Japan Injection Molded Plastics Market Report by Raw Material (Polypropylene (PP), Acrylonitrile Butadiene Styrene (ABS), High-Density Polyethylene (HDPE), Polystyrene (PS), and Others), Application (Packaging, Consumables and Electronics, Automotive and Transportation, Building and Construction, Medical, and Others), and Region 2026-2034

Market Overview:

Japan injection molded plastics market size reached USD 19,263.4 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 26,174.3 Million by 2034, exhibiting a growth rate (CAGR) of 3.47% during 2026-2034. The increasing demand for lightweight and durable materials, which are utilized for a wide range of applications in industries, such as automotive, aerospace, and consumer goods, is driving the injection molded plastics market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 19,263.4 Million |

| Market Forecast in 2034 | USD 26,174.3 Million |

| Market Growth Rate 2026-2034 | 3.47% |

Injection molded plasticsare a versatile and widely used method of manufacturing a vast array of products across numerous industries. This process involves melting plastic pellets until they become malleable enough to be injected under pressure into a mold, which is a hollow cavity of the desired shape. Once in the mold, the plastic is allowed to cool and solidify, forming a precise and highly reproducible part. The strength of this technique lies in its efficiency and ability to produce complex shapes with great accuracy, often integrating multiple components into a single piece. Materials used in injection molding are diverse, ranging from common plastics like polyethylene and PVC to engineering plastics like polycarbonate and polyamide. Applications are virtually limitless, encompassing items from automotive components and medical devices to household products and toys. The technology’s precision helps to reduce waste material, contributing to its popularity in today’s cost-conscious and environmentally aware manufacturing landscape.

Japan Injection Molded Plastics Market Trends:

The injection molded plastics market in Japan is experiencing robust growth, driven by several key factors. Firstly, the increasing demand for lightweight and durable materials across various industries has propelled the market forward. Moreover, the automotive sector, in particular, has been a significant driver, with automakers opting for injection molded plastics to reduce vehicle weight and enhance fuel efficiency. Additionally, the healthcare industry's growing need for precision components and packaging solutions has spurred the adoption of injection molded plastics due to their versatility and cost-effectiveness. Furthermore, environmental concerns have played a pivotal role in the market's expansion. The push for eco-friendly materials has led to a surge in bio-based and recycled plastics, aligning with sustainability goals. Moreover, the inherent design flexibility of injection molding has made it a preferred choice for manufacturers seeking intricate and customized products, further fueling market growth. Apart from this, numerous technological advancements, such as 3D printing and Industry 4.0 integration, which continue to enhance production efficiency and quality, are expected to drive the injection molded plastics market in Japan during the forecast period.

Japan Injection Molded Plastics Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2026-2034. Our report has categorized the market based on raw material and application.

Raw Material Insights:

- Polypropylene (PP)

- Acrylonitrile Butadiene Styrene (ABS)

- High-Density Polyethylene (HDPE)

- Polystyrene (PS)

- Others

The report has provided a detailed breakup and analysis of the market based on the raw material. This includes polypropylene (PP), acrylonitrile butadiene styrene (abs), high-density polyethylene (HDPE), polystyrene (PS), and others.

Application Insights:

- Packaging

- Consumables and Electronics

- Automotive and Transportation

- Building and Construction

- Medical

- Others

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes packaging, consumables and electronics, automotive and transportation, building and construction, medical, and others.

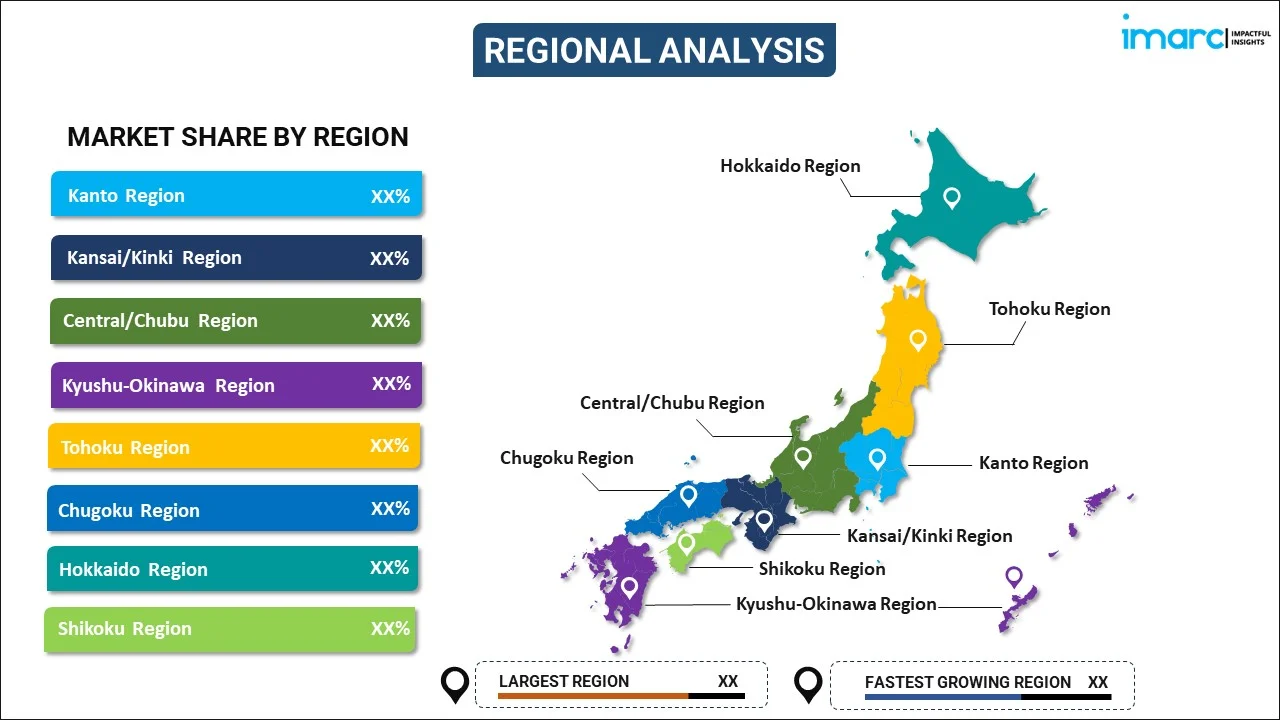

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Injection Molded Plastics Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical and Forecast Trends, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Raw Materials Covered | Polypropylene (PP), Acrylonitrile Butadiene Styrene (ABS), High-Density Polyethylene (HDPE), Polystyrene (PS), Others |

| Applications Covered | Packaging, Consumables and Electronics, Automotive and Transportation, Building and Construction, Medical, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan injection molded plastics market performed so far and how will it perform in the coming years?

- What has been the impact of COVID-19 on the Japan injection molded plastics market?

- What is the breakup of the Japan injection molded plastics market on the basis of raw material?

- What is the breakup of the Japan injection molded plastics market on the basis of application?

- What are the various stages in the value chain of the Japan injection molded plastics market?

- What are the key driving factors and challenges in the Japan injection molded plastics?

- What is the structure of the Japan injection molded plastics market and who are the key players?

- What is the degree of competition in the Japan injection molded plastics market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan injection molded plastics market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan injection molded plastics market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan injection molded plastics industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)