Clay Brick Cost Model: Detailed Profitability Analysis

What is Clay Brick?

Clay bricks are one of the oldest and most extensively used construction materials in the globe, appreciated for their strength, durability, insulation against heat, and beauty. They are produced mainly from natural clay and shale, which are fashioned, dried, and subjected to high-temperature firing to produce a hard, dense material that can resist multiple environmental and structural stresses.

Key Applications Across Industries:

The mix generally consists of alumina, silica, lime, iron oxide, and magnesia that collectively decide the color, texture, and performance properties of the brick. Clay bricks are classified into types like facing bricks, engineering bricks, and common building bricks that fulfill specific uses in dwelling, commercial, and infrastructural works. Contemporary production of bricks has shifted from age-old clamp kilns to energy-efficient tunnel kilns and computer-controlled extrusion processes, promoting consistency, minimized waste, and fuel efficiency. In addition, clay brick production has followed sustainability directions through developments such as low-emission firing technology, waste heat recovery, and the use of recycled materials. The aesthetic variety and long life of clay bricks make them suitable for purposes beyond their structural applications, they are the choice for architectural design and landscaping as well. Their capacity to control indoor climates, withstand fire, and be low maintenance makes them an ecologically friendly material. With construction activity expanding day by day across the world, clay bricks continue to be a staple of contemporary architecture, combining traditional skill with modern technology to address the needs of sustainable and resilient building.

What the Expert Says: Market Overview & Growth Drivers

The global clay brick market reached a value of USD 1,106.8 Billion in 2024. According to IMARC Group, the market is projected to reach USD 1,469.5 Billion by 2033, at a projected CAGR of 2.8% during 2025-2033. The global market for clay bricks is spurred by strong demand from the infrastructure and construction industries, fueled by population growth, urbanization, and increasing housing demand in emerging economies.

India, China, and other African countries are experiencing huge residential and commercial building developments, which are driving clay brick demand very substantially. The strength of the material, energy efficiency, and affordability make it an ideal option for constructors requiring long-term structural integrity. Another key driver is the growth in emphasis on energy-efficient and sustainable materials. Contemporary clay brick production includes the use of renewable energy, green kilns, and recycled materials, moving towards worldwide green building certifications and green regulations. The thermal insulation of clay bricks results in reduced energy usage in buildings, further encouraging the use of clay bricks in green architecture. Also, technology development in automation, extrusion, and kiln design is enhancing manufacturing efficiency and decreasing carbon footprints, making the manufacturing of clay bricks competitive with other options such as concrete blocks and AAC. Government programs for housing such as affordable housing schemes and rural infrastructure building are also major drivers of market growth. Additionally, visual diversity and architectural creativity have made clay bricks a prominent design feature with manufacturers launching novel textures, colors, and sizes for contemporary facades. Increased disposable income and growing demand for low-maintenance, fire-resistant materials in both developed and emerging economies drive demand ever higher. Overall, the expansion of the clay brick industry rests on its qualities of sustainability, economy, and long-lasting performance, keeping it pertinent amidst the shifting global building paradigm.

Case Study on Cost Model of Clay Brick Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale clay brick manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed clay brick manufacturing plant in India. This plant is designed to produce 6,500,000 units of clay brick annually.

Manufacturing Process: Production of clay bricks entails some rigorously managed phases which turn raw clay into hard, high-quality construction materials. The operation usually starts with raw material mining and preparation, where shale, clay, and additives (like fly ash or sand) are dug and trucked to the plant. The raw materials are next crushed, ground, and separated to have a consistent particle size before being mixed with water to produce a uniform, plastic mass that can be molded. The second step is molding or shaping, which is possible with three primary techniques like soft mud, stiff mud (extrusion), or dry press, depending on the water content and product to be made. Extrusion in stiff mud is the most prevalent process in contemporary brick production, wherein the prepared clay is pushed through a die to produce a continuous column, which is cut into separate bricks by wire cutters. Following shaping, the green bricks are dried in controlled rooms or natural air-drying conditions to drive off surplus moisture, minimizing crack risk at firing. Dried bricks are subsequently fired in kilns, historically in clamp kilns or, more currently, in tunnel kilns, at temperatures between 900°C and 1,100°C. Firing fixes the clay particles into a glassy state, making the bricks stronger, harder, and more colorful. Lastly, the cooling and quality inspection processes guarantee that only bricky and evenly sized, textured, and colored bricks are packaged for distribution. This well-engineered process produces clay bricks that are weather resistant, durable, and perfect for contemporary construction use.

Get a Tailored Feasibility Report for Your Project Request Sample

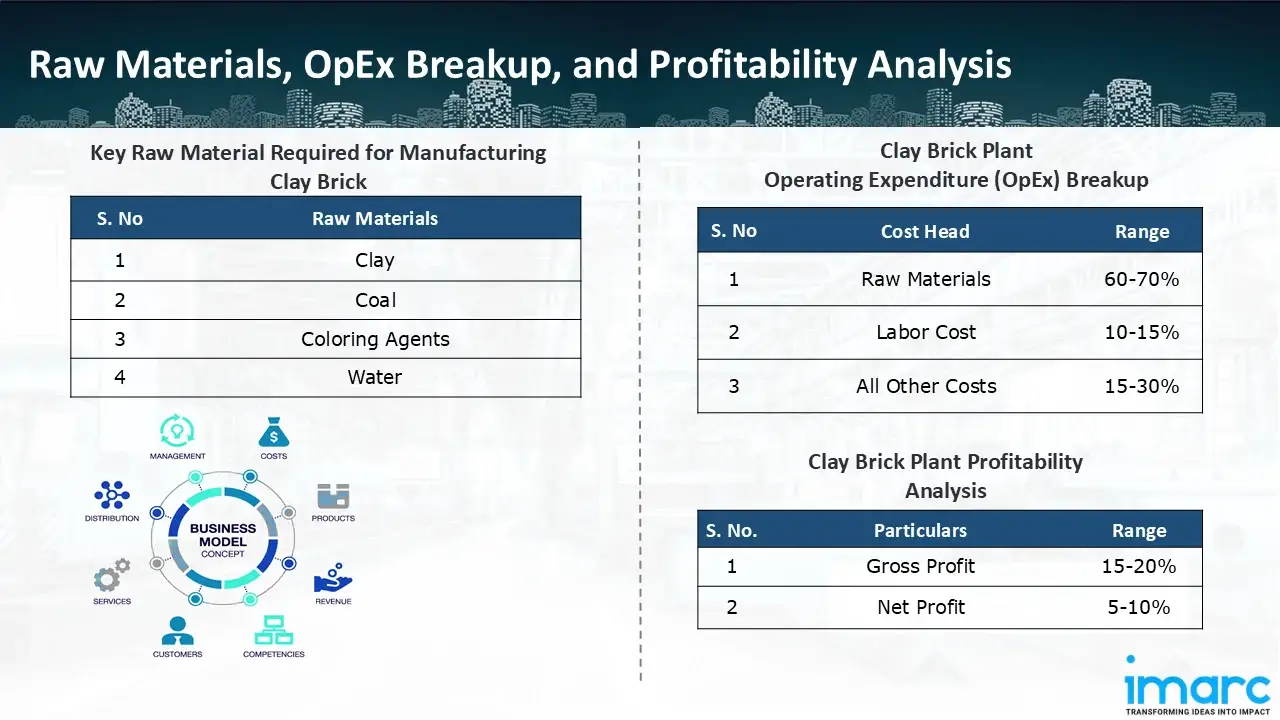

Raw Material Required:

The basic raw materials required for clay brick manufacturing include:

- Clay

- Coal

- Coloring Agents

- Water

Machineries Required:

- Excavators & Loaders

- Conveyors / Hoppers

- Weighing Systems

- Jaw Crusher / Hammer Mill / Roller Crusher

- Pug Mill / Pan Mixer

- Water Spray Systems

- Moulding Machine

- Extruder / Wire-Cut Machine

- Semi-Automatic Brick Presses

- Sun Drying Racks

- Tunnel Dryers / Chamber Dryers

- Clamp Kiln/ Hoffman Kiln/ Tunnel Kiln

- Cooling Conveyors

- Automated Sizing / Weight Checking Systems and Conveyors

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a clay brick manufacturing plant ranges between 60-70%, labor cost ranges between 10% to 15%, and all other costs ranges between 15-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the clay brick manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 6,500,000 units of clay brick annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In June 2025, Ibstock, a brick maker, has increased production capacity at multiple sites, helping to alleviate the lack of building materials in Britain. In reaction to a slowdown in the high-margin new-build industry, Ibstock, which controls 40% of the UK brick market, closed its factories in Lancashire in 2023 and Surrey in 2024.

- In November 2024, Wienerberger unveiled their updated brick factory in Uttendorf, Austria. The facility, which has the biggest industrial electric kiln in the world, raises the bar for environmentally friendly brick manufacturing. By using green electricity, such as that generated by the plant's photovoltaic system, Wienerberger is cutting emissions from brick manufacture by about 90% and energy use by a third.

- In October 2024, Palmetto Brick is building a US$ 5M robotic packaging system in Wallace, on the heels of US Brick's US$ 5.5M Richland County expansion. Meanwhile, Evonik has broken ground on a major silica expansion in Charleston.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104