Optimizing Cigarette Lighter Production: A Comprehensive Cost Analysis

What is Cigarette Lighter?

A plastic cigarette lighter is a small portable hand-held device that gives a flame generally used for lighting cigarettes, cigars, candles, and other small things.

Key Applications Across Industries:

They are mostly butane-gas fuelled, which makes them easily disposable after all the fuel has been depleted. It's manufactured using polycarbonate or polypropylene plastic, so it's very lightweight and affordable. The lighter has a manual ignition system which involves a flint wheel and a valve to allow butane gas when lit thus producing flame.

What the Expert Says: Market Overview & Growth Drivers

An IMARC study suggests that the India cigarette lighter market reached USD 550.40 Million in 2025, the market is expected to grow at 3.90% from 2026 to 2034 and reach approximately USD 776.48 Million by 2034. Some of the reasons behind the increasing demand for cigarette lighters are the growth in the number of smokers all over the world and the ever-increasing need for portable and practical ignition tools.

The more designs of cigarette lighters are now offered in the market. These include high-end, ornamental and refillable cigarette lighters. Innovations, such as rechargeable and windproof lighters, contribute to this growth since it attracts outdoor enthusiasts and environmentally conscious individuals. Cigarette lighters are easily accessible through online and physical channels that ensure that customers easily access them. The market demand for cigarette lighters is further supported by marketing methods that focus on both function and beauty and increasing disposable incomes of individuals in developing nations.

Case Study on Cost Model of Cigarette Lighter Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale cigarette lighter manufacturing plant in Punjab, India.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a comprehensive financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 100,000 units of cigarette lighter per day.

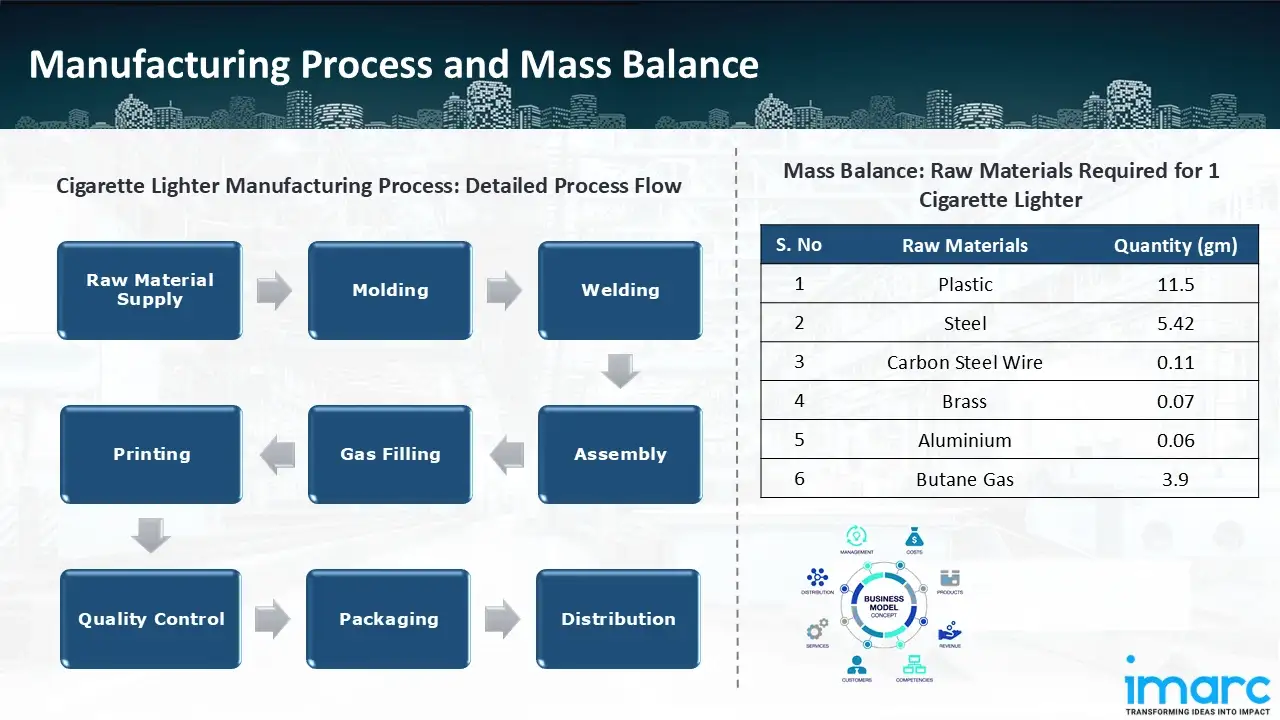

Manufacturing Process: Cigarette lighters are manufactured using a number of crucial processes that guarantee durability, safety, and functionality. It starts with the delivery of raw materials, which includes butane gas, metal for the ignition components, and plastic for the body. These materials are moulded using sophisticated injection moulding equipment to create the lightweight body and other parts. The next step is welding, which firmly joins components like the nozzle and ignition wheel. Parts including the body, ignition system, and flame regulator are put together during the assembly phase. The next step is gas filling, which involves carefully injecting butane into the lighter's fuel chamber. The lighter is then personalised with logos or ornamental motifs using the printing process. Techniques like heat transfer and pad printing are frequently used for this. The lighters are tested for durability, ignition efficiency, and gas leakage as part of quality control to make sure they adhere to safety regulations. After approval, the lighters are placed in attractive and long-lasting packaging to keep them safe while being stored and transported. To ensure that the lighters reach customers effectively and in perfect condition, they are finally disseminated through a variety of channels, such as retail, e-commerce, and wholesale networks. The manufacturing of dependable and user-friendly cigarette lighters is guaranteed by this efficient technique.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the cigarette lighter manufacturing plant include plastic, steel, carbon steel wire, brass, aluminium, and butane gas. To manufacture 1 cigarette lighter, around 5.42 grams of steel, 0.07 grams of brass, 0.06 grams of aluminium, 0.11 grams of carbon steel wire, 11.46 grams plastic and 3.9-gram butane gas would be required as the raw materials. Around 0.00116 KW of electric power would be required during the manufacturing process.

List of Machinery

The following equipment was required for the proposed plant:

- Injection Molding Machine

- Auxilaries

- Mould

- Printing Machine

- Welding machine

- Quantitative Gas filling machine

- Accessories

- Spring Coiling Machine

- Fiber Laser Cutting Machine

- Die Casting Machine

- Diesel Furnace

- Other Machinery

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

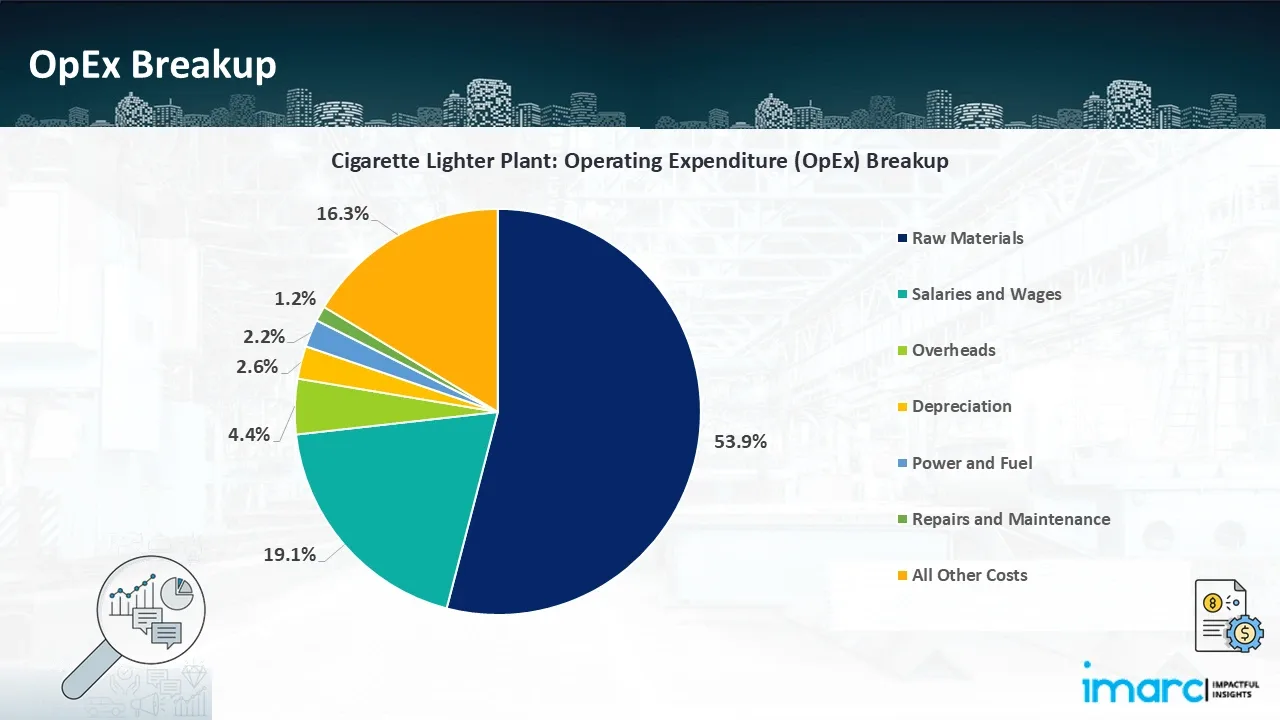

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

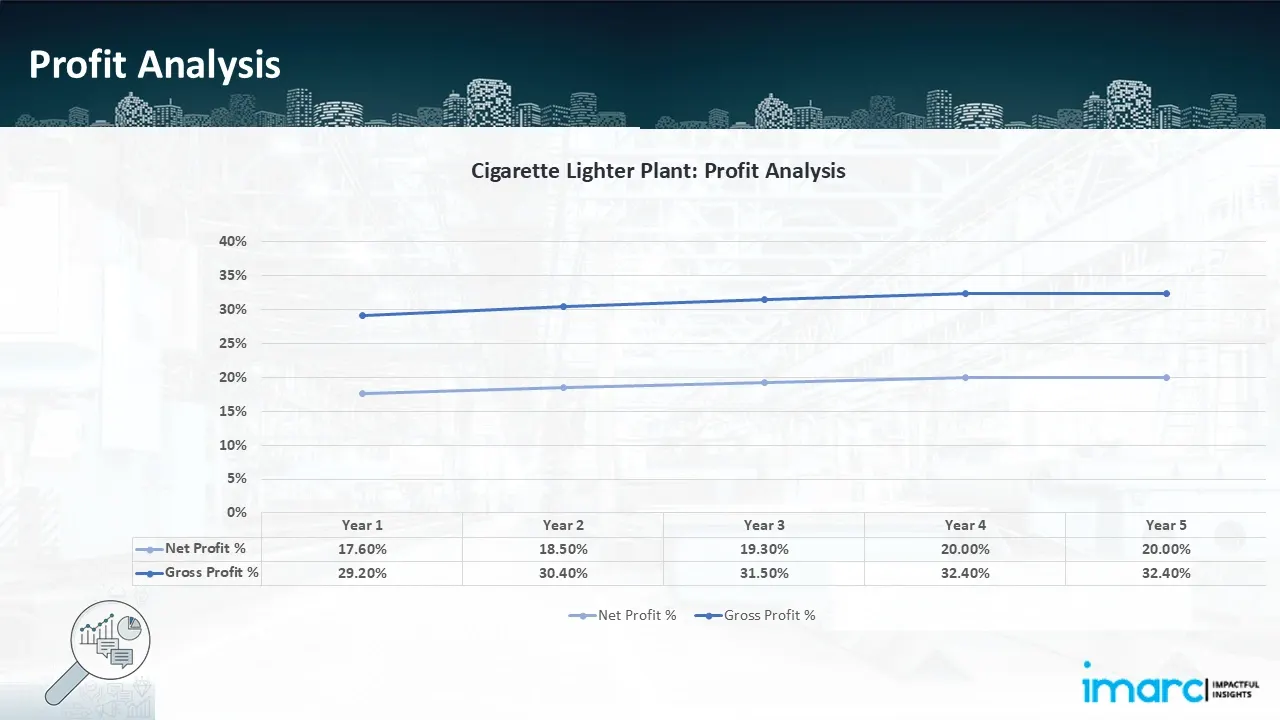

- Profitability Analysis Year on Year Basis: The proposed cigarette lighter plant, with a capacity of 100,000 units of cigarette lighters per day, achieved an impressive revenue of US$ 1.68 Million in its first year. We assisted our client in developing a detailed cost model with its revenue rising throughout the years. Gross profit margin improved from 29.2% to 32.4% throughout the years, and net profit went up from 17.6% to 20.0%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the cigarette lighter manufacturing plant was carefully crafted to meet the client's objectives. It provided a detailed analysis of production costs including raw materials, manufacturing processes, capital expenditure, and operational expenses. Tailored to the specific requirement of producing 100,000 units of cigarette lighters per day the model highlights key cost drivers and forecasts profitability considering market trends, inflation, and potential fluctuations in raw material prices. This integrated financial model will give the client strategic decision-making insight that will demonstrate our commitment to providing accurate and client-centric solutions for large-scale manufacturing projects.

Latest News and Developments:

- In January 2025, the official website for Zippo windproof lighters and accessories in India, Zippo.in, has undergone a facelift to enhance Indian customers' in-store buying experiences. The redesigned platform highlights Zippo's recognisable product line while concentrating on providing a simplified user-friendly online experience.

- In October 2024, BIC has celebrated the partnership between Snoop Dogg and Martha Stewart by launching their newest EZ Reach lighter styles. Convenient, safe and functional these limited-edition lighters are perfect for candles, barbecues and more. They also have distinctive artwork. Their collaboration reflects their mutual inventiveness and pleasure.

- In June 2023, The Indian government has banned the importation of cigarette lighters that cost less than INR 20 as part of the "Make in India" campaign to encourage indigenous production. The goal of this action is to increase domestic production while reducing the flow of low-cost imports especially from nations like China. The notification, which was released by the Directorate General of Foreign Trade (DGFT) was in line with the government's overarching goal of encouraging manufacturing self-reliance.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104