Techno-Economic Study of Automotive Wiring Harness Manufacturing Plant: A Detailed Cost Model

What is Automotive Wiring Harness?

An automotive wiring harness is an organized assembly of electrical wires, connectors, and terminals that transmit power and signals across a vehicle’s electrical system.

Key Applications Across Industries:

It guarantees effective communication between several parts, including the engine control unit, lighting, and sensors. Wiring harnesses are intended to increase vehicle performance and safety by lowering the possibility of short circuits. By maximising electrical connectivity and lowering wire complexity, they are utilised in both conventional and electric automobiles and are essential to contemporary automotive technology.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global automotive wiring harness market was valued at USD 86.5 Billion in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 3.44% from 2025 to 2033, reaching a projected value of USD 121.3 Billion by 2033.

Growing automotive production, the trend towards electric and hybrid vehicles, and the growing demand for sophisticated vehicle electronics are the main factors propelling the automotive wire harness market. Complex wiring solutions are becoming much more necessary due to the increasing use of safety and connection technologies like ADAS, infotainment systems, and telematics. Automakers are also being encouraged to incorporate effective wiring harness systems by strict government standards for vehicle safety and pollution control. The demand for lightweight, energy-efficient components and the development of EV infrastructure are driving additional market expansion. Global market demand is being driven by technological developments in smart wiring and modular harness designs, which also enhance vehicle performance and cut down on assembly time.

Case Study on Cost Model of Automotive Wiring Harness Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale automotive wiring harness manufacturing plant in Hyderabad, India.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 1,200,000 cables annually.

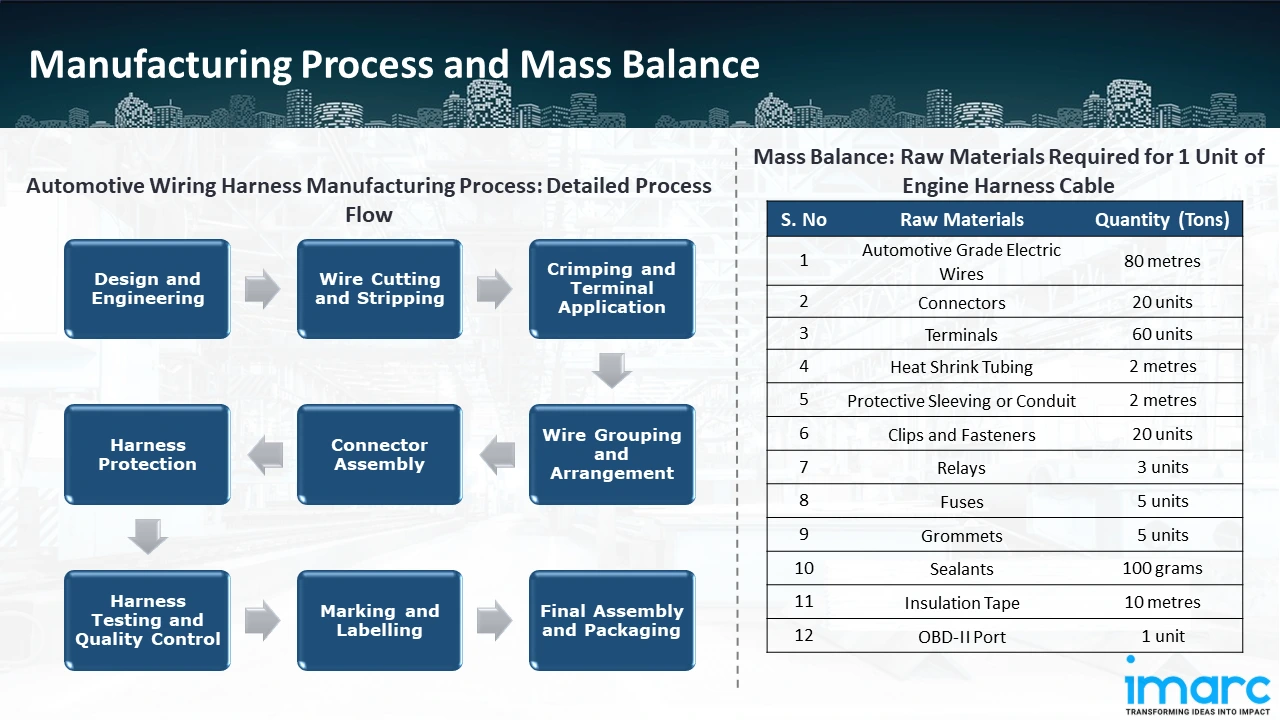

Manufacturing Process: An automobile wiring harness's manufacturing process starts with design and engineering, where standards are created in accordance with the needs of the vehicle. Wires are cut and stripped to exact lengths after completion to guarantee adequate electrical conductivity. Terminals are fastened to wire ends for safe connections during the crimping and terminal application stages. To conform to the electrical architecture of the vehicle, wires are then bundled and placed into certain patterns. Connectors are integrated during the connection assembly phase, guaranteeing compatibility with a range of vehicle components. Techniques for harness protection such as shielding, tubing, and wrapping are used to increase durability. After that, quality control and harness testing are carried out to verify mechanical strength, insulation, and electrical continuity. Easy identification and proper installation are ensured by marking and labelling. The wiring harness is then wrapped, examined, and ready to be shipped to suppliers or automakers during final assembly and packing.

Mass Balance and Raw Material Required: The primary raw materials utilized in the cable manufacturing plant include automotive grade electric wires, connectors, terminals, heat shrink tubing, protective sleeving or conduit, clips and fasteners, relays, fuses, grommets, sealants, insulation tape, and OBD-II port. To produce 1 unit of engine harness cable, around 80 metres of automotive grade electric wires, 20 units of connectors, 60 units of terminals, 2 metres heat shrink tubing, 2 metres of protective sleeving or conduit, 20 units of clips and fasteners, 3 units of relays, 5 units of fuses, 5 units of grommets, 100 grams of sealants, 10 metres of insulation tape, and 1 unit of OBD-II port is required.

List of Machinery:

The following equipment was required for the proposed plant:

- KOMAX Zeta 650 Series - 13 Station Machine with 10 Crimping Stations & 3 Seal Stations Including KOMAX 1630 Jet Printers + Topwin Standard 22.4 Software

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

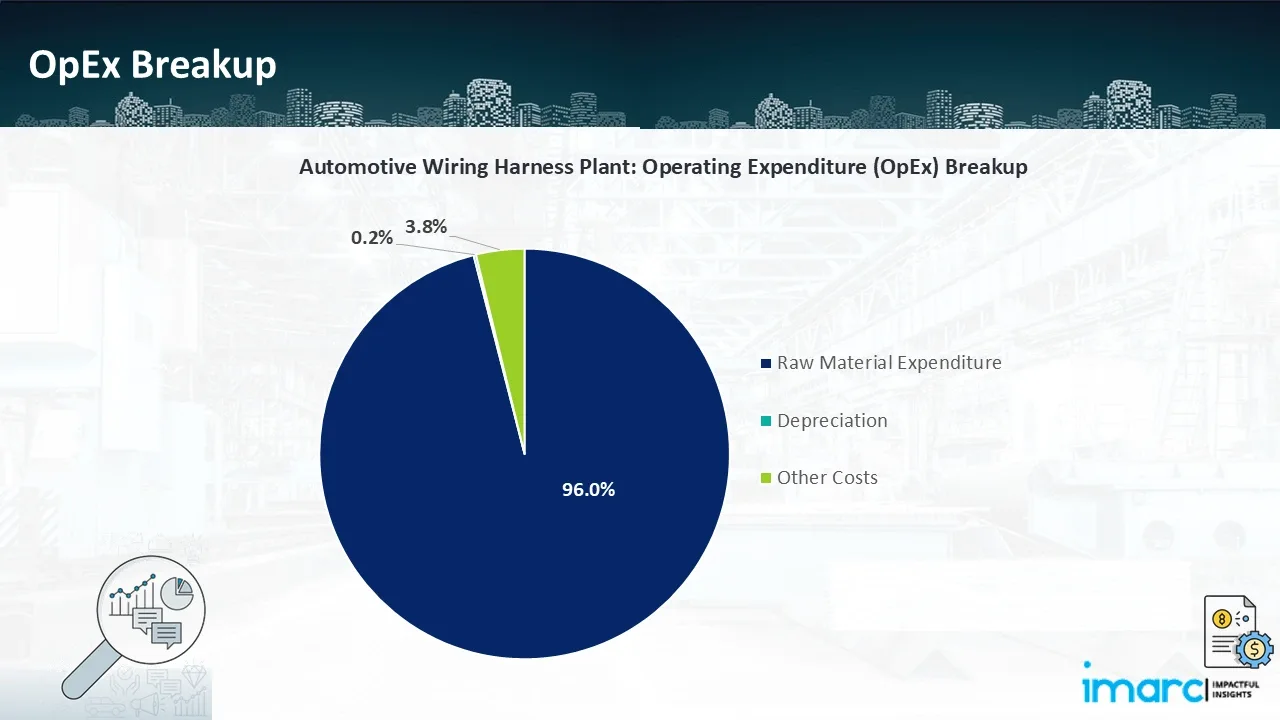

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

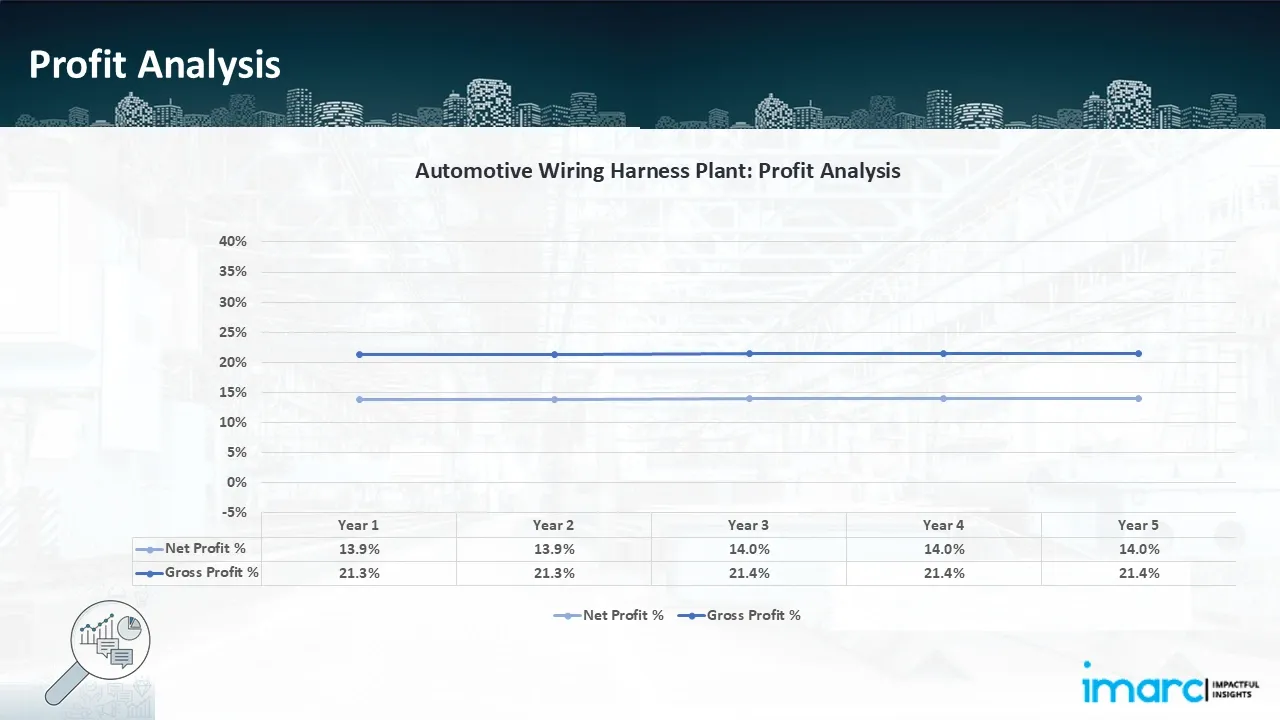

- Profitability Analysis Year on Year Basis: The proposed automotive wiring harness plant, with a capacity of 1,200,000 cables annually, achieved an impressive revenue of US$ 64.8 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit slightly improved from 21.3% to 21.4%, and net profit rise from 13.9% to 14.0%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our automotive wiring harness manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 1,200,000 cables annually. Our commitment to offering precise, client-centered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In January 2025, Bain Capital, which values Dhoot Transmission Group at $1 Billion, has purchased a 40–45% interest in the company. The purpose of this strategic investment is to help Dhoot's expansion by utilising Bain's worldwide automotive experience, specifically in the areas of wire harnesses and a variety of electric vehicle solutions for global markets.

- In October 2024, Leoni Egypt has announced plans to establish a new factory dedicated to manufacturing automotive electrical harnesses. The facility, which will cost €40 Million, will be built on a 13,000-square-meter plot of land in Al-Robeky City. It is anticipated that the project will provide over 3,000 direct and indirect job opportunities. With an annual objective of €240 Million by 2026, Leoni wants to increase its export capacity by 50%.

- In August 2024, Motherson Group inaugurated a state-of-the-art facility in Huakai Siping, China. The goal of this factory is to meet the increasing demand in the electric vehicle (EV) industry by producing high voltage wiring harnesses, stamping, and injection moulding parts.

- In May 2024, Yazaki Corporation and Toray Industries together have created a recycled polybutylene terephthalate (PBT) resin grade that is used to create automobile wire harness connectors using leftover materials from production operations.

- In May 2023, Sumitomo Electric Wiring Systems Inc. announced plans to invest USD 100 Million and build a 150,000 square metre facility in Egypt to create the largest electric car wiring harness plant in the world. The project is anticipated to provide about 10,000 job opportunities and begin operations by the end of 2023.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104