Japan Engineering Plastics Market Report by Resin Type (Fluoropolymer, Liquid Crystal Polymer (LCP), Polyamide (PA), Polybutylene Terephthalate (PBT), Polycarbonate (PC), Polyether Ether Ketone (PEEK), Polyethylene Terephthalate (PET), Polyimide (PI), Polymethyl Methacrylate (PMMA), Polyoxymethylene (POM), Styrene Copolymers (ABS and SAN)), End Use Industry (Aerospace, Automotive, Building and Construction, Electrical and Electronics, Industrial and Machinery, Packaging, and Others), and Region 2026-2034

Market Overview:

Japan engineering plastics market size reached USD 7,669.7 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 12,228.6 Million by 2034, exhibiting a growth rate (CAGR) of 5.32% during 2026-2034. The increasing emphasis on innovation and high-quality manufacturing processes, along with the continuous advancements in polymer technology, is primarily driving the market growth.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 7,669.7 Million |

| Market Forecast in 2034 | USD 12,228.6 Million |

| Market Growth Rate (2026-2034) | 5.32% |

Engineering plastics are typically employed in the creation of mechanical components, packaging materials, and containers. They are often chosen over metals and ceramics due to their lightweight nature. In addition to this, engineering plastics offer exceptional load-bearing capability, mechanical robustness, thermal resilience, and longevity, along with the flexibility in design. Several prevalent variants of engineering plastics are polyamides (PA), polycarbonates (PC), nylon 6, acrylonitrile butadiene styrene (ABS), and polysulphone (PSU). These materials find extensive applications in fabricating items like car bumpers, dashboard accents, ski boots, helmets, and optical discs, serving a myriad of industries.

Japan Engineering Plastics Market Trends:

The engineering plastics market in Japan is emblematic of the nation’s profound engagement with innovative industrial materials, exemplifying a synergy between advanced technology and diverse application needs. Additionally, engineering plastics, characterized by their superior mechanical properties, durability, and thermal stability, are pivotal in manufacturing a range of products including mechanical parts and packaging materials. These plastics are lauded as advantageous alternatives to metals and ceramics, primarily owing to their lightweight attributes and design flexibility. Variants such as polyamides (PA), polycarbonates (PC), nylon 6, acrylonitrile butadiene styrene (ABS), and polysulphone (PSU) are extensively integrated into multiple sectors in Japan. Besides this, they are instrumental in the production of items like car bumpers, dashboard trims, ski boots, helmets, and optical discs, underlining the material's versatile application. Moreover, the escalating demand for engineering plastics in Japan is fueled by the relentless pursuit of lightweight and durable materials, especially in the automotive and electronics sectors. The market is witnessing continual growth, driven by the incorporation of these plastics in innovative manufacturing practices and the ongoing developments in polymer technology. Furthermore, the prevalent culture of technological precision and high-quality manufacturing standards in Japan augments the adoption of engineering plastics, fostering the exploration of new applications and enhancing the efficiency and functionality of products across various industries, which in turn, is expected to catalyze the regional market in the coming years.

Japan Engineering Plastics Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2026-2034. Our report has categorized the market based on resin type and end use industry.

Resin Type Insights:

To get more information on this market, Request Sample

- Fluoropolymer

- Ethylenetetrafluoroethylene (ETFE)

- Fluorinated Ethylene-Propylene (FEP)

- Polytetrafluoroethylene (PTFE)

- Polyvinylfluoride (PVF)

- Polyvinylidene Fluoride (PVDF)

- Others

- Liquid Crystal Polymer (LCP)

- Polyamide (PA)

- Aramid

- Polyamide (PA) 6

- Polyamide (PA) 66

- Polyphthalamide

- Polybutylene Terephthalate (PBT)

- Polycarbonate (PC)

- Polyether Ether Ketone (PEEK)

- Polyethylene Terephthalate (PET)

- Polyimide (PI)

- Polymethyl Methacrylate (PMMA)

- Polyoxymethylene (POM)

- Styrene Copolymers (ABS and SAN)

The report has provided a detailed breakup and analysis of the market based on the resin type. This includes fluoropolymer (ethylenetetrafluoroethylene (ETFE), fluorinated ethylene, propylene (FEP), polytetrafluoroethylene (PTFE), polyvinylfluoride (PF), polyvinylidene, fluoride (PYDF), and others), liquid crystal polymer (LCP), polyamide (PA) (aramid, polyamide (PA) 6, polyamide (PA) 66, polyphthalamide), polybutylene terephthalate (PBT), polycarbonate (PC), polyether ether ketone (PEEK), polyethylene terephthalate (PET), polyimide (PI), polymethyl methacrylate (PMMA), polyoxymethylene (POM), and styrene copolymer (ABS and SAN).

End Use Industry Insights:

- Aerospace

- Automotive

- Building and Construction

- Electrical and Electronics

- Industrial and Machinery

- Packaging

- Others

A detailed breakup and analysis of the market based on the end use industry have also been provided in the report. This includes aerospace, automotive, building and construction, electrical and electronics, industrial and machinery, packaging, and others.

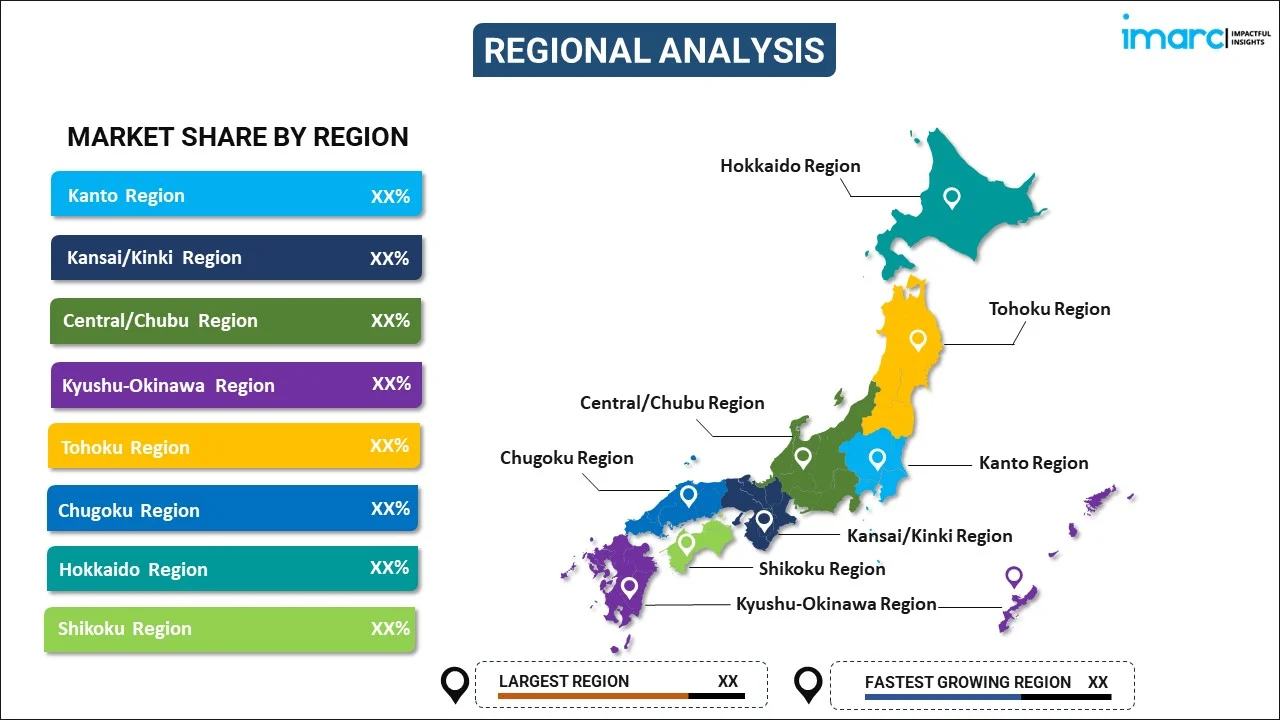

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape in the market. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided. Some of the key players include:

- Kureha Corporation

- Sumitomo Chemical Co. Ltd.

- Teijin Limited

- UBE Corporation

(Please note that this is only a partial list of the key players, and the complete list is provided in the report.)

Japan Engineering Plastics Market News:

- July 2025: Mitsubishi Chemical Corporation (MCC) and ENEOS, oil and petrochemical firms, have initiated a facility that utilizes Mura Technology’s water-based recycling method to transform used plastic into oil for creating new chemicals and plastic items.

- April 2025: Mitsubishi Chemical Corporation proclaimed that its bio-based engineering plastic DURABIOTM has been chosen as a primary material for 3D-printed “algae stools” by the “Sokaku” Co-Creation Project, a key Partner of the Japan Pavilion for Expo 2025 Osaka, Kansai, Japan, which commenced on April 13, 2025. Crafted from a mixture of algae and DURABIO™, the stool showcases an elegant design and gradient hues.

- April 2024: A group of Japanese scientists announced that they have created a new bioplastic that is both strong and quickly breaks down in seawater, while also being suitable for mass production. The study conducted by researchers at Kobe University and additional institutions raises optimism that plastic pollution in the world's oceans could eventually be eliminated.

Japan Engineering Plastics Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical and Forecast Trends, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Resin Types Covered |

|

| End Use Industries Covered | Aerospace, Automotive, Building and Construction, Electrical and Electronics, Industrial and Machinery, Packaging, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Companies Covered | Kureha Corporation, Sumitomo Chemical Co. Ltd., Teijin Limited, UBE Corporation, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan engineering plastics market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan engineering plastics market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan engineering plastics industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The engineering plastics market in Japan was valued at USD 7,669.7 Million in 2025.

The Japan engineering plastics market is projected to exhibit a CAGR of 5.32% during 2026-2034, reaching a value of USD 12,228.6 Million by 2034.

The Japan engineering plastics market is driven by factors such as increasing demand for lightweight materials in automotive and electronics industries, advancements in material performance, rising focus on sustainability, and the growing adoption of engineering plastics in various applications due to their high strength, durability, and heat resistance.

Some of the major players in the Japan engineering plastics market include Kureha Corporation, Sumitomo Chemical Co. Ltd., Teijin Limited, UBE Corporation, etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)