Japan 3D Scanning Market Size, Share, Trends and Forecast by Type, Range, Application, End Use Industry, and Region, 2025-2033

Japan 3D Scanning Market Size and Share:

The Japan 3D scanning market size was valued at USD 432.3 Million in 2024. Looking forward, IMARC Group estimates the market to reach USD 1,913.8 Million by 2033, exhibiting a CAGR of 8.7% from 2025-2033. The market is experiencing growth because of the growing technological advancements, which enhance scanning accuracy, speed, and portability. Apart from this, its applications in quality control, prototyping, and electric vehicle development are expanding the Japan 3D scanning market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 432.3 Million |

|

Market Forecast in 2033

|

USD 1,913.8 Million |

| Market Growth Rate 2025-2033 | 8.7% |

Automotive manufacturers use 3D scanning for design, prototyping, and ensuring precision in complex component production. Scanners capture detailed geometries of parts, enabling streamlined workflows and faster product development cycles. Reverse engineering benefits from 3D scanning, helping manufacturers replicate or enhance existing components with accuracy. Quality control processes rely on these scanners to detect defects and ensure dimensional accuracy in assemblies. The transition to autonomous and electric vehicles (EVs) increases the demand for scanning to meet evolving design needs. Scanners enable the development of lightweight components, improving vehicle efficiency and adhering to sustainability goals. Automotive testing processes rely on 3D scanning to validate performance, facilitating compliance with stringent safety standards. Scanning integration with computer-aided design (CAD) software facilitates real-time data processing, enhancing design optimization and collaboration.

.webp)

3D scanning technology supports the making of detailed digital models for characters and environments. Game developers use scanners to capture real-world objects, enhancing realism and user immersion in gameplay. The film industry leverages scanning for lifelike animations and visual effects, meeting high production standards. Virtual reality (VR) and augmented reality (AR) applications depend on 3D scanning for immersive content creation. 3D scanning facilitates motion capture by recording intricate facial expressions and body movements for animations. The demand for hyper-realistic experiences in gaming and films drives the adoption of advanced 3D scanner. Scanning technology is also used to digitize historical artifacts for interactive cultural and educational media projects. Collaboration between entertainment companies and scanning providers accelerates innovation, expanding possibilities for creative industries. Portable scanners allow on-site digitization of locations, simplifying the production process for films and games.

Japan 3D Scanning Market Trends:

Technological advancements

Continuous improvements in scanning technologies like laser, structured light, and photogrammetry are significantly enhancing precision, speed, and usability. These innovations cater to the demands of industries like automotive, banking, manufacturing, healthcare, and construction by delivering highly accurate 3D models and measurements. For example, in July 2024, Japan introduced new high-tech banknotes featuring 3D portraits for enhanced security. These notes incorporate advanced printing techniques, such as holograms and raised features, to prevent counterfeiting. The redesigned currency aims to strengthen the country's financial system and align with modern technological advancements. Besides this, handheld and portable scanners are gaining traction due to miniaturization and portability advancements, allowing users to scan objects in diverse settings. Integration with advanced software featuring artificial intelligence (AI) and machine learning ML further streamlines data processing, automating workflows and improving efficiency. These developments address the growing need for real-time analysis and seamless integration into digital ecosystems, which is driving the Japan 3D scanning market demand in global markets.

Growing requirement for inspection and quality control in production

Key players depend on precise measurements for maintaining product accuracy, performance, and adherence to strict standards. As per the data published by the International Trade Administration, Japanese manufacturers have spent $890 million on digital infrastructure, with projections to reach $4.1 billion by 2030. Over the past decade, value-added manufacturing has contributed more than 20% to Japan’s GDP. The demand for 3D scanning is growing because of the escalating demand for quality control as well as inspection in the manufacturing sector. 3D scanning technologies enable non-contact inspections, ideal for fragile or intricately designed components. High-resolution scanners identify defects and deviations, improving product quality and reducing production errors. Automated scanning processes minimize human error, enhancing reliability in quality assurance workflows. Manufacturers save time and costs by identifying issues early, reducing waste and improving efficiency. The ability to create digital replicas supports reverse engineering and rapid prototyping with unparalleled accuracy. Integration of scanning with advanced software enables detailed analysis and seamless reporting for quality management. Japan’s advanced automotive and electronics industries increasingly adopt scanning for consistent production standards and precision. The growing shift to electric and autonomous vehicles increases the need for accurate component inspections. Portable and handheld scanners make quality control accessible across diverse manufacturing environments and workflows.

Growing demand for precision sensors

Precision sensors enhance the accuracy of 3D scanning devices, enabling detailed and reliable measurements. Industries like healthcare, automotive and manufacturing are increasingly reling on precise data for critical applications. Sensors with advanced capabilities improve the performance of laser and structured-light scanners. The need for high-resolution imaging in healthcare fosters demand for precision sensors in medical scanning devices. Automotive manufacturers use sensor-equipped scanners for quality control, ensuring dimensional accuracy and reducing production defects. Precision sensors support reverse engineering, capturing intricate geometries of complex components with high reliability. The construction sector benefits from sensor-driven scanners for accurate building information modeling (BIM) and project planning. In February 2024, Shimizu Corporation launched a metaverse-based inspection system for remote building assessments. The system combines 3D scan models with BIM data and uses the xR Checker tool for consistency verification. These advancements in sensor technology enable faster data acquisition, improving scanning efficiency across various industries.

Japan 3D Scanning Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the Japan 3D scanning market, along with forecasts at the country and regional levels from 2025-2033. The market has been categorized based on type, range, application, and end use industry.

Analysis by Type:

- Hardware

- Optical Scanners

- Structured Light Scanners

- Laser Scanners

- Others

- Software

Hardware forms the foundation of the market, including scanners and related equipment. These devices enable high-precision measurements critical for industries like manufacturing and healthcare. Advancements in sensor technology are improving scanning accuracy and usability. The rising demand for portable and handheld 3D scanners is also fueling hardware market growth. Hardware innovations focus on faster processing and integration with existing workflows. The automotive and aerospace sectors are considerably investing in advanced scanners for quality assurance.

Software complements hardware by processing raw scan data into usable models for analysis and application. Enhanced algorithms allow greater accuracy and efficiency in converting 3D scans into detailed representations. Industries use 3D scanning software for modeling, simulation, and design optimization purposes. Cloud-based solutions make software more accessible, promoting real-time collaboration among stakeholders. AI integration helps automate processes, reducing manual intervention and increasing productivity.

Analysis by Range:

- Short Range

- Medium Range

- Long Range

Short-range 3D scanning focuses on capturing fine details of small objects with high accuracy. Industries like healthcare and manufacturing rely on these scanners for intricate modeling and quality control. Portable and handheld scanners dominate this range, providing flexibility for detailed applications. Jewelry design, reverse engineering, and cultural heritage preservation benefit significantly from short-range technology. The market sees growth due to increasing demand for precise, small-scale digital replicas.

Medium-range scanners address scanning needs for objects and environments up to several meters in size. Architecture, construction, and manufacturing utilize these scanners for spatial analysis and project planning. Medium-range technology bridges the gap between close-detail and large-area scanning requirements. These scanners offer versatility for indoor spaces, mid-sized objects, and factory environments. Enhanced scanning capabilities improve workflow efficiency in industries requiring accurate spatial data.

Long-range 3D scanning captures expansive areas and large structures, essential for construction and infrastructure projects. These scanners are widely used in surveying, urban planning, and large-scale industrial installations. High accuracy over extended distances makes them suitable for monitoring and analyzing structural integrity. Long-range devices play a vital role in preserving historical monuments and mapping landscapes. Technological advancements improve range, precision, and data-processing speeds, enhancing project outcomes.

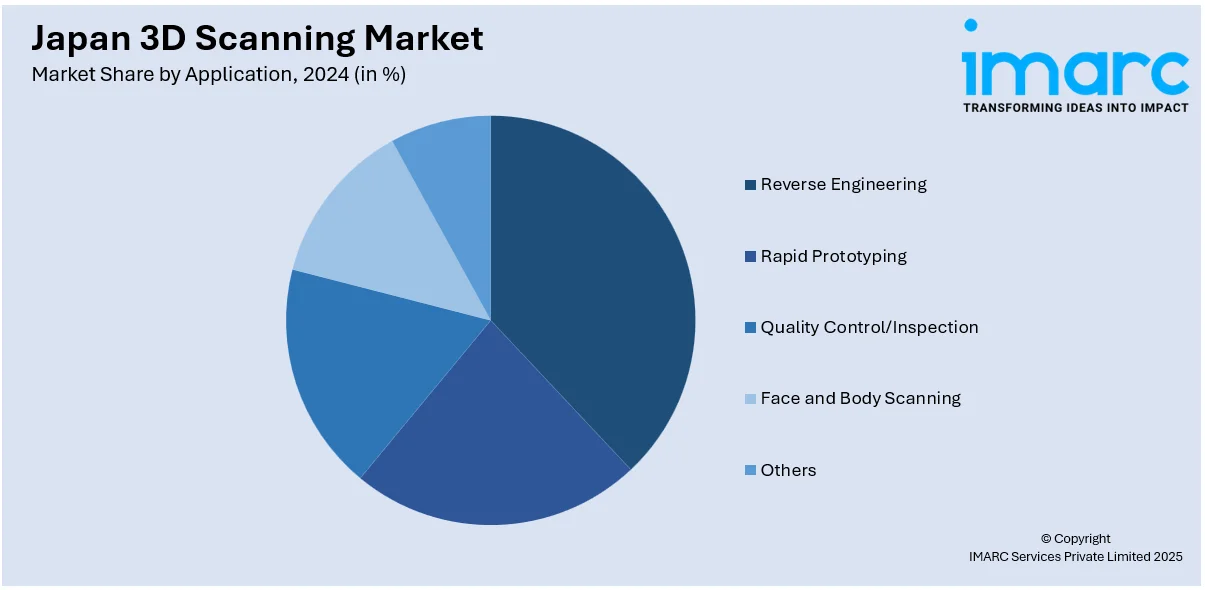

Analysis by Application:

- Reverse Engineering

- Rapid Prototyping

- Quality Control/Inspection

- Face and Body Scanning

- Others

Reverse engineering utilizes 3D scanning to create accurate digital models of physical objects for analysis. It is widely used in manufacturing, automotive, and aerospace industries for redesign and optimization. 3D scanning aids in streamlining reverse engineering by securing precise dimensions and complex geometries efficiently. This application supports legacy part replication and the improvement of existing designs. As industries demand greater innovation, reverse engineering grows in significance for product development.

3D scanning plays a vital role in rapid prototyping by creating detailed digital models for production. It accelerates product development cycles by reducing manual design and enhancing precision in modeling. Industries like automotive, healthcare, and consumer goods rely on this process for faster innovation. Prototyping ensures the accuracy of designs before mass production, minimizing errors and waste. Integration with 3D printing is further increasing the efficiency of prototyping processes.

3D scanning enhances quality control by enabling precise inspection of products for defects or deviations. Industries, such as manufacturing and aerospace rely on this application for maintaining stringent standards. Advanced scanning ensures dimensional accuracy and consistency across components, ensuring high-quality outputs. Automated inspection processes significantly reduce human error, saving time and operational costs. Non-contact scanning techniques are ideal for fragile or complex products needing careful evaluation.

Face and body scanning leverages 3D technology for applications in healthcare, entertainment, and retail sectors. It supports medical applications like prosthetics design, surgical planning, and cosmetic treatments with personalized solutions. In entertainment, scanning creates realistic avatars for video games, movies, and virtual reality experiences. Retailers use body scanning for custom clothing, enhancing overall customer satisfaction, and minimizing returns. Advancements in scanning increases speed and accuracy, enhancing overall user experiences across these applications.

Analysis by End Use Industry:

- Aerospace and Defense

- Automotive

- Healthcare

- Manufacturing

- Media and Entertainment

- Architecture and Construction

- Others

The aerospace and defense sectors use 3D scanning for precise measurements and quality assurance processes. High accuracy ensures critical components meet stringent safety and performance standards. Scanning technology aids in reverse engineering obsolete parts for continued equipment functionality. It is essential for prototyping and testing in aircraft design and manufacturing. Defense applications include mapping terrains and creating digital simulations for operational planning. Growing investments in advanced manufacturing drive the demand for 3D scanning in this industry.

In the automotive sector, 3D scanning is integral for design, prototyping, and quality control processes. Scanning helps streamline workflows by accurately capturing complex vehicle components and assembly details. Manufacturers use this technology to optimize designs and enhance production efficiency. Quality inspection with 3D scanners ensures dimensional accuracy of parts, reducing defects and recalls. Scanning is also used for reverse engineering to replicate or improve existing parts.

Healthcare relies on 3D scanning for personalized treatments, prosthetics, and surgical planning with enhanced precision. Scanners capture anatomical details for custom medical devices like implants, braces, and prosthetics. It supports advanced diagnostics and preoperative planning, improving patient outcomes significantly. Dental practices use 3D scanning for accurate orthodontic models and restorative treatments. Scanning assists in creating life-like prosthetics, enhancing comfort and functionality for patients.

Manufacturing industries use 3D scanning to ensure quality control, streamline workflows, and optimize production processes. The technology is essential for reverse engineering and prototyping, reducing development cycles and costs. Scanning improves precision in assembly line operations by identifying defects and deviations in real time. Integration with advanced manufacturing methods like 3D printing, enhances efficiency and innovation. High demand for automation and digitization across manufacturing encourages the adoption of 3D scanning.

3D scanning transforms media and entertainment by enabling realistic animations, characters, and virtual environments. Game developers and filmmakers use this technology to create detailed digital replicas of real-world objects. Scanning enhances immersive experiences in virtual reality and augmented reality applications. This technology captures facial expressions and movements for lifelike animation in movies and games. Demand for high-quality content and visual effects drives the adoption of adoption of 3D scanning in this sector.

In architecture and construction, 3D scanning aids in precise project planning, renovations, and structural analysis. Scanners capture detailed data for creating accurate building information models (BIM). This technology enhances efficiency in construction projects by identifying potential design flaws early. It supports historical preservation efforts by documenting monuments and aging structures for restoration. Scanning streamlines construction workflows, saving time and costs through accurate measurements and visualization.

Regional Analysis:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The Kanto region, home to Tokyo, drives the market due to its expanding industrial base. It hosts significant manufacturing, technology, and healthcare hubs, fostering widespread adoption of advanced scanning solutions. The region’s infrastructure and construction sectors leverage scanning for efficient project planning and execution. Automotive and electronics industries in Kanto use 3D scanning for quality control and prototyping. High demand for innovation aligns with Kanto’s focus on cutting-edge technologies.

The Kansai region including Osaka, Kyoto, and Kobe, is a critical market for 3D scanning technologies. Renowned for its automotive, electronics, and cultural industries, Kansai integrates scanning into diverse applications. Historical preservation projects benefit from advanced scanning for documenting Kyoto’s cultural heritage sites. The automotive industry in Kansai uses scanning for prototyping, quality control, and reverse engineering. Increasing demand for high-precision manufacturing catalyzes their adoption in electronics production.

The Kyushu-Okinawa region leverages 3D scanning technologies in its growing industrial and infrastructure sectors. Kyushu’s automotive and semiconductor industries adopt scanning for design optimization and defect identification. The construction sector uses scanning for large-scale infrastructure projects and historical site preservation. Okinawa’s tourism-driven initiatives integrate scanning to digitize and protect cultural and natural heritage. Government initiatives promoting smart manufacturing in Kyushu enhance scanning adoption across industries.

The Tohoku region’s adoption of 3D scanning is driven by its focus on reconstruction and development. After the 2011 earthquake, scanning technologies supported the infrastructure rehabilitation and historical preservation projects. Manufacturing sectors utilize scanning for quality assurance, design, and prototyping in industrial applications. Tohoku’s renewable energy initiatives including wind farms, integrate scanning for project planning and maintenance. Government investments in regional development further promote scanning adoption in construction and manufacturing.

The Chugoku region, known for its manufacturing and port industries, drives the demand for 3D scanning solutions. Automotive and shipbuilding industries rely on scanning for quality inspection and structural analysis. The construction sector integrates scanning to optimize workflows for infrastructure and building projects. Historical preservation efforts use scanning to document and protect cultural landmarks unique to the region. Chugoku’s industrial focus and government-supported technological advancements strengthen the Japan 3D scanning market growth.

Hokkaido adopts 3D scanning technologies to support its construction, agriculture, and tourism-focused industries. Construction projects in Hokkaido use scanning for large-scale infrastructure development and land surveys. The agricultural sector integrates scanning to improve equipment design and optimize farming processes. Tourism and cultural preservation benefit from digitizing natural landscapes and heritage sites for enhanced visitor experiences.

The Shikoku region employs 3D scanning for applications in construction, manufacturing, and cultural preservation. Its industrial sector uses scanning to enhance production processes, including quality control and prototyping. Construction projects in Shikoku benefit from precise measurements for infrastructure development and urban planning. Cultural preservation initiatives use scanning to document and protect Shikoku’s historical landmarks. Increased regional focus on modernizing industries supports scanning adoption in diverse applications.

Competitive Landscape:

Key players in the market play a pivotal role in advancing the industry by introducing innovative technologies and addressing diverse industry needs. Companies focus on developing high-precision scanners and software solutions tailored for applications like manufacturing, healthcare, construction, and entertainment. Their investments in research and development (R&D) ensure continuous enhancement like faster scanning speeds, improved accuracy, and enhanced portability. Major contributors also collaborate to offer specialized scanners for automotive design, heritage preservation, or medical applications. Major players in healthcare 3D scanning develop specialized scanners and software for medical imaging, prosthetics, and surgical planning. Their innovations enable precise anatomical modeling, personalized treatments, and enhanced diagnostic capabilities. For instance, in May 2024, Japanese startup Novius launched groundbreaking 3D medical image conversion technology. This innovation transforms traditional 2D medical images into accurate 3D models. It aims to enhance diagnostic precision and treatment planning for medical professionals. The technology offers advanced visualization, improving the overall quality of patient care. Furthermore, key companies actively participate in government-backed initiatives encouraging smart manufacturing and digital transformation. By aligning with Japan’s focus on high-tech solutions, they contribute to the adoption of 3D scanning across sectors.

The report provides a comprehensive analysis of the competitive landscape in the Japan 3D scanning market with detailed profiles of all major companies.

Latest News and Developments:

- October 2024: Smiths Detection provided advanced 3D X-ray scanners to Kansai International Airport for enhanced security. The equipment, installed at Terminal 1's new security checkpoint, ensures passenger safety with cutting-edge technology. These scanners offer high-resolution imaging and efficient threat detection to meet evolving aviation security standards.

- March 2024: Fujitsu tech launched an urban digital twin platform utilizing 3D technology to revolutionize city management. The system combines real-time data with 3D models, offering a comprehensive visualization of urban infrastructure.

- January 2024: Fukuoka International Airport announced to upgrade its security with Smiths Detection’s HI-SCAN 6040 CTiX X-ray scanners, which relies on 3D X-ray technology. These systems enable faster baggage screening by allowing passengers to leave electronics and liquids in bags. The scanners, already implemented at other Japanese airports, aim to improve screening efficiency with up to 250 passengers processed per hour.

- January 2024: Revopoint presented its latest 3D scanners, including RANGE 2, at TCT Japan 2024, offering visitors the chance to experience cutting-edge technology. The company aims to demonstrate enhanced scanning solutions designed for accuracy and efficiency in various industries.

Japan 3D Scanning Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical and Forecast Trends, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Types Covered |

|

| Ranges Covered | Short Range, Medium Range, Long Range |

| Applications Covered | Reverse Engineering, Rapid Prototyping, Quality Control/Inspection, Face and Body Scanning, Others |

| End Use Industries Covered | Aerospace and Defense, Automotive, Healthcare, Manufacturing, Media and Entertainment, Architecture and Construction, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, Japan 3D scanning market outlook, and dynamics of the market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the Japan 3D scanning market.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan 3D scanning industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The Japan 3D scanning market was valued at USD 432.3 Million in 2024.

Key factors driving the market include advancements in scanning technologies, such as laser and structured light, which improve accuracy, speed, and ease of use. The automotive and manufacturing sectors leverage 3D scanning for prototyping, quality control, and design optimization. Growing applications in healthcare, including surgical planning and prosthetics, further drives the demand. The construction industry uses 3D scanning for efficient project planning and heritage preservation. Government initiatives supporting smart manufacturing and digital transformation also expands market expansion, encouraging technological adoption across industries for enhanced productivity and innovation.

IMARC estimates the Japan 3D scanning market to exhibit a CAGR of 8.7% during 2025-2033.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)