Industrial Mixer Market Report by Product Type (Agitators, Special Mixers, Submersible Mixers, High-shear Mixers, Static Mixers, Jet Mixers), Type (Solid-Solid, Solid-Liquid, Liquid-Gas, Liquid-Liquid), End Use (Food and Beverages, Mineral Industry, Chemicals, Pharmaceuticals, Plastic Industry, Wastewater, and Others), and Region 2026-2034

Industrial Mixer Market Size:

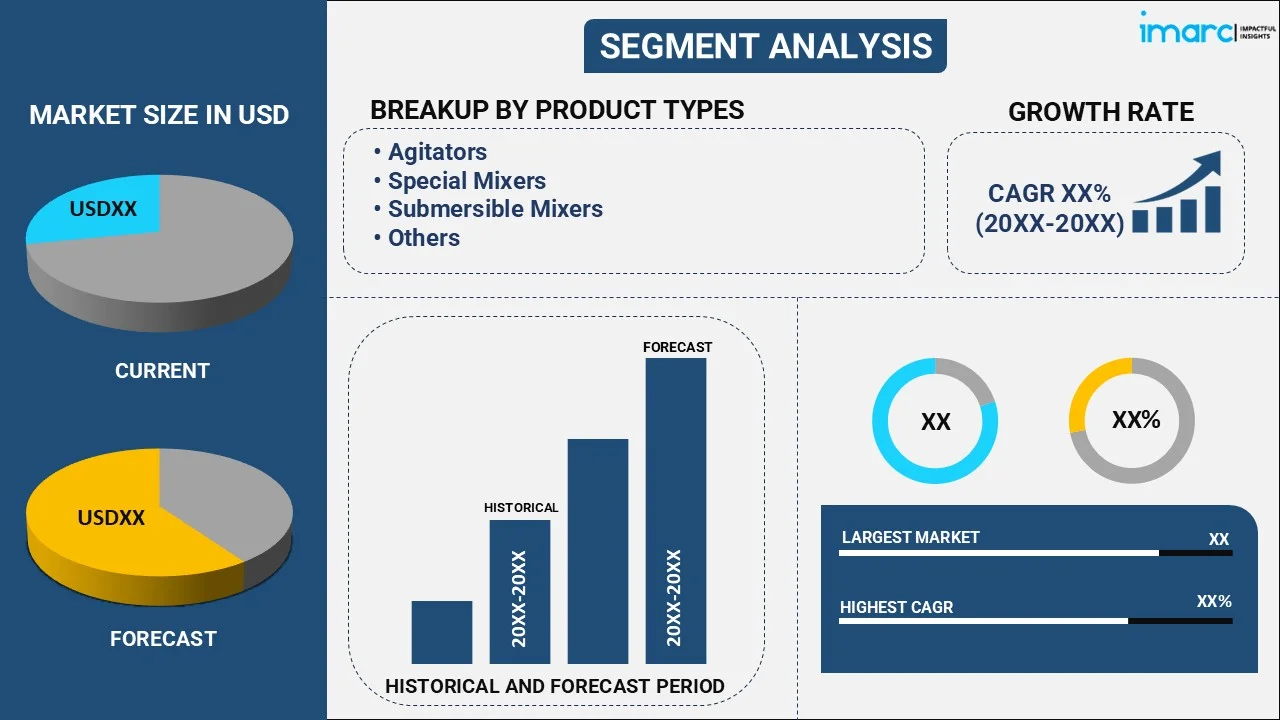

The global industrial mixer market size reached USD 2.9 Billion in 2025. Looking forward, IMARC Group expects the market to reach USD 4.8 Billion by 2034, exhibiting a growth rate (CAGR) of 5.36% during 2026-2034. The market is primarily driven by the significant expansion in the food and beverage (F&B) industry, the technical advancement in industrial automation, and the expanding global beauty and personal care sectors.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

|

Market Size in 2025

|

USD 2.9 Billion |

|

Market Forecast in 2034

|

USD 4.8 Billion |

| Market Growth Rate 2026-2034 | 5.36% |

Industrial Mixer Market Analysis:

- Major Market Drivers: The market is growing due to rising consumer demand for processed foods and technical developments that have produced industrial mixers that are more effective and adaptable. Additionally, the industrial mixer market growth is due to the increasing use of industrial mixers in the chemicals, pharmaceutical, and cosmetics sectors.

- Key Market Trends: The key market trends include the popularity of customization and integration of automation and Internet of Things technology for better process control and efficiency in industrial mixers. In addition, the market is further propelled by the growing preference for small and transportable mixers that can accommodate a variety of production demands and space restrictions.

- Geographical Trends: The emerging economies in Asia-Pacific, particularly China and India, witnessing rapid industrialization and urbanization across the region. Besides, North America and Europe have been steadily expanding due to several developments, and growing emphasis on product quality and regulatory compliance across the region.

- Competitive Landscape: Some of the major industrial mixer companies include Alfa Laval AB, Amixon GmbH, Charles Ross & Son Company, Ekato Holding GmbH, GEA Group Aktiengesellschaft, Komax Systems Inc., Landia Inc., Mixer Systems Inc., Nov Inc., Silverson Machines Inc., SPX Flow Inc., Statiflo Group, Sulzer Ltd., Xylem Inc., and Zhejiang Greatwall Mixers Co. Ltd., among many others.

- Challenges and Opportunities: Process optimization, new product innovation, changing customer taste, and strict regulatory compliance are some challenges manufacturers faces. On the other hand, the industrial mixer market recent opportunities lie in satisfying the surging need for customized solutions, particularly in nutraceuticals and biopharmaceuticals sectors. Additionally, predictive maintenance and digital twin technologies are widely used, which gives suppliers more opportunities to stand out from the competition and offer value-added services.

To get more information on this market Request Sample

Industrial Mixer Market Trends:

Increased Food and Beverage Production

The Food and Agriculture Organization (FAO) projects that by 2050, global food production will increase by 70%. This increase is due to the need to feed the growing global population, influencing the industrial mixer market growth. In the food and beverage business, industrial mixers play a crucial role in processing and producing food items in large quantities. These mixers efficiently combine ingredients while upholding stringent hygiene requirements, ensuring the consistency and quality of food products. For instance, the FAO estimates that the demand for cereal used for food and animal feed will reach approximately 3 billion tons by 2050, requiring a nearly one-billion-ton increase in production from the current estimate of 487 million tonnes of global cereal trade for the 2023–2024 period, which represents a 1.7% increase from the trade levels observed in 2022–2023. As the need for food production increases, the demand for industrial mixers also increases, pushing producers to develop and broaden their product lines to meet the industry's expanding demands. Thus, this development immediately supports the industrial mixer market's growth, since these tools are essential for the efficient, large-scale production required in modern food processing operations.

Growing Personal Care and Cosmetics Sector

The global increase in consumer expenditure on cosmetics and personal care products is driving the beauty and personal care products industry. The global market for cosmetics and personal care products was estimated by IMARC Group to be worth US$ 506.2 billion in 2023. Looking ahead, the IMARC Group projects the market to expand at a 4.5% compound annual growth rate (CAGR) from 2024 to 2032, reaching US$ 759.3 billion. Industrial mixers are necessary for producing numerous goods, including lotions and creams, makeup, and hair care items. Components are fully mixed to achieve the necessary texture, consistency, and homogeneity for high-end cosmetic products with the use of industrial mixers. As a result, the market for industrial mixers is expected to grow due to manufacturers' growing expenditures on state-of-the-art mixing equipment that can handle these complex formulations, thus creating a favorable industrial mixer market outlook.

Technological Advancements in Industrial Automation

The capabilities of industrial mixers have significantly improved by the incorporation of automation into industrial processes. The sales of industrial robots have significantly increased, indicating a wider trend toward automated production processes, according to the International Federation of Robotics (IFR). For instance, according to the most recent World Robotics report, industries installed 553,052 industrial robots globally in 2022 a 5% increase from the year before. Geographically, Asia accounted for 73% of these installations, followed by Europe at 15% and America at 10%. Additionally, greater production rates, better control, and precision in industrial mixers resulted in the widespread adoption of industrial automation, essential for remaining competitive across numerous sectors. Furthermore, automated mixers can produce high-quality mixtures with reduced human intervention, error, and cost. Thus, the need for these sophisticated mixers is anticipated to increase as firms continue to implement smart manufacturing practices, thus positively generating industrial mixers market revenue.

Industrial Mixer Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the global, regional, and country levels for 2026-2034. Our report has categorized the market based on product type, type, and end use.

Breakup by Product Type:

To get detailed segment analysis of this market Request Sample

- Agitators

- Special Mixers

- Submersible Mixers

- High-shear Mixers

- Static Mixers

- Jet Mixers

Special mixers account for the majority of the market share

The report has provided a detailed breakup and analysis of the market based on the product type. This includes agitators, special mixers, submersible mixers, high-shear mixers, static mixers, and jet mixers. According to the report, special mixers represented the largest segment.

The industrial mixer market overview indicates that the largest sector is dominated by special mixers. Special mixers are developed for special uses and provide customized solutions to the chemical, food processing, and pharmaceutical sectors. These mixers stand out for their capacity to manage unusual materials, exacting processing specifications, and sophisticated mixing methods. They are extremely versatile and precise in a wide range of production industries, which makes them invaluable in guaranteeing product quality, consistency, and efficiency. Special mixers continue to be important in the industrial mixer market, as companies need customized solutions to satisfy changing needs and regulatory requirements. For instance, on 28 March 2024, Lindor delivers a tailored gentle touch mixer to a German tea company. It successfully delivered a custom-made industrial tea mixer to a satisfied customer in Germany. This medium-sized rotating drum mixer has a batch capacity of 2000 liters (71 cubic feet), with Lindor's exclusive gentle touch mixing technique, and a retractable inlet and outlet for easy cleaning and maintenance. For this specific commission, the regular Lindor tea blender was modified by replacing the present outlet with a bigger one to meet the client's product's distinct qualities. This change was required to enable a smooth and efficient product discharge, according to the client's unique needs.

Breakup by Type:

- Solid-Solid

- Solid-Liquid

- Liquid-Gas

- Liquid-Liquid

Solid-solid holds the largest share of the industry

A detailed breakup and analysis of the market based on the type have also been provided in the report. This includes solid-solid, solid-liquid, liquid-gas, and liquid-liquid. According to the report, solid-solid accounted for the largest market share.

Solid-solid mixers play a pivotal role in industries requiring precise blending of dry materials such as powders, granules, and particles. These mixers are favored for their ability to achieve uniformity in blending, essential for applications in pharmaceuticals, food processing, and chemical manufacturing. They are widely employed for their versatility which extends to processes demanding gentle mixing to preserve product integrity or intense agitation for thorough homogenization. As a result, solid-solid mixers cater to a diverse range of industrial needs, thus escalating the industrial mixer market demand.

Breakup by End Use:

- Food and Beverages

- Mineral Industry

- Chemicals

- Pharmaceuticals

- Plastic Industry

- Wastewater

- Others

Food and beverages represent the leading market segment

The report has provided a detailed breakup and analysis of the market based on the end use. This includes food and beverages, mineral industry, chemicals, pharmaceuticals, plastic industry, wastewater, and others. According to the report, food and beverages represented the largest segment.

Food and beverages encompass numerous applications ranging from bakery goods to dairy products and beyond. Additionally, industrial mixers are essential in ensuring consistent quality, efficient production, and precise mixing of ingredients crucial for food safety standards and flavor consistency. It is widely employed for the blending of ingredients for sauces, the kneading of dough for bread, or the emulsification of beverages, industrial mixers cater to the diverse needs of the food and beverage industry, driving innovation and enhancing production capabilities to meet evolving consumer demands. For instance, on 12 March 2024, Lindor delivered refurbished industrial coffee in Vietnam. A Lindor machine, previously used and now refurbished, has started a new chapter with a global coffee company in Vietnam. This mixer, which boasts a drum capacity of 2000 liters, is sent to Vietnam to begin its second operational life. This older mixer has been upgraded with a retractable inlet and outlet system, enhancing its efficiency by reducing downtime and simplifying cleaning and inspection processes. Lindor's gentle mixing machines are known for their durability, typically lasting at least 35 years with minimal maintenance and service.

Breakup by Region:

To get more information on the regional analysis of this market Request Sample

- North America

- United States

- Canada

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

Asia Pacific leads the market, accounting for the largest industrial mixer market share

The report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, Asia Pacific was the largest regional market for industrial mixers.

As per the industrial mixer market forecast, Asia Pacific is dominating the market. Additionally, in this expansive region, countries like China, India, and Japan emerge as key contributors to this trend, fueled by rapid industrialization, burgeoning manufacturing sectors, and increasing demand across various end user industries such as food and beverages, chemicals, and pharmaceuticals. The robust economic growth, coupled with infrastructural developments and favorable government initiatives promoting industrial expansion, further propel the demand for industrial mixers in Asia Pacific.

Competitive Landscape:

- The market research report has also provided a comprehensive analysis of the competitive landscape in the market. Detailed profiles of all major companies have also been provided. Some of the major market players in the industrial mixer industry include Alfa Laval AB, Amixon GmbH, Charles Ross & Son Company, Ekato Holding GmbH, GEA Group Aktiengesellschaft, Komax Systems Inc., Landia Inc., Mixer Systems Inc., Nov Inc., Silverson Machines Inc., SPX Flow Inc., Statiflo Group, Sulzer Ltd., Xylem Inc., Zhejiang Greatwall Mixers Co. Ltd., etc.

(Please note that this is only a partial list of the key players, and the complete list is provided in the report.)

- The key players in the industrial mixer market are implementing various strategies to strengthen market growth. They are investing significantly in research and development to innovate and introduce advanced mixing technologies that enhance efficiency, reduce energy consumption, and improve product quality. These companies are focusing on strategic partnerships and collaborations with other industry stakeholders to expand their market presence and reach new customer segments. Moreover, many players are actively engaging in mergers and acquisitions to broaden their product portfolios, acquire new technologies, and penetrate emerging markets. For instance, on 23 January 2023, Cemen Tech, a company with 55 years of global leadership in volumetric concrete solutions, announced the launch of the CD2, a new milestone in its series of computerized models. The CD2 is a fully automated unit in the C Series and features a distinctive dual bin design that allows for the separate transportation and mixing of various supplementary cementing materials (SCMs). This mixer is also capable of processing fly ash, an essential ingredient often required by Department of Transportation (DOT) regulations and local government standards.

Industrial Mixer Market News:

- 16 April 2024: Cytiva introduced the Xcellerex magnetic mixer, a single-use mixing system tailored for large-scale manufacturing in monoclonal antibody, vaccine, and genomic medicine production. It is available in 2000 and 3000 L capacities and the mixer provides multiple configurations to accommodate a variety of mixing requirements.

- 6 May 2024: ROSS VersaMix for high-viscosity applications was introduced with the ROSS line of multi shaft mixers. It is specifically engineered for challenging high viscosity and high shear applications, making it perfect for use with chemicals, coatings, adhesives, composites, and more. It is designed to meet the needs of high volume, precise production processes, the featured PVM-500-gallon VersaMix model comes equipped with a robust 30 HP three-wing anchor agitator and a 75 HP high-speed disperser with a 15” blade, ideal for quick powder wet-out and dispersion.

Industrial Mixer Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Product Types Covered | Agitators, Special Mixers, Submersible Mixers, High-shear Mixers, Static Mixers, Jet Mixers |

| Types Covered | Solid-Solid, Solid-Liquid, Liquid-Gas, Liquid-Liquid |

| End Uses Covered | Food and Beverages, Mineral Industry, Chemicals, Pharmaceuticals, Plastic Industry, Wastewater, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Alfa Laval AB, Amixon GmbH, Charles Ross & Son Company, Ekato Holding GmbH, GEA Group Aktiengesellschaft, Komax Systems Inc., Landia Inc., Mixer Systems Inc., Nov Inc., Silverson Machines Inc., SPX Flow Inc., Statiflo Group, Sulzer Ltd., Xylem Inc., Zhejiang Greatwall Mixers Co. Ltd., etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the industrial mixer market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the global industrial mixer market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's five forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the industrial mixer industry and its attractiveness.

- The competitive landscape allows stakeholders to understand their competitive environment and provides insight into the current positions of key players in the market.

Key Questions Answered in This Report

The industrial mixer market was valued at USD 2.9 Billion in 2025.

The industrial mixer market is projected to exhibit a CAGR of 5.36% during 2026-2034, reaching a value of USD 4.8 Billion by 2034.

The industrial mixer market is growing because of factors like rising demand for efficient and uniform mixing in industries such as F&B, chemicals, and pharmaceuticals. Advancements in automation, the need for energy-efficient solutions, and the growth of manufacturing sectors also contribute to the market expansion. Additionally, innovations in mixer design and technology boost performance and reliability.

Asia Pacific currently dominates the industrial mixer market. The dominance of the region is because of rapid industrialization, particularly in countries like China and India. The robust manufacturing base, demand for efficient production processes, and significant growth in sectors such as food processing, chemicals, and pharmaceuticals drive the need for advanced industrial mixing solutions in the Asia Pacific.

Some of the major players in the industrial mixer market include Alfa Laval AB, Amixon GmbH, Charles Ross & Son Company, Ekato Holding GmbH, GEA Group Aktiengesellschaft, Komax Systems Inc., Landia Inc., Mixer Systems Inc., Nov Inc., Silverson Machines Inc., SPX Flow Inc., Statiflo Group, Sulzer Ltd., Xylem Inc., Zhejiang Greatwall Mixers Co. Ltd., etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)