India Ceramic Matrix Composites Market Size, Share, Trends and Forecast by Composite Type, Fiber Type, Fiber Material, Application, and Region, 2025-2033

Market Overview:

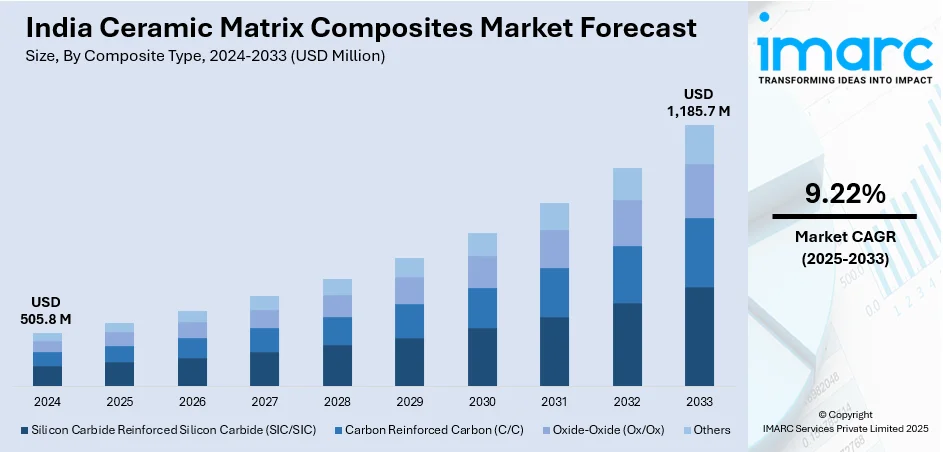

India ceramic matrix composites market size reached USD 505.8 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 1,185.7 Million by 2033, exhibiting a growth rate (CAGR) of 9.22% during 2025-2033. The rising demand for high-performance materials in advancing technological capabilities across several sectors is primarily propelling the market growth across the country.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 505.8 Million |

| Market Forecast in 2033 | USD 1,185.7 Million |

| Market Growth Rate (2025-2033) | 9.22% |

Ceramic matrix composites (CMCs) represent advanced composite materials consisting of ceramic fibers embedded within a ceramic matrix structure. Commonly utilized CMCs include silicon carbide reinforced silicon carbide (SiC/SiC), carbon-reinforced carbon (C/C), and oxide-oxide (Ox/Ox). These materials have diverse applications, including use in gas turbines, structural re-entry thermal protection, heat exchangers, and the walls of fusion reactors. In comparison to traditional composite materials, they offer several advantages. Ceramic matrix composites are characterized by their lightweight nature, ability to withstand elevated temperatures, high chemical stability, and resilience against everyday wear and tear. Additionally, they demonstrate outstanding stiffness, exceptional thermal shock resistance, non-magnetic and non-conductive properties, as well as stability in terms of mechanical, thermal, dimensional, and chemical aspects. Consequently, ceramic matrix composites find broad utilization across various industries such as automotive, electrical, electronics, and power generation, owing to their remarkable combination of properties.

To get more information on this market, Request Sample

India Ceramic Matrix Composites Market Trends:

The ceramic matrix composites market in India is experiencing notable growth and adoption, reflecting the country's increasing emphasis on advanced materials in various industries. One of the key drivers for the growth of the market in the nation is the exceptional set of properties offered by these materials. Moreover, ceramic matrix composites are renowned for being lightweight, allowing for enhanced efficiency in numerous applications. Furthermore, their ability to withstand high temperatures, coupled with high chemical stability, positions them as vital components in industries requiring materials with superior heat resistance and durability. In comparison to traditional material composites, CMCs present a compelling advantage. Besides this, they exhibit excellent stiffness, high thermal shock resistance, and are resistant to everyday wear and tear. Additionally, ceramic matrix composites showcase non-magnetic and non-conductive properties, contributing to their versatility in diverse applications. The automotive, electrical, electronics, and power generation industries in India are witnessing increased integration of CMCs due to their unique combination of properties. Apart from this, with ongoing developments in research and manufacturing, the India ceramic matrix composites market is poised for continued expansion, contributing to the country's strides in technological innovation and industrial advancement.

India Ceramic Matrix Composites Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2025-2033. Our report has categorized the market based on composite type, fiber type, fiber material, and application.

Composite Type Insights:

- Silicon Carbide Reinforced Silicon Carbide (SIC/SIC)

- Carbon Reinforced Carbon (C/C)

- Oxide-Oxide (Ox/Ox)

- Others

The report has provided a detailed breakup and analysis of the market based on the composite type. This includes silicon carbide reinforced silicon carbide (SIC/SIC), carbon reinforced carbon (C/C), oxide-oxide (Ox/Ox), and others.

Fiber Type Insights:

- Short Fiber

- Continuous Fiber

A detailed breakup and analysis of the market based on the fiber type have also been provided in the report. This includes short fiber and continuous fiber.

Fiber Material Insights:

- Alumina Fiber

- Refractory Ceramic Fiber (RCF)

- SiC Fiber

- Others

The report has provided a detailed breakup and analysis of the market based on the fiber material. This includes alumina fiber, refractory ceramic fiber (RCF), SiC fiber, and others.

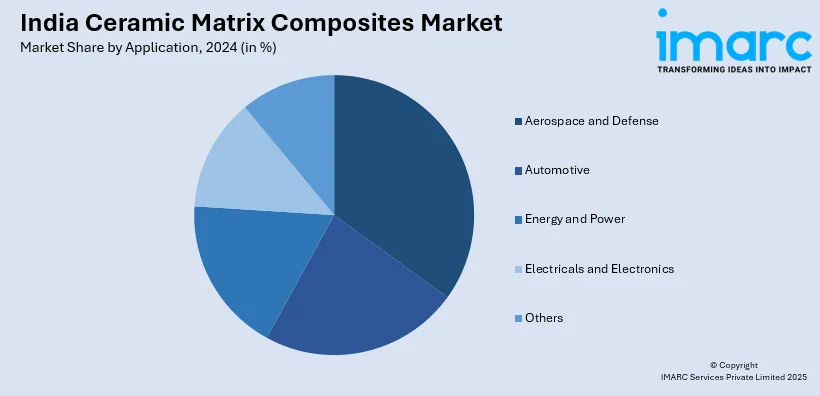

Application Insights:

- Aerospace and Defense

- Automotive

- Energy and Power

- Electricals and Electronics

- Others

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes aerospace and defense, automotive, energy and power, electricals and electronics, and others.

Regional Insights:

- North India

- West and Central India

- South India

- East and Northeast India

The report has also provided a comprehensive analysis of all the major regional markets, which include North India, West and Central India, South India, and East and Northeast India.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

India Ceramic Matrix Composites Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Composite Types Covered | Silicon Carbide Reinforced Silicon Carbide (SIC/SIC), Carbon Reinforced Carbon (C/C), Oxide-Oxide (Ox/Ox), Others |

| Fiber Types Covered | Short Fiber, Continuous Fiber |

| Fiber Materials Covered | Alumina Fiber, Refractory Ceramic Fiber (RCF), SiC Fiber, Others |

| Applications Covered | Aerospace and Defense, Automotive, Energy and Power, Electricals and Electronics, Others |

| Regions Covered | North India, West and Central India, South India, East and Northeast India |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the India ceramic matrix composites market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the India ceramic matrix composites market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the India ceramic matrix composites industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The ceramic matrix composites market in India was valued at USD 505.8 Million in 2024.

The India ceramic matrix composites market is projected to exhibit a CAGR of 9.22% during 2025-2033, reaching a value of USD 1,185.7 Million by 2033.

The main factors contributing to the growth of the ceramic matrix composites market in India are the rising need for lightweight and heat-resistant materials in the aerospace and defense sectors, expansion in industrial manufacturing, and the growing use of these materials in automotive parts to enhance fuel efficiency, lower emissions, and improve overall durability in high-performance applications.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)