Japan Ball Bearing Market Size, Share, Trends and Forecast by Application and Region, 2025-2033

Japan Ball Bearing Market 2024 Size and Share:

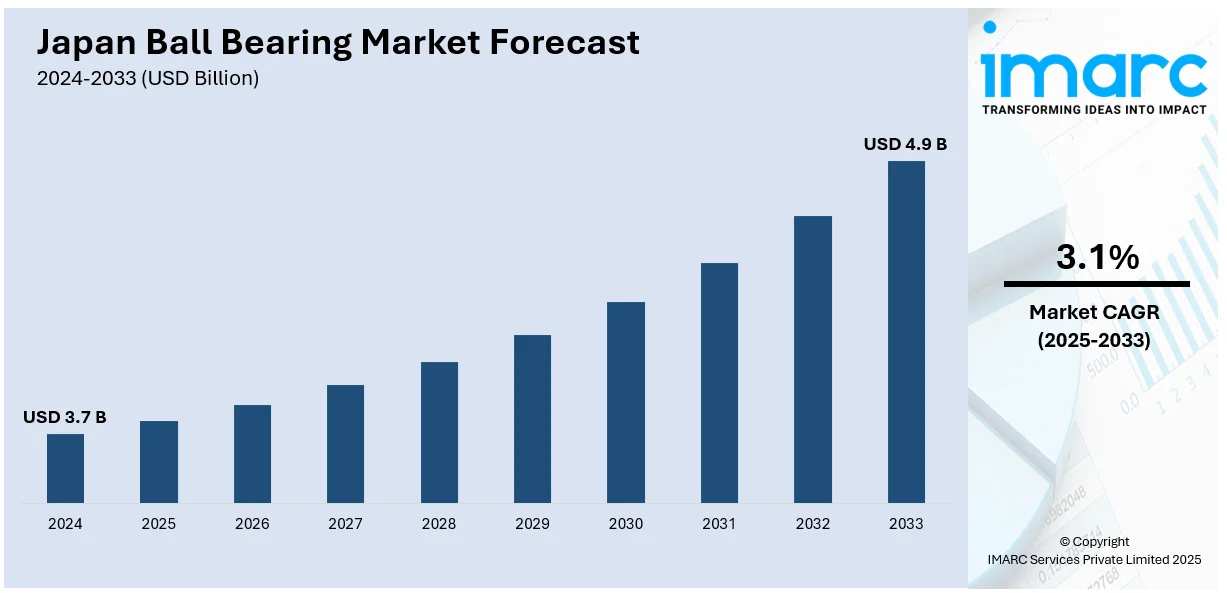

The Japan ball bearing market size was valued at USD 3.7 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 4.9 Billion by 2033, exhibiting a CAGR of 3.1% from 2025-2033. The Japan ball bearing market is driven by factors such as increasing demand from the automotive industry for improved fuel efficiency, rising adoption of precision bearings in robotics and automation, growth in renewable energy projects, innovations in bearing technologies, and the integration of IoT-enabled solutions for enhanced operational efficiency and predictive maintenance.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 3.7 Billion |

| Market Forecast in 2033 | USD 4.9 Billion |

| Market Growth Rate (2025-2033) | 3.1% |

The market in Japan is primarily being driven by the growing requirement from the automotive industry, focusing on improving fuel efficiency and reducing friction in mechanical systems. Additionally, the increasing precision bearing adoption in robotics and automation industries is also supporting the market's expansion. Moreover, growing renewable energy project demands, particularly wind turbines, are driving up the demand for high-performance ball bearings. For instance, the country's efforts to decarbonize are increasing the deployment of wind turbines, each requiring precision bearings. Renewable energy projects saw a 10% increase in capacity installations in 2024, thereby bolstering demand for advanced bearing technologies. Also, developments in bearing materials and manufacturing technologies are providing better durability and reliability, leading to the growth of the market.

The market is also driven by the increasing interest in industrial machinery upgrades that require smooth operations and energy efficiency in ball bearings. For instance, On April 5, 2024, JTEKT Corporation announced its latest advancements in bearing technology, focusing on enhanced environmental performance and energy efficiency. The company unveiled new product developments, including low-torque bearings designed to reduce energy consumption, catering to the rising demand for industrial solutions that are sustainable. These innovations reflect JTEKT's commitment to contributing to a carbon-neutral society by addressing contemporary industry needs while aligning with global sustainability goals. In addition, the investment in research and development activities by key manufacturers is also encouraging innovation, which helps the market to grow steadily. Apart from this, the integration of smart technologies, such as IoT-enabled bearings, allows for real-time monitoring and predictive maintenance and is thereby propelling the market.

Japan Ball Bearing Market Trends:

Integration of smart bearings

The market in Japan is driven by the escalating trend towards intelligent bearings integrated with IoT sensors. Such smart bearings monitor operational parameters such as temperature, vibration, and rotational speed in real-time. For instance, Kashima Bearings produces miniature and small-sized ball bearings that are increasingly important for information equipment, miniaturization, and weight reduction. These bearings are used in applications such as fishing reels, medical instruments, and PCs, where rotational accuracy is prioritized. Primarily made of plastic, these bearings have advantages such as lubrication-free operation and resistance to corrosion, making them suitable for environments unsuitable for metal bearings. Moreover, this trend is improving the operational efficiency of machinery so that it can perform at optimal levels. Apart from this, the growing demand for predictive maintenance solutions that minimize downtime and costs incurred for repairs is increasing the adoption by industries such as automotive and manufacturing. The intelligent bearings are allowing industries to adapt to Industry 4.0 practices, thereby highly changing the traditional workflows and also leading to market growth.

Lightweight and High-Performance Materials

The market emphasizes the development of ball bearings, especially using lightweight materials. Such materials include ceramics and advanced composites, which hold more strength, durability against heat and corrosion, respectively. This trend supports other industries such as aerospace when performance and weight reduction need to be crucial. Moreover, ongoing technological advancements in material science is pushing manufacturers in designing bearings with longer and more precise life expectancies, which is supportive of the growing demand in energy-efficient solutions. For instance, NTN has developed large diameter deep groove ball bearings for coaxial e-Axles in electric vehicles, engineered to run at high speed and low torque. The product offers more than 50% lower torque than standard products, and it is resistant to electrical pitting, which enhances efficiency. The company will roll out the product globally because of the increasing demand for compact, lightweight, and efficient driving sources in EVs and improving cruising distance.

Growth in the Electric Vehicle (EV) Market

With the increasing demand of electric vehicle (EV) market in Japan, there is huge demand for advanced ball bearings to make EVs efficient enough with reduced energy losses to enable superior drivetrain performance. More investments in the mass production of EVs along with policies from the government continue to encourage innovation in customized bearings for high-speed applications with low noise. For instance, NSK has designed a low-friction hub unit bearing that reduces friction by 40% to increase the efficiency of electric vehicles. It could, therefore, potentially extend annual driving distances by 1,000 kilometers. This innovation utilizes advanced seal technologies such as laser processing and low-viscosity seal grease. NSK is targeting global sales of 20 billion yen by 2026, and the focus is on the electric vehicle market to encourage the adoption of this product. This also fits in with the growing forces of sustainability and thus charges manufacturers to conceive unique bearing designs for electric powertrains and battery systems.

Japan Ball Bearing Industry Segmentation:

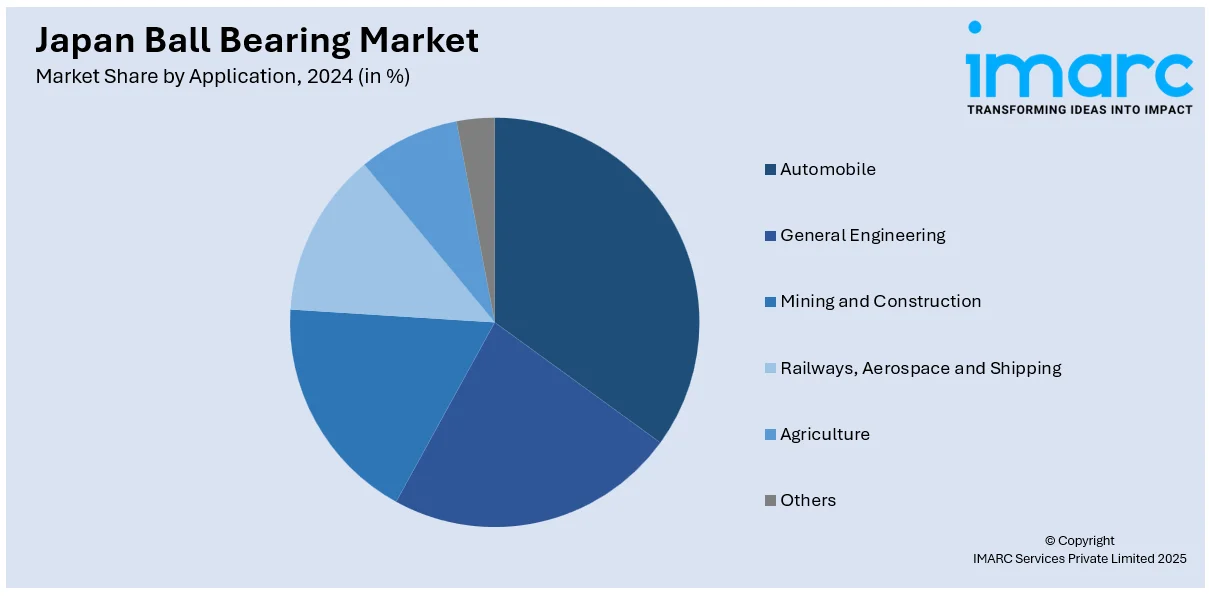

IMARC Group provides an analysis of the key trends in each segment of the Japan ball bearing market, along with forecasts at the country and regional levels from 2025-2033. The market has been categorized based on application.

Analysis by Application:

- Automobile

- General Engineering

- Mining and Construction

- Railways, Aerospace and Shipping

- Agriculture

- Others

Automobile industry plays a crucial role in the ball bearing market in Japan as it ensures smooth rotation in key vehicle components such as engines, transmissions, and wheels. The bearings reduce friction, improve fuel efficiency, and improve the overall lifespan and performance of vehicles. Their importance is amplified as automakers focus on the development of electric vehicles, where precision and durability are paramount.

General engineering plays a vital role in the market as it is necessary for machinery with precise movement under heavy loads and at high speeds. Their role in industries such as robotics, manufacturing, and automation calls for minimal friction and low maintenance. The demand for innovative, high-performance bearings remains on the rise as more industries focus on increased productivity and reliability.

Heavy machinery such as crushers, conveyors, and excavators play a crucial role in the market for their smooth running. The mining and construction industries thus rely very heavily on them. In industries where equipment performs under the most extreme conditions, it's necessary that ball bearings ensure that there is durability in high-performance equipment and for long-term functionality in critical equipment. The ability to reduce friction in harsh conditions will help support efficient and safe operation of the mining and construction industry.

Regional Analysis:

- Kanto Region

- Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The Kanto Region is a crucial area in the ball bearing market in Japan due to its strong industrial base, with the hubs of Tokyo and Yokohama being key manufacturing centers for the automotive and machinery industries. Advanced infrastructure and proximity to major port facilities foster efficient production and export of ball bearings, supporting the automotive, electronics, and general engineering industries.

The Kinki Region is important due to its diversified manufacturing industries, such as automotive and robotics. Being a major industrial area, it houses leading companies in bearing technology, which is the source of demand for high-performance ball bearings. The region's extensive network of manufacturers drives significant market demand, especially in precision and automation.

The Central/Chubu Region is crucial for Japan's ball bearing market, with Nagoya being a major automotive and aerospace manufacturing hub. The region's focus on precision engineering and cutting-edge technology, coupled with its robust automotive and machinery industries, creates a steady demand for specialized bearings in various applications, strengthening the market's growth prospects.

The Kyushu-Okinawa Region is another important area in Japan's ball bearing market due to its increasing emphasis on advanced manufacturing and heavy industries. Also, the importance of automotive and electronics production, especially in Fukuoka and Kitakyushu has led to an increased investments in automation and technology within the region which in turn is increasing demand for high-quality, durable bearings to enhance machinery efficiency.

The Tohoku Region is the hub of precision manufacturing and heavy industry in Japan, and it is a key player in the country's ball bearing market. Tohoku's technological advancements and industrial output, focused on the automotive and renewable energy sectors, support the demand for high-performance bearings, particularly in the wind power and machinery sectors.

The Chugoku Region plays a vital role in the Japan’s ball bearing market as it concentrates on manufacturing and energy industries. Heavy industries such as steel and automotive manufacturing in the region require robust bearings that ensure smooth operations with less wear on large machinery-the key to long-term industry sustainability.

The Hokkaido Region is significant to the ball bearing market of Japan due to the region’s emphasis resource extraction and agriculture, which are resource-hungry industries that demand special bearings for efficient functioning of the equipment. Hokkaido is less industrialized, yet its equipment reliability in extreme conditions necessitates niche demand for durable and high-performance bearings.

The Shikoku Region is very significant to the automotive, textile, and machine tool industries. Its manufacturing facilities, mainly in Kagawa and Ehime, have significantly increased the demand for precision ball bearings, further increasing the need for advanced bearing solutions in many applications in this region.

Competitive Landscape:

The market is highly competitive, with numerous domestic and international players driving innovation and market growth. Companies are increasingly focusing on developing advanced products, such as high-precision, low-friction, and miniaturized bearings, to meet the demands of sectors like automotive, electronics, and industrial machinery. Strategic investments in R&D and technological advancements, such as IoT-enabled bearings and eco-friendly solutions, are enhancing product offerings. Intense competition also exists in terms of price and quality, as well as customer service, creating a dynamic market environment.

The report provides a comprehensive analysis of the competitive landscape in the Japan ball bearing market with detailed profiles of all major companies.

Latest News and Developments:

- On October 8, 2024, NTN Corporation announced the introduction of an on-site Power Purchase Agreement (PPA) at its Wakayama Works, significantly reducing CO₂ emissions by 589 tons annually. This initiative aligns with NTN’s commitment to achieving carbon neutrality by 2035 through the adoption of renewable energy and innovative technologies. Wakayama Works, producing EV ball bearings, exemplifies NTN's sustainable manufacturing efforts by utilizing advanced systems and CO₂-free electricity to minimize environmental impact.

Japan Ball Bearing Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Applications Covered |

Automobile, General Engineering, Mining and Construction, Railways, Aerospace and Shipping, Agriculture, Others |

| Regions Covered | Kanto Region, Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan ball bearing market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the Japan ball bearing market.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan ball bearing industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

Ball bearings are mechanical components that reduce friction between moving parts by using spherical balls to support loads. They are commonly used in automotive, industrial machinery, electronics, and aerospace applications, providing smooth rotational movement and enhancing operational efficiency.

The Japan ball bearing market was valued at USD 3.7 Billion in 2024.

IMARC estimates the Japan ball bearing market to exhibit a CAGR of 3.1% during 2025-2033.

The market is driven by rising demand from the automotive industry for enhanced fuel efficiency, growing adoption of precision bearings in robotics, and increasing renewable energy projects, particularly in wind turbines. Additionally, innovations in bearing technologies and the integration of IoT-enabled solutions are supporting market growth.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)