India Industrial Valves Market Size, Share, Trends and Forecast by Product Type, Functionality, Material, Size, End Use Industry, and Region, 2026-2034

Market Overview:

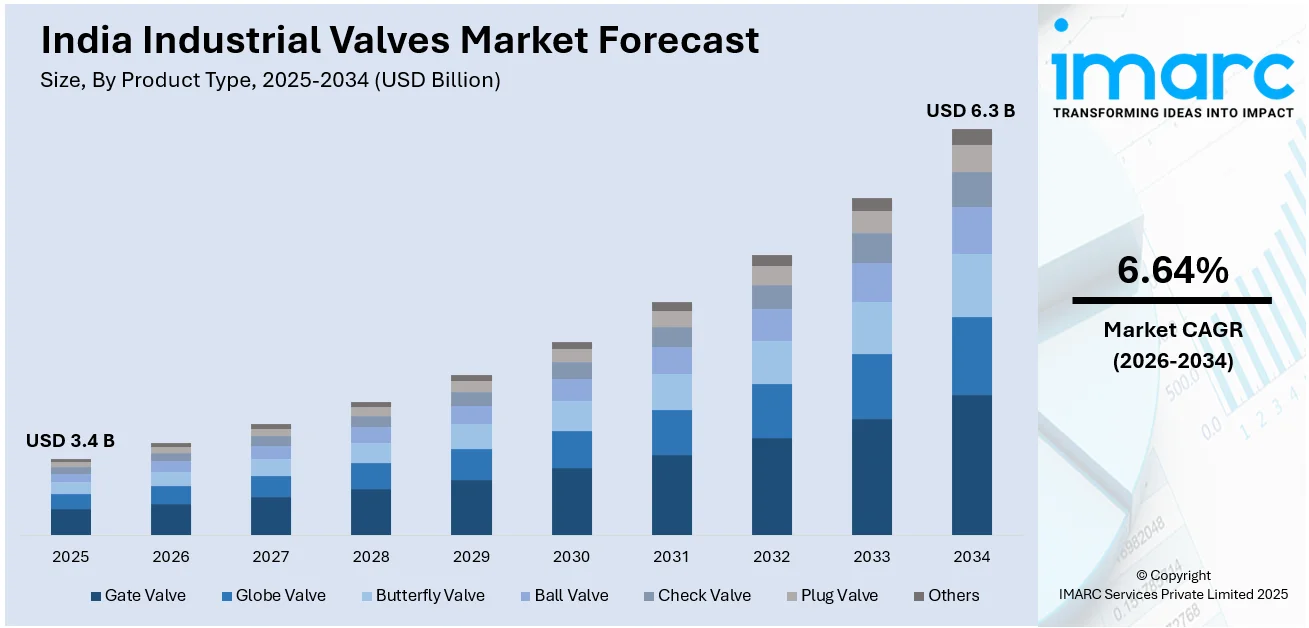

India industrial valves market size reached USD 3.4 Billion in 2025. Looking forward, IMARC Group expects the market to reach USD 6.3 Billion by 2034, exhibiting a growth rate (CAGR) of 6.64% during 2026-2034. The implementation of stringent government regulations regarding safety and environmental standards and the rising focus of key players on energy efficiency are primarily driving the market growth across the country.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

|

Market Size in 2025

|

USD 3.4 Billion |

|

Market Forecast in 2034

|

USD 6.3 Billion |

| Market Growth Rate 2026-2034 | 6.64% |

Industrial valves play a crucial role in a variety of industrial processes, facilitating the management and adjustment of fluid and gas flow. Crafted from high-quality materials like stainless steel, cast iron, or brass, they are designed to ensure durability and dependability. The manufacturing process involves precision techniques such as machining, casting, or forging, followed by rigorous testing to adhere to strict quality standards. Once installed, valves function by opening and closing to regulate the rate and direction of fluid or gas flow. Comprising essential components such as the body, bonnet, seat, disc, stem, and actuator, industrial valves offer advantages through their capacity to control flow, prevent backflow, and deliver a secure shut-off when needed. This functionality significantly contributes to enhancing both the efficiency and safety of industrial processes.

To get more information on this market Request Sample

India Industrial Valves Market Trends:

The industrial valves market in India stands as a cornerstone in the nation's industrial landscape, serving a pivotal role in the regulation and control of fluid and gas flow across diverse sectors. The manufacturing process involves precision techniques such as machining, casting, or forging, coupled with stringent testing to meet and surpass rigorous quality standards. Additionally, in India, the demand for industrial valves is driven by their indispensable role in various industries, including manufacturing, energy, oil and gas, chemicals, and water treatment. As industrial activities in the country continue to expand, the need for efficient flow control mechanisms becomes increasingly critical. Besides this, the components of industrial valves, including the body, bonnet, seat, disc, stem, and actuator, collectively contribute to their functionality. Their ability to provide a tight shut-off, when necessary, adds an extra layer of safety to industrial operations. Furthermore, the advantages offered by industrial valves in terms of flow regulation and process safety contribute to their widespread adoption across the Indian industrial landscape. Apart from this, as industries continue to evolve and demand sophisticated solutions, the industrial valves market in India is poised for sustained growth in the coming years.

India Industrial Valves Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2026-2034. Our report has categorized the market based on product type, functionality, material, size, and end use industry.

Product Type Insights:

- Gate Valve

- Globe Valve

- Butterfly Valve

- Ball Valve

- Check Valve

- Plug Valve

- Others

The report has provided a detailed breakup and analysis of the market based on the product type. This includes gate valve, globe valve, butterfly valve, ball valve, check valve, plug valve, and others.

Functionality Insights:

- On-Off/Isolation Valves

- Control Valves

A detailed breakup and analysis of the market based on the functionality have also been provided in the report. This includes on-off/isolation valves and control valves.

Material Insights:

- Steel

- Cast Iron

- Alloy Based

- Others

The report has provided a detailed breakup and analysis of the market based on the material. This includes steel, cast iron, alloy based, and others.

Size Insights:

- Upto 1”

- 1”-6”

- 7”-25”

- 26”-50”

- 51” and Above

A detailed breakup and analysis of the market based on the size have also been provided in the report. This includes upto 1”, 1”-6”, 7”-25”, 26”-50”, and 51” and above.

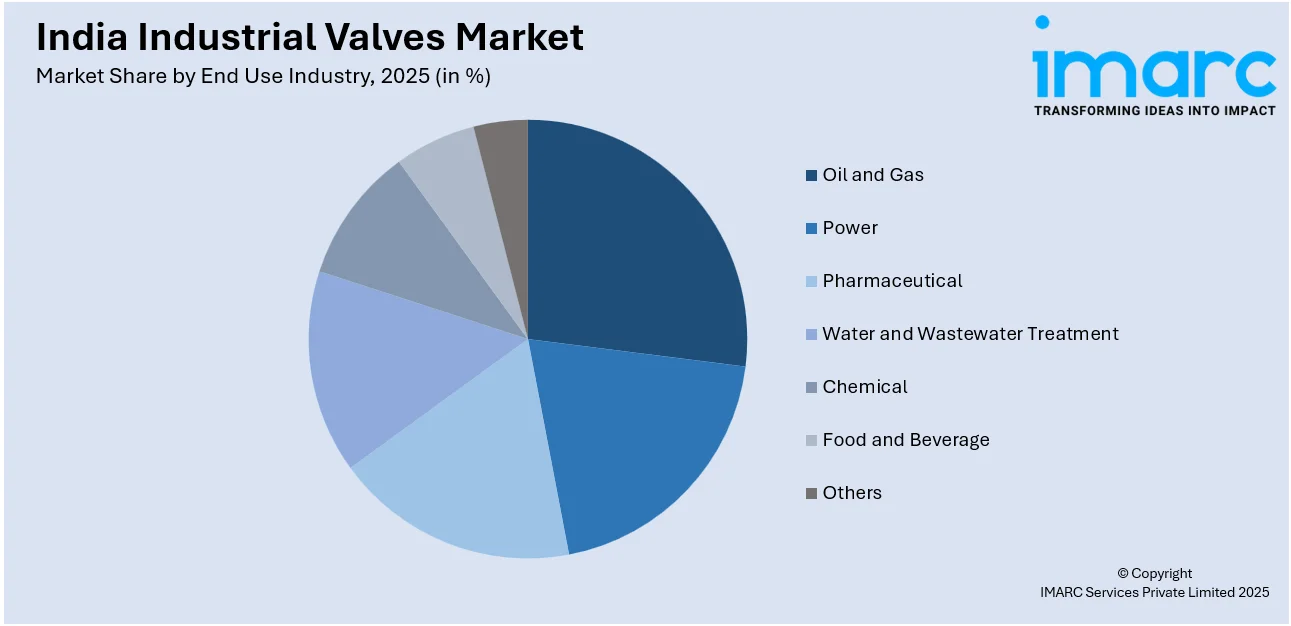

End Use Industry Insights:

Access the comprehensive market breakdown Request Sample

- Oil and Gas

- Power

- Pharmaceutical

- Water and Wastewater Treatment

- Chemical

- Food and Beverage

- Others

The report has provided a detailed breakup and analysis of the market based on the end use industry. This includes oil and gas, power, pharmaceutical, water and wastewater treatment, chemical, food and beverage, and others.

Regional Insights:

- North India

- West and Central India

- South India

- East and Northeast India

The report has also provided a comprehensive analysis of all the major regional markets, which include North India, West and Central India, South India, and East and Northeast India.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

India Industrial Valves Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Product Types Covered | Gate Valve, Globe Valve, Butterfly Valve, Ball Valve, Check Valve, Plug Valve, Others |

| Functionalities Covered | On-Off/Isolation Valves, Control Valves |

| Materials Covered | Steel, Cast Iron, Alloy Based, Others |

| Sizes Covered | Upto 1”, 1”-6”, 7”-25”, 26”-50”, 51” and Above |

| End Use Industries Covered | Oil and Gas, Power, Pharmaceutical, Water and Wastewater Treatment, Chemical, Food and Beverage, Others |

| Regions Covered | North India, West and Central India, South India, East and Northeast India |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the India industrial valves market performed so far and how will it perform in the coming years?

- What has been the impact of COVID-19 on the India industrial valves market?

- What is the breakup of the India industrial valves market on the basis of product type?

- What is the breakup of the India industrial valves market on the basis of functionality?

- What is the breakup of the India industrial valves market on the basis of material?

- What is the breakup of the India industrial valves market on the basis of size?

- What is the breakup of the India industrial valves market on the basis of end use industry?

- What are the various stages in the value chain of the India industrial valves market?

- What are the key driving factors and challenges in the India industrial valves?

- What is the structure of the India industrial valves market and who are the key players?

- What is the degree of competition in the India industrial valves market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the India industrial valves market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the India industrial valves market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the India industrial valves industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)