On the Path of Sustainability Riding an Electric Kick Scooter: A Comprehensive Cost Model

_11zon.webp)

What is Electric Kick Scooter?

Electric kick scooters are small, battery-operated personal transportation vehicles intended for short-distance and urban movement. They offer an economical and environmentally responsible substitute for conventional modes of mobility thanks to their electric engine, rechargeable battery, and lightweight frame.

Key Applications Across Industries:

The need for sustainable transportation options, traffic congestion, and growing urbanisation have all contributed to their rise in popularity. Electric kick scooters are now the go-to option for last-mile connectivity and personal commuting because to developments in battery technology, connectivity features, and government programs encouraging micro-mobility.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global electric kick scooter market size reached USD 3.8 Billion in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 9.3% from 2025 to 2033, reaching a projected size of USD 8.5 Billion by 2033.

The demand for electric kick scooters is being driven by increased environmental concerns, rising gasoline prices, and increasing urban congestion. Incentives, rules, and infrastructure development are being used by governments around the world to encourage the use of sustainable transportation. Demand has increased even more as shared micro-mobility services have expanded throughout cities. Improved energy efficiency, lightweight materials, and intelligent connection features are examples of technological developments that boost user experience and market appeal. Furthermore, shifting consumer attitudes towards flexible, affordable, and environmentally friendly commuting options—particularly for short-distance travel—are driving expansion. Further propelling the market for electric kick scooters is the notable shift towards personal mobility solutions that has occurred since the pandemic.

Case Study on Cost Model of Electric Kick Scooter Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale electric kick scooter manufacturing plant in Sweden.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 74 units of electric kick scooter in the first year and the production capacity further rises to 378 units of scooters by the tenth year.

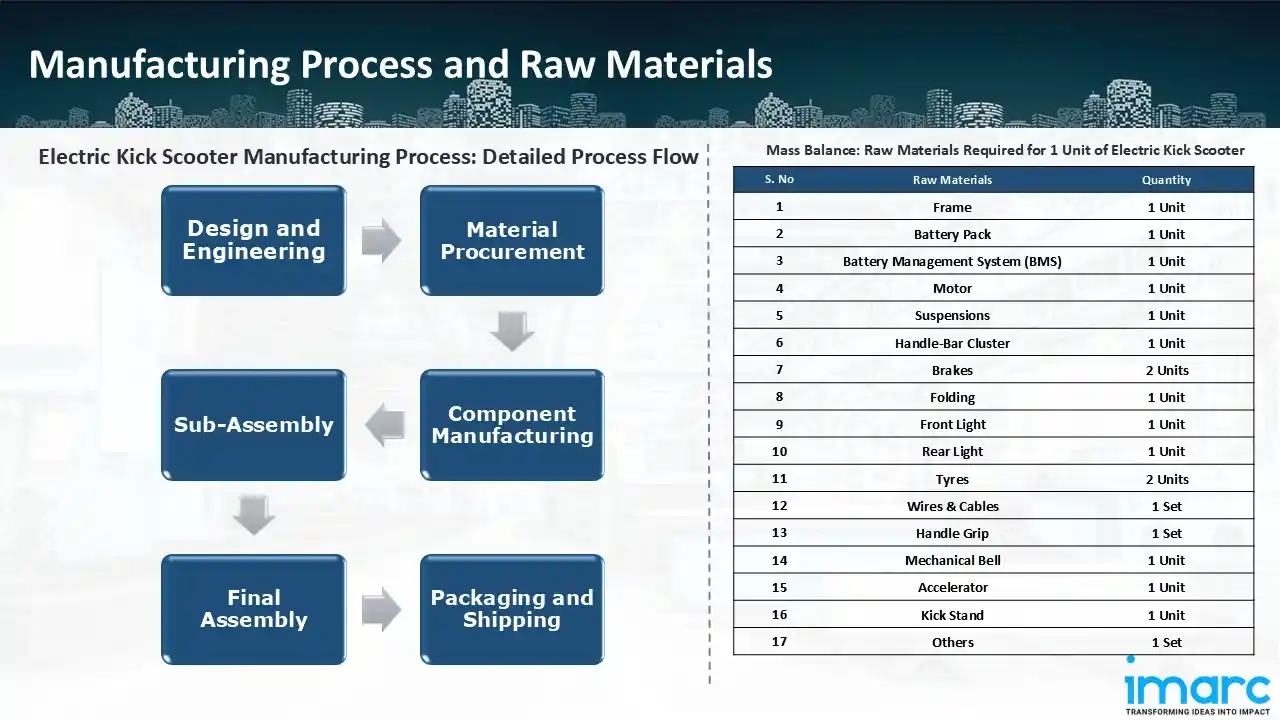

Manufacturing Process: Design and engineering are the first steps in the manufacturing of an electric kick scooter. To guarantee performance, safety, and durability, manufacturers create structural frameworks, electrical systems, and battery integration. Prototyping and testing are part of this phase to improve the finished design. After everything is decided, the next step is material procurement, which involves finding necessary parts such motors, tires, lithium-ion batteries, steel or aluminium frames, and electronic control units. At this point, quality control is essential to guarantee longevity and effectiveness. Decks, handlebars, electronic circuits, and brake systems are examples of specific pieces that are manufactured in component manufacturing. After that, these parts go through a sub-assembly stage where they are assembled into smaller pieces such as wheel assemblies, motor housings, and battery packs before being included into the main construction. All the subassemblies come together to form a fully functional scooter during final assembly. The scooter is put through a thorough testing process to ensure that it meets industry requirements for performance and safety. Finally, scooters are packaged and sent safely to prevent damage during transit before being delivered to stores or to clients directly.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the electric kick scooter manufacturing plant include frame, battery pack, battery management system, motor, suspensions, handle-bar cluster, brakes, folding, front light, rear light, tyres, wires and cables, handle grip, mechanical bell, accelerator, kick stand and others. To produce 1 unit of electric kick scooter, we require 1 unit of frame, 1 unit of battery pack, 1 unit of battery management system, 1 unit of motor, suspensions, 1 unit of handle-bar cluster, 2 units of brakes, 1 unit of folding, 1 unit of front light, 1 unit of rear light, 2 units of tyres, 1 set of wires and cables, 1 set of handle grip, 1 unit of mechanical bell, 1 unit of accelerator, 1 unit of kick stand and 1 set of other components.

List of Machinery:

The following equipment was required for the proposed plant:

- Line Body

- Scooter Upside Down Stand Fixtures

- Scooter Stand Fixture

- Control Systems

- Air Driving Gun

- Pneumatic Screwdriver

- Spring Balancer

- Spiral Pipe

- Air Compressor

- Filter

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

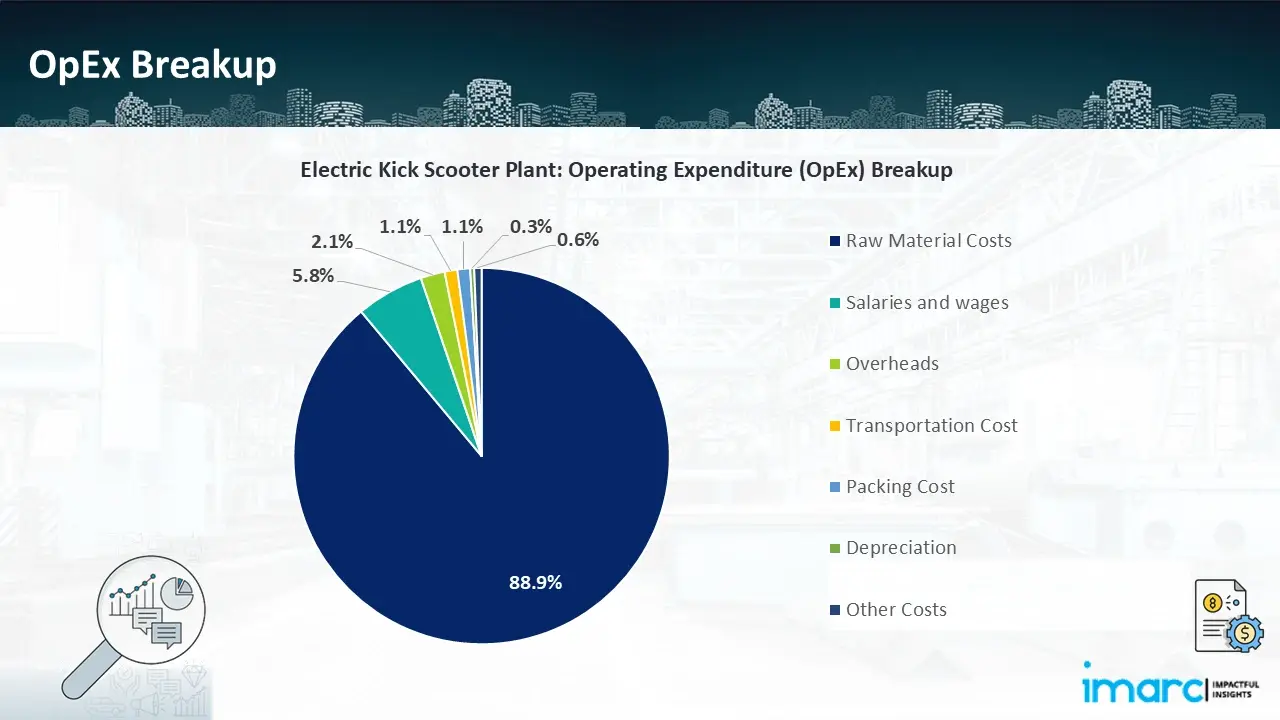

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

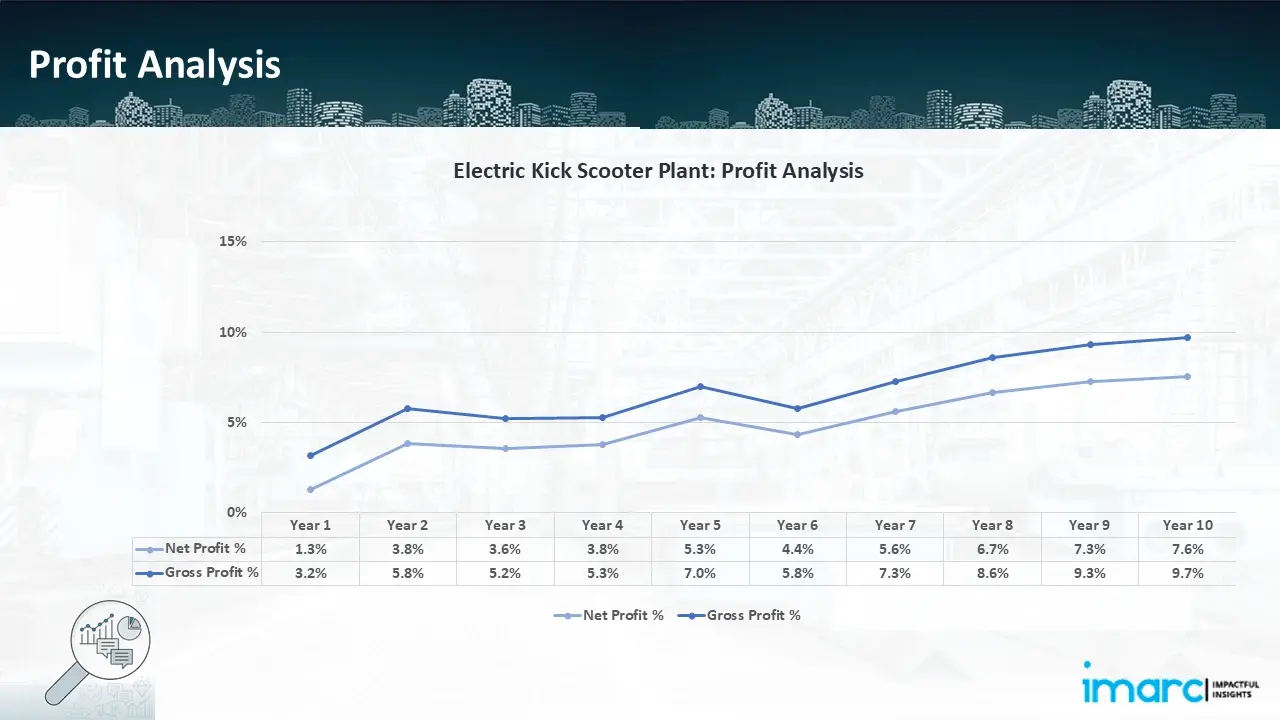

- Profitability Analysis Year on Year Basis: The proposed electric kick scooter plant, with a capacity of 74 units of electric kick scooter in the first year to 378 units of electric kick scooter by the tenth year, achieved an impressive revenue of USD 8.6 Million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit improved from 3.2% to 9.7%, and net profit rise from 1.3% to 7.6%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our electric kick scooter manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 74 units of electric kick scooter in the first year itself and further increasing the production to 378 units of electric kick scooter. Our commitment to offering precise, client-cantered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In January 2025, Segway debuted improved third-generation versions of their well-liked electric scooters at CES 2025. With performance improvements and industry-leading technology, these new models are designed to give riders an exceptional riding experience.

- In November 2024, Otherlab unveiled the 'Lightfoot,' a cutting-edge electric scooter with solar panels to alleviate range anxiety. The Lightfoot, which retails for D4,995, may be preordered and should arrive in January 2025.

- In November 2024, A new line of high-performance maxi-scooters is scheduled to be released by Harley-Davidson in 2026 through its all-electric LiveWire division. These scooters, which were developed in partnership with Taiwanese scooter company KYMCO, are intended to meet the increasing demand for electric two-wheelers.

- In October 2023, an Indian e-scooter company, Ola Electric raised USD 240 Million in loan and USD 140 Million in equity to build the Ola Gigafactory, a lithium-ion battery manufacturing facility in Tamil Nadu.

- In November 2022, a micro-mobility company Helbiz, Inc. declared that it has successfully merged with Wheels Labs, Inc. ("Wheels"), as previously disclosed. By increasing Helbiz's global footprint to 67 markets, the acquisition is anticipated to improve the company's operational capabilities, develop a more diverse business plan, and improve its financial profiles.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104