Industrial Automation Services Market Report by Type of Service (Project Engineering and Installation, Maintenance and Support Services, Consulting Services, Operational Services), Product Type (DCS, SCADA, PLC, MES, and Others), End User (Discrete Industries, Process Industries), and Region 2025-2033

Industrial Automation Services Market Size:

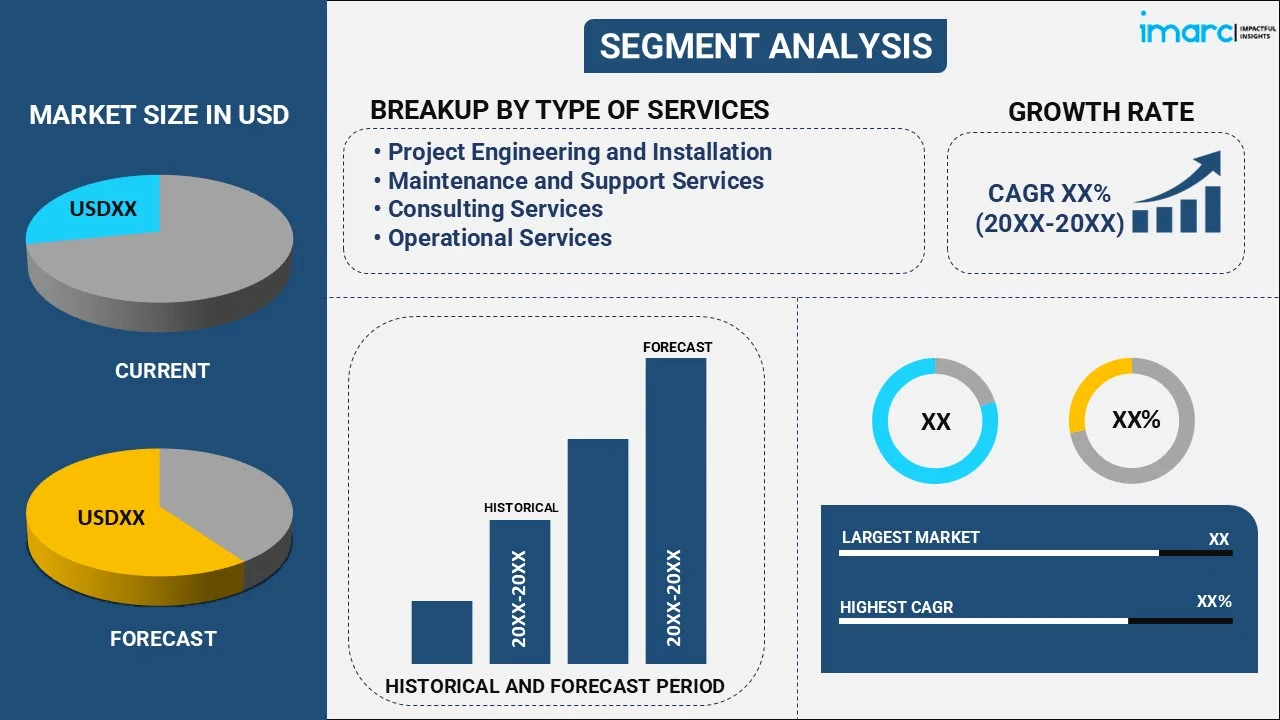

The global industrial automation services market size reached USD 233.5 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 459.5 Billion by 2033, exhibiting a growth rate (CAGR) of 7.42% during 2025-2033. Europe represents the largest segment due to the increasing number of smart factories and heightened usage of industry 4.0 technologies. Apart from this, the heightened need for automation to improve operational efficiency, increasing addition of advanced technologies, such as internet of things (IoT), artificial intelligence (AI), and big data analytics, and rising number of smart factories are impelling the market growth.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 233.5 Billion |

|

Market Forecast in 2033

|

USD 459.5 Billion |

| Market Growth Rate 2025-2033 | 7.42% |

Industrial Automation Services Market Analysis:

- Major Market Drivers: The market is experiencing moderate growth owing to the increasing adoption of industry 4.0 systems in various sectors to improve the work efficiency. Moreover, the heightened focus on not relying on human labor is propelling the market growth.

- Key Market Trends: Major trends include the rising need for automation for improving operational efficiency in industrial settings and join requirements for compliance with various regulations and standards. Apart from this, the increasing awareness about the benefits of lowering energy consumption is encouraging companies to invest in automation.

- Geographical Trends: Europe represents the largest segment due to the increasing number of smart factories and heightened usage of industry 4.0 technologies.

- Competitive Landscape: Some of the major market players in the industrial automation services industry include Siemens AG, Honeywell International Inc., General Electric Company, Mitsubishi Electric, Rockwell Automation, Johnson Controls Inc., Schneider Electric, Yokogawa Electric Corporation, OMRON Corporation, and Danaher Corporation.

- Challenges and Opportunities: The high initial costs, along with cyber security concerns, are some of the challenges. However, the integration of cloud computing and the rise of smart manufacturing are expected to overcome these issues.

To get more information on this market, Request Sample

Industrial Automation Services Market Trends:

Increasing need for operational efficiency

The market for industrial automation services is experiencing steady growth as organizations increasingly emphasize enhancing operational efficiency. Organizations from manufacturing, energy, automotive, and other industry sectors are implementing automation services to automate production processes, lower downtime, and enhance resource utilization. Through the implementation of automation solutions, organizations are lowering their reliance on human labor, which tends to be error-prone and inefficient. The North American robotics sector maintained its progress during the initial six months of 2025. Recent information from the Association for Advancing Automation (A3) indicates that robot orders grew by 4.3% and revenue increased by 7.5% when compared to the first half of 2024, a positive indicator for ongoing investment in automation within a challenging economic environment. Sophisticated monitoring and predictive maintenance solutions are keeping equipment running at maximum performance, hence eliminating unexpected breakdowns. In addition, automation is complementing the convergence of real-time analytics, which is helping companies detect bottlenecks and improve processes. Companies are achieving huge cost savings through waste reduction, energy conservation, and the prolongation of equipment life. This need for greater productivity and reduced costs of operation is constantly driving the use of automation services.

Growing Use of Industry 4.0 and Smart Manufacturing

The industrial automation services market is growing as industries are adopting Industry 4.0 concepts and smart manufacturing methods increasingly. Industry 4.0 is promoting the adoption of digital technologies like the Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML) into manufacturing processes. Firms are embracing such services to support intelligent decision-making, predictive maintenance, and better supply chain management. The smart factory trend is streamlining communication between machines, increasing flexibility, and supporting mass customization in the production process. With the availability of real-time data and analysis, organizations are gaining better process visibility and responsiveness. Industrial automation services providers are providing solutions that are facilitating industries in their shift toward digital manufacturing ecosystems. Connected systems and cyber-physical integration pressures are creating the need for automation services that enable digital transformation. This trend is making Industry 4.0 adoption a driving force behind the growth of the market for automation services. IMARC Group predicts that the Industry 4.0 market is projected to reach USD 570.5 Billion by 2033.

Increased Labor Cost and Workforce Issues

The market for industrial automation services is growing as businesses are increasingly dealing with labor cost and workforce availability challenges. Increasing wages in emerging markets and lack of talent in specialized industrial positions are motivating businesses to embrace automation as a long-term solution. Companies are banking on automation services to undertake repetitive, dangerous, and time-consuming work that is increasingly becoming expensive and hard to man. Compensation and earnings rose by 1.0%, while benefit expenses grew by 0.7% compared to March 2025, as per the U.S. Bureau of Labor Statistics. The embracement of automation is guaranteeing uniformity in operations and diminishing reliance on human labor for key manufacturing processes. Additionally, the labor force is demanding sophisticated technical competencies, and most organizations are fighting hard to bridge the skills gap. By adopting automation services, businesses are avoiding these workforce risks and enhancing operational resilience. With industries continuing to experience recruitment and retention issues, automation is proving to be a viable option, and service providers are providing scalable solutions to meet these labor market pressures optimally.

Industrial Automation Services Market Growth Drivers:

Growing Emphasis on Workplace Safety and Compliance

The market for industrial automation services is growing as businesses are placing greater focus on workplace safety and regulatory compliance. Firms are increasingly implementing automation services to lower the human factor in risky tasks and unsafe environments. Automated systems are performing risky operations like chemical processing, heavy material handling, and high-temperature manufacturing, thus lowering the risk of accidents. With severe government regulations and industry-specific compliance checks, companies are resorting to automation solutions to see to it that safety standards are always being maintained. Automation service providers are delivering monitoring and control systems that are improving environmental, health, and safety management throughout facilities. The application of robotics, sensors, and artificial intelligence-based monitoring tools is assisting organizations to detect risks in real time and implement corrective actions. Prioritizing the safety and compliance of workers, firms are driving the demand for automation services, affirming their position in shaping safer and more sustainable industrial settings.

Driving Digital Transformation Across Industries

The industrial automation services market is being fueled by the speeding up of digital transformation across industries. Organizations are more and more turning to automation services to incorporate digital technologies into their production and operational systems. Digital transformation is facilitating improved data gathering, real-time analysis, and predictive decision-making that is enhancing business performance. Industries are adopting automation solutions that are integrating equipment, software, and data systems to make operations more responsive and adaptive. Increasing cloud computing and edge computing adoption is further aiding automation services by providing capabilities to remotely monitor and control industrial processes. With businesses going digital-first, automation is taking a lead role in achieving process optimization and competitiveness. Automation service providers are creating sophisticated solutions that are in line with digital transformation objectives, making sure that this continuous phenomenon is greatly driving the growth of the industrial automation services market.

Emerging Demand for Energy Efficiency and Sustainability

The industrial automation services market is growing as companies are increasingly seeking energy efficiency and sustainability in operations. Increased energy prices and green issues are compelling businesses to embrace automation services that facilitate intelligent resource utilization. Automation technology is constantly assisting industries to monitor real-time energy usage, streamline power consumption, and cut down on waste. Businesses are incorporating automation in their sustainability strategy to meet carbon reduction goals and meet environmental standards. The use of energy-efficient production systems is helping organizations reduce their cost of operations while improving their environmental performance. Service providers are providing automation solutions that are facilitating the adoption of circular economy models as well as sustainable production methods. Through its ability to facilitate improved utilization of renewable sources of energy, automation is helping provide long-term energy security. The increasing significance of environmental accountability is keeping sustainability a key influence that continues to propel demand in the industrial automation services sector.

Industrial Automation Services Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the global and regional levels for 2025-2033. Our report has categorized the market based on type of service, product type, and end user.

Breakup by Type of Service:

- Project Engineering and Installation

- Maintenance and Support Services

- Consulting Services

- Operational Services

The report has provided a detailed breakup and analysis of the market based on the type of service. This includes project engineering and installation, maintenance and support services, consulting services, and operational services.

Project engineering and installation services govern the design, planning, and implementation of automation systems within industrial environments, thereby influencing the industrial automation services market dynamics. This aspect often involves detailed project management, including system integration, hardware and software installation, and the starting of setup process.

In the lifecycle of an automation system, maintenance and support services help in ensuring ongoing efficiency and reliability. It provides ongoing maintenance, troubleshooting, and repair services to ensure that you have automated systems that operate efficiently with minimal downtime.

Consulting services focus on presenting expert advice and strategy guidance to businesses seeking to implement or enhance their automation infrastructure and capabilities.

Operational services involve the everyday management and optimization of automation systems. This segment includes monitoring system performance, managing operational workflows, and continuously improving processes to enhance the productivity and efficiency.

Breakup by Product Type:

- DCS

- SCADA

- PLC

- MES

- Others

DCS holds the largest share of the industry

A detailed breakup and analysis of the market based on the product type have also been provided in the report. This includes DCS, SCADA, PLC, MES, and others. According to the report, DCS accounted for the largest industrial automation market share.

Distributed control systems (DCS) have been the primary solution for controlling complex processes such as those found in the oil and gas, chemical and power generation industries. DCSs are designed to interconnect and control multiple subsystems throughout a plant, making them the central hub for all monitoring and control. This centralized implementation ensures effective processing of tremendous data volumes with striking accuracy, which is paramount for any mission-critical industrial process, hence making DCSs an imperative tool of use in such commanding industrial operations. Increasing the complexity of industrial functions and ensuring real-time data analysis and process optimization are the key factors driving the demand for DCS. Moreover, DCS are increasingly improving with technological evolutions. The best DCS systems offer improved connectivity, integration with IoT, and even AI capabilities, so DCSs are more practical and exciting than ever. The IMARC Group reports that the global distributed control systems market is expected to reach US$ 31.5 Billion by 2032.

Breakup by End User:

- Discrete Industries

- Process Industries

Process industries represent the leading market segment

The report has provided a detailed breakup and analysis of the market based on the end user. This includes discrete industries and process industries. According to the report, process industries represented the largest segment.

The largest segment underlined for the industrial automation services market revenue caters to process industries that consist of oil and gas, chemicals, power generation, water and wastewater treatment, pharmaceuticals, and food and beverages (F&B). Continuous production and a necessity for reliable monitoring and control have led to these industries being governed by strict standards of safety and quality adhering to strict regulatory requirements. The nature of the process industries is such that they have major scale of operations and complexity, driving the need for a high level of automation to control and optimize production. An example is in 2024 when SLB combined efforts with Nabors Industries to deploy the use of fully automated drilling solutions for the oil and gas operators as well as drilling contractors.

Breakup by Region:

- North America

- Asia Pacific

- Europe

- Middle East and Africa

- Latin America

Europe leads the market, accounting for the largest industrial automation services market share

The report has also provided a comprehensive analysis of all the major regional markets, which include North America, Asia Pacific, Europe, the Middle East and Africa, and Latin America. According to the report, Europe represents the largest regional market for industrial automation services.

Europe's market is witnessing massive adoption of Industry 4.0 technologies such as AI, IoT, and advanced robotics, providing a favorable industrial automation services industry outlook. European industries are now increasingly integrating these technologies to drive higher operational efficiency, lower downtime, attain better levels of accuracy, and improve overall productivity. In addition, the concentration on sustainability and energy conservation is becoming more important. European companies are under pressure to minimize energy consumption and reduce carbon footprints, aligning with stringent environmental regulations and the EU's Green Deal objectives. The emphasis on smart factories, powered by automation systems that support real-time data analytics and predictive maintenance, is also gaining momentum. For example, to address the increased need for engineering-to-order products associated with energy transition and digitalization, Schneider Electric opened a new smart factory in Hungary in 2024.

Competitive Landscape:

- The industrial automation services market research report has also provided a comprehensive analysis of the competitive landscape in the market. Detailed profiles of all major companies have also been provided. Some of the major market players in the industrial automation services industry include Siemens AG, Honeywell International Inc., General Electric Company, Mitsubishi Electric, Rockwell Automation, Johnson Controls Inc., Schneider Electric, Yokogawa Electric Corporation, OMRON Corporation, Danaher Corporation, etc.

(Please note that this is only a partial list of the key players, and the complete list is provided in the report.)

- Businesses are pouring huge amounts of capital into advanced technology like artificial intelligence, machine learning, and IoT. It allows the incorporation of advanced automation solutions, such as predictive maintenance, real-time tracking, and analytics. These companies can deploy even smarter, more flexible automation systems that actually learn and self-adapt as the need arises by utilizing AI within the systems and combining it with IoT. One example is that Siemens developed in 2024 as an innovative solution to the traditional problem of tightly managing the multitude of hardware control points in factory environments. The most successful industrial automation service providers are moving towards more customer-centric support and custom solutions. Companies are scaling their consulting armies to cater to more comprehensive scope discovery to provide tailored automation strategies that match business purposes. Better customer training and stronger aftermarket support allow users to get the most out of their automation equipment and helps ensure greater customer satisfaction and repeat sales.

Industrial Automation Services Market News:

- July 2025: Accenture has purchased SYSTEMA, a company offering software solutions and consulting services for manufacturing automation, located in Dresden, Germany. SYSTEMA’s extensive experience with semiconductor manufacturers and other high-tech firms will enhance Accenture’s ability to thoroughly assist clients in these sectors.

- June 2025: Honeywell revealed new digital technologies that utilize artificial intelligence aimed at speeding up the industrial transition from automation to autonomy. Additionally, the company disclosed the expansion of the Honeywell Digital Prime platform to include a comprehensive set of solutions that efficiently test and adjust engineering projects prior to implementation, thereby reducing plant downtime and enhancing throughput when put into production.

- May 2025: At Automate 2025 in Detroit, Siemens is unveiling an expansion of its industrial AI solutions featuring sophisticated AI agents intended to integrate smoothly within its existing Industrial Copilot framework. This innovative technology marks a significant transition from AI assistants answering questions to genuinely independent agents that actively carry out complete processes without any human involvement. Siemens' latest AI agent framework includes an advanced orchestrator. Similar to a tradesperson, it utilizes a set of specialized tools to address intricate tasks throughout the complete industrial value chain. These agents operate wisely and independently – comprehending purpose, enhancing efficiency through ongoing learning, and utilizing external tools and other agents when required.

- May 2025: Cache Valley Electric (CVE) is excited to declare the purchase of Rouser Automation LLC, a company specializing in precision industrial control systems and automation services. The incorporation of Rouser signifies a tactical growth of CVE's internal capabilities, enhancing its capacity to provide comprehensive, end-to-end project execution in vital markets.

- February 2025: Türkiye-based ELiAR, a leader in industrial automation solutions, has revealed its growth into the Netherlands by establishing a European R&D center at Brainport Industries Campus (BIC). The initiative was emphasized during a recent trip by Reinette Klever, the Netherlands’ Minister for Foreign Trade, along with a sizable Dutch delegation to the company's main office in Istanbul.

- June 2024: Honeywell announced the launch of its Battery Manufacturing Excellence Platform (MXP), which is an artificial intelligence (AI)-powered software solution created to optimize the operation of giga factories from the initial day by improving battery cell yields and expediting facility startups for manufacturers.

Industrial Automation Services Industry Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Industrial Automation Services Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Type of Services Covered | Project Engineering and Installation, Maintenance and Support Services, Consulting Services, Operational Services |

| Product Types Covered | DCS, SCADA, PLC, MES, Others |

| End Users Covered | Discrete Industries, Process Industries |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Companies Covered | Siemens AG, Honeywell International Inc., General Electric Company, Mitsubishi Electric, Rockwell Automation, Johnson Controls Inc., Schneider Electric, Yokogawa Electric Corporation, OMRON Corporation, Danaher Corporation, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the global industrial automation services market performed so far, and how will it perform in the coming years?

- What are the drivers, restraints, and opportunities in the global market?

- What is the impact of each driver, restraint, and opportunity on the global market?

- What are the key regional markets?

- What is the breakup of the market based on the type of service?

- Which is the most attractive type of service in the market?

- What is the breakup of the market based on the product type?

- Which is the most attractive product type in the market?

- What is the breakup of the market based on the end-user?

- Which is the most attractive end-user in the market?

- What is the competitive structure of the market?

- Who are the key players/companies in the global industrial automation services market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, industrial automation services market forecasts, and dynamics of the market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the global industrial automation services market.

- The study maps the leading, as well as the fastest-growing, regional markets.

- Porter's five forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the industrial automation services industry and its attractiveness.

- The competitive landscape allows stakeholders to understand their competitive environment and provides insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)