Japan Blister Packaging Market Report by Product Type (Carded, Clamshell), Raw Material (Polyvinyl Chloride (PVC), Aclar, Polyvinylidene Chloride (PVDC), Cyclic Olefin Copolymer (COC), Polypropylene (PP)), Technology (Thermoforming, Cold Forming), End Use (Healthcare, Consumer Goods, Industrial Goods, Food), and Region 2026-2034

Market Overview:

Japan blister packaging market size reached USD 953.3 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 1,286.8 Million by 2034, exhibiting a growth rate (CAGR) of 3.39% during 2026-2034. The rapid growth of the pharmaceutical sector across the country, stringent safety regulations regarding product safety and consumer welfare, and continuous advancements in sustainable materials and packaging technology represent some of the key factors driving the market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 953.3 Million |

| Market Forecast in 2034 | USD 1,286.8 Million |

| Market Growth Rate 2026-2034 | 3.39% |

Access the full market insights report Request Sample

Blister packaging is a prominent method for packing consumer goods, pharmaceuticals, and other products. Consisting of a pre-formed plastic shell, this packaging format effectively encloses the product from the front. A paperboard or aluminum foil then seals the product from the back. Due to its design, blister packaging offers excellent product visibility and display attributes. In the pharmaceutical industry, it is extensively employed for unit-dose packaging of pills, capsules, and lozenges. This packaging approach enhances product integrity and extends shelf life by providing a barrier against external elements like moisture, light, and oxygen. Moreover, it is an ideal choice for tamper-evident packaging, as any tampering becomes immediately evident. In consumer goods, manufacturers are increasingly adopting blister packaging for small, fragile items. The method enables easy handling, storage, and transportation owing to its compact form and robust construction. It also allows for cost-efficient, high-speed automation during the packaging process, which is vital for large-scale production. As a result, blister packaging is gaining immense traction for its capability to offer product protection, display aesthetics, and manufacturing efficiency, catering to a wide range of industries.

Japan Blister Packaging Market Trends:

The Japan blister packaging market is currently experiencing growth propelled by various factors. One of the primary drivers is the expanding pharmaceutical sector in Japan, where an aging population necessitates an increasing demand for medicines. Moreover, the Japanese populace is becoming more health-conscious, further fueling the need for safe and reliable packaging methods. Blister packaging ensures product integrity and offers a barrier against environmental conditions, making it a preferred choice for unit-dose medications. In addition to pharmaceuticals, the rise in consumer electronics manufacturing represents another major growth-inducing factor. With Japan being a hub for high-quality electronics, blister packaging is increasingly being used for small components, ensuring protection against damage and contamination. This form of packaging is particularly beneficial for products that are sensitive to moisture, light, and other environmental factors. Besides this, the country's stringent regulations concerning product safety and consumer welfare also play a pivotal role. These regulations mandate that packaging be tamper-evident and child-resistant, both of which are attributes inherent to blister packaging. Compliance with these rules is driving companies to opt for this type of packaging, thus stimulating market growth. Furthermore, the evolution in retail formats, such as the rapid growth of supermarkets and convenience stores across Japan, has led to a heightened need for shelf-ready packaging solutions. Blister packaging allows for excellent product visibility and aesthetic appeal, which is essential for capturing consumer attention in a retail setting. In line with this, environmental concerns have resulted in innovations in recyclable and biodegradable materials for blister packs, making them more eco-friendly, which aligns with Japan's sustainability goals. Also, technological advancements in packaging machinery are enabling faster, more efficient production processes. This efficiency is crucial for meeting the rising demand and is, therefore, accelerating market growth.

Japan Blister Packaging Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2026-2034. Our report has categorized the market based on product type, raw material, technology, and end use.

Product Type Insights:

To get detailed segment analysis of this market Request Sample

- Carded

- Clamshell

The report has provided a detailed breakup and analysis of the market based on the product type. This includes carded and clamshell.

Raw Material Insights:

- Polyvinyl Chloride (PVC)

- Aclar

- Polyvinylidene Chloride (PVDC)

- Cyclic Olefin Copolymer (COC)

- Polypropylene (PP)

A detailed breakup and analysis of the market based on the raw material have also been provided in the report. This includes polyvinyl chloride (PVC), aclar, polyvinylidene chloride (PVDC), cyclic olefin copolymer (COC), and polypropylene (PP).

Technology Insights:

- Thermoforming

- Cold Forming

The report has provided a detailed breakup and analysis of the market based on the technology. This includes thermoforming and cold forming.

End Use Insights:

- Healthcare

- Consumer Goods

- Industrial Goods

- Food

A detailed breakup and analysis of the market based on the end use have also been provided in the report. This includes healthcare, consumer goods, industrial goods, and food.

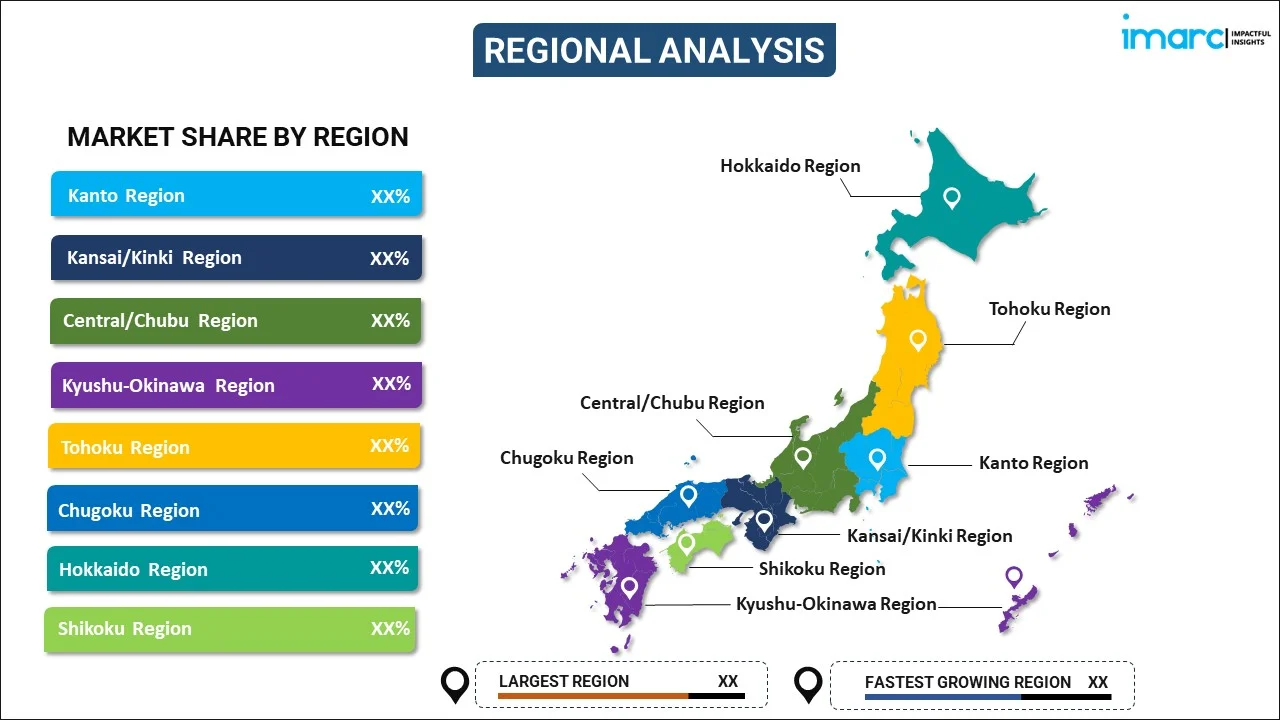

Regional Insights:

To get detailed regional analysis of this market Request Sample

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Blister Packaging Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical and Forecast Trends, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Product Types Covered | Carded, Clamshell |

| Raw Materials Covered | Polyvinyl Chloride (PVC), Aclar, Polyvinylidene Chloride (PVDC), Cyclic Olefin Copolymer (COC), Polypropylene (PP) |

| Technologies Covered | Thermoforming, Cold Forming |

| End Uses Covered | Healthcare, Consumer Goods, Industrial Goods, Food |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan blister packaging market performed so far and how will it perform in the coming years?

- What has been the impact of COVID-19 on the Japan blister packaging market?

- What is the breakup of the Japan blister packaging market on the basis of product type?

- What is the breakup of the Japan blister packaging market on the basis of raw material?

- What is the breakup of the Japan blister packaging market on the basis of technology?

- What is the breakup of the Japan blister packaging market on the basis of end use?

- What are the various stages in the value chain of the Japan blister packaging market?

- What are the key driving factors and challenges in the Japan blister packaging?

- What is the structure of the Japan blister packaging market and who are the key players?

- What is the degree of competition in the Japan blister packaging market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan blister packaging market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan blister packaging market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan blister packaging industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)