Japan Tooling Market Report by Product Type (Dies and Molds, Forging, Jigs and Fixtures, Machines Tools, Gauges), Material Type (Stainless Steel, Iron, Aluminum, and Others), End Use Industry (Automotive, Electronics and Electrical, Aerospace, Marine, and Defense, Plastics Industry, Construction and Mining, and Others), and Region 2025-2033

Market Overview:

The Japan tooling market size reached USD 14.7 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 27.2 Billion by 2033, exhibiting a growth rate (CAGR) of 6.4% during 2025-2033. The growing focus on developing tools and processes that reduce waste, energy consumption, and environmental impact, increasing demand for automated and ergonomic tools, and rising construction of residential, commercial, and industrial infrastructure represent some of the key factors driving the market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024 |

| Market Size in 2024 | USD 14.7 Billion |

| Market Forecast in 2033 | USD 27.2 Billion |

| Market Growth Rate (2025-2033) | 6.4% |

Tooling refers to the collection of tools, equipment, machinery, and related components used in various industries and manufacturing processes. It comprises wrenches, hammers, screwdrivers, drills, saws, milling cutters, and lathe tools. It plays a vital role in streamlining production, improving efficiency, and ensuring consistent quality. Tooling encompasses a wide range of tools, from simple handheld devices to complex automated machinery. It enables mass production by automating repetitive tasks, reducing labor costs, and increasing productivity. It is crucial for maintenance and repair activities across industries. It allows technicians and engineers to diagnose, disassemble, repair, and reassemble machinery, equipment, and structures efficiently. Tooling ensures consistent and high-quality output by providing precise control over manufacturing processes. It helps in maintaining tight tolerances, reducing defects, and meeting customer specifications consistently. It also helps in cost reduction by optimizing processes, reducing scrap and rework, and enhancing resource utilization. It is extensively used in manufacturing processes to shape, cut, drill, and assemble various materials, such as metal, wood, plastic, and composites. Furthermore, as it streamlines manufacturing workflows and eliminates inefficiencies, resulting in significant cost savings, the demand for tooling is rising in Japan.

Japan Tooling Market Trends:

At present, the increasing demand for tooling, as it contributes to higher production rates, reduced lead times, and improved quality, making businesses more competitive, represents one of the crucial factors influencing the market positively in Japan. Moreover, the rising adoption of advanced manufacturing technologies, such as automation, robotics, and artificial intelligence (AI), is strengthening the growth of the market. Apart from this, the growing focus on developing tools and processes that reduce waste, energy consumption, and environmental impact is offering a positive market outlook. Additionally, the rising digitalization of tooling processes for optimizing production cycles, and facilitating predictive maintenance, leading to cost savings and improved operational efficiency, is offering lucrative growth opportunities to investors in Japan. In line with this, the increasing demand for automated and ergonomic tools that can assist workers in their tasks, ensuring productivity and reducing the risk of injuries, is impelling the market growth. Besides this, the rising trend of nearshoring and reshoring of manufacturing activities is propelling the growth of the market in the country. In addition, the increasing construction of residential, commercial, and industrial infrastructure is bolstering the growth of the market. Furthermore, the rising availability of training programs to help ensure proper handling, maintenance, and troubleshooting of tools is contributing to the growth of the market in Japan.

Japan Tooling Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the Japan tooling market report, along with forecasts at the country level for 2025-2033. Our report has categorized the market based on product type, material type, and end use industry.

Product Type Insights:

- Dies and Molds

- Forging

- Jigs and Fixtures

- Machines Tools

- Gauges

The report has provided a detailed breakup and analysis of the market based on the product type. This includes dies and molds, forging, jigs and fixatures, machines tools, and gauges.

Material Type Insights:

- Stainless Steel

- Iron

- Aluminum

- Others

A detailed breakup and analysis of the market based on the material type has also been provided in the report. This includes stainless steel, iron, aluminum, and others.

End Use Industry Insights:

- Automotive

- Electronics and Electrical

- Aerospace, Marine, and Defense

- Plastics Industry

- Construction and Mining

- Others

A detailed breakup and analysis of the market based on the end use industry has also been provided in the report. This includes automotive, electronics and electrical, aerospace, marine, and defense, plastics industry, construction and mining, and others.

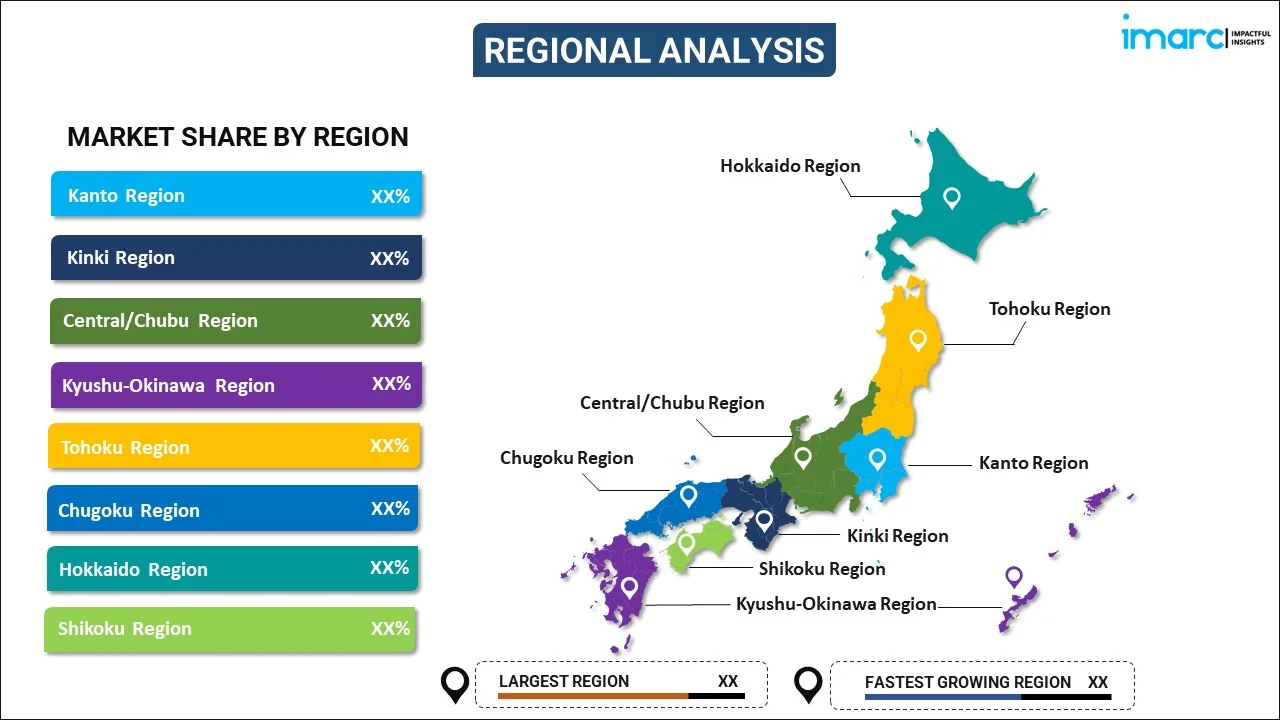

Regional Insights:

- Kanto Region

- Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto region, Kinki region, Central/Chubu Region, Kyushu-Okinawa region, Tohoku region, Chugoku region, Hokkaido region, and Shikoku region.

Competitive Landscape:

The report has also provided a comprehensive analysis of the competitive landscape in the Japan tooling market. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Tooling Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical and Forecast Trends, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Product Types Covered | Dies and Molds, Forging, Jigs and Fixtures, Machines Tools, Gauges |

| Material Types Covered | Stainless Steel, Iron, Aluminum, Others |

| End Use Industries Covered | Automotive, Electronics and Electrical, Aerospace, Marine, and Defense, Plastics Industry, Construction and Mining, Others |

| Regions Covered | Kanto Region, Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan tooling market performed so far and how will it perform in the coming years?

- What has been the impact of COVID-19 on the Japan tooling market?

- What is the breakup of the Japan tooling market on the basis of product type?

- What is the breakup of the Japan tooling market on the basis of material type?

- What is the breakup of the Japan tooling market on the basis of end use industry?

- What are the various stages in the value chain of the Japan tooling market?

- What are the key driving factors and challenges in the Japan tooling market?

- What is the structure of the Japan tooling market and who are the key players?

- What is the degree of competition in the Japan tooling market?

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan tooling market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the Japan tooling market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan tooling industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)