Honeycomb Sandwich Material Market Report by Material Type (Aluminum, Steel, Composites, Titanium, Inconel, and Others), Technology (Expansion, Corrugation, Molding, Extrusion, and Others), Application (Aerospace, Automotive, Marine, Locomotive, Construction, and Others), and Region 2025-2033

Honeycomb Sandwich Material Market Size:

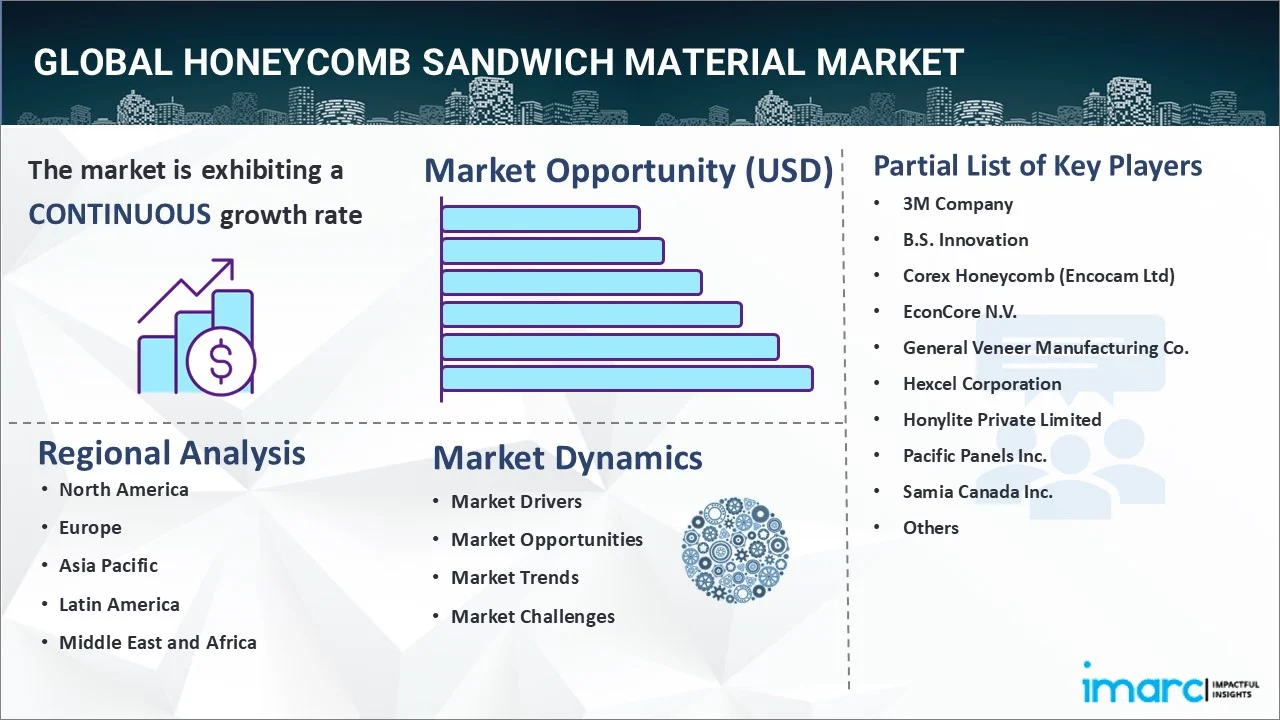

The global honeycomb sandwich material market size reached USD 1.8 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 2.5 Billion by 2033, exhibiting a growth rate (CAGR) of 3.37% during 2025-2033. The rising demand in aerospace, automotive, and construction sectors due to its lightweight, high strength, and energy absorption properties, continuous advancements in manufacturing processes, and escalating environmental concerns promoting energy-efficient materials are some of the factors contributing to the market expansion.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 1.8 Billion |

|

Market Forecast in 2033

|

USD 2.5 Billion |

| Market Growth Rate (2025-2033) | 3.37% |

Honeycomb Sandwich Material Market Analysis:

- Major Market Drivers: The market is primarily driven by the honeycomb sandwich’s crucial role in the aerospace and defense industries due to its excellent strength-to-weight ratio. These materials are essential for manufacturing lightweight, efficient aircraft and military vehicles. Moreover, the automotive and construction sectors also significantly contribute to the market growth with their extensive demand for materials that offer durability, energy efficiency, and superior mechanical properties.

- Key Market Trends: Advancements in manufacturing technologies, such as the expansion method, allowing for the cost-effective and efficient creation of these structures is one of the major honeycomb sandwich material market trends. Along with this, there is a growing shift towards the use of sustainable and recyclable materials, wherein aluminum honeycomb panels are widely favored for their environmental benefits alongside their mechanical properties, driving further adoption across different industries.

- Geographical Trends: North America leads the market, supported by a strong aerospace sector and advanced manufacturing capabilities. The presence of major aerospace companies and a focus on innovative manufacturing techniques help maintain its dominant market position. Moreover, the honeycomb sandwich material market forecast showcases Asia-Pacific as a rapidly growing market due to expanding aerospace and automotive manufacturing sectors in countries like China and India, which are increasingly adopting lightweight materials to boost efficiency and performance.

- Competitive Landscape: Some of the major market players in the honeycomb sandwich material industry include 3M Company, B.S. Innovation, Corex Honeycomb (Encocam Ltd), EconCore N.V., General Veneer Manufacturing Co., Hexcel Corporation, Honylite Private Limited, Pacific Panels Inc., Samia Canada Inc., Schütz GmbH & Co. KGaA, The Gill Corporation, among many others.

- Challenges and Opportunities: The high cost of raw materials and processing for honeycomb sandwich materials, which can inhibit broader adoption, particularly in cost-sensitive markets is challenging market growth. Meanwhile, opportunities lie in the increasing demand for environmentally friendly and energy-efficient construction materials as honeycomb sandwich materials offer considerable potential in green building initiatives, driving market expansion and innovation.

Honeycomb Sandwich Material Market Trends:

Increasing demand in the aerospace and defense industries

According to the honeycomb sandwich material market report, the aerospace and defense industries are the major contributors to its growth. These materials are highly valued in these sectors due to their exceptional strength-to-weight ratio, which is crucial for applications where weight reduction helps enhance fuel efficiency and performance. Moreover, honeycomb sandwich materials are extensively used in the manufacturing of aircraft components such as fuselage, wings, and flight control surfaces. They also find applications in military vehicles and equipment, where lightweight materials can significantly improve mobility and load-carrying capacity. As global air traffic continues to grow and military spending increases in response to geopolitical tensions, the demand for advanced materials that can contribute to more efficient and effective aerospace and defense systems is bolstering the honeycomb sandwich material demand.

Advancements in manufacturing technologies

Ongoing advancements in manufacturing technologies have broadened the application scope of honeycomb sandwich materials. New fabrication methods, such as three-dimensional (3D) printing and automated lay-up processes, have improved the precision, customization, and cost-effectiveness of producing these materials. These technological developments allow for more complex designs and finer structural details, which are particularly advantageous in industries like automotive and marine, where customization is often required. Additionally, the integration of computer-aided engineering and high-precision tools has optimized the performance of honeycomb sandwich structures, making them more appealing for a variety of industrial applications, thereby positively impacting the honeycomb sandwich material market outlook.

Growing emphasis on sustainable construction practices

There is an increasing trend towards sustainable construction practices, where honeycomb sandwich materials are becoming more prevalent due to their energy-efficient properties. These materials provide excellent insulation and strength, making them ideal for eco-friendly building solutions. In addition to this, they are used in applications such as façades, roofing, and flooring systems where durability and thermal efficiency are paramount. The construction industry's shift towards green building standards and the global push for more energy-efficient buildings have led to an increased adoption of honeycomb sandwich materials. Furthermore, supportive governmental regulations and incentives encouraging the use of environmentally friendly materials in construction projects are impelling the honeycomb sandwich material market growth.

Honeycomb Sandwich Material Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the global, regional, and country levels for 2025-2033. Our report has categorized the market based on material type, technology, and application.

Breakup by Material Type:

- Aluminum

- Steel

- Composites

- Titanium

- Inconel

- Others

Aluminum accounts for the majority of the market share

The report has provided a detailed breakup and analysis of the market based on the material type. This includes aluminum, steel, composites, titanium, inconel, and others. According to the report, aluminum represented the largest segment.

The demand for aluminum honeycomb sandwiches is driven by its optimal blend of properties that are highly valued across various industries, particularly aerospace and automotive. As a material, aluminum offers an excellent strength-to-weight ratio, which is crucial for applications requiring lightweight yet strong components. Its inherent resistance to corrosion, good thermal conductivity, and ease of fabrication make it an ideal choice for honeycomb structures. These properties ensure that aluminum honeycomb sandwich panels are not only durable and efficient but also contribute to energy savings and improved performance of the final products. Moreover, aluminum is recyclable, aligning with the growing demands for sustainable materials in manufacturing processes, which is further propelling the honeycomb sandwich material market size.

Breakup by Technology:

- Expansion

- Corrugation

- Molding

- Extrusion

- Others

Expansion holds the largest share of the industry

A detailed breakup and analysis of the market based on the technology have also been provided in the report. This includes expansion, corrugation, molding, extrusion, and others. According to the report, expansion accounted for the largest market share.

The rising demand for expansion methods due to their cost-effectiveness and efficiency in producing large quantities is bolstering the honeycomb sandwich material market share. This process involves expanding a block of thin, stacked sheets of material, such as aluminum or thermoplastics, which are then stretched to form a honeycomb structure. The expansion technique allows for consistent cell size and uniform structural integrity, essential for maintaining the material's strength while minimizing weight. The method is highly favored in industries like aerospace, automotive, and construction, where large panels and complex contours require precise dimensional stability and mechanical properties. Moreover, the scalability and versatility of the expansion method make it a preferred choice, driving its prevalence in the market.

Breakup by Application:

- Aerospace

- Automotive

- Marine

- Locomotive

- Construction

- Others

Aerospace represents the leading market segment

The report has provided a detailed breakup and analysis of the market based on the application. This includes aerospace, automotive, marine, locomotive, construction, and others. According to the report, aerospace represented the largest segment.

Aerospace is the leading market segment due to the critical demand for materials that offer exceptional strength-to-weight ratios, essential for aerospace applications. Honeycomb sandwich material market research report reveals that these materials are extensively used in the manufacture of aircraft components such as fuselage, wing sections, and flight control surfaces. The lightweight nature of honeycomb sandwich structures significantly reduces the overall weight of aircraft, leading to improved fuel efficiency and performance, which are paramount in the aerospace industry. In addition to this, the excellent thermal and acoustic insulating properties of these materials contribute to enhanced passenger comfort and safety. The aerospace industry's stringent standards for durability and resistance to harsh environmental conditions further heighten the demand for honeycomb sandwich materials in this sector.

Breakup by Region:

- North America

- United States

- Canada

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

North America leads the market, accounting for the largest honeycomb sandwich material market share

The report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, North America represents the largest regional market for honeycomb sandwich material.

Honeycomb sandwich material market analysis revealed that North America enjoys the leading position in the market, largely driven by its robust aerospace and defense sectors which extensively utilize these materials for aircraft and military equipment manufacturing. Moreover, the presence of prominent aerospace companies and suppliers further fuels the demand for lightweight, high-strength materials like honeycomb sandwich structures. Along with this, North America's advanced manufacturing infrastructure and substantial investments in research and development (R&D) contribute to innovation and market growth. Furthermore, the region's stringent regulatory standards for energy efficiency and environmental sustainability also promote the adoption of lightweight and durable materials in the construction and automotive industries, further solidifying its position in the global market.

Competitive Landscape:

- The market research report has also provided a comprehensive analysis of the competitive landscape in the market. Detailed profiles of all major companies have also been provided. Some of the major market players in the honeycomb sandwich material industry include 3M Company, B.S. Innovation, Corex Honeycomb (Encocam Ltd), EconCore N.V., General Veneer Manufacturing Co., Hexcel Corporation, Honylite Private Limited, Pacific Panels Inc., Samia Canada Inc., Schütz GmbH & Co. KGaA, The Gill Corporation, etc.

(Please note that this is only a partial list of the key players, and the complete list is provided in the report.)

- The competitive landscape of the honeycomb sandwich material market is characterized by a mix of well-established companies and innovative startups, each striving to enhance its market position through technological advancements and strategic alliances. These companies invest heavily in research and development (R&D) to innovate and improve the performance and manufacturing processes of honeycomb sandwich materials, which are crucial for applications in the aerospace, automotive, and construction sectors. Additionally, market competition is intensified by collaborations and partnerships with end-use industries to tailor products to specific requirements. Moreover, new entrants and smaller firms focus on niche markets and specialized applications, adding to the market dynamics. This competitive environment drives technological innovation and market growth as companies continuously seek to provide more efficient, durable, and cost-effective solutions.

Honeycomb Sandwich Material Market News:

- In April 2023, EconCore and Solarge introduced a groundbreaking lightweight, fully circular solar panel at JEC World 2023. This new panel, developed through intensive collaboration since 2018, replaces heavy glass with lightweight honeycomb materials, reducing the weight of solar installations by up to 65% for rooftops.

Honeycomb Sandwich Material Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Material Types Covered | Aluminum, Steel, Composites, Titanium, Inconel, Others |

| Technologies Covered | Expansion, Corrugation, Molding, Extrusion, Others |

| Applications Covered | Aerospace, Automotive, Marine, Locomotive, Construction, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | 3M Company, B.S. Innovation, Corex Honeycomb (Encocam Ltd), EconCore N.V., General Veneer Manufacturing Co., Hexcel Corporation, Honylite Private Limited, Pacific Panels Inc., Samia Canada Inc., Schütz GmbH & Co. KGaA, The Gill Corporation, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the honeycomb sandwich material market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the global honeycomb sandwich material market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's five forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the honeycomb sandwich material industry and its attractiveness.

- The competitive landscape allows stakeholders to understand their competitive environment and provides insight into the current positions of key players in the market.

Key Questions Answered in This Report

The global honeycomb sandwich material market was valued at USD 1.8 Billion in 2024.

We expect the global honeycomb sandwich material market to exhibit a CAGR of 3.37% during 2025-2033.

The rising demand for honeycomb sandwich materials, such as aluminum, titanium, steel, etc., as they are lightweight and offer high strength, stiffness, corrosive resistance, and strong energy absorption properties that improves fuel efficiency, is primarily driving the global honeycomb sandwich material market.

The sudden outbreak of the COVID-19 pandemic had led to the implementation of stringent lockdown regulations across several nations, resulting in the temporary halt in numerous production activities for honeycomb sandwich materials.

Based on the material type, the global honeycomb sandwich material market can be segmented into aluminum, steel, composites, titanium, inconel, and others. Currently, aluminum accounts for the majority of the total market share.

Based on the technology, the global honeycomb sandwich material market has been divided into expansion, corrugation, molding, extrusion, and others. Among these, expansion currently holds the largest market share.

Based on the application, the global honeycomb sandwich material market can be bifurcated into aerospace, automotive, marine, locomotive, construction, and others. Currently, aerospace exhibits a clear dominance in the market.

On a regional level, the market has been classified into North America, Asia-Pacific, Europe, Latin America, and Middle East and Africa, where North America currently dominates the global market.

Some of the major players in the global honeycomb sandwich material market include 3M Company, B.S. Innovation, Corex Honeycomb (Encocam Ltd), EconCore N.V., General Veneer Manufacturing Co., Hexcel Corporation, Honylite Private Limited, Pacific Panels Inc., Samia Canada Inc., Schütz GmbH & Co. KGaA, and The Gill Corporation.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)