Japan Automated Guided Vehicles Market Report by Type (Two Vehicles, Unit Load Carriers, Pallet Trucks, Assembly Line Vehicles, Forklift Trucks), Mode of Operation (Indoor, Outdoor), Navigation Technology (Laser Guidance, Magnetic Guidance, Inductive Guidance, Optical Tape Guidance, Vision Guidance, and Others), Application (Transportation, Distribution, Storage, Assembly, Packaging, Waste Handling), Industry (Automotive, Manufacturing, Food and Beverages, Aerospace, Healthcare, Logistics, Retail, and Others), and Region 2026-2034

Japan Automated Guided Vehicles Market Size:

Japan automated guided vehicles market size reached USD 286.6 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 908.9 Million by 2034, exhibiting a growth rate (CAGR) of 13.68% during 2026-2034. Advanced manufacturing automation, rising labor shortages, significant technological innovations, increasing need for efficiency in warehousing and logistics, growing government support for Industry 4.0 initiatives, and widespread adoption of smart factory solutions are some of the major factors propelling the market growth.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 286.6 Million |

| Market Forecast in 2034 | USD 908.9 Million |

| Market Growth Rate (2026-2034) | 13.68% |

Japan Automated Guided Vehicles Market Analysis:

- Major Market Drivers: The advanced manufacturing sector’s push toward automation and efficiency represents the major driver of the market. The aging population and resulting labor shortages in the country necessitate the adoption of AGVs to maintain productivity levels in factories and warehouses.

- Key Market Trends: The increasing integration of artificial intelligence (AI) and machine learning (ML) to enhance AGV capabilities, such as improved navigation and real-time decision-making represents a key trend in Japan automated guided vehicles market growth. The rise of e-commerce is also increasing the need for efficient and flexible logistics solutions, driving the adoption of AGVs in warehouses and distribution centers.

- Competitive Landscape: Some of the major market players in the Japan automated guided vehicles industry include Daifuku Co. Ltd., Murata Machinery Ltd., Sakae Co. Ltd. (Kintetsu Group Holdings Co. Ltd.), and Toyota Industries Corporation, among many others.

- Challenges and Opportunities: The market faces various challenges including high initial investment costs and the complexity of integrating AGVs into existing workflows. However, the market also faces several opportunities such as the growing demand for automation due to labor shortages and the push for Industry 4.0 initiatives.

Japan Automated Guided Vehicles Market Trends:

Growing Labor Shortages

Japan's aging population and declining birth rates are leading to a significant labor shortage in various industries. Automated guided vehicles offer an effective solution to this problem by automating material handling and other repetitive tasks, thus maintaining productivity levels without relying on human labor. According to industry reports, the current population of 124.35 million has been falling for 13 years. And Japan's labor force is expected to continue to decline by 12% from 2022 to 2040, by which time it is estimated that the country will lack 11 million workers. Meanwhile, Asia's second-biggest economy is already home to the world's oldest population, with 29% of people aged 65 or above. This is further boosting Japan automated guided vehicles market share over the period.

Significant Technological Advancements

Continuous innovations in robotics, artificial intelligence (AI), and IoT (Internet of Things) technologies enhance the capabilities of AGVs, which makes them more efficient, reliable, and adaptable to complex industrial environments. These advancements drive the adoption of AGVs across various sectors. For instance, in November 2022, Eve Autonomy a leading autonomous transportation company announced that it launched the all-in-one autonomous transportation service "Eve Auto" which it has jointly developed with Yamaha Motor and TIER IV. This commercial autonomous transportation service with Level 4 driverless autonomous electric vehicles (EVs) is the first of its kind in Japan. This is fueling Japan automated guided vehicles market revenue over the period.

Rising Industry 4.0 Initiatives

The Japanese government and industries are strongly pushing for the adoption of Industry 4.0 principles, which emphasize smart manufacturing and automation. Government support and incentives for implementing advanced manufacturing technologies further boost the demand for AGVs in the country. According to the Korean Institute for Industrial Economics & Trade, The Japanese government, especially METI, is continuously actively creating various strategies and concrete policies & roadmaps to respond to the issues that occur in the process of the Fourth Industrial Revolution. Therefore, Japan has been actively responding to the new wave through IoT (Internet of Things), Big Data, Artificial Intelligence (AI), and robotics since 2015. Japan has had the world's highest record in terms of factory automation robot utilization, etc. For instance, in August 2023, The Indonesian and Japanese governments continued to collaborate to build a competitive manufacturing industry, including through training and mentoring manufacturing human resources (HR) to apply digital technology or Industry 4.0. This is expected to boost Japan automated guided vehicles market forecast in the coming years.

Japan Automated Guided Vehicles Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on type, mode of operation, navigation technology, application, and industry.

Breakup by Type:

- Two Vehicles

- Unit Load Carriers

- Pallet Trucks

- Assembly Line Vehicles

- Forklift Trucks

The report has provided a detailed breakup and analysis of the market based on the type. This includes two vehicles, unit load carriers, pallet trucks, assembly line vehicles, and forklift trucks.

The demand for two vehicles in the market is driven by their ability to efficiently move large volumes of goods across long distances within factories and warehouses. They enhance productivity by reducing the need for manual labor and improving the speed and reliability of material transport in logistics and manufacturing operations.

Unit load carriers are in demand for their capability to handle and transport large, single loads efficiently. They are essential in industries like automotive and electronics manufacturing, where precise and safe movement of parts and products is critical for maintaining production flow and reducing handling times.

The demand for pallet trucks is driven by their versatility and efficiency in handling palletized loads. Widely used in warehouses and distribution centers, these AGVs streamline the loading and unloading processes, improve inventory management, and enhance overall operational efficiency.

Assembly line vehicles are crucial for automating the transportation of components and products along production lines. They support just-in-time manufacturing practices, increase production speed, and reduce labor costs by ensuring smooth and consistent delivery of parts in automotive, electronics, and appliance manufacturing sectors.

The demand for automated forklift trucks is driven by their ability to safely and efficiently lift and transport heavy loads. They are essential in various industries, including logistics, warehousing, and manufacturing, where they enhance operational efficiency, reduce workplace injuries, and improve overall material handling capabilities.

Breakup by Mode of Operation:

- Indoor

- Outdoor

A detailed breakup and analysis of the market based on the mode of operation have also been provided in the report. This includes indoor and outdoor.

The demand for AGVs in indoor operations is driven by the need for automation in manufacturing, warehousing, and logistics to enhance efficiency and productivity. AGVs improve material handling, inventory management, and assembly line processes in controlled environments, reducing labor costs and minimizing human error.

Outdoor AGVs are in demand due to their ability to perform robust material transport and logistics tasks in challenging environments. They are essential for industries like agriculture, construction, and mining, where durability and reliability in various weather conditions are critical for maintaining operational efficiency and reducing manual labor dependency.

Breakup by Navigation Technology:

- Laser Guidance

- Magnetic Guidance

- Inductive Guidance

- Optical Tape Guidance

- Vision Guidance

- Others

The report has provided a detailed breakup and analysis of the market based on the navigation technology. This includes laser guidance, magnetic guidance, inductive guidance, optical tape guidance, vision guidance, and others.

The demand for laser-guided AGVs is driven by their precision and flexibility in navigating complex environments. Laser guidance allows for highly accurate positioning and obstacle detection, making it ideal for industries requiring precise material handling, such as automotive and electronics manufacturing.

Magnetic guidance systems are popular for their reliability and ease of installation. They offer consistent and stable navigation, making them suitable for applications in warehouses and distribution centers where straightforward, repetitive paths are needed for efficient material transport.

Inductive guidance is favored for its ability to function in harsh environments and maintain accuracy despite floor conditions. This technology is essential in heavy industries and outdoor applications where robust and durable navigation systems are required.

Optical tape guidance provides a cost-effective and easily reconfigurable navigation solution. It is ideal for facilities with frequently changing layouts, such as retail distribution centers, allowing quick adaptation to new paths and operational requirements.

Vision-guided AGVs are in demand for their advanced navigation capabilities, including real-time environment mapping and obstacle avoidance. This technology supports dynamic and complex environments, making it suitable for high-precision industries like aerospace, healthcare, and high-tech manufacturing, where adaptability and precision are crucial.

Breakup by Application:

- Transportation

- Distribution

- Storage

- Assembly

- Packaging

- Waste Handling

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes transportation, distribution, storage, assembly, packaging, and waste handling.

The demand for AGVs in transportation is driven by the need for efficient and reliable movement of goods within industrial facilities. AGVs enhance operational flow, reduce transportation times, and minimize manual labor, ensuring timely and precise material handling.

In distribution centers, AGVs streamline sorting and dispatching processes, improving speed and accuracy. Automation helps manage high volumes of goods efficiently, reducing labor costs and ensuring reliable distribution.

AGVs optimize space utilization and inventory management in storage facilities. They improve retrieval times, reduce errors, and maintain better control over stock levels, enhancing overall storage efficiency and organization.

AGVs ensure smooth and uninterrupted production processes in assembly lines by providing consistent delivery of components. They enhance productivity by reducing manual handling and enabling flexible, scalable assembly operations.

In packaging, AGVs streamline the movement of products between different stages, ensuring consistent handling and reducing the risk of damage. Automation improves packaging efficiency and productivity, supporting high-volume operations.

AGVs improve waste management by efficiently collecting and transporting waste materials within facilities. They enhance cleanliness and safety, and reduce the labor required for waste-handling tasks, contributing to a more organized and hygienic environment.

Breakup by Industry:

- Automotive

- Manufacturing

- Food and Beverages

- Aerospace

- Healthcare

- Logistics

- Retail

- Others

Japan automated guided vehicles market report has provided a detailed breakup and analysis of the market based on the industry. This includes automotive, manufacturing, food and beverages, aerospace, healthcare, logistics, retail, and others.

The demand for AGVs in the automotive industry is driven by the need for precision, efficiency, and flexibility in assembly lines and parts handling. Automation helps streamline production processes, reduce labor costs, and enhance operational efficiency, especially in high-volume manufacturing environments.

In the manufacturing sector, AGVs are essential for optimizing material handling, reducing human error, and improving productivity. The drive towards smart factories and Industry 4.0 initiatives further boosts AGV adoption to enhance efficiency and competitiveness.

AGVs in the food and beverages industry help maintain hygiene standards, reduce contamination risks, and ensure efficient handling and storage of products. Automation in material handling and inventory management enhances productivity and compliance with stringent safety regulations.

The aerospace industry uses AGVs to handle large, heavy components with precision and efficiency. AGVs support lean manufacturing practices, improve workflow efficiency, and ensure the safe transport of delicate and valuable aerospace parts.

In healthcare, AGVs streamline the transportation of medical supplies, pharmaceuticals, and equipment within hospitals and laboratories. Automation enhances efficiency, reduces labor costs, and minimizes human contact, thus improving overall healthcare delivery and patient safety.

The logistics sector benefits from AGVs through improved warehouse automation, efficient material handling, and reduced labor dependency. AGVs enhance order fulfillment speed, accuracy, and overall supply chain efficiency, addressing the growing demand for fast and reliable logistics services.

In retail, AGVs support efficient inventory management, order picking, and material handling in warehouses and distribution centers. Automation helps retailers meet the demands of e-commerce, ensuring timely and accurate order fulfillment, and enhancing overall operational efficiency. This is further creating a positive Japan automated guided vehicles market outlook.

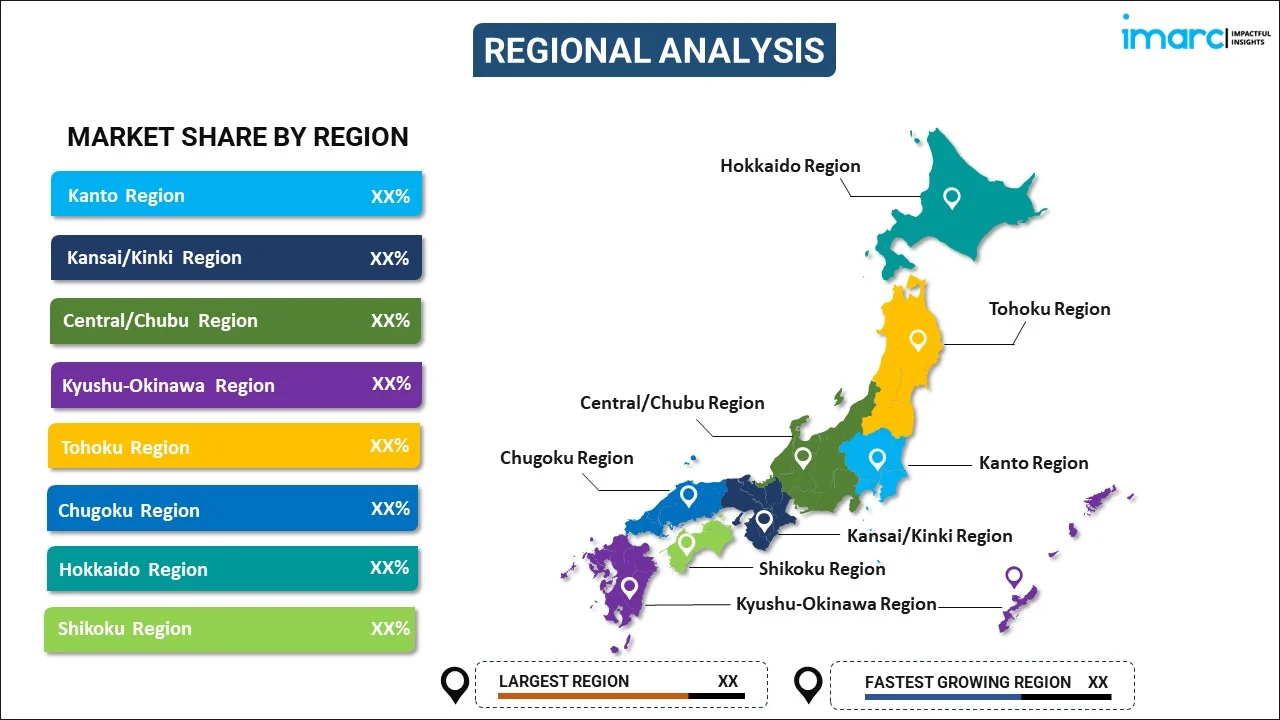

Breakup by Region:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major markets in the region, which include Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

The Kanto region, including Tokyo, drives the market growth through its dense industrial and commercial activities. High demand for automation in manufacturing and logistics to enhance efficiency and productivity, coupled with advanced infrastructure and strong investment in technology, propels the adoption of AGVs in this economically significant area.

In the Kansai region, encompassing Osaka and Kyoto, the robust automotive and electronics industries fuel the market. The region's focus on smart factory initiatives and improving operational efficiency in manufacturing processes drives demand for AGVs to streamline production and logistics operations.

The Chubu region, known for its automotive manufacturing hub in Nagoya, sees significant AGV adoption to optimize production lines and manage supply chains. The rising need for precision and efficiency in high-volume automotive manufacturing processes is driving Japan automated guided vehicles demand.

The Kyushu-Okinawa region leverages AGVs to support its diverse industrial base, including automotive, electronics, and chemical manufacturing. The focus on technological innovation and improving productivity in these sectors, along with regional government support, drives the growth of the market.

In the Tohoku region, AGV adoption is driven by the reconstruction and revitalization efforts following the 2011 earthquake. Investments in modernizing industrial infrastructure and enhancing manufacturing capabilities support the integration of AGVs for efficient material handling and production processes.

The Chugoku region, with its strong industrial base in Hiroshima, drives the market growth through its focus on improving manufacturing efficiency and competitiveness. AGVs are increasingly used to optimize logistics and production workflows in various industries, including shipbuilding and machinery.

In Hokkaido, the AGV market is driven by the need to improve logistics and distribution in the food processing and agricultural industries. The region's focus on enhancing productivity and reducing labor dependency in these sectors promotes the adoption of AGVs.

The Shikoku region, characterized by its chemical and machinery industries, sees AGV adoption driven by the need for operational efficiency and automation. Efforts to modernize manufacturing processes and improve supply chain management in this less densely populated area support the market growth.

Competitive Landscape:

- The market research report has also provided a comprehensive analysis of the competitive landscape in the market. Detailed profiles of all major companies have been provided. Some of the major market players in Japan automated guided vehicles industry include Daifuku Co. Ltd., Murata Machinery Ltd., Sakae Co. Ltd. (Kintetsu Group Holdings Co. Ltd.), Toyota Industries Corporation, among many others.

(Please note that this is only a partial list of the key players, and the complete list is provided in the report.)

- Japan automated guided vehicles companies are highly competitive, including Daifuku Co., Ltd., Murata Machinery, Ltd., and Toyota Industries Corporation. These companies focus on technological innovation, advanced AI integration, and strategic partnerships to enhance their AGV offerings. International players are also entering the market, intensifying competition. For instance, in February 2023, Nidec-Shimpo Corporation announced that it has newly added direct-current (DC), 24V modules to its product lineup of drive modules for automated guided vehicles (“AGVs”) and autonomous mobile robots (“AMRs”) currently on sale.

Japan Automated Guided Vehicles Market News:

- In March 2024, Mitsubishi Logisnext Co., Ltd., a part of MHI Group, announced that it has completed a demonstration of loading trucks utilizing automated guided forklifts (AGFs). The demonstration was conducted jointly with logistics services provider Konoike Transport Co., Ltd., which this month began utilizing the system for actual business operations in Japan.

- In December 2023, Daifuku Co., Ltd. announced that it has started operational testing of its newest high-speed, high-rise automated storage and retrieval system (AS/RS) stacker cranes in its new high-rise testing facility at its core production base, Shiga Works.

- In September 2023, The town of Eiheiji in Fukui Prefecture launched Japan’s first transportation service under new government regulation allowing fully automated driving. Leading auto manufacturers are pouring resources into self-driving technologies, but numerous hurdles remain before autonomous models take over the roads.

Japan Automated Guided Vehicles Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | Two Vehicles, Unit Load Carriers, Pallet Trucks, Assembly Line Vehicles, Forklift Trucks |

| Mode of Operations Covered | Indoor, Outdoor |

| Navigation Technologies Covered | Laser Guidance, Magnetic Guidance, Inductive Guidance, Optical Tape Guidance, Vision Guidance, Others |

| Applications Covered | Transportation, Distribution, Storage, Assembly, Packaging, Waste Handling |

| Industries Covered | Automotive, Manufacturing, Food and Beverages, Aerospace, Healthcare, Logistics, Retail, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Companies Covered | Daifuku Co. Ltd., Murata Machinery Ltd., Sakae Co. Ltd. (Kintetsu Group Holdings Co. Ltd.), Toyota Industries Corporation, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan automated guided vehicles market performed so far, and how will it perform in the coming years?

- What has been the impact of COVID-19 on the Japan automated guided vehicles market?

- What is the breakup of the Japan automated guided vehicles market on the basis of type?

- What is the breakup of the Japan automated guided vehicles market on the basis of mode of operation?

- What is the breakup of the Japan automated guided vehicles market on the basis of navigation technology?

- What is the breakup of the Japan automated guided vehicles market on the basis of application?

- What is the breakup of the Japan automated guided vehicles market on the basis of industry?

- What are the various stages in the value chain of the Japan automated guided vehicles market?

- What are the key driving factors and challenges in the Japan automated guided vehicles market?

- What is the structure of the Japan automated guided vehicles market, and who are the key players?

- What is the degree of competition in the Japan automated guided vehicles market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan automated guided vehicles market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan automated guided vehicles market.

- Porter's five forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan automated guided vehicles industry and its attractiveness.

- The competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)