving on materials. This growing demand is contributing to a rise in laser marking machine market size, particularly in automation-driven production environments.

Rising Semiconductor Industry Demand

Rising demand in electronics, automotive, and medical device manufacturing is fueling adoption of advanced laser technologies. The growing semiconductor industry further reinforces this trend, with the Semiconductor Industry Association reporting that the global semiconductor market experienced its highest-ever sales year in 2024, surpassing USD 600 Billion in annual sales, with double-digit growth projected for 2025. As compared to traditional material marking techniques, laser markings are more durable and convenient to read and scan, which is resulting in the increasing demand for marking machines. In line with this, these machines are also used in the automotive industry for engraving serial numbers on tires without altering the tire structure. These developments are positively shaping the laser marking machine market outlook, supported by strong growth in high-precision manufacturing sectors.

Advancements in Laser Marking Technology

Additionally, various technological advancements, such as the development of green-laser marking machines, are acting as other growth-inducing factors. For instance, in May 2024, FOBA announced the launch of the compact UV and green laser marking systems, reducing size and weight by over 50% for easier integration. The lasers offer high-precision marking on plastics, supporting reliable, UDI-compliant processes in medical device production with camera-based verification systems. These innovative machines facilitate high-speed markings on electrical components, microchips, capacitors, and circuit boards with minimal environmental impact. These developments reflect evolving laser marking machine market trends focused on precision, compact design, and sustainability. Other factors, including the rising consumer demand for personalized products, such as jewelry, leather purses, and handbags, along with increasing expenditure capacities of consumers, are anticipated to drive the market further.

Laser Marking Machine Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global laser marking machine market, along with forecast at the global, regional, and country levels from 2025-2033. The market has been categorized based on type and application.

Analysis by Type:

- CO2 Laser

- Fiber Laser

- Green Laser

- UV Laser

- YAG Laser

- Others

Fiber laser stand as the largest type in 2024, holding around 45.3% of the market, owing to its superior performance, reliability, and efficiency across a broad range of industrial applications. It offers high beam quality, longer operational life, and low maintenance requirements, making it ideal for marking metals and high-contrast plastics. Industries such as automotive, electronics, aerospace, and medical devices widely adopt fiber laser systems for marking serial numbers, barcodes, logos, and traceability codes. Additionally, fiber lasers support high-speed marking with minimal heat-affected zones, preserving the structural integrity of the material. The growing demand for precise, permanent, and cost-effective marking solutions continues to drive the expansion of this segment globally.

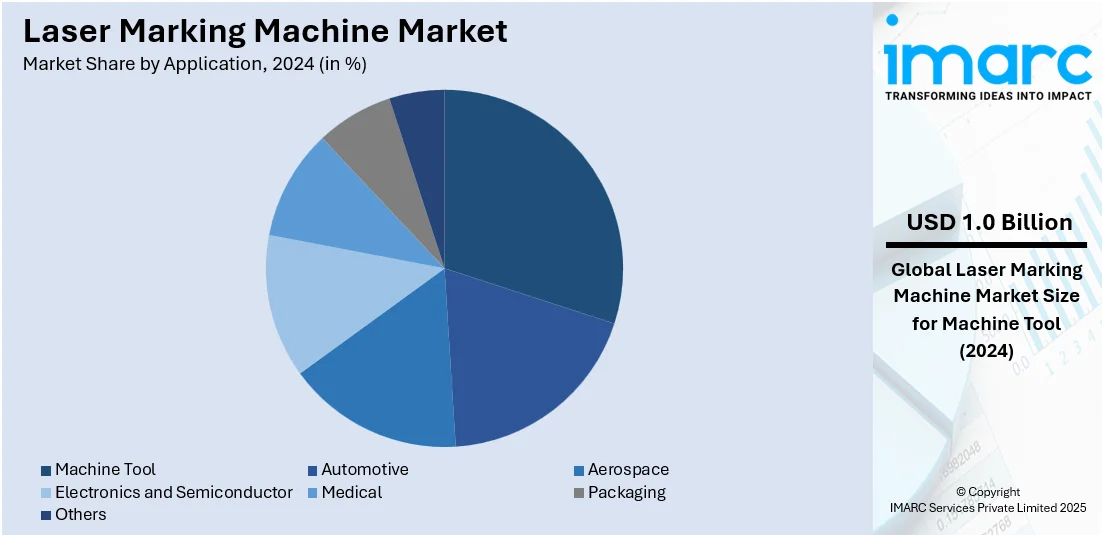

Analysis by Application:

- Automotive

- Aerospace

- Machine Tool

- Electronics and Semiconductor

- Medical

- Packaging

- Others

Machine tool leads the market with around 24.8% of laser marking machine market share in 2024, due to the critical need for durable, high-precision marking on metal components. These machines are extensively used for engraving serial numbers, logos, and traceability codes on equipment and parts in sectors such as automotive, aerospace, and industrial machinery. Laser marking offers significant advantages over conventional methods, including non-contact processing, high-speed operation, and long-lasting marks that withstand harsh conditions. Additionally, the increasing adoption of automation and smart manufacturing practices is boosting the integration of laser marking systems into machine tool production lines. The demand for compliance, quality assurance, and component identification continues to drive growth in this segment globally.

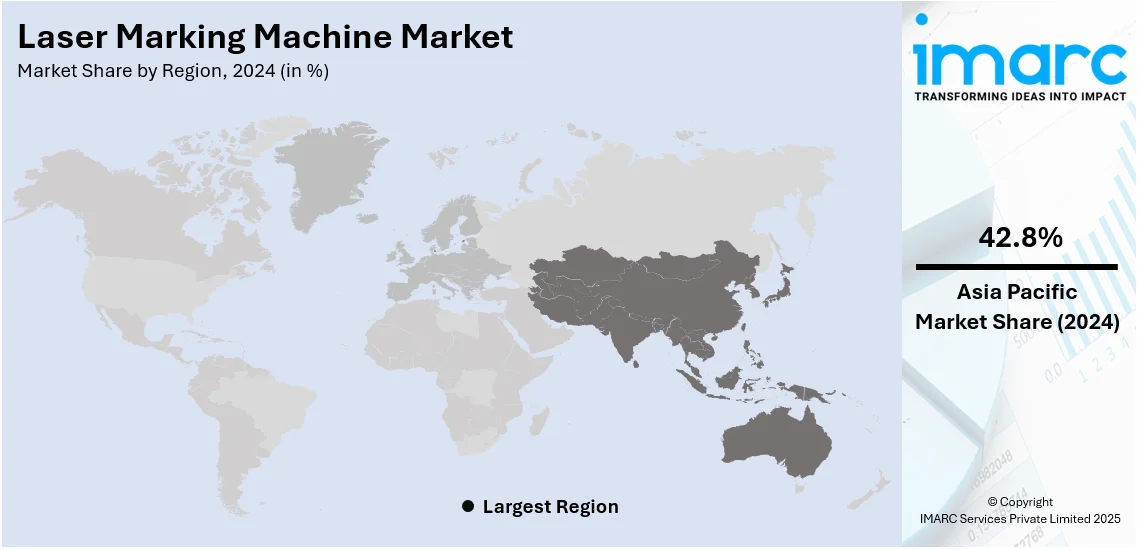

Regional Analysis:

- North America

- United States

- Canada

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

In 2024, Asia-Pacific accounted for the largest market share of over 42.8%, driven by rapid industrialization, strong manufacturing output, and increased adoption of automation technologies. Countries such as China, Japan, South Korea, and India are key contributors due to their robust automotive, electronics, and semiconductor industries. The presence of large-scale production facilities and favorable government policies supporting advanced manufacturing are further accelerating market growth. Additionally, rising demand for product traceability, anti-counterfeiting measures, and permanent marking solutions across sectors such as medical devices and aerospace is reinforcing regional dominance. The availability of cost-effective labor and raw materials also supports large-scale deployment of laser marking systems across diverse industrial applications in the region.

Key Regional Takeaways:

United States Laser Marking Machine Market Analysis

In 2024, United States accounted for 87.60% of the market share in North America. The United States laser marking machine market is experiencing significant growth, driven by the rising demand for permanent and high-precision marking solutions across industries like automotive, electronics, and healthcare. The increasing adoption of advanced manufacturing technologies and the growing need for product traceability and anti-counterfeiting measures are propelling market expansion. Laser marking machines are widely used for engraving barcodes, serial numbers, and logos on materials such as metal, plastic, and glass, ensuring product identification and regulatory compliance. Furthermore, the semiconductor industry is poised to contribute to this growth, with projections indicating that the U.S. will triple its domestic semiconductor manufacturing capacity from 2022 to 2032, as outlined in a report by the Semiconductor Industry Association (SIA) and Boston Consulting Group (BCG). This 203% growth, the largest projected increase globally, will likely boost demand for high-precision and durable marking solutions, particularly for semiconductor components and electronic products. The growing preference for fiber laser marking machines due to their high speed, durability, and energy efficiency will further drive demand in this sector. Additionally, advancements in laser technology, automation, and software integration are enhancing the machines' capabilities, supporting their adoption in medical devices, aerospace, packaging, and semiconductor industries. With ongoing technological innovations and rising industrial automation, the laser marking machine market in the United States is expected to witness steady growth in the coming years.

North America Laser Marking Machine Market Analysis

The North America laser marking machine market is expanding due to increasing industrial automation, stringent product identification regulations, and rising demand in aerospace, automotive, and electronics industries. The region benefits from advanced manufacturing capabilities and high adoption of precision marking technologies. Growth in the semiconductor and medical device sectors further drives demand for high-accuracy engraving solutions. For instance, in April 2024, Laser Photonics Corporation announced that L3Harris Technologies has ordered its LaserTower COMPACT system for use at its semiconductor division in Florida. The system offers precise, permanent marking and easy integration into production lines with user-friendly, plug-and-play functionality. Additionally, advancements in fiber and green-laser marking technologies enhance efficiency and sustainability, reducing environmental impact. The rising trend of personalized consumer products also contributes to market expansion. Investments in R&D and smart manufacturing solutions position North America as a key hub for innovation in laser marking applications.

Europe Laser Marking Machine Market Analysis

The Europe laser marking machine market is expanding steadily, driven by stringent product identification regulations and increasing demand for high-quality marking solutions across various industries. The widespread use of laser marking machines in the automotive, electronics, and packaging sectors is fueling market growth. The region's focus on sustainable manufacturing processes and the rising adoption of fiber and UV laser marking machines for their energy efficiency and eco-friendly characteristics are supporting market expansion. Additionally, the growing emphasis on product traceability and anti-counterfeiting measures is encouraging industries to adopt laser marking technologies. According to reports, counterfeited and pirated products account for about 5% of imports to the EU, which has further accelerated the demand for permanent and tamper-proof marking solutions to enhance product authentication and protect brand integrity. With continuous advancements in laser technology and industrial automation, the laser marking machine market in Europe is expected to experience consistent growth in the coming years.

Asia Pacific Laser Marking Machine Market Analysis

The Asia Pacific laser marking machine market is witnessing rapid growth, driven by the region's expanding electronics, automotive, and packaging industries. The rising demand for high-precision marking systems and the growing trend of industrial automation are key factors supporting market expansion. Countries are adopting fiber laser marking machines due to their efficiency, precision, and low maintenance requirements. The increasing focus on product traceability, counterfeit prevention, and regulatory compliance in manufacturing industries is further boosting demand. Additionally, the booming packaging industry, particularly in countries like India, is contributing to market growth. According to the India Brand Equity Foundation, packaging is currently the 5th largest sector of the Indian economy and is projected to grow at a CAGR of 26.7% to reach USD 204.81 billion by 2025, creating significant demand for laser marking machines for product labeling and branding.

Latin America Laser Marking Machine Market Analysis

The Latin America laser marking machine market is growing steadily, driven by the increasing adoption of automated marking systems in the automotive, electronics, and packaging sectors. The region's rising focus on product identification, branding, and regulatory compliance is boosting demand for laser marking machines as manufacturers seek efficient and high-precision marking solutions. The increasing adoption of factory automation and industrial control systems, particularly in countries like Brazil, is supporting the demand for laser marking machines. According to IMARC Group, Brazil's factory automation and industrial controls market size reached USD 10.5 Billion in 2024 and is projected to reach USD 17.8 Billion by 2033, exhibiting a CAGR of 5.94% during 2025-2033. This trend is encouraging manufacturers to invest in advanced laser marking technologies to enhance production efficiency and traceability.

Middle East and Africa Laser Marking Machine Market Analysis

The Middle East and Africa laser marking machine market is growing due to increasing demand for product identification solutions in the automotive, electronics, and packaging industries. The region's focus on industrial automation and regulatory compliance supports market expansion, with fiber laser marking machines being increasingly adopted for efficiency, precision, and durability. Additionally, the expanding smart manufacturing sector is positively influencing market growth. For instance, Saudi Arabia's smart manufacturing market size reached USD 3,324.9 Million in 2024, and IMARC Group expects it to reach USD 10,974.7 Million by 2033, exhibiting a CAGR of 14.2% during 2025-2033. This shift toward automated and connected systems is driving the demand for advanced laser marking technologies in the region.

Competitive Landscape:

The laser marking machine market is highly competitive, driven by technological advancements, industry-specific customization, and regulatory compliance requirements. Leading manufacturers focus on high-speed, precision marking solutions to meet growing demand in automotive, aerospace, electronics, and medical sectors. Additionally, market players emphasize R&D, strategic partnerships, and automation integration to stay ahead. For instance, in August 2024, Friedrich Daniels announced the acquisition of the Trumpf Micro Mark 1020 and Mark Station 7000 to enhance surgical instrument marking. The system offers precise, ultra-fast laser marking with Data-Matrix code validation and no surface damage, ensuring accuracy and product integrity. The increasing demand for traceability, anti-counterfeiting, and high-resolution engraving further intensifies competition. Moreover, manufacturers are expanding their presence in emerging markets and smart factories to capitalize on growing industrial automation trends. Furthermore, continuous innovation in software-controlled laser marking and AI-driven quality inspection is reshaping the competitive landscape, driving differentiation and market expansion.

The report provides a comprehensive analysis of the competitive landscape in the laser marking machine market with detailed profiles of all major companies, including:

- Epilog Laser

- Gravotech Engineering Pvt. Ltd.

- Han's Laser Technology Industry Group Co. Ltd.

- LaserStar Technologies Corporation

- MECCO

- Sea Force Co. Ltd.

- Telesis Technologies Inc. (Hitachi Industrial Equipment Systems Co. Ltd.)

- Trotec Laser GmbH (Trodat Inc.)

- TYKMA Electrox Inc. (600 Group PLC)

- Videojet Technologies Inc. (Danaher Corporation)

Latest News and Developments:

- September 2024: FOBA introduced its new compact UV laser marking machine at the IMTS 2024 in Chicago, highlighting the lightweight V-Series integrated into the FOBA M1000 workstation. The machine offers higher precision for marking plastics and composites while reducing waste and operating costs, supporting sustainable product identification solutions.

- August 2024: Gravotech, a global leader in laser marking machines and engraving solutions, was acquired by Brady Corporation. The acquisition aimed to expand Gravotech's laser marking machine portfolio across Europe, Asia, and the Americas, aligning with Brady's product identification and traceability solutions business.

Laser Marking Machine Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | CO2 Laser, Fiber Laser, Green Laser, UV Laser, YAG Laser, Others |

| Applications Covered | Automotive, Aerospace, Machine Tool, Electronics and Semiconductor, Medical, Packaging, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Epilog Laser, Gravotech Engineering Pvt. Ltd., Han's Laser Technology Industry Group Co. Ltd., LaserStar Technologies Corporation, MECCO, Sea Force Co. Ltd., Telesis Technologies Inc. (Hitachi Industrial Equipment Systems Co. Ltd.), Trotec Laser GmbH (Trodat Inc.), TYKMA Electrox Inc. (600 Group PLC) and Videojet Technologies Inc. (Danaher Corporation), etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the laser marking machine market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the global laser marking machine market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the laser marking machine industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The laser marking machine market was valued at USD 3.35 Billion in 2024.

IMARC estimates the global dimethyl ether market to reach USD 7.33 Billion in 2033, exhibiting a CAGR of 8.30% during 2025-2033.

The market is driven by growing industrial automation, stricter product traceability regulations, and rising demand in automotive, aerospace, electronics, and medical sectors. Advancements in fiber, CO2, and green-laser technologies improve speed and precision. Increasing focus on anti-counterfeiting, sustainability, and high-quality engraving further accelerates market growth.

Asia Pacific currently dominates the market, holding a market share of over 42.8% in 2024. This leadership is driven by strong manufacturing growth, rising industrial automation, and expanding electronics and automotive sectors. The region is also benefits from cost-effective production, advanced infrastructure, and increasing demand for high-precision marking solutions across diverse industries.

Some of the major players in the laser marking machine market include Epilog Laser, Gravotech Engineering Pvt. Ltd., Han's Laser Technology Industry Group Co. Ltd., LaserStar Technologies Corporation, MECCO, Sea Force Co. Ltd., Telesis Technologies Inc. (Hitachi Industrial Equipment Systems Co. Ltd.), Trotec Laser GmbH (Trodat Inc.), TYKMA Electrox Inc. (600 Group PLC) and Videojet Technologies Inc. (Danaher Corporation), etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)