Breaking Down the Economics of a Frameless Shower Door Manufacturing Plant: An Insightful Analysis

What is Frameless Shower Door?

A frameless shower door is a modern and aesthetically appealing bathroom fixture that has gained popularity for its sleek and minimalist design.

Key Applications Across Industries:

They are constructed without the bulky metal framing that surrounds the glass panels and are typically made from thick, tempered glass that is securely attached to the wall and floor using hinges or brackets. The absence of a visible frame creates a seamless and open look in the bathroom, making it appear more spacious and inviting.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global frameless shower door market was valued at US$ 5.12 Billion in 2024, growing at a CAGR of 4.9% from 2019 to 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 7.4% from 2025 to 2033, reaching a projected value of US$ 9.80 Billion by 2033. The global frameless shower door market is influenced by a multitude of factors, such as the increasing demand for modern and aesthetically pleasing bathroom designs and the escalating trend of open and spacious bathroom layouts.

Furthermore, the growing awareness of the advantages of frameless shower doors, such as ease of maintenance and cleaning, is encouraging consumers to opt for these products. Additionally, the rapid expansion of the hospitality industry, the increasing urbanization, and the surging demand for sleek and minimalist bathroom aesthetics are fueling the market expansion. Another notable factor is the advancements in glass technology and manufacturing processes. In line with this, the emphasis on bathroom renovations and remodelling projects in residential spaces and the availability of various customization options and innovative designs are providing a thrust to the market growth.

Case Study on Cost Model of Frameless Shower Door Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale frameless shower door manufacturing plant in New Hampshire, US.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 180,000 sqm frameless shower door per year.

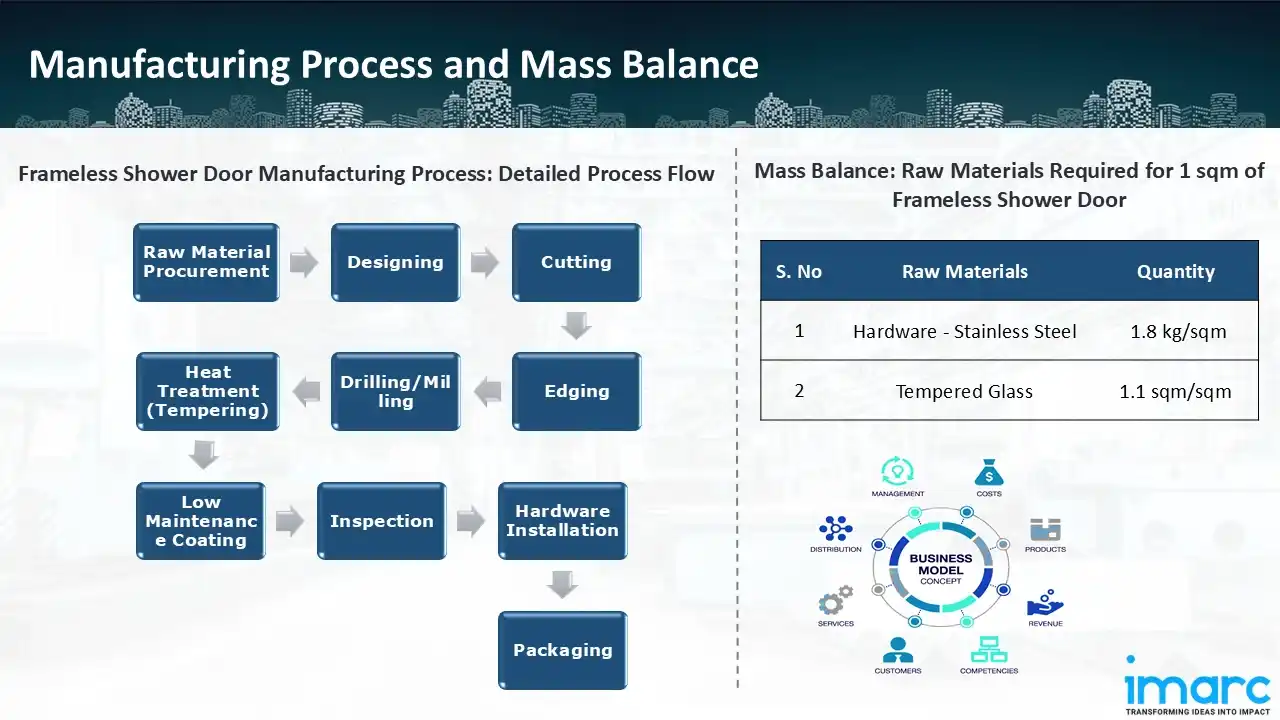

Manufacturing Process: The first step in the production of frameless shower doors is the acquisition of raw materials, where premium tempered glass and long-lasting metal components, like brass or stainless steel, are found. In order to ensure a perfect fit for the shower space, digital templates are created using exact measurements and customer specifications throughout the designing phase. During the cutting phase, glass panels are shaped in accordance with the design criteria using automated CNC machines or laser cutters. To improve safety and attractiveness, edging smoothes the glass edges after cutting. After that, holes or slots are made for hardware installation using drilling or milling to guarantee smooth assembly. A critical process called heat treatment, or tempering, involves carefully heating and quickly cooling glass to increase its strength and resistance to breaking. To ensure long-term clarity and ease of washing, a low-maintenance coating is then sprayed to the glass surface to minimise mineral buildup, water stains, and spots. A comprehensive inspection after manufacture guarantees that the glass satisfies industry standards for safety and durability. Handles, hinges, and brackets are fastened during the hardware installation stage. The completed frameless shower doors are then prepared for distribution after being carefully packed to guard against damage during transit.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the frameless shower door manufacturing plant include tempered glass and hardware-stainless steel. Around 1.1 kg/sqm of tempered glass and around 1.8 sqm/sqm of hardware- stainless steel are required to make 1 sqm of frameless shower door.

List of Machinery

The following equipment was required for the proposed plant:

- CNC Glass Cutting Machine

- Glass Edge Polishing Machine

- Glass Tempering Furnace

- Glass Drilling Machine

- Glass Washing and Drying Machine

- CNC Metal Cutting Machine

- CNC Metal Drilling Machine

- Polishing and Buffing Machine

- Metal Bending Machine

- Assembly Workstations

- Quality Inspection Tools

- Air Compressors

- Overhead Crane

- Forklifts

- Coating Application Machine

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

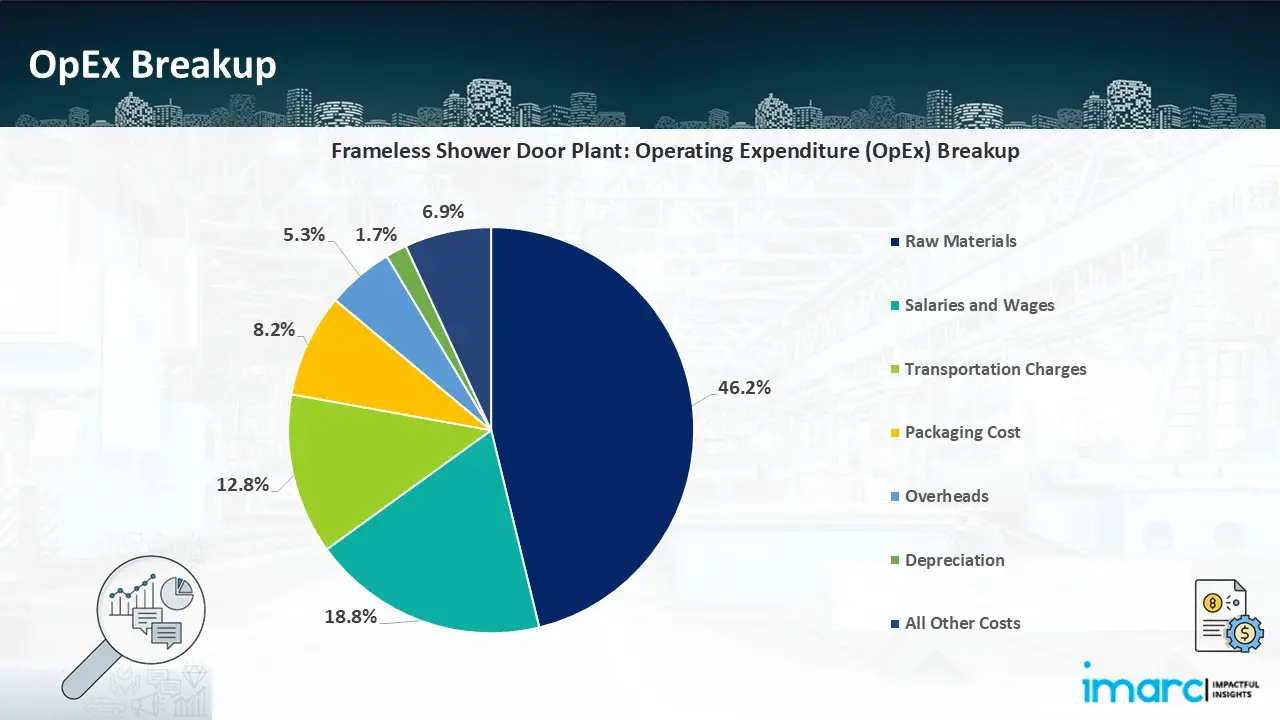

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

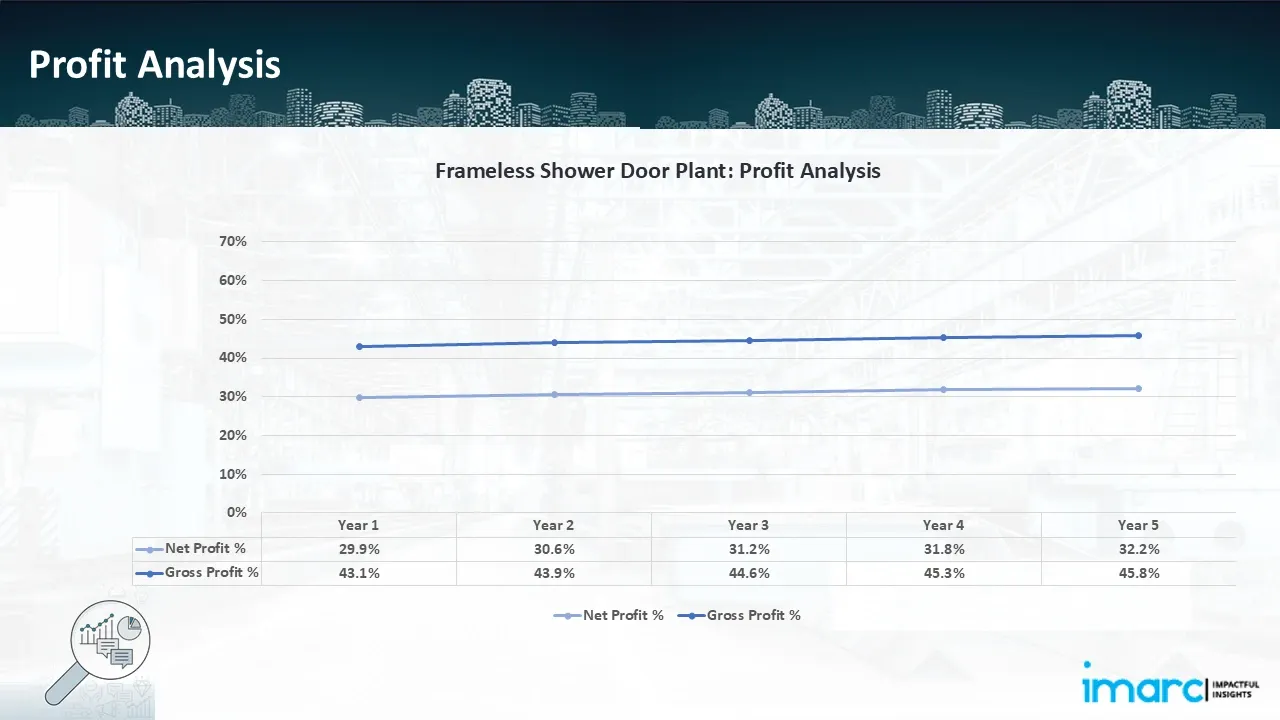

- Profitability Analysis Year on Year Basis: The proposed frameless shower door plant, with a capacity of 180,000 sqm frameless shower door per year, achieved an impressive revenue of US$ 17.64 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit improved from 43.1% to 45.8%, and net profit rise from 29.9% to 32.2%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our financial model for the frameless shower door manufacturing plant was meticulously designed to meet the client’s objectives. It offered a comprehensive examination of production costs, covering capital expenditures, manufacturing procedures, raw materials, and operating costs. The model, which is specifically designed to meet the need of manufacturing 180,000 sqm frameless shower door per year, anticipates profitability while taking market trends, inflation, and any changes in raw material prices into account. This thorough financial model shows our dedication to providing accurate, customer-focused solutions that guarantee the long-term success of major industrial projects by providing the client with insightful information for strategic decision-making.

Latest News and Developments:

- In December 2024, Wayne Door announced that it had purchased Miceli Glass. Wayne Door anticipates that this action will broaden its offerings and bolster its dedication to provide outside solutions for homes and businesses. Wayne Door will add a broad range of glass services, from custom installs to maintenance for both residential and commercial clients, to its product line as part of this transaction.

- In January 2023, the Tokyo-based Lixil Corp., a manufacturer of housing and water goods, has purchased Basco, a shower door manufacturer in the United States. According to officials, the strategic acquisition allows Lixil to provide customers complete showering and bathroom solutions and grow its extensive kitchen and bath offering in the Americas.

- In December 2022, The Frameless Hardware Company (FHC) acquired Morse Architectural from M-D Building Products Inc. to increase its market share. All product designs and inventory were acquired, along with three U.S. factories in Brea, California; Columbia, South Carolina; and Kent, Washington.

- In January 2022, Basco Shower Enclosures partnered with Glassource, a Michigan-based company that offers shower door and tempered glass solutions. By supplying more regional services and a wider range of products, this strategic alliance broadens Basco's business reach.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.